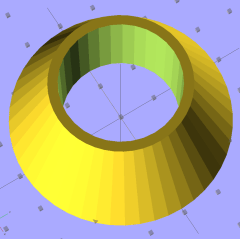

The main tube connects the camera mounting plate and the snout on the front, so it’s a structural element of a sort. The ID fits over the non-moving lens turret base on the camera and the inner length is a few millimeters longer than the maximum lens turret extension:

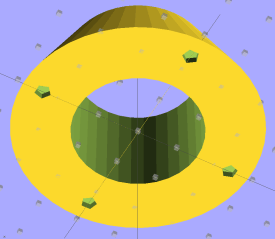

As you might expect by now, the front bulkhead has four alignment peg holes for the snout:

The OpenSCAD code sets the wall thickness to 3 thread widths, but Skeinforge prints two adjacent threads with no fill at all. I think the polygon corners eliminate the one-thread-width fill and the perimeter threads wind up near enough to merge properly.

I assembled snouts to main tubes first, because it was easier to clamp bare cylinders to the bench:

Then glue the tube to the mounting plate using a couple of clamps:

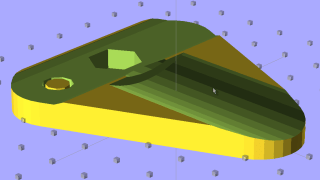

The alignment is pretty close to being right, but if when I do this again I’ll add alignment pegs along the trench in the mounting plate to make sure the tube doesn’t ease slightly to one side, thusly:

You can see the entrance pupil isn’t quite filled in the last picture there, so a bit more attention to detail is in order. A bigger doublet lens would help, too.

The current version of the OpenSCAD source code with those pegs:

// Close-up lens mount & Microscope adapter for Canon SX230HS camera

// Ed Nisley KE4ZNU - Nov 2011

Mount = "LEDRing"; // End result: LEDRing Eyepiece

Layout = "Show"; // Assembly: Show

// Parts: Plate Tube LEDRing Camera Eyepiece

// Build Plates: Build1..4

Gap = 10; // between "Show" objects

include </home/ed/Thing-O-Matic/lib/MCAD/units.scad>

include </home/ed/Thing-O-Matic/Useful Sizes.scad>

include </home/ed/Thing-O-Matic/lib/visibone_colors.scad>

//-------

//- Extrusion parameters must match reality!

// Print with +1 shells, 3 solid layers, 0.2 infill

ThreadThick = 0.33;

ThreadWidth = 2.0 * ThreadThick;

HoleFinagle = 0.2;

HoleFudge = 1.00;

function HoleAdjust(Diameter) = HoleFudge*Diameter + HoleFinagle;

Protrusion = 0.1; // make holes end cleanly

function IntegerMultiple(Size,Unit) = Unit * ceil(Size / Unit);

//-------

// Dimensions

// doublet lens

LensDia = 25.0;

LensRad = LensDia/2;

LensClearance = 0.2;

LensEdge = 6.7;

LensThick = 8.6;

LensRimThick = IntegerMultiple((2.0 + LensThick),ThreadThick);

// LED ring light

LEDRingOD = 50.0;

LEDRingID = 36.0;

LEDBoardThick = 1.5;

LEDThick = 4.0;

LEDRingClearance = 0.5;

LEDWireHoleDia = 3.0;

// microscope eyepiece

EyepieceOD = 30.0;

EyepieceID = 24.0;

EyepieceLength = 25.0;

// camera

// Origin at base of [0] ring, Z+ along lens axis, X+ toward bottom, Y+ toward left

CameraBodyWidth = 2*10.6; // 2 x center-to-curve edge

CameraBaseWidth = 15.5; // flat part of bottom front to back

CameraBaseRadius = (CameraBodyWidth - CameraBaseWidth)/2; // edge rounding

CameraBaseLength = 60.0; // centered on lens axis

CameraBaseHeight = 55.0; // main body height

CameraBaseThick = 0.9; // downward from lens ring

echo(str("Camera base radius: ",CameraBaseRadius));

