After adding bling to the Prusa MK4, I touched up the belt tensions and re-measured the axis resonances with the Prusa Accelerometer gadget to update the Input Shaper settings.

The Prusa belt tension guide pretty much explains that subject, with their Belt Tuner making up for my utter tone deafness. FWIW, if the Belt Tuner produces inconsistent results differing by an octave, either up or down from the correct value, the belt is way too loose: give the axis belt tension screw a turn or two to drag the results into the right time zone, then fine-tune from there.

While it is possible to reach both tensioning screws without too much trouble, they’re definitely not convenient.

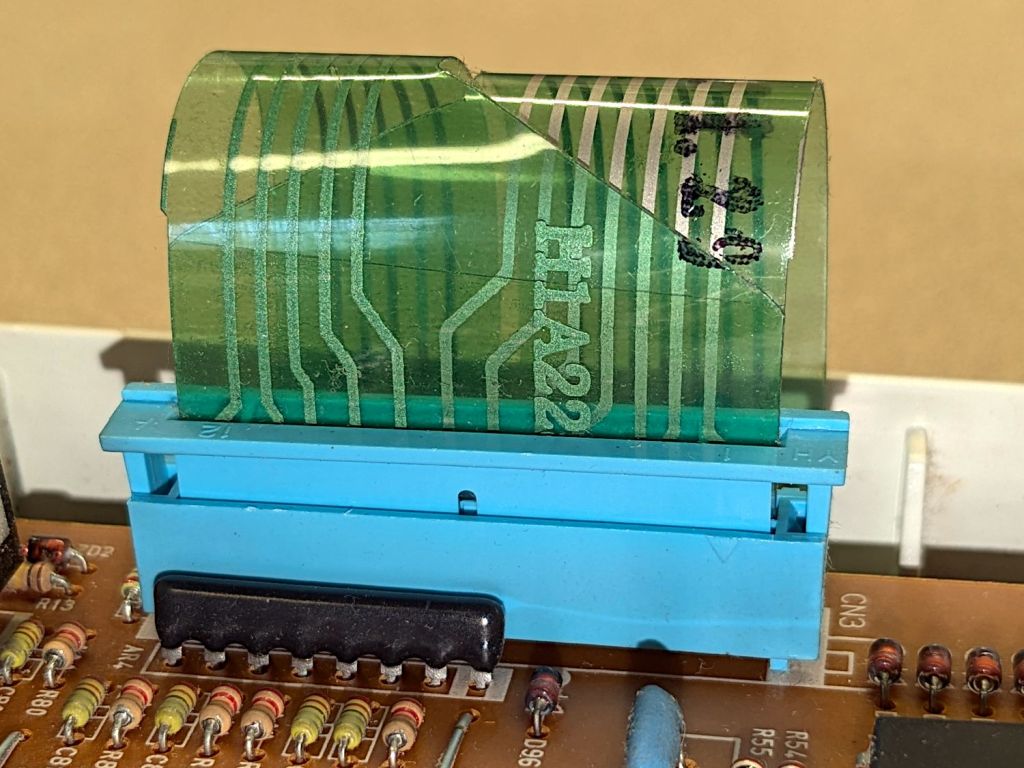

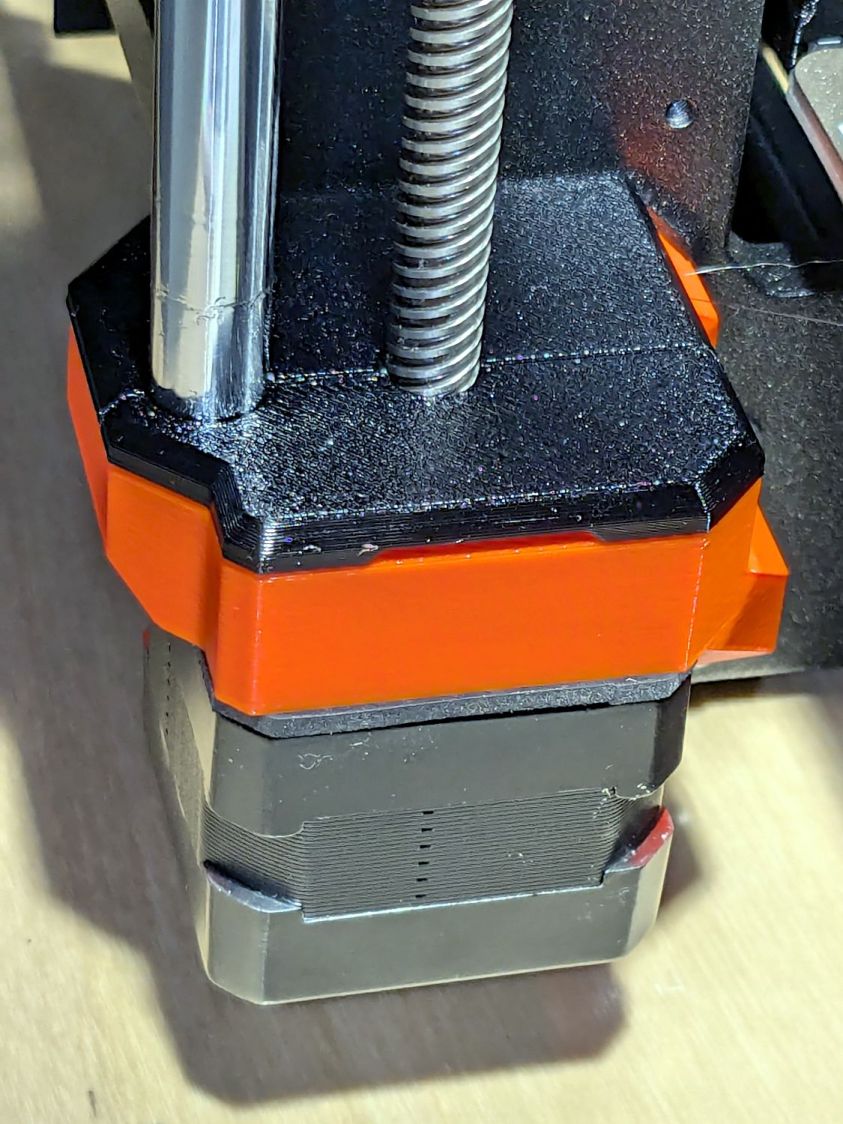

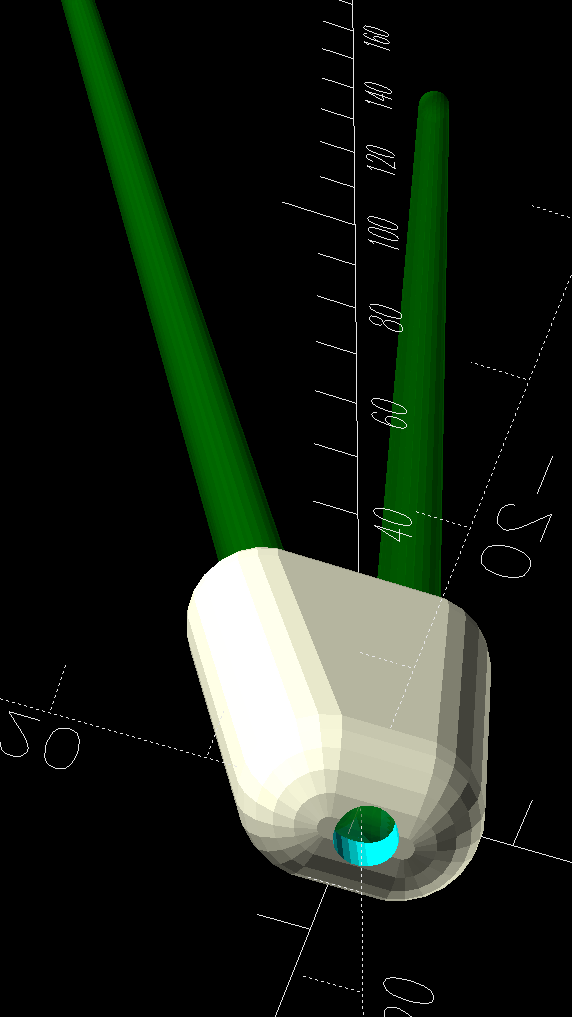

The accelerometer fits on the hot end:

