|

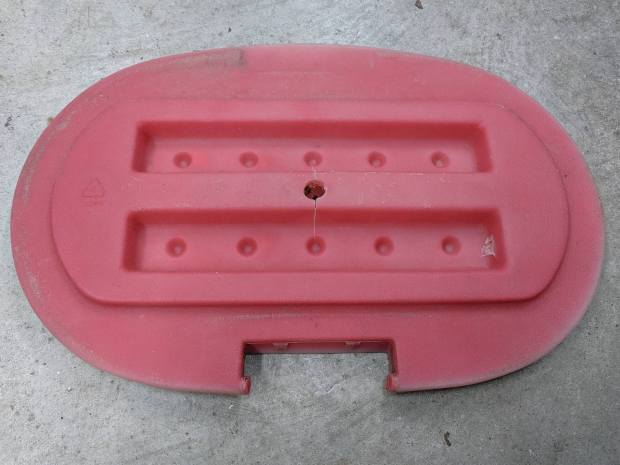

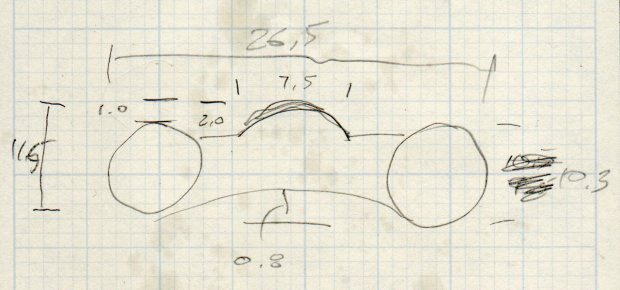

// Hinge brackets for rolling garden stool |

|

// Ed Nisley – KE4ZNU – 2019-06 |

|

|

|

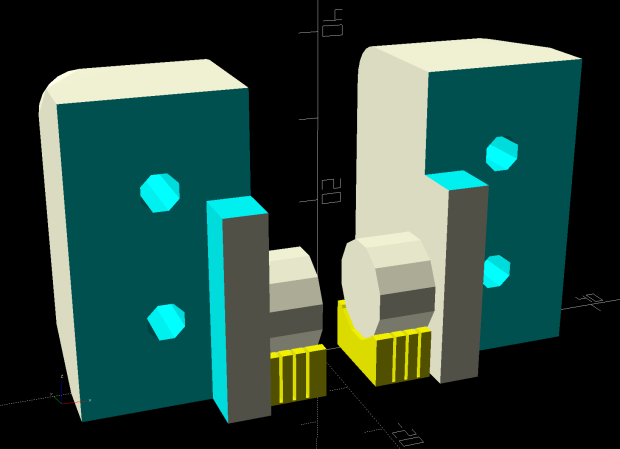

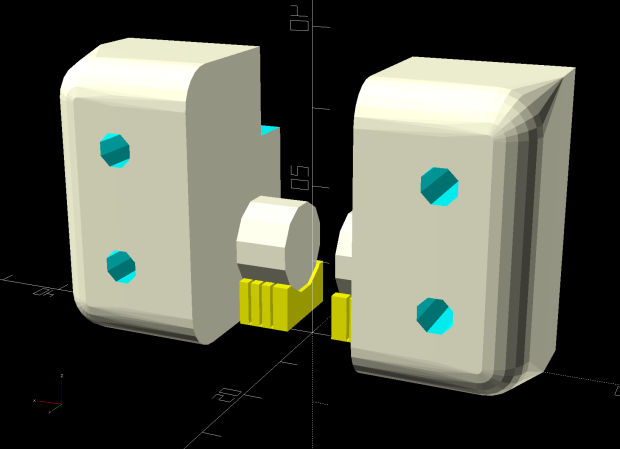

Layout = "Build"; // [Block,Build,Show] |

|

|

|

Support = true; |

|

|

|

/* [Hidden] */ |

|

|

|

ThreadThick = 0.20; |

|

ThreadWidth = 0.40; |

|

|

|

HoleWindage = 0.2; |

|

|

|

Protrusion = 0.1; // make holes end cleanly |

|

|

|

ID = 0; |

|

OD = 1; |

|

LENGTH = 2; |

|

|

|

//———————- |

|

// Dimensions |

|

|

|

SeatThick = 6.0; // seat panel above cart body |

|

|

|

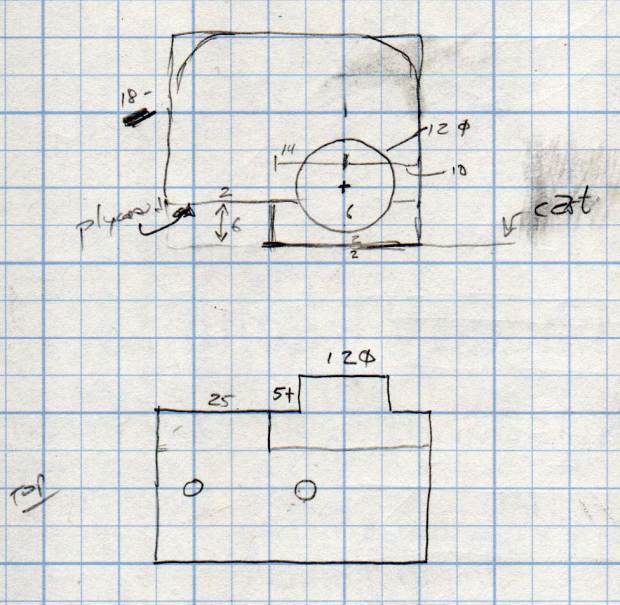

HingePin = [11.5,12.0,7.0]; // ID = tip OD = base |

|

|

|

HingeOffset = 8.0; // hinge axis above cart body (larger than radius!) |

|

HingeBolster = [5.0,24.0,SeatThick]; // backing block below hinge |

|

|

|

Block = [25.0,HingeOffset + 30.0,23.0]; // Z = above cart body |

|

|

|

Screw = [3.8,11.0,2.5]; // self-tapping #8 OD=head LENGTH=head thickness |

|

ScrewOC = 15.0; // spacing > greater than head OD |