TripodHoleOffset = -19.0; // mount screw wrt lens centerline

TripodHoleDia = Clear025_20; // clearance hole

TripodScrewHeadDia = 14.5; // recess for screw mounting camera

TripodScrewHeadRad = TripodScrewHeadDia/2;

TripodScrewHeadThick = 3.0;

// main lens tube

TubeDia = [53.0, 44.0, 40.0, 37.6]; // lens rings, [0] is fixed to body

TubeLength = [8.1, 20.6, 17.6, 12.7];

TubeEndClearance = 2.0; // camera lens end to tube end

TubeEndThickness = IntegerMultiple(1.5,ThreadThick);

TubeInnerClearance = 0.5;

TubeInnerLength = TubeLength[0] + TubeLength[1] + TubeLength[2] + TubeLength[3] +

TubeEndClearance;

TubeOuterLength = TubeInnerLength + TubeEndThickness;

TubeID = TubeDia[0] + TubeInnerClearance;

TubeOD = TubeID + 6*ThreadWidth;

TubeWall = (TubeOD - TubeID)/2;

TubeSides = 48;

echo(str("Main tube outer length: ",TubeOuterLength));

echo(str(" ID: ",TubeID," OD: ",TubeOD," wall: ",TubeWall));

// camera mounting base

BaseWidth = IntegerMultiple((CameraBaseWidth + 2*CameraBaseRadius),ThreadThick);

BaseLength = 60.0;

BaseThick = IntegerMultiple((1.0 + Nut025_20Thick + CameraBaseThick),ThreadThick);

// LED ring mount

LEDBaseThick = IntegerMultiple(2.0,ThreadThick); // base under lens + LED ring

LEDBaseRimWidth = IntegerMultiple(6.0,ThreadWidth);

LEDBaseRimThick = IntegerMultiple(LensThick,ThreadThick);

LEDBaseOD = max((LEDRingOD + LEDRingClearance + LEDBaseRimWidth),TubeOD);

echo(str("LED Ring OD: ",LEDBaseOD));

// alignment pins between tube and LED ring / microscope eyepiece

AlignPinOD = 2.9;

SnoutPins = 4;

SnoutPinCircleDia = TubeOD - 2*TubeWall - 2*AlignPinOD; // 2*PinOD -> more clearance

// alignment pins between tube and base plate

BasePins = 2;

BasePinOffset = 10.0;

BasePinSpacing = BaseLength/3;

//-------

module PolyCyl(Dia,Height,ForceSides=0) { // based on nophead's polyholes

Sides = (ForceSides != 0) ? ForceSides : (ceil(Dia) + 2);

FixDia = Dia / cos(180/Sides);

cylinder(r=HoleAdjust(FixDia)/2,h=Height,$fn=Sides);

}

module ShowPegGrid(Space = 10.0,Size = 1.0) {

Range = floor(50 / Space);

for (x=[-Range:Range])

for (y=[-Range:Range])

translate([x*Space,y*Space,Size/2])

%cube(Size,center=true);

}

//-------

//- Camera body segment

// Including lens base and peg for tripod hole access

// Z=0 at edge of lens base ring, X=0 along lens axis

module CameraBody() {

translate([0,0,-CameraBaseThick])

rotate(90)

union() {

translate([0,0,(CameraBaseHeight/2 + CameraBaseRadius)])

minkowski() {

cube([CameraBaseWidth,

(CameraBaseLength + 2*Protrusion),

CameraBaseHeight],center=true);

rotate([90,0,0])

cylinder(r=CameraBaseRadius,h=Protrusion,$fn=8);

