|

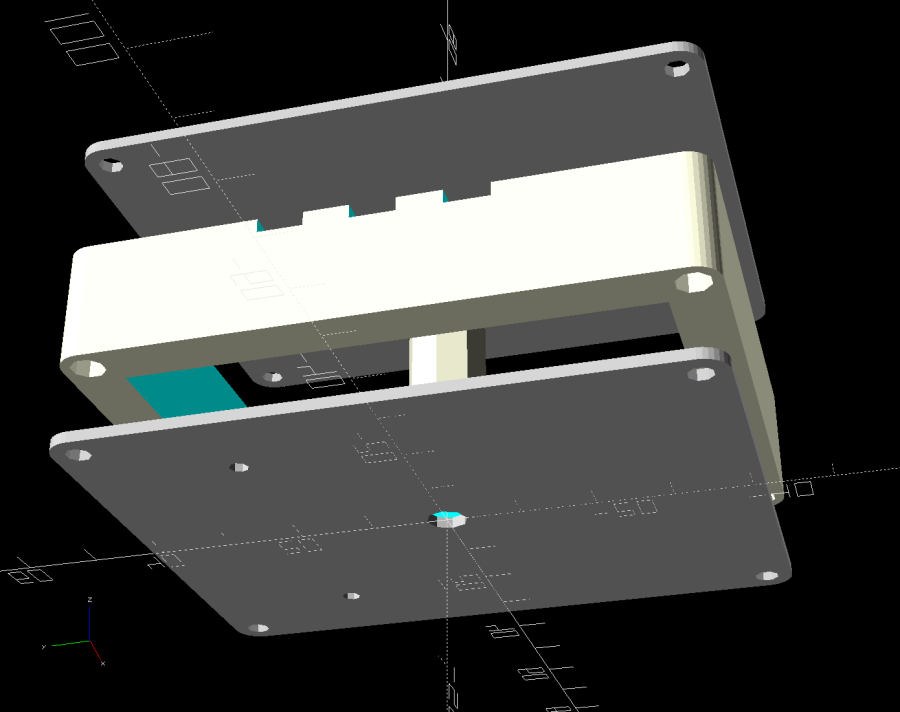

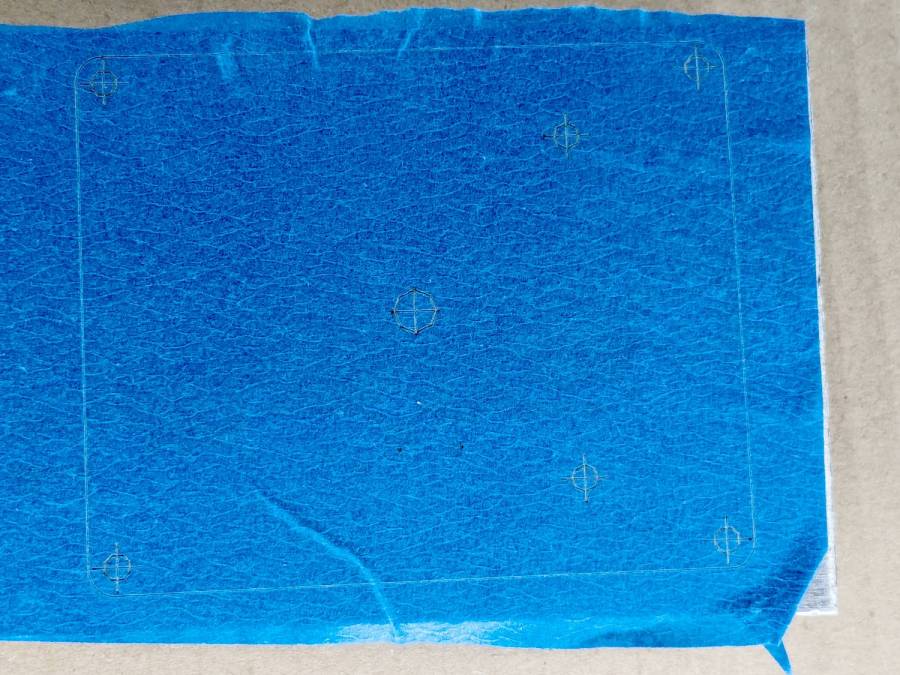

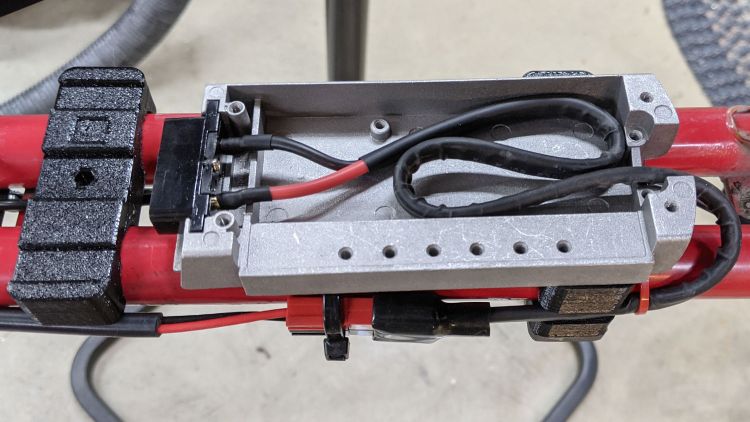

// Tour Easy Bafang Battery Mount |

|

// Ed Nisley KE4ZNU 2021-04 |

|

|

|

Layout = "Build"; // [Frame,Block,Show,Build,Bushing,Cateye] |

|

|

|

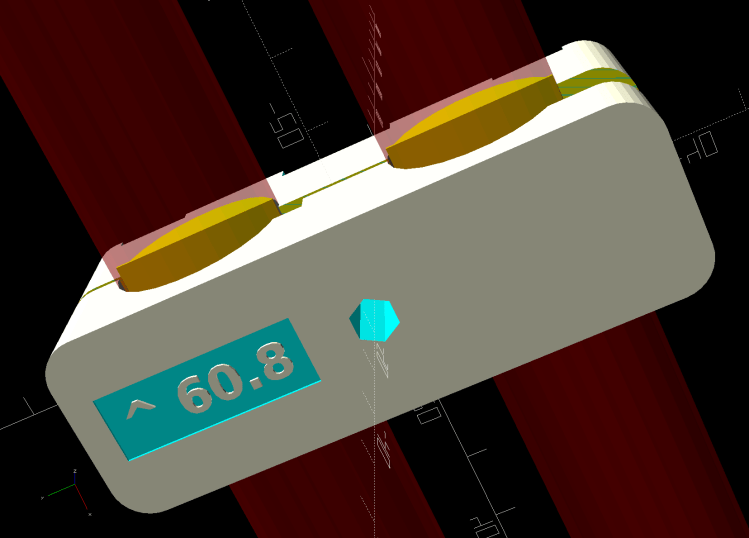

FrameWidths = [60.8,62.0,63.4,66.7]; // last = rear overhang support block |

|

|

|

Support = true; |

|

|

|

//- Extrusion parameters must match reality! |

|

|

|

/* [Hidden] */ |

|

|

|

ThreadThick = 0.25; |

|

ThreadWidth = 0.40; |

|

|

|

HoleWindage = 0.2; |

|

|

|

Protrusion = 0.1; // make holes end cleanly |

|

|

|

inch = 25.4; |

|

|

|

function IntegerMultiple(Size,Unit) = Unit * ceil(Size / Unit); |

|

|

|

ID = 0; |

|

OD = 1; |

|

LENGTH = 2; |

|

|

|

|

|

//———- |

|

// Dimensions |

|

// Bike frame lies along X axis, rear to +X |

|

|

|

FrameTube = [350,22.6 + HoleWindage,22.6 + HoleWindage]; // X = longer than anything else |

|

|

|

FrameAngle = atan((65.8 – 59.4)/300); // measured distances = included angle between tubes |

|

TubeAngle = FrameAngle/2; // .. frame axis to tube |

|

|

|

FrameSides = 24; |

|

|

|

echo(str("Frame angle: ",FrameAngle)); |

|

|

|

SpeedOD = 3.5; // speed sensor cable along frame |

|

|

|

PowerOD = 6.7; // power cable between frame tubes |

|

|

|

BatteryBoss = [5.5,16.0,2.5]; // battery mount boss, center is round |

|

BossSlotOAL = 32.0; // .. end bosses are elongated |

|

BossOC = 65.0; // .. along length of mount |

|

|

|

LatchWidth = 10.0; // battery latches to mount plate |

|

LatchThick = 1.5; |

|

LatchOC = 56.0; |

|

|

|

WallThick = 5.0; // thinnest wall |

|

|

|

Block = [25.0,78.0,FrameTube.z + 2*WallThick]; // must be larger than frame tube spacing |

