Our medical practice has been Borged by Optum, which is, through a number of corporate cutout layers, owned by UnitedHealth Group, so (despite claims to the contrary) our doctors effectively work for a health insurance company. No, they may not be paid by UHG, but following the money in reverse shows the flow of influence.

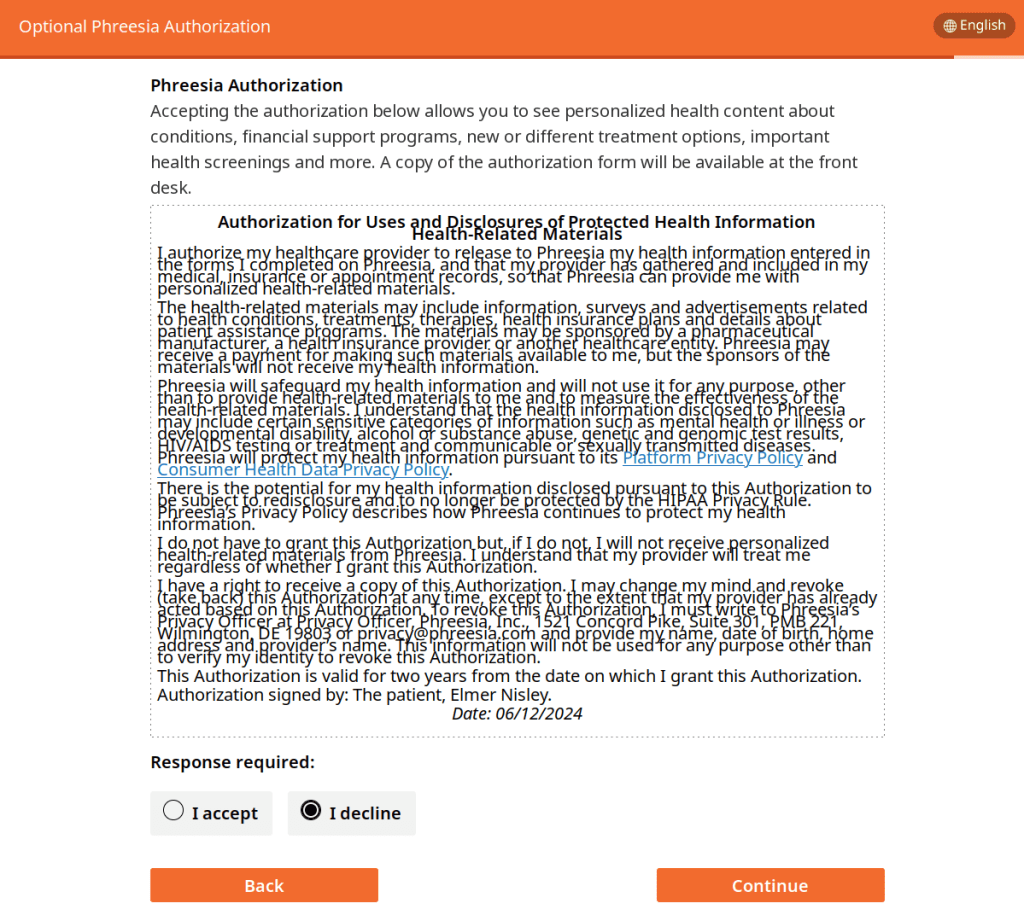

Apparently this has slightly affected the original practice’s reliance on Phreesia for pre-visit sign-in information collection although, as before, Phreesia still really wants to scatter your precious personal bits to the far corners of the InterWebs:

The wall o’ text is a bit shorter then the earlier version and cannot be scrolled or printed. It still admits:

There is the potential for my health information … to be subject to redisclosure and to no longer be protected by the HIPAA Privacy Rule.

Yes, I understand that’s the whole point of getting me to agree to release my private bits to Phreesia, so they can make money by selling it to the highest bidder(s).

What’s new is the previous page in the sequence, of which I do not have a screenshot, presumably coming from Optum, emphasizing in bold type that I do not have to authorize Phreesia’s data collection.

I infer this means two things:

- Optum / UHG has had their awareness raised about this nonsense

- Phreesia contractually requires that dark-pattern page

Yes, I understand that I have no privacy and should get over it, but somehow this sort of behavior rankles …