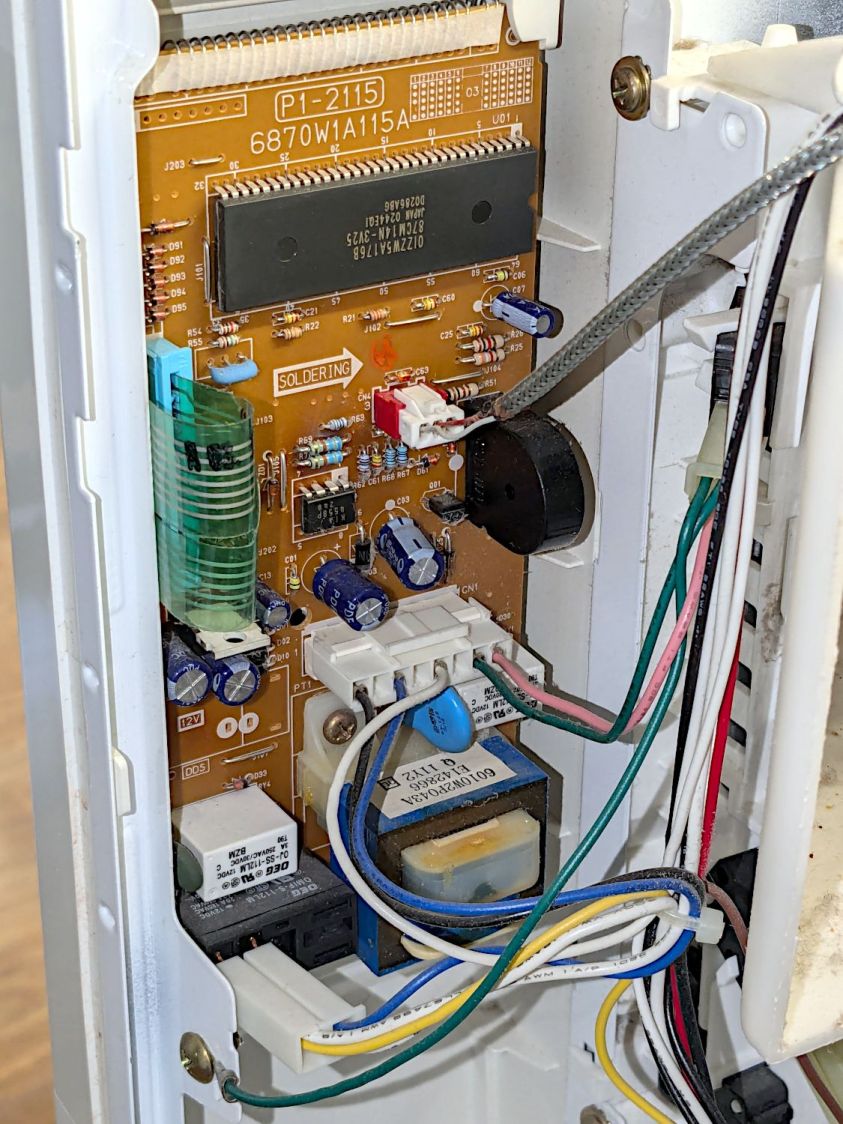

Then under the steel sheet, where it’s clamped by the platform magnets:

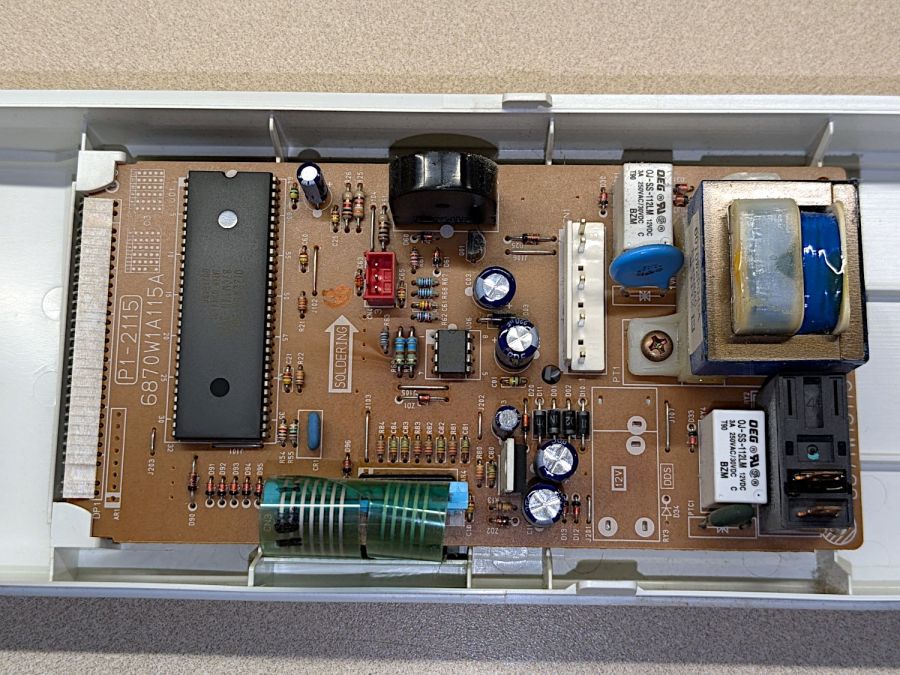

The MK4 firmware measures the resonant frequencies while prompting you to put the accelerometer in the proper locations, then computes the best shaper values.