|

echo(str("Block: ",Block)); |

|

|

|

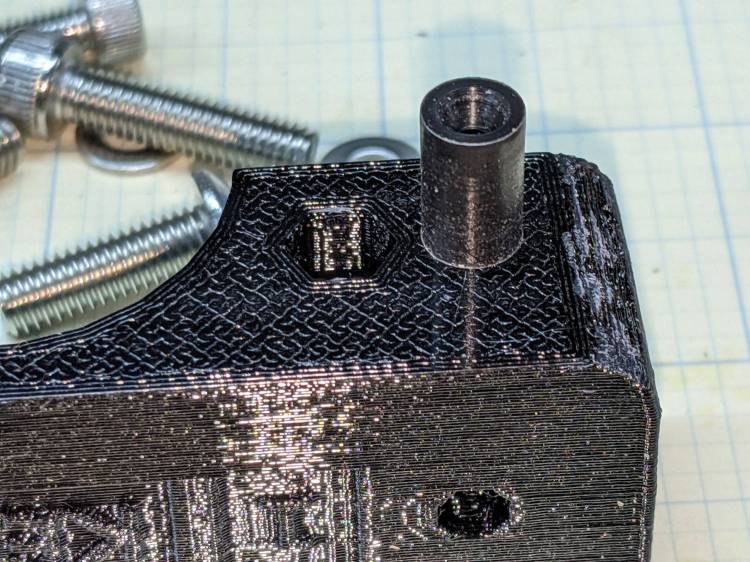

// M5 SHCS nyloc nut |

|

Screw = [5.0,8.5,5.0]; // OD, LENGTH = head |

|

Washer = [5.5,10.1,1.0]; |

|

Nut = [5.0,9.0,5.0]; |

|

|

|

// 10-32 Philips nyloc nut |

|

Screw10 = [5.2,9.8,3.6]; // OD, LENGTH = head |

|

Washer10 = [5.5,11.0,1.0]; |

|

Nut10 = [5.2,10.7,6.2]; |

|

|

|

Kerf = 1.0; // cut through middle to apply compression |

|

|

|

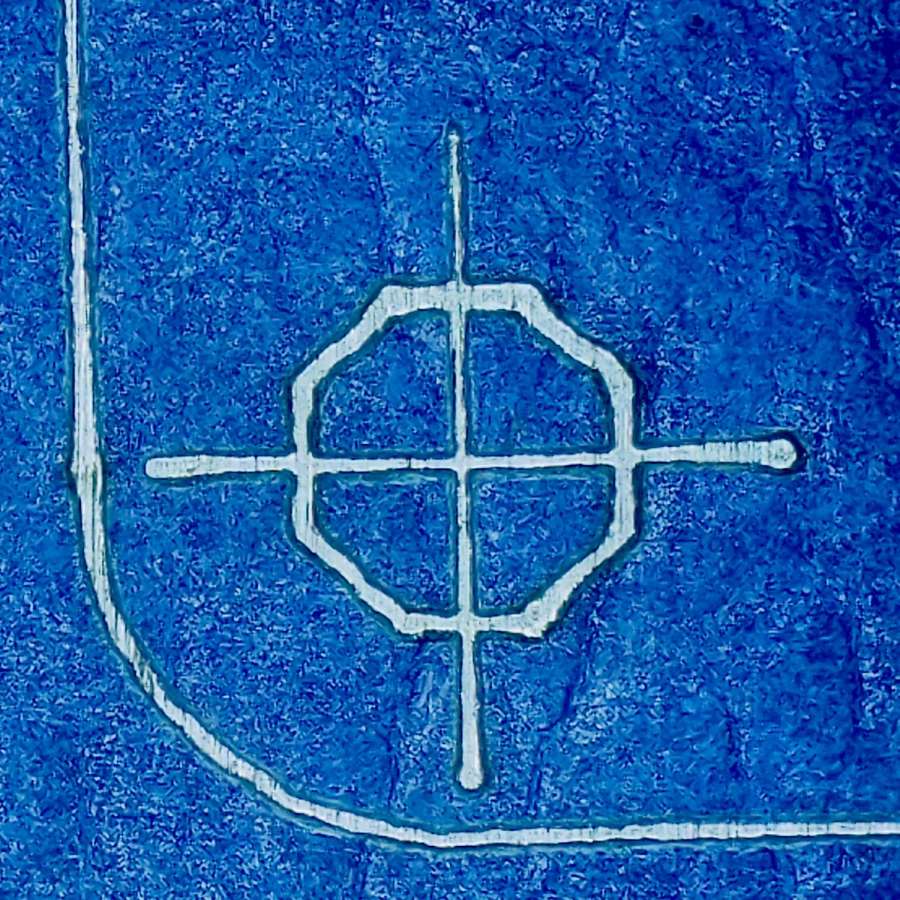

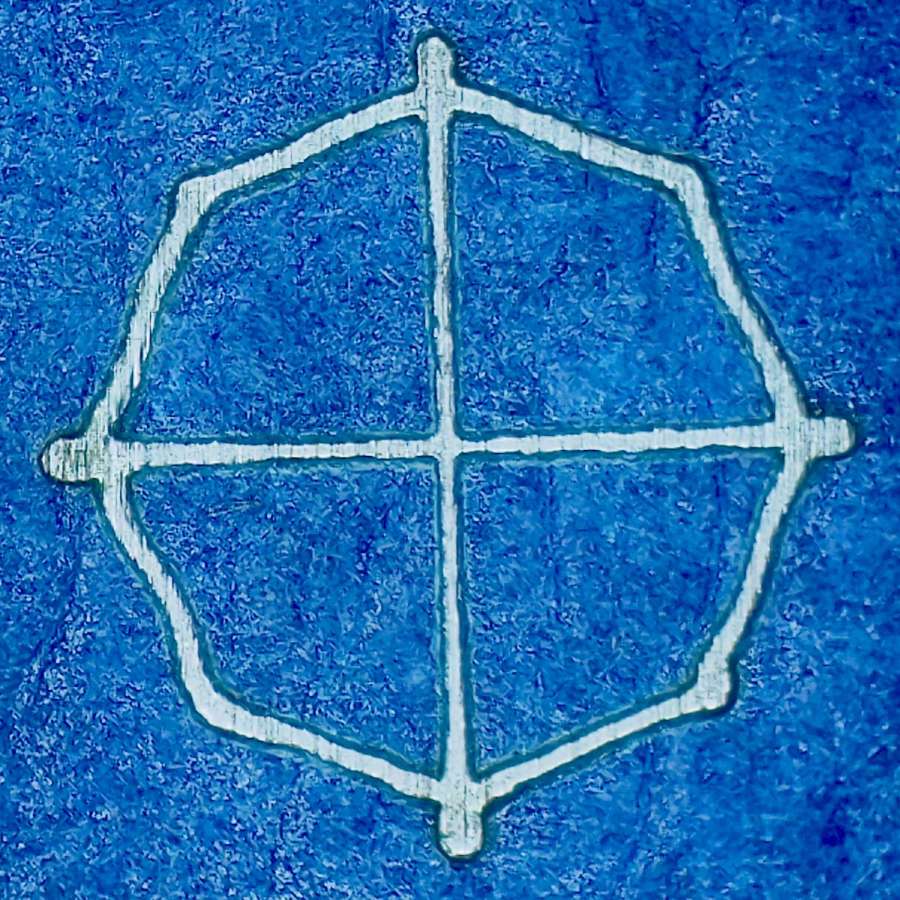

CornerRadius = 5.0; |

|

|

|

EmbossDepth = 2*ThreadThick; // lettering depth |

|

|

|

//———————- |

|

// Useful routines |

|

|

|

module PolyCyl(Dia,Height,ForceSides=0) { // based on nophead's polyholes |

|

Sides = (ForceSides != 0) ? ForceSides : (ceil(Dia) + 2); |

|

FixDia = Dia / cos(180/Sides); |

|

cylinder(d=(FixDia + HoleWindage),h=Height,$fn=Sides); |

|

} |

|

|

|

|

|

|

|

// clamp overall shape |

|

|

|

module ClampBlock() { |

|

difference() { |

|

hull() |

|

for (i=[-1,1], j=[-1,1]) |

|

translate([i*(Block.x/2 – CornerRadius),j*(Block.y/2 – CornerRadius),-Block.z/2]) |