|

ScrewOffset = Block.y/2 – (ScrewOC/2 + Screw[OD]/2 + HingeOffset); // space for head behind hinge |

|

|

|

BlockRadius = 7.0; // corner rounding |

|

|

|

//———————- |

|

// Useful routines |

|

|

|

module PolyCyl(Dia,Height,ForceSides=0) { // based on nophead's polyholes |

|

|

|

Sides = (ForceSides != 0) ? ForceSides : (ceil(Dia) + 2); |

|

|

|

FixDia = Dia / cos(180/Sides); |

|

|

|

cylinder(r=(FixDia + HoleWindage)/2, |

|

h=Height, |

|

$fn=Sides); |

|

} |

|

|

|

// Basic block shape |

|

// X axis collinear with hinge axes, hinge base at X=0 |

|

|

|

module HingeBlock() { |

|

|

|

PinSides = 3*4; |

|

PinSupport = [HingePin[LENGTH] – 2*ThreadWidth,0.6*HingeOffset,HingePin[OD]]; // pre-rotated |

|

|

|

union() { |

|

translate([Protrusion,Block.y/2 – HingeOffset,HingeOffset]) |

|

rotate([0,-90,0]) |

|

rotate(180/PinSides) |

|

cylinder(d=HingePin[OD],h=HingePin[LENGTH] + Protrusion,$fn=PinSides); |

|

difference() { |

|

hull() { |

|

translate([Block.x – BlockRadius,-(Block.y/2 – BlockRadius),Block.z – BlockRadius]) |

