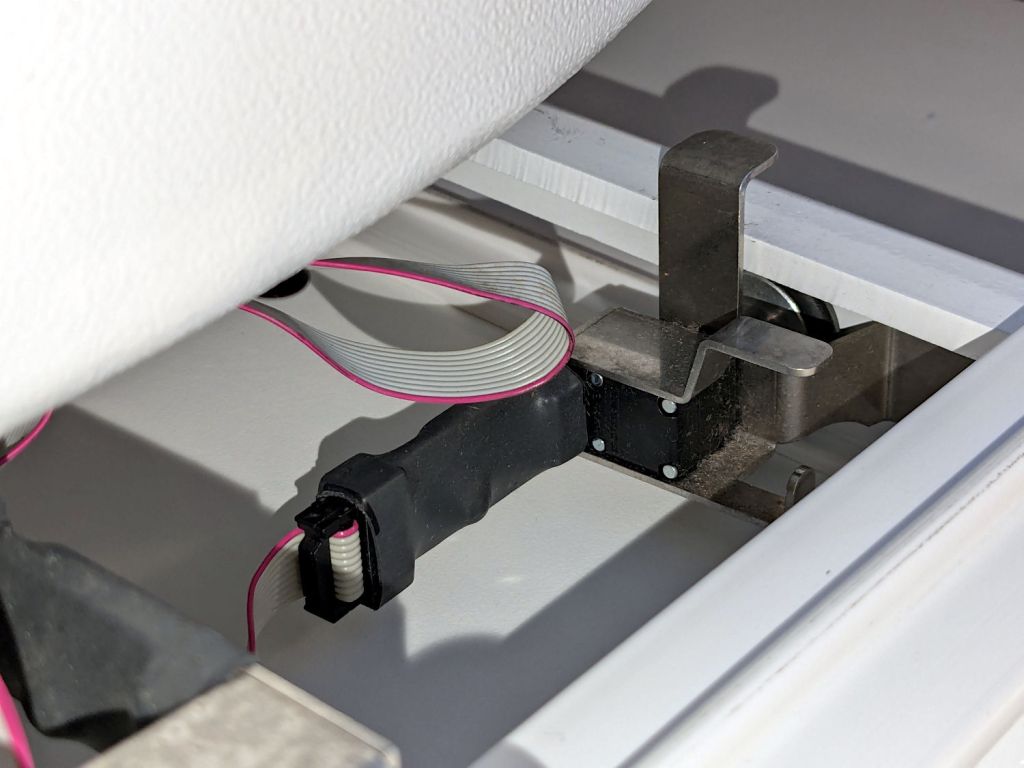

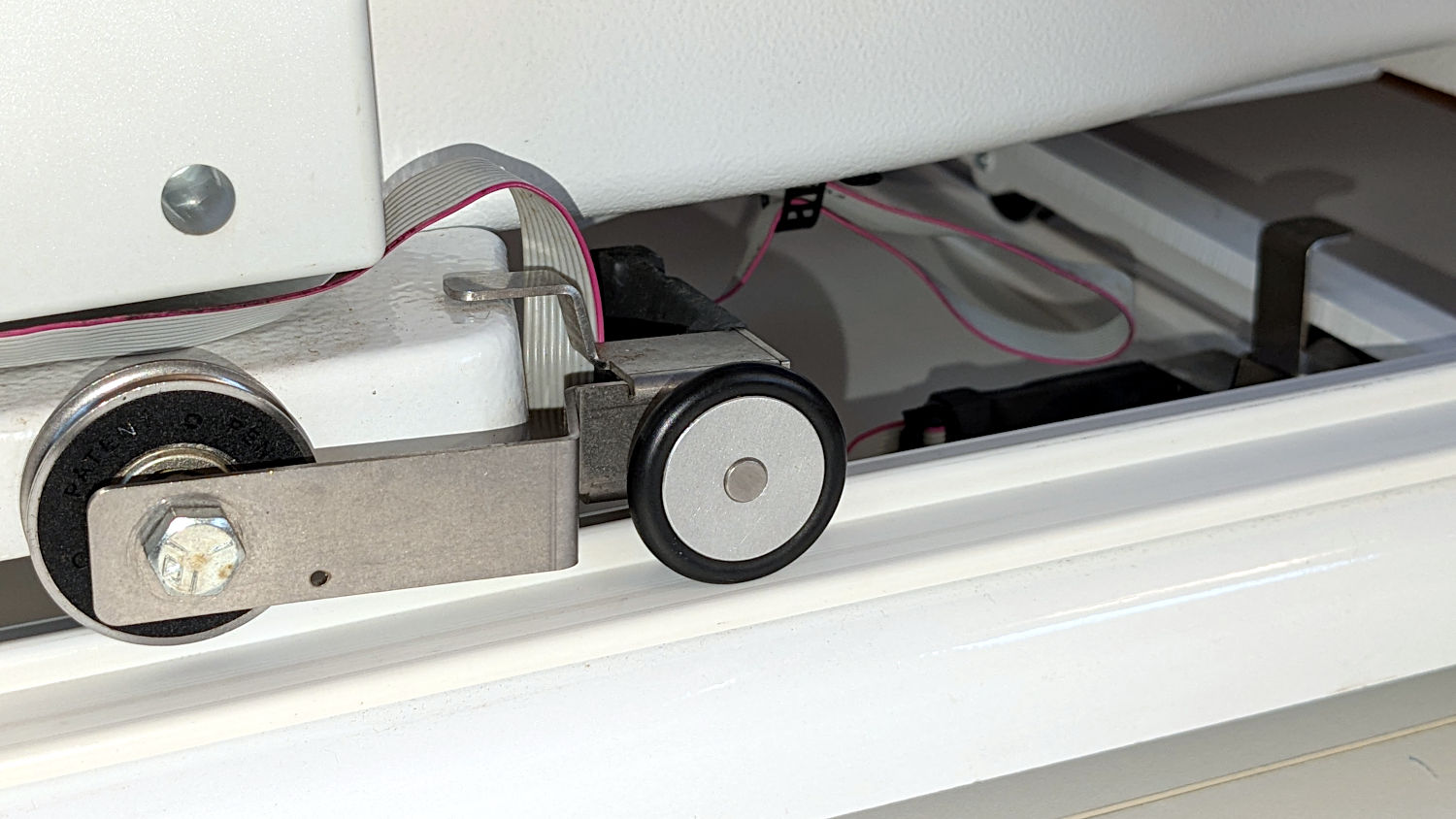

The stitch regulator on our Handi-Quilter HQ Sixteen uses a pair of encoder wheels running along the tracks supporting the machine:

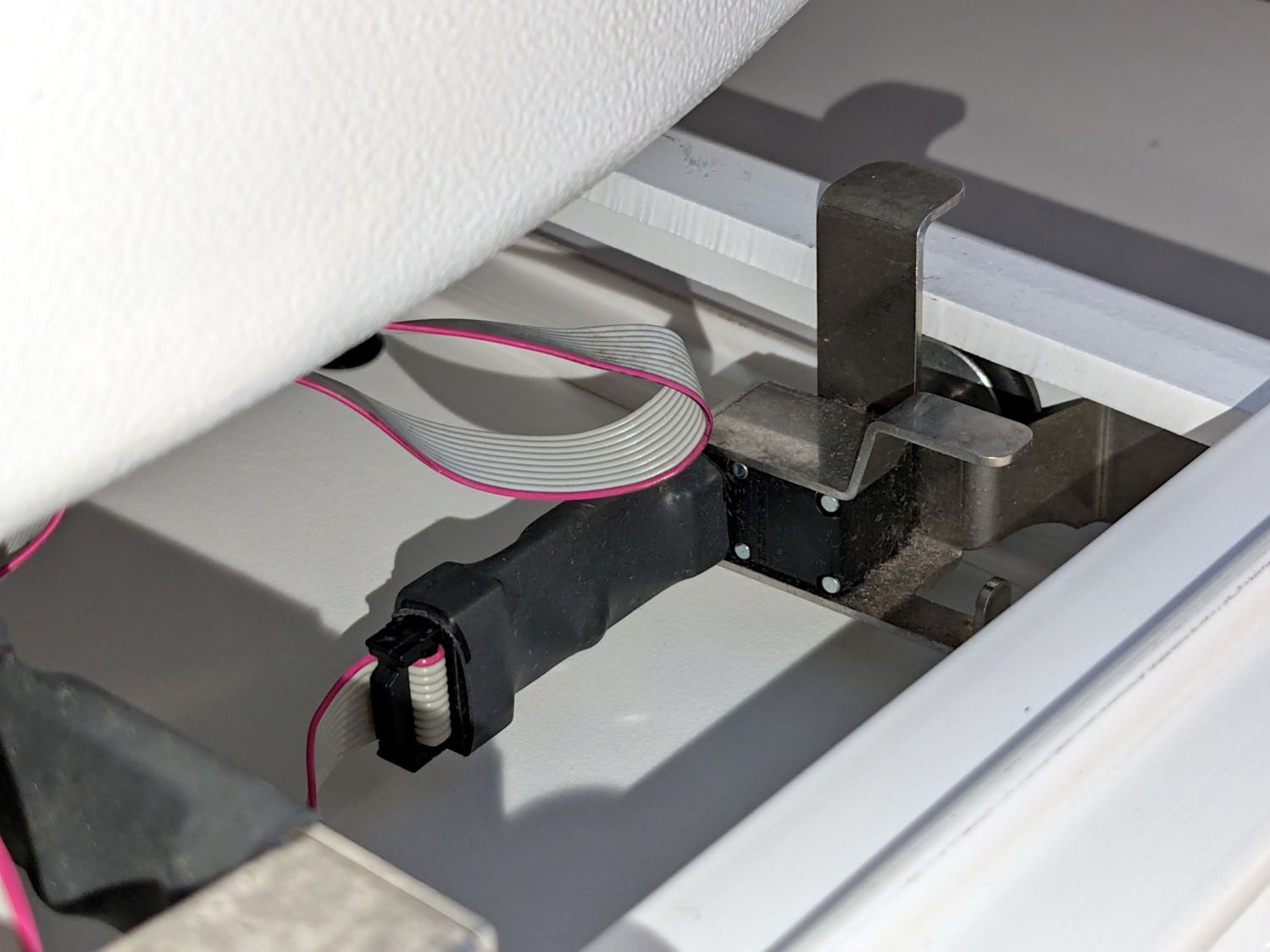

This must be HandiQuilter’s very first encoder version, because a ribbon cable connects the encoders to the control pod:

I stuck an adhesive cable clamp under the machine to rein in some of the slack, but the jank is strong with that arrangement and I must figure out a better arrangement with supple cable and better support. We’ll run this lashup for a while.

Anyhow …

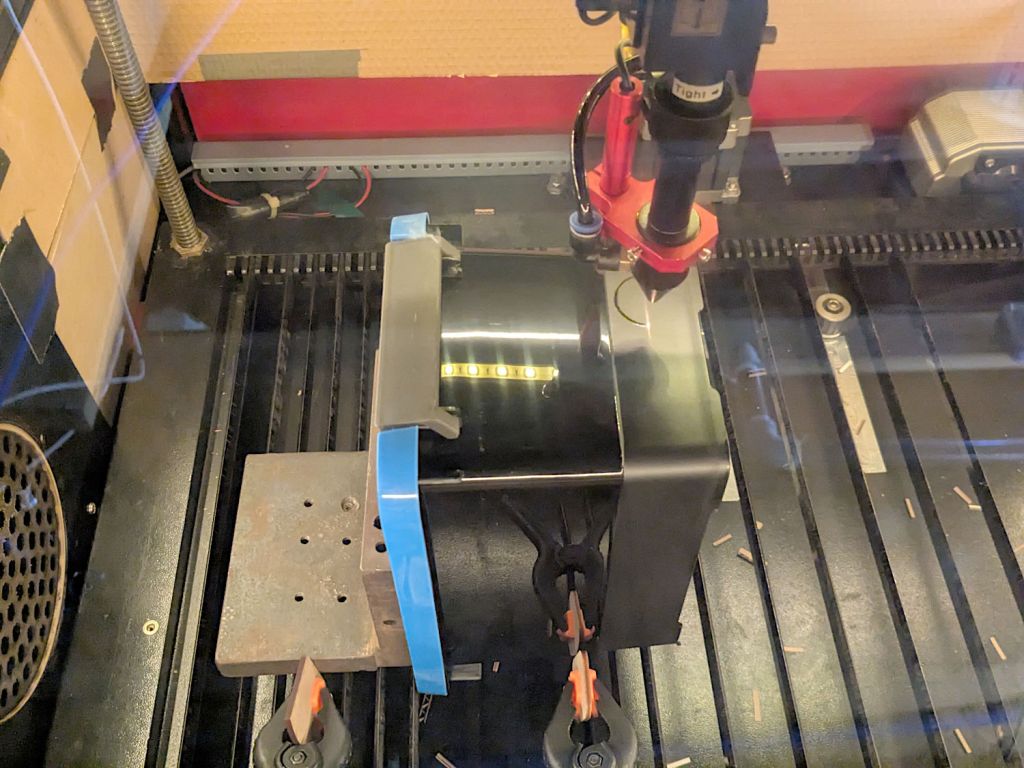

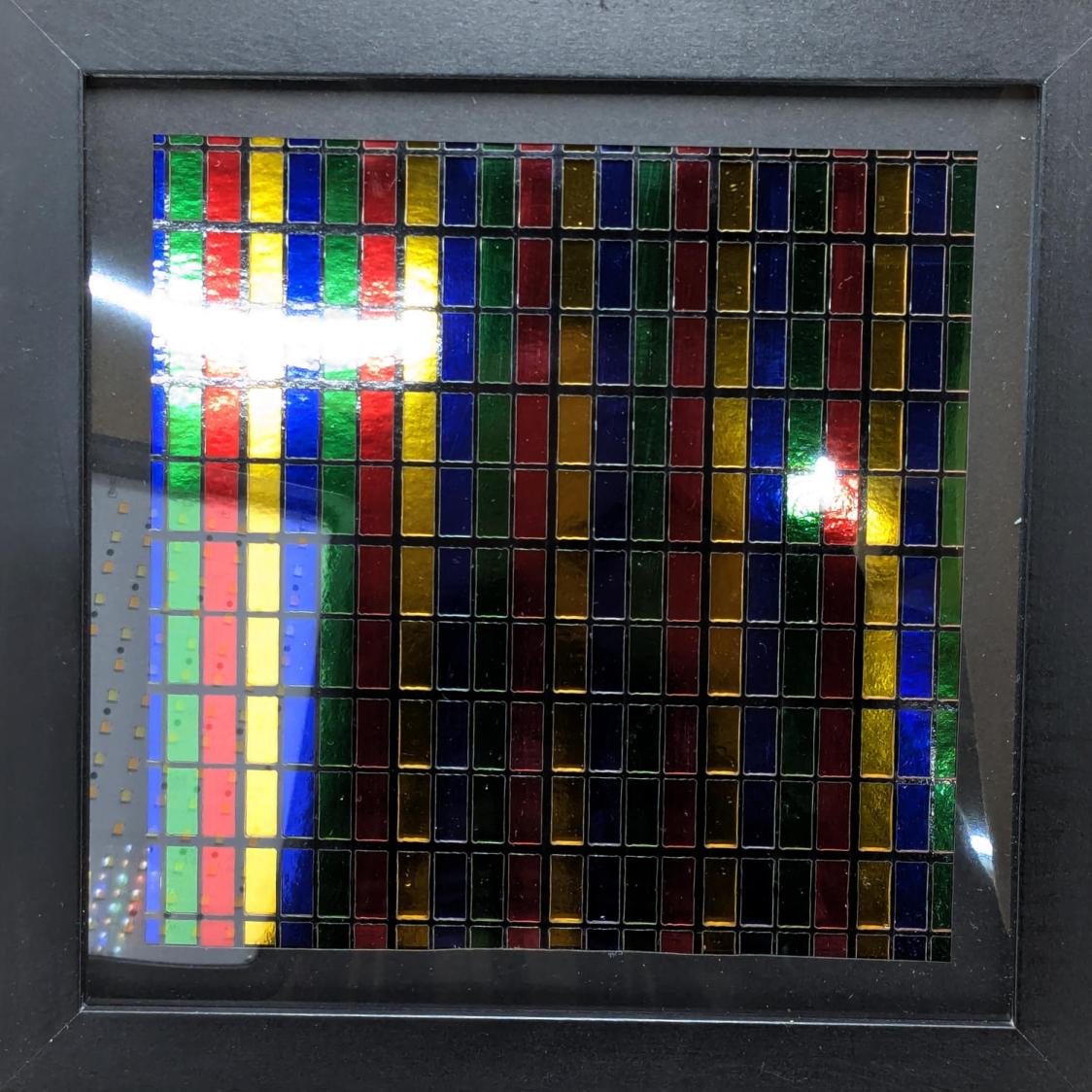