|

cylinder(r=CornerRadius,h=Block.z,$fn=4*8); |

|

|

|

translate([0,0,-(Block.z/2 + Protrusion)]) |

|

rotate(0*180/6) |

|

PolyCyl(Screw[ID],Block.z + 2*Protrusion,6); |

|

|

|

cube([2*Block.x,2*Block.y,Kerf],center=true); |

|

|

|

translate([0,-(Block.y/2 – PowerOD + Protrusion/2),-PowerOD/2]) |

|

cube([2*Block.x,2*PowerOD + Protrusion,PowerOD],center=true); |

|

|

|

} |

|

|

|

} |

|

|

|

// frame tube layout with measured side-to-side width |

|

|

|

module Frame(Outer = FrameWidths[0],AdjustDia = 0.0) { |

|

|

|

TubeOC = Outer – FrameTube.y/cos(TubeAngle); // increase dia for angle |

|

|

|

for (i=[-1,1]) |

|

translate([0,i*TubeOC/2,0]) |

|

rotate([0,90,i*TubeAngle]) rotate(180/FrameSides) |

|

cylinder(d=FrameTube.z + AdjustDia,h=FrameTube.x,center=true,$fn=FrameSides); |

|

} |

|

|

|

// complete clamp block |

|

|

|

module Clamp(Outer = FrameWidths[0]) { |

|

|

|

TubeOC = Outer – FrameTube.y/cos(TubeAngle); // increase dia for angle |

|

|

|

difference() { |

|

ClampBlock(); |

|

Frame(Outer); |

|

|

|

translate([0,(TubeOC/2 – FrameTube[OD]/2),-SpeedOD/2]) |

|

cube([2*Block.x,2*SpeedOD,SpeedOD],center=true); |

|

|

|

translate([0,15,Block.z/2 – EmbossDepth/2 + Protrusion]) |

|

cube([9.0,8,EmbossDepth],center=true); |

|

translate([0,22,-Block.z/2 + EmbossDepth/2 – Protrusion]) |

|

cube([9.0,26,EmbossDepth],center=true); |

|

|

|

if (Outer == FrameWidths[len(FrameWidths) – 1]) { // special rear block |

|

translate([0,0,Block.z/2 – 2*Screw10[LENGTH]]) |

|

PolyCyl(Washer10[OD],2*Screw10[LENGTH] + Protrusion,6); |

|

} |

|

else { // other blocks have channels |

|

translate([0,0,Block.z/2 – BatteryBoss[LENGTH]/2 + Protrusion]) |

|

cube([BossSlotOAL,BatteryBoss[OD],BatteryBoss[LENGTH] + Protrusion],center=true); |

|

|

|

for (i=[-1,1]) |

|

translate([0,i*LatchOC/2,Block.z/2 – LatchThick/2 + Protrusion]) |

|

cube([BossSlotOAL,LatchWidth,LatchThick + Protrusion],center=true); |

|

} |

|

} |

|

|

|

translate([0,15,Block.z/2 – EmbossDepth]) |

|

linear_extrude(height=EmbossDepth) |

|

rotate(90) |

|

text(text="^",size=5,spacing=1.00,font="Bitstream Vera Sans:style=Bold", |

|

halign="center",valign="center"); |

|

|

|

translate([0,22,-Block.z/2]) |

|

linear_extrude(height=EmbossDepth) |

|

rotate(-90) mirror([0,1,0]) |

|

text(text=str("^ ",Outer),size=4.5,spacing=1.00,font="Bitstream Vera Sans:style=Bold", |

|

halign="center",valign="center"); |

|

|

|

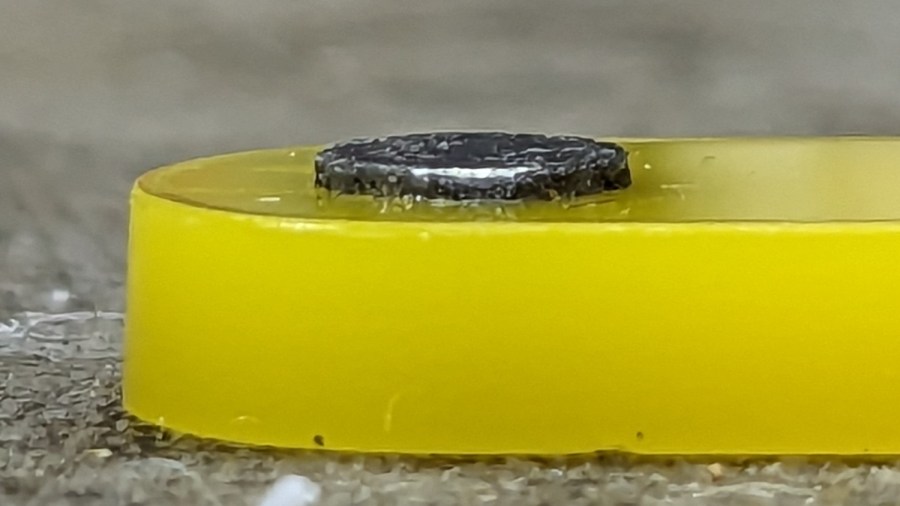

if (Support) |

|

color("Yellow") { |

|

NumRibs = 7; |

|

RibOC = Block.x/(NumRibs – 1); |

|

intersection() { |

|

translate([0,0,Block.z/2 + Kerf/2]) |

|

cube([2*Block.x,2*Block.y,Block.z],center=true); |

|

union() for (j=[-1,1]) { |

|

translate([0,j*TubeOC/2,Kerf/2]) |

|

cube([1.1*Block.x,FrameTube.y – 2*ThreadThick,4*ThreadThick],center=true); |

|

for (i=[-floor(NumRibs/2):floor(NumRibs/2)]) |

|

translate([i*RibOC,j*TubeOC/2,0]) |

|

rotate([0,90,0]) rotate(180/FrameSides) |

|

cylinder(d=FrameTube.z – 2*ThreadThick,h=2*ThreadWidth,$fn=FrameSides,center=true); |