For reference, the stock OEM values:

- X = MZV 50 Hz

- Y = MZV 40 Hz

Just after I got the accelerometer and without doing anything to prep the MK4, these results popped out:

- X = MZV 56 Hz

- Y = MZV 42 Hz

Now, with bling and properly tensioned belts:

- X = MZV 59 Hz

- Y = MZV 45 Hz

The most recent values were also the most stable, once again pointing out the value of careful assembly and maintenance.

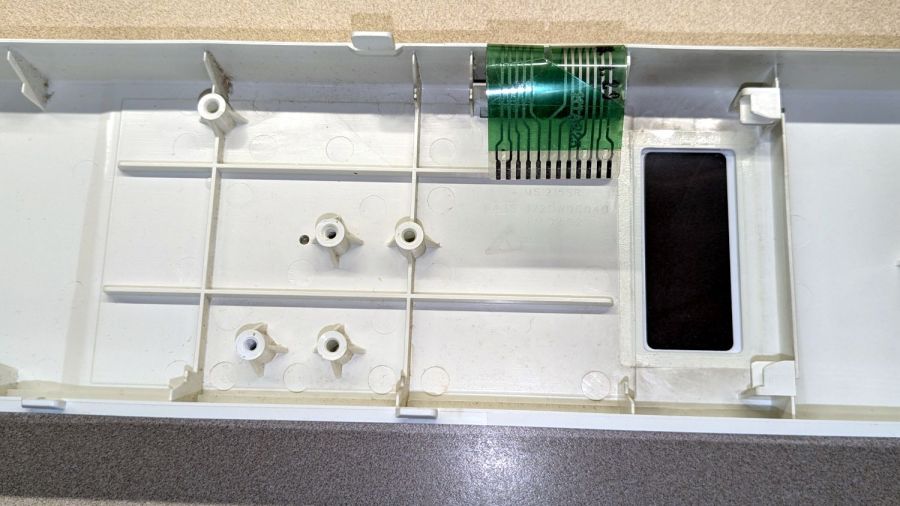

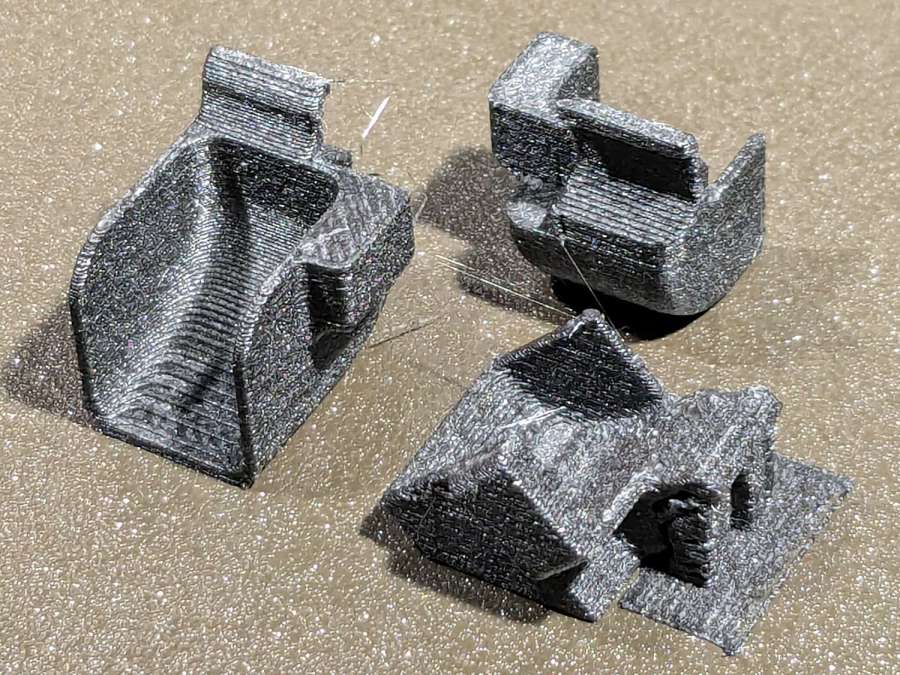

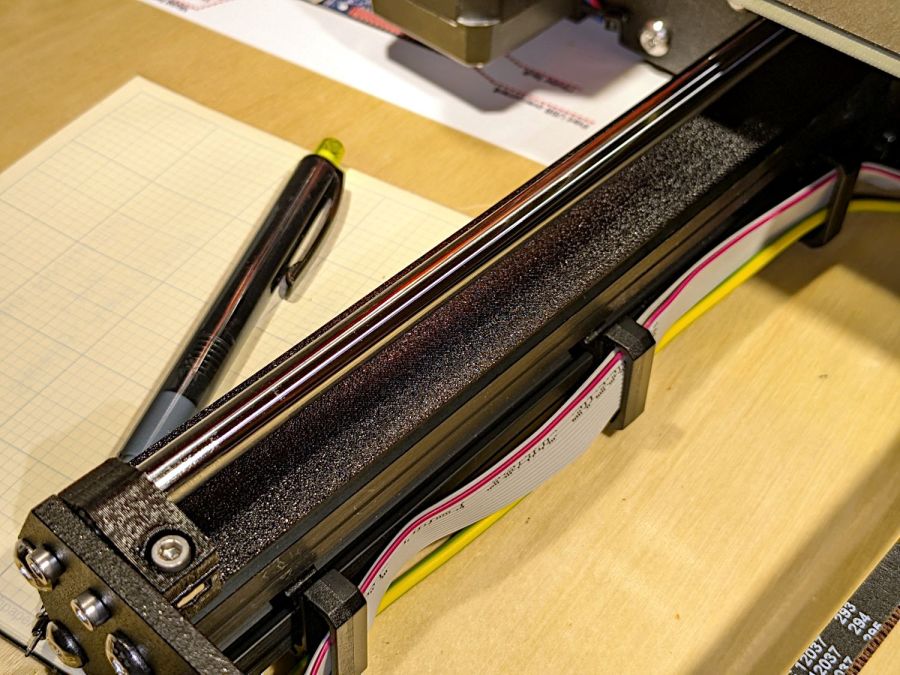

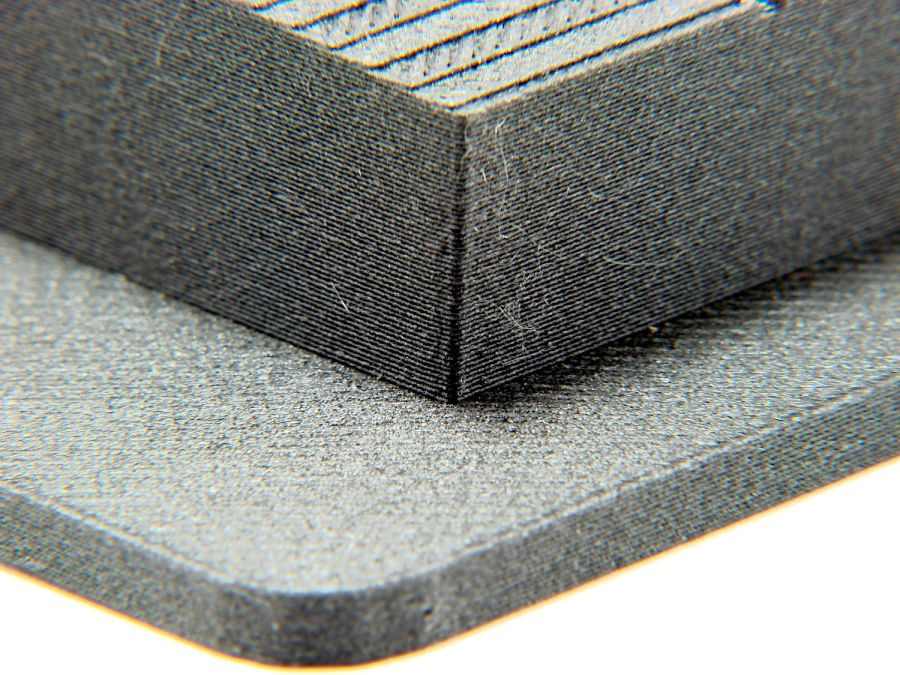

With that in mind, though, I built the laser ramp focus fixture shortly after doing the first recalibration and it has no visible ripples on any of its walls:

That’s a square corner perpendicular to the sloped top surface at the default 45 mm/s. It’s not as difficult a test as some you’ll see, but it suffices for my simple needs. The MK4 definitely behaves better around corners than the Makergear M2.