|

rotate(180/PinSides) |

|

sphere(r=BlockRadius/cos(180/PinSides),$fn=PinSides); |

|

translate([0,-(Block.y/2 – BlockRadius),Block.z – BlockRadius]) |

|

rotate([0,90,0]) rotate(180/PinSides) |

|

cylinder(r=BlockRadius/cos(180/PinSides),h=Block.x/2,$fn=PinSides); |

|

translate([Block.x – BlockRadius,(Block.y/2 – BlockRadius),Block.z – BlockRadius]) |

|

sphere(r=BlockRadius/cos(180/PinSides),$fn=PinSides); |

|

translate([0,(Block.y/2 – BlockRadius),Block.z – BlockRadius]) |

|

rotate([0,90,0]) rotate(180/PinSides) |

|

cylinder(r=BlockRadius/cos(180/PinSides),h=Block.x/2,$fn=PinSides); |

|

translate([0,-Block.y/2,0]) |

|

cube([Block.x,Block.y – HingeOffset,Block.z/2],center=false); |

|

translate([0,Block.y/2 – HingeOffset,HingeOffset]) |

|

rotate([0,90,0]) rotate(180/PinSides) |

|

cylinder(r=HingeOffset/cos(180/PinSides),h=Block.x,$fn=PinSides); |

|

} |

|

translate([Block.x/2 + HingeBolster.x,0,(SeatThick – Protrusion)/2]) |

|

cube([Block.x,2*Block.y,SeatThick + Protrusion],center=true); |

|

translate([0,-HingeBolster.y,(SeatThick – Protrusion)/2]) |

|

cube([3*Block.x,Block.y,SeatThick + Protrusion],center=true); |

|

for (j=[-1,1]) |

|

translate([Block.x/2,j*ScrewOC/2 + ScrewOffset,-4*ThreadThick]) |

|

rotate(180/8) |

|

PolyCyl(Screw[ID],Block.z,8); |

|

} |

|

} |

|

|

|

if (Support) { // totally ad-hoc |

|

color("Yellow") render(convexity=4) |

|

difference() { |

|

translate([-(PinSupport.x/2 + 2*ThreadWidth),Block.y/2 – PinSupport.y/2,HingeOffset]) |

|

cube(PinSupport,center=true); |

|

translate([Protrusion,Block.y/2 – HingeOffset,HingeOffset]) |

|

rotate([0,-90,0]) |

|

rotate(180/PinSides) |

|

cylinder(d=HingePin[OD] + 2*ThreadThick,h=2*HingePin[LENGTH],$fn=PinSides); |

|

for (i=[-1:1]) |

|

translate([i*4*ThreadWidth – HingePin[LENGTH]/2, |

|

Block.y/2 – (PinSupport.y + 1*ThreadThick), |

|

HingeOffset]) |

|

cube([2*ThreadWidth,2*PinSupport.y,2*PinSupport.z],center=true); |

|

} |

|

} |

|

} |

|

|

|

module Blocks(Hand = "Left") { |

|

if (Hand == "Left") |

|

HingeBlock(); |

|

else |

|

mirror([1,0,0]) |

|

HingeBlock(); |

|

} |

|

|

|

//- Build it |

|

|

|

if (Layout == "Block") |

|

HingeBlock(); |

|

|

|

if (Layout == "Show") { |

|

translate([1.5*HingePin[LENGTH],0,0]) |

|

Blocks("Left"); |

|

translate([-1.5*HingePin[LENGTH],0,0]) |

|

Blocks("Right"); |

|

} |

|

|

|

if (Layout == "Build") { |

|

translate([0,-Block.z/2,Block.y/2]) |

|

rotate([-90,0,0]) { |

|

translate([1.5*HingePin[LENGTH],0,0]) |

|

Blocks("Left"); |

|

translate([-1.5*HingePin[LENGTH],0,0]) |

|

Blocks("Right"); |

|

} |

|

|

|

} |