|

|

|

} |

|

} |

|

} |

|

} |

|

|

|

// Half clamp sections for printing |

|

|

|

module HalfClamp(i = 0, Section = "Upper") { |

|

|

|

render() |

|

intersection() { |

|

translate([0,0,Block.z/4]) |

|

cube([Block.x,Block.y,Block.z/2],center=true); |

|

if (Section == "Upper") |

|

translate([0,0,-Kerf/2]) |

|

Clamp(FrameWidths[i]); |

|

else |

|

translate([0,0,Block.z/2]) |

|

Clamp(FrameWidths[i]); |

|

} |

|

} |

|

|

|

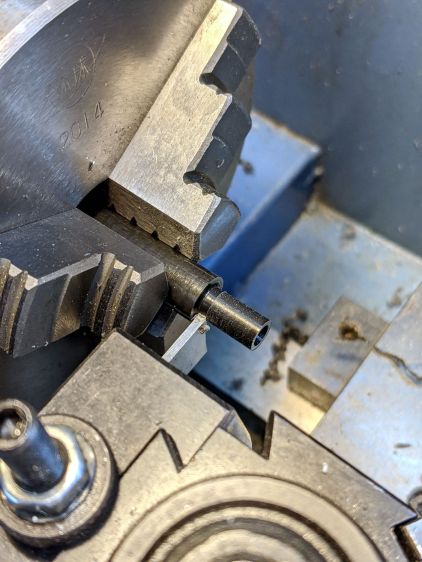

// Handlebar bushing for controller |

|

|

|

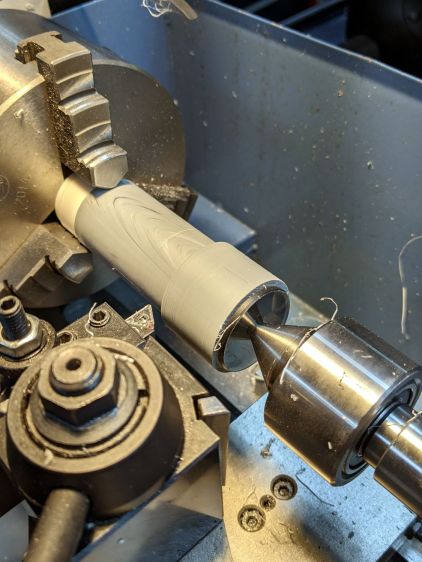

BushingSize = [16.0,22.2,15.0]; |

|

|

|

module Bushing() { |

|

|

|

difference() { |

|

|

|

cylinder(d=BushingSize[OD],h=BushingSize[LENGTH],$fn=24); |

|

translate([0,0,-Protrusion]) |

|

cylinder(d=BushingSize[ID],h=2*BushingSize[LENGTH],$fn=24); |

|

translate([0*(BushingSize[OD] – BushingSize[ID])/4,0,BushingSize[LENGTH]/2]) |