}

translate([0,0,(TubeDia[0]/2 + CameraBaseThick)])

rotate([0,90,0])

rotate(180/TubeSides)

cylinder(r=(TubeDia[0]/2 + CameraBaseThick),

h=(CameraBodyWidth/2 + Protrusion),

$fn=TubeSides);

translate([CameraBodyWidth/2,0,(TubeDia[0]/2 + CameraBaseThick)])

rotate([0,90,0])

cylinder(r=TubeDia[0]/2,h=TubeLength[0]);

translate([(TubeLength[0] + CameraBodyWidth/2),

0,(TubeDia[0]/2 + CameraBaseThick)])

rotate([0,90,0])

cylinder(r=TubeDia[1]/2,h=TubeLength[1]);

translate([(TubeLength[0] + TubeLength[1] + CameraBodyWidth/2),

0,(TubeDia[0]/2 + CameraBaseThick)])

rotate([0,90,0])

cylinder(r=TubeDia[2]/2,h=TubeLength[2]);

translate([(TubeLength[0] + TubeLength[1] + TubeLength[2] + CameraBodyWidth/2),

0,(TubeDia[0]/2 + CameraBaseThick)])

rotate([0,90,0])

cylinder(r=TubeDia[3]/2,h=TubeLength[3]);

translate([0,TripodHoleOffset,-BaseThick])

PolyCyl(TripodHoleDia,(BaseThick + 2*Protrusion));

}

}

//- Main tube

module Tube() {

difference() {

cylinder(r=TubeOD/2,h=TubeOuterLength,$fn=TubeSides);

translate([0,0,TubeEndThickness])

PolyCyl(TubeID,(TubeInnerLength + Protrusion),TubeSides);

translate([0,0,-Protrusion]) {

if (Mount == "LEDRing")

cylinder(r=LensRad,h=(TubeEndThickness + 2*Protrusion));

if (Mount == "Eyepiece")

cylinder(r=EyepieceID/2,h=(TubeEndThickness + 2*Protrusion));

}

for (Index = [0:SnoutPins-1])

rotate(Index*90)

translate([(SnoutPinCircleDia/2),0,-ThreadThick])

rotate(180) // flat sides outward

PolyCyl(AlignPinOD,TubeEndThickness);

for (Index = [0:BasePins-1])

translate([0,-(TubeOD/2 + Protrusion),

(TubeOuterLength - BasePinOffset - Index*BasePinSpacing)])

rotate([-90,90,0]) // y = flat toward camera

PolyCyl(AlignPinOD,(TubeWall + 2*Protrusion));

}

}

//- Base plate

module BasePlate() {

union() {

difference() {

linear_extrude(height=BaseThick)

hull() {

translate([-(BaseLength/2 - BaseWidth/2),0,0])

circle(BaseWidth/2);

translate([ (BaseLength/2 - BaseWidth/2),0,0])

circle(BaseWidth/2);

translate([0,(0.75*BaseLength),0])

circle(BaseWidth/2);

}

translate([0,0,BaseThick])

CameraBody();

translate([0,(TubeOuterLength + CameraBodyWidth/2),

(BaseThick + TubeDia[0]/2)])

rotate([90,0,0])

PolyCyl(TubeOD,TubeOuterLength,$fn=TubeSides);

for (Index = [0:BasePins-1])

translate([0,(CameraBodyWidth/2 + BasePinOffset + Index*BasePinSpacing),

3*ThreadThick])

rotate(90) // flat toward camera

PolyCyl(AlignPinOD,BaseThick);

translate([0,0,3*ThreadThick])

PolyCyl((Nut025_20Dia*sqrt(3)/2),2*Nut025_20Thick,6); // dia across hex flats

translate([0,0,-Protrusion])

PolyCyl(Clear025_20,(BaseThick + 2*Protrusion));

translate([TripodHoleOffset,0,3*ThreadThick])

PolyCyl((Nut025_20Dia*sqrt(3)/2),2*Nut025_20Thick,6); // dia across hex flats

translate([TripodHoleOffset,0,-Protrusion])

PolyCyl(Clear025_20,(BaseThick + 2*Protrusion));

translate([-TripodHoleOffset,0,-Protrusion])

PolyCyl(TripodScrewHeadDia,(TripodScrewHeadThick + Protrusion));

}

translate([-TripodHoleOffset,0,0]) { // support for tripod screw hole

for (Index=[0:3])

rotate(Index*45)

translate([-ThreadWidth,-TripodScrewHeadRad,0])

cube([2*ThreadWidth,TripodScrewHeadDia,TripodScrewHeadThick]);

cylinder(r=0.4*TripodScrewHeadRad,h=(BaseThick - CameraBaseThick),$fn=9);

}

}

}

//- LED mounting ring

module LEDRing() {

difference() {

cylinder(r=LEDBaseOD/2,h=LensRimThick,$fn=48);

translate([0,0,-Protrusion])

PolyCyl((LensDia + LensClearance),

(LensRimThick + 2*Protrusion));

translate([0,0,LEDBaseRimThick])

difference() {

PolyCyl(LEDBaseOD,LensThick);

PolyCyl(LEDRingID,LensThick);

}

translate([0,0,LEDBaseThick])

difference() {

PolyCyl((LEDRingOD + LEDRingClearance),LensThick);

cylinder(r1=HoleAdjust(LEDRingID - LEDRingClearance)/2,

r2=HoleAdjust(LensDia + LensClearance)/2 + 2*ThreadWidth,

h=LensThick);

}

for (Index = [0:SnoutPins-1])

rotate(Index*90)

translate([(SnoutPinCircleDia/2),0,-ThreadThick])

rotate(180) // flat sides outward

PolyCyl(AlignPinOD,LEDBaseThick);

rotate(45)

translate([0,LEDRingID/2,(LEDBaseThick + 1.2*LEDWireHoleDia/2)])

rotate([0,-90,0]) // flat side down

rotate([-90,0,0])

PolyCyl(LEDWireHoleDia,2*LEDBaseRimWidth);

}

}

//- Microscope eyepiece adapter

module EyepieceMount() {

difference() {

cylinder(r1=TubeOD/2,

r2=(EyepieceOD + 8*ThreadWidth)/2,

h=EyepieceLength,

$fn=TubeSides);

translate([0,0,-Protrusion])

PolyCyl(EyepieceOD,(EyepieceLength + 2*Protrusion));

for (Index = [0:SnoutPins-1])

rotate(Index*90)

translate([(SnoutPinCircleDia/2),0,-ThreadThick])

rotate(180) // flat sides outward

PolyCyl(AlignPinOD,6*ThreadThick);

}

}

//-------

// Build it!

if (Layout != "Show")

ShowPegGrid();

if (Layout == "Tube")

Tube();

if (Layout == "LEDRing")

LEDRing();

if (Layout == "Plate")

BasePlate();

if (Layout == "Camera")

CameraBody();

if (Layout == "Eyepiece")

EyepieceMount();

if (Layout == "Build1")

translate([0,-BaseLength/3,0])

BasePlate();

if (Layout == "Build2")

Tube();

if (Layout == "Build3")

LEDRing();

if (Layout == "Build4")

EyepieceMount();

if (Layout == "Show") {

translate([0,TubeOuterLength,TubeDia[0]/2]) {

rotate([90,0,0])

color(LTC) Tube();

translate([0,(Gap/2 - TubeEndThickness - Protrusion),0])

rotate([-90,0,0])

for (Index = [0:SnoutPins-1])

rotate(Index*90)

translate([(SnoutPinCircleDia/2),0,0])

rotate(180) // flat sides outward

PolyCyl(AlignPinOD,(TubeEndThickness + LEDBaseThick));

translate([0,Gap,0])

rotate([-90,0,0]) {

if (Mount == "LEDRing")

color(OOR) LEDRing();

if (Mount == "Eyepiece")

color(OOR) EyepieceMount();

}

}

translate([0,-CameraBodyWidth/2,0])

color(PG) CameraBody();

color(PDA)

render()

translate([0,-CameraBodyWidth/2,-(BaseThick + Gap)])

BasePlate();

for (Index = [0:BasePins-1])

translate([0,(BasePinOffset + Index*BasePinSpacing),

-Gap/2])

rotate([180,0,90]) // flat toward camera

PolyCyl(AlignPinOD,BaseThick/2);

}