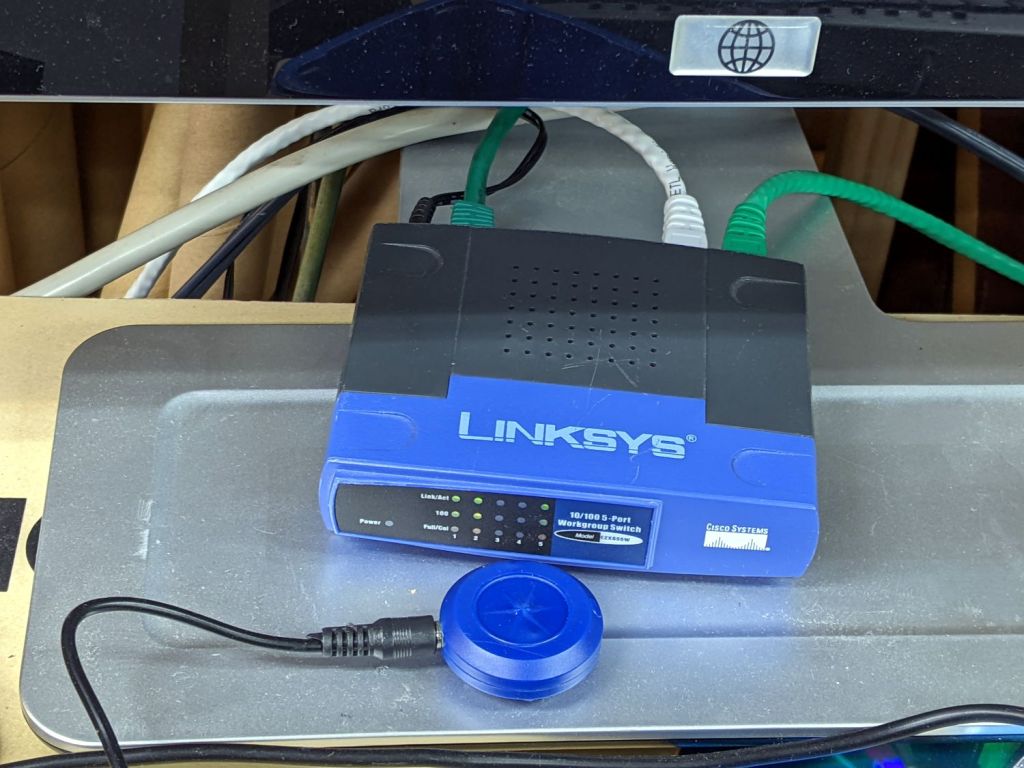

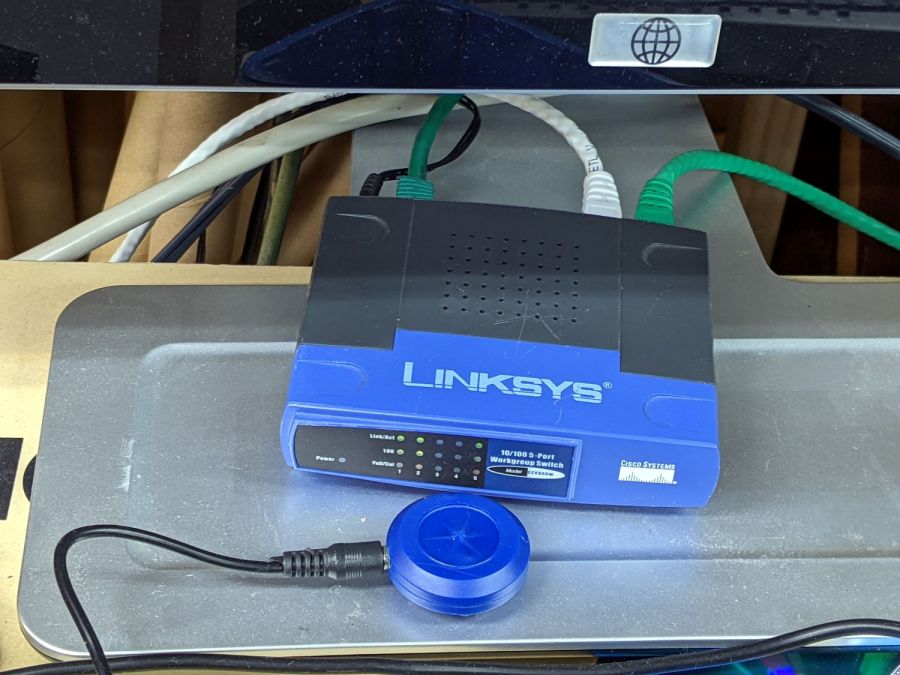

The CNC-3018XL and MPCNC machines each have a Raspberry Pi feeding G-Code into an Arduino clone controlling the stepper motors. The former grew a USB WiFi interface in place of its internal WiFi hardware when it seemed to have difficulty connecting to the house router, while the latter pretty much worked. Of late, however, I’ve been trying to reduce the number of WiFi devices cluttering the airwaves, with the result of wiring both machines to an old Ethernet switch from the Box o’ Network Stuff:

The blue puck is the KVM button to select one of the machines for the keyboard / mouse / monitor on the bench.

One key point I generally screw up: the WiFi IP address cannot become the wired IP address without rebooting everything else on the network. Instead, just change the IP addresses and be done with it.

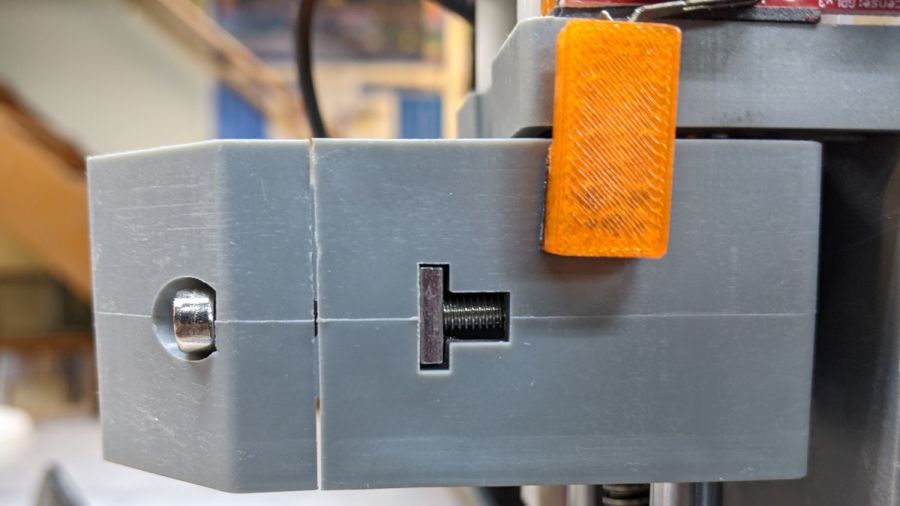

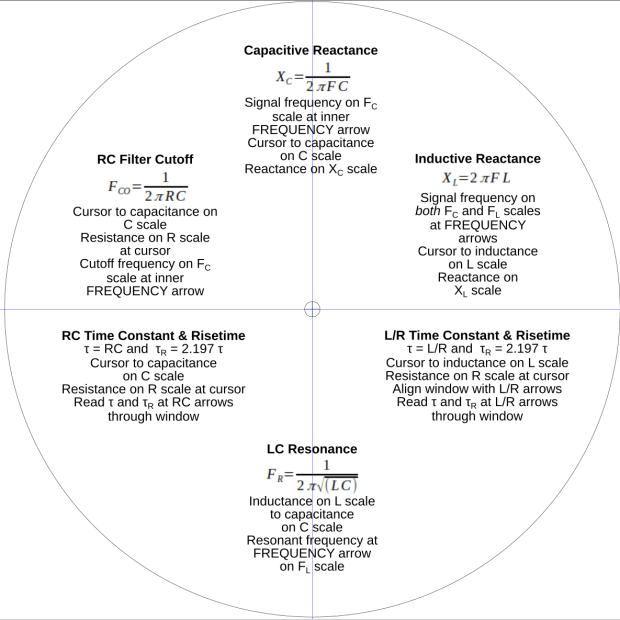

Collecting all the pieces in one place:

Disable the both internal WiFi hardware and Bluetooth in /boot/config.txt, thereby eliminating the need to force the WiFi down in /etc/rc.local:

dtoverlay=pi3-disable-wifi

dtoverlay=pi3-disable-bt

Define the static IP address in /etc/dhcpcd.conf:

interface eth0

static ip_address=192.168.1.34/24

static routers=192.168.1.1

static domain_name_servers=192.168.1.2

Kill IPV6 activity in /etc/sysctl.conf:

net.ipv6.conf.all.disable_ipv6=1

I very much doubt this information is either complete or correct, but it serves the purpose as of early 2022.