|

cube([2*BushingSize[OD],2*ThreadWidth,2*BushingSize[LENGTH]],center=true); |

|

|

|

} |

|

} |

|

|

|

// Cateye cadence sensor bracket |

|

|

|

module Cateye() { |

|

|

|

Pivot = [3.0,10.0,8.0]; |

|

Slot = [4.2,14.0,14.0]; |

|

Clip = [8.0,Slot.y,Slot.z + Pivot[OD]/2]; |

|

|

|

translate([0,0,Clip.z]) |

|

difference() { |

|

union() { |

|

translate([0,0,-Clip.z/2]) |

|

cube(Clip,center=true); |

|

translate([-Clip.x/2,0,0]) |

|

rotate([0,90,0]) |

|

cylinder(d=Clip.y,h=Clip.x,$fn=12); |

|

} |

|

translate([-Clip.x,0,0]) |

|

rotate([0,90,0]) rotate(180/6) |

|

PolyCyl(3.0,2*Clip.x,6); |

|

|

|

translate([0,0,-(Clip.z – Slot.z/2)]) |

|

cube(Slot + [0,Protrusion,Protrusion],center=true); |

|

} |

|

|

|

} |

|

|

|

//———- |

|

// Build them |

|

|

|

if (Layout == "Frame") |

|

Frame(); |

|

|

|

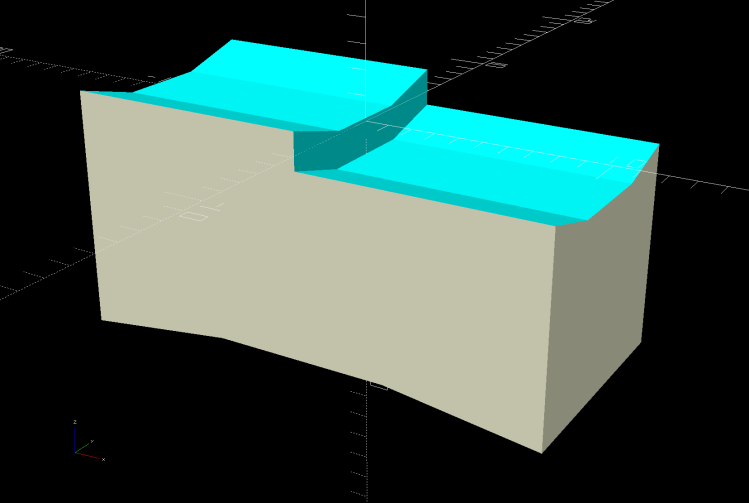

