A knife found in Mary’s Bucket o’ Gardening Gear was in need of a sheath:

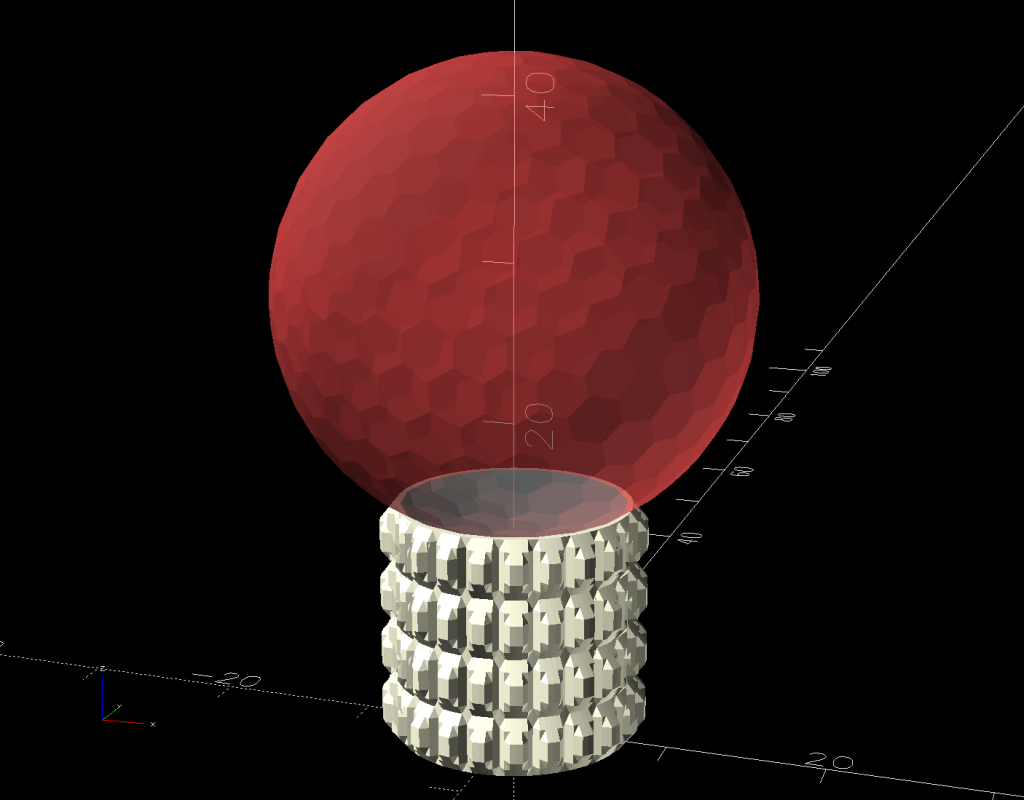

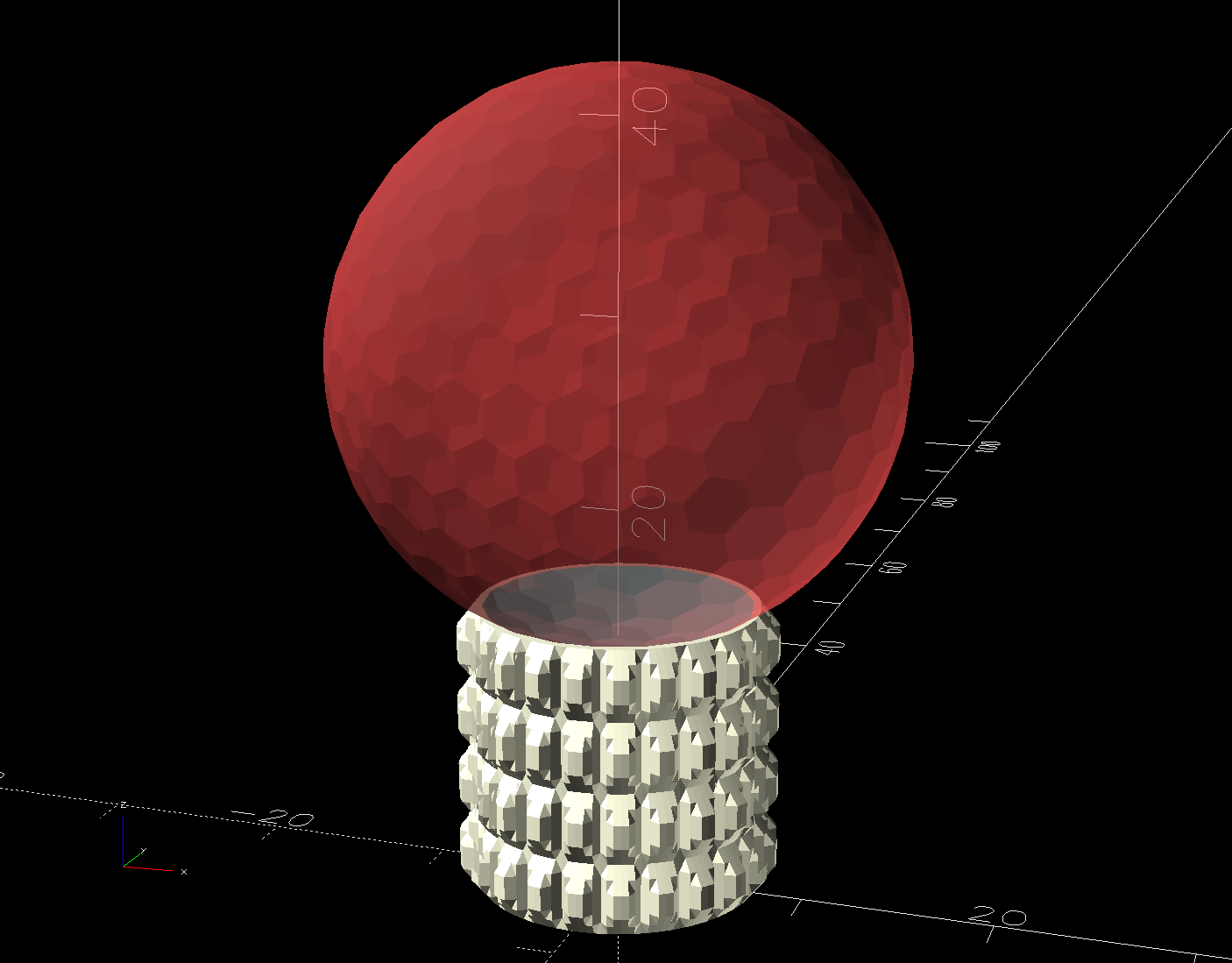

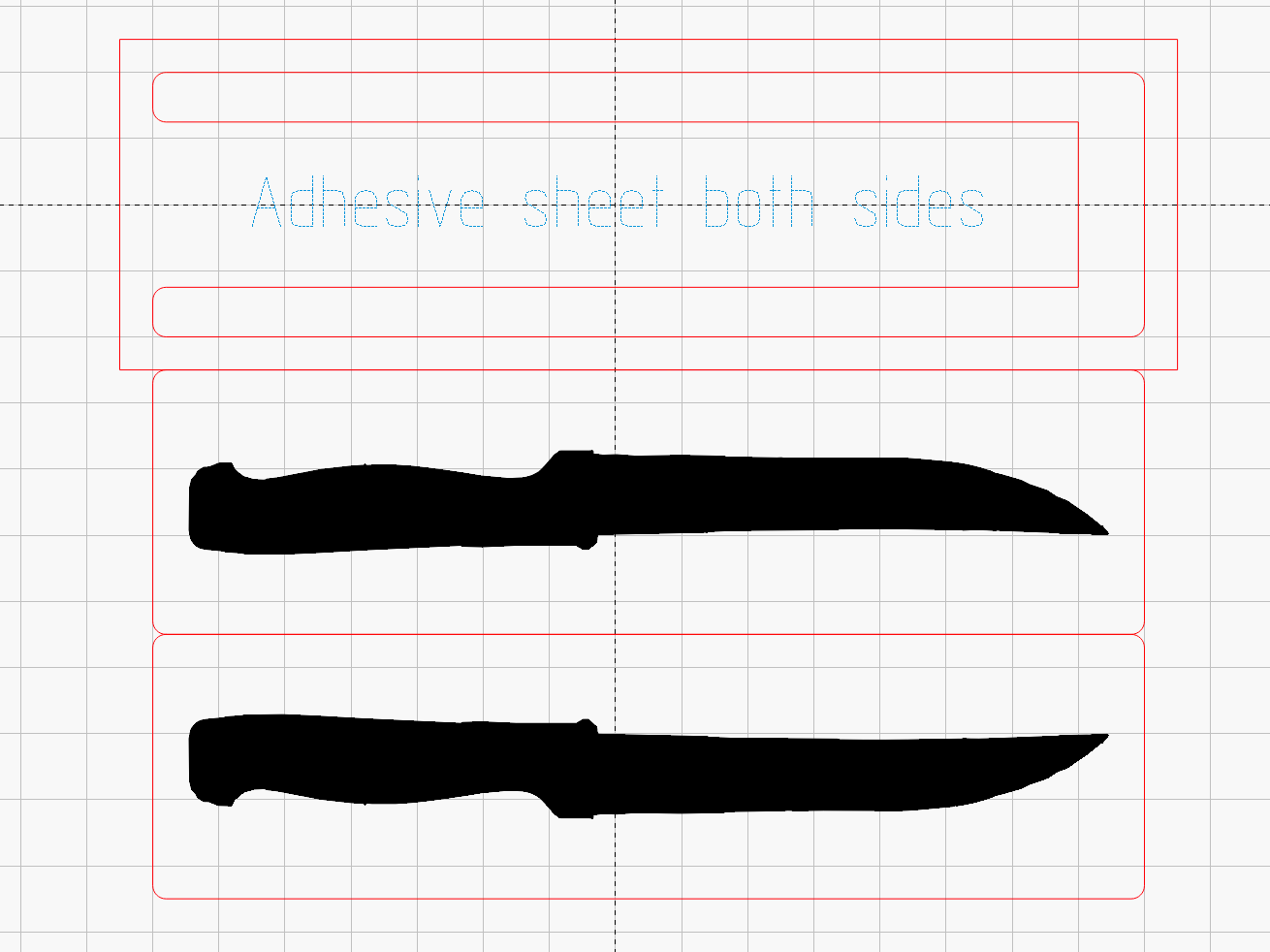

Unlike the time before or the time before that, a few minutes with LightBurn laid out the overall pattern:

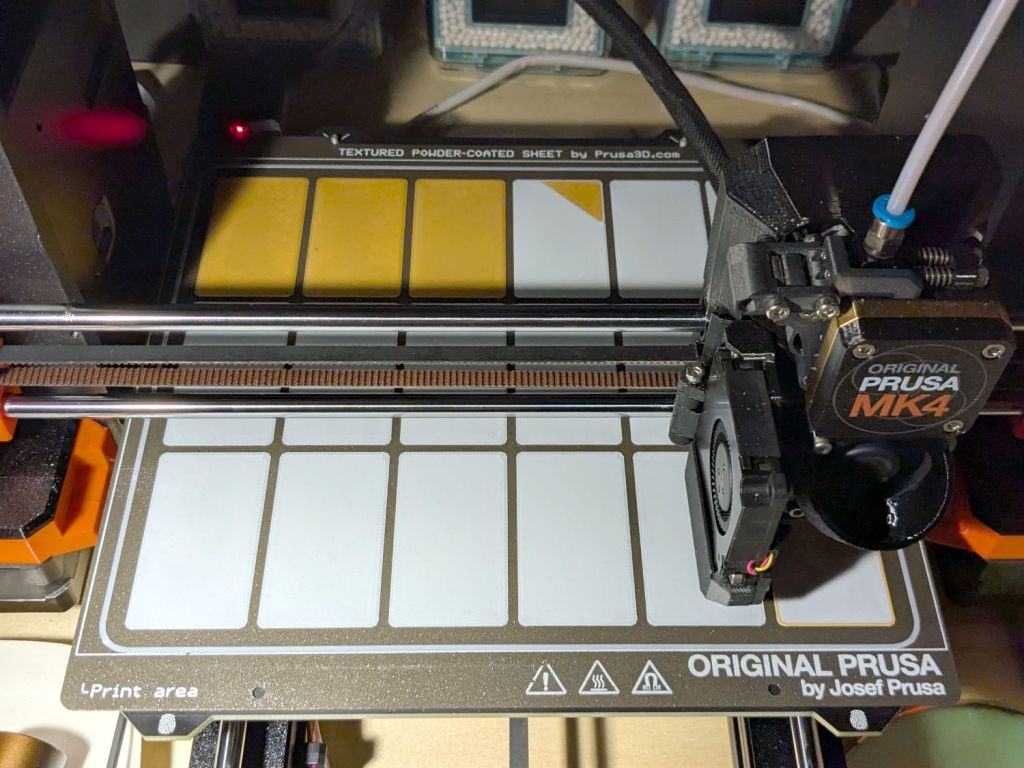

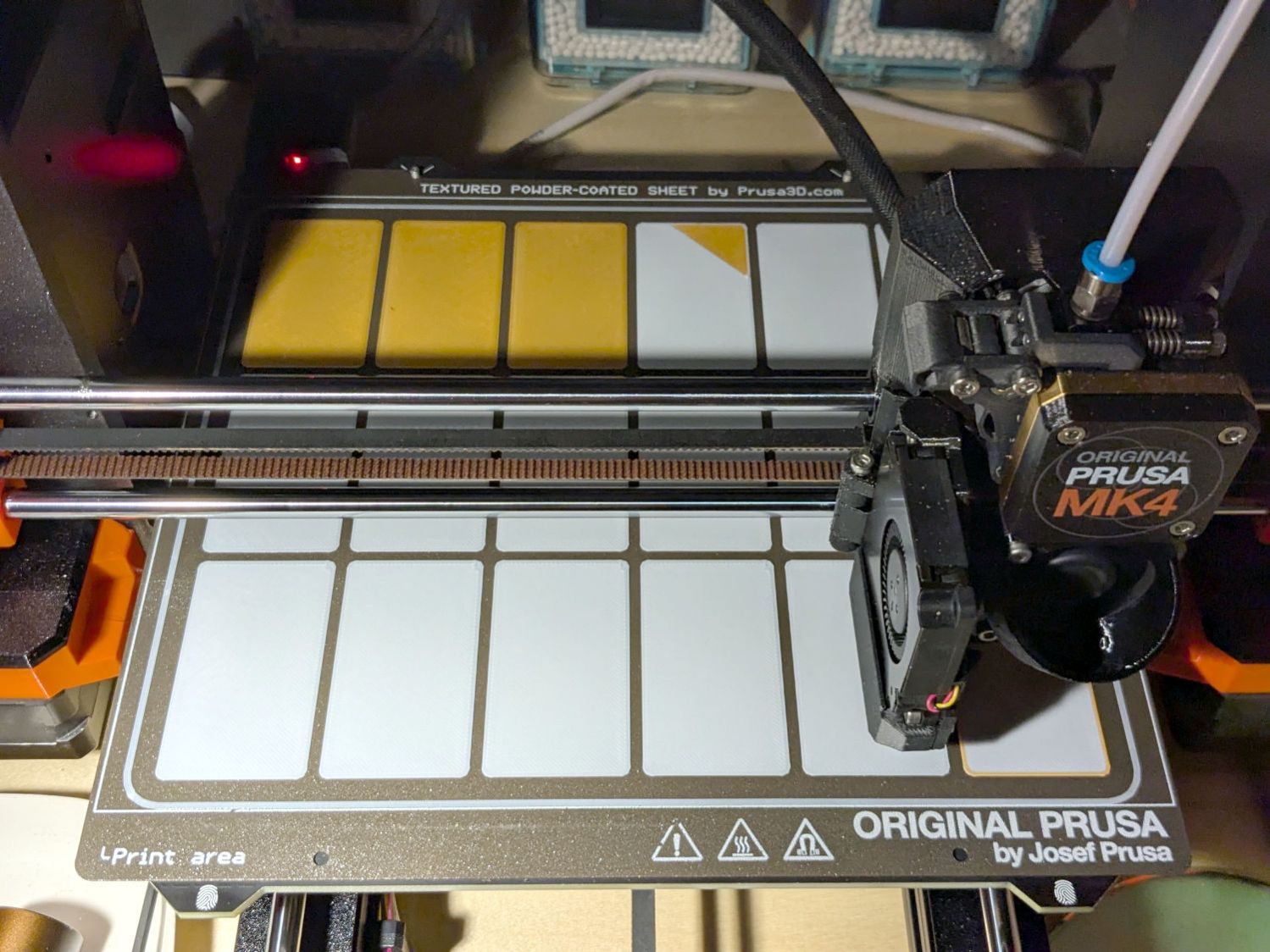

The knife’s silhouette came from a few minutes with GIMP, because cleaning up the edges on a graphics tablet is easier than fiddling with precise spline curves. Export the selection as an SVG, import into LightBurn, set to Fill, and Fire The Laser:

The upper block in the LightBurn layout is an oversized rectangle so I could cut that out first, stick craft adhesive on both sides, trim the edges, drop it back into the hole, then cut the middle part of the sheath.

It’s made of recycled through-dyed chipboard and it won’t last forever, but that’s not a problem because these things tend to wander off before they disintegrate.

I must do a few more for the other garden bucket, but those should be straightforward.