if (Layout == "Block") |

|

ClampBlock(); |

|

|

|

if (Layout == "Bushing") |

|

Bushing(); |

|

|

|

if (Layout == "Cateye") |

|

Cateye(); |

|

|

|

if (Layout == "Upper" || Layout == "Lower") |

|

HalfClamp(0,Layout); |

|

|

|

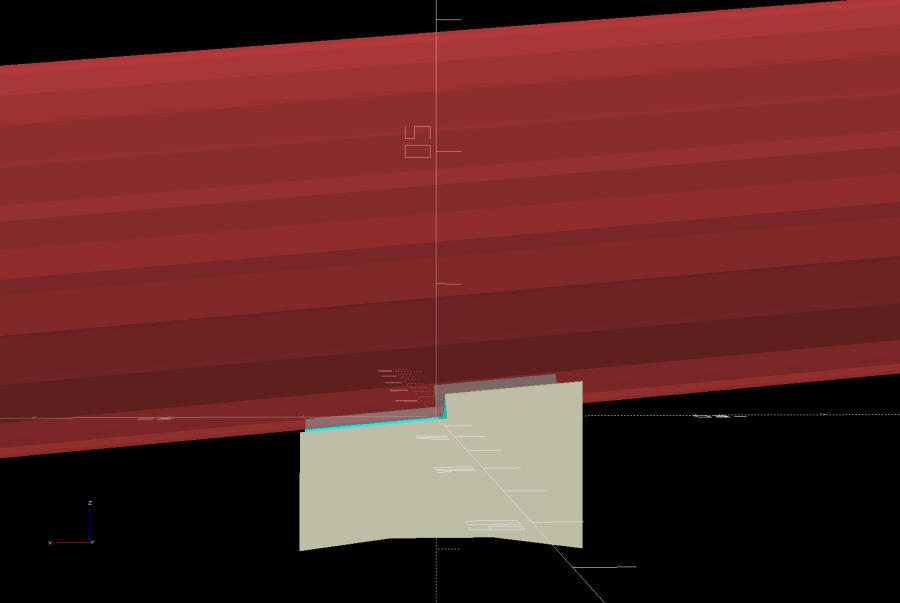

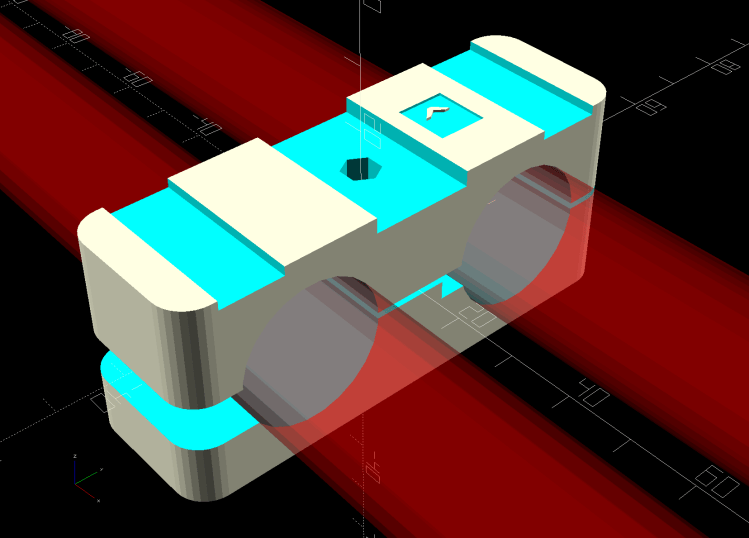

if (Layout == "Show") { |

|

Clamp(); |

|

color("Red", 0.3) |

|

Frame(); |

|

} |

|

|

|

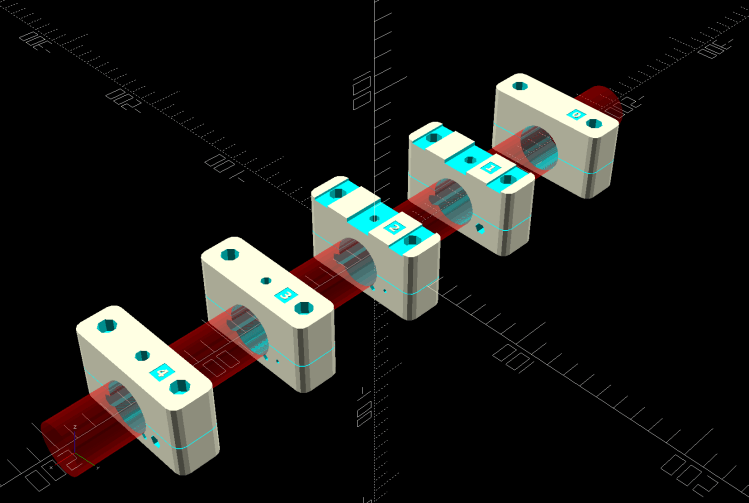

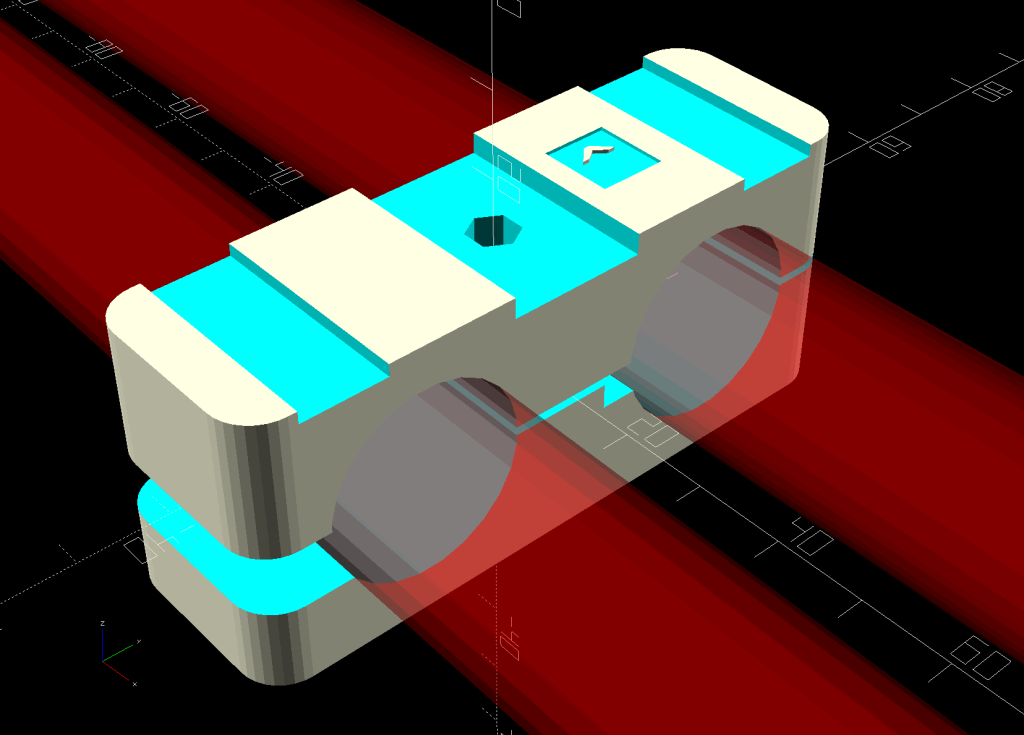

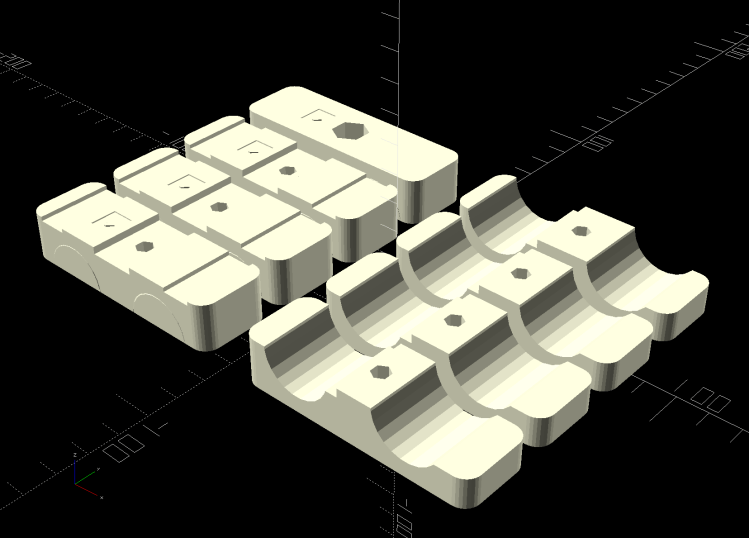

if (Layout == "Build") { |

|

n = len(FrameWidths); |

|

gap = 1.2; |

|

|

|

for (i=[0:n-1]) { |

|

j = i – ceil((n-1)/2); |

|

translate([-gap*Block.y/2,j*gap*Block.x,0]) |

|

rotate(90) |

|

HalfClamp(i,"Upper"); |

|

translate([gap*Block.y/2,j*gap*Block.x,0]) |

|

rotate([0,0,90]) |

|

HalfClamp(i,"Lower"); |

|

} |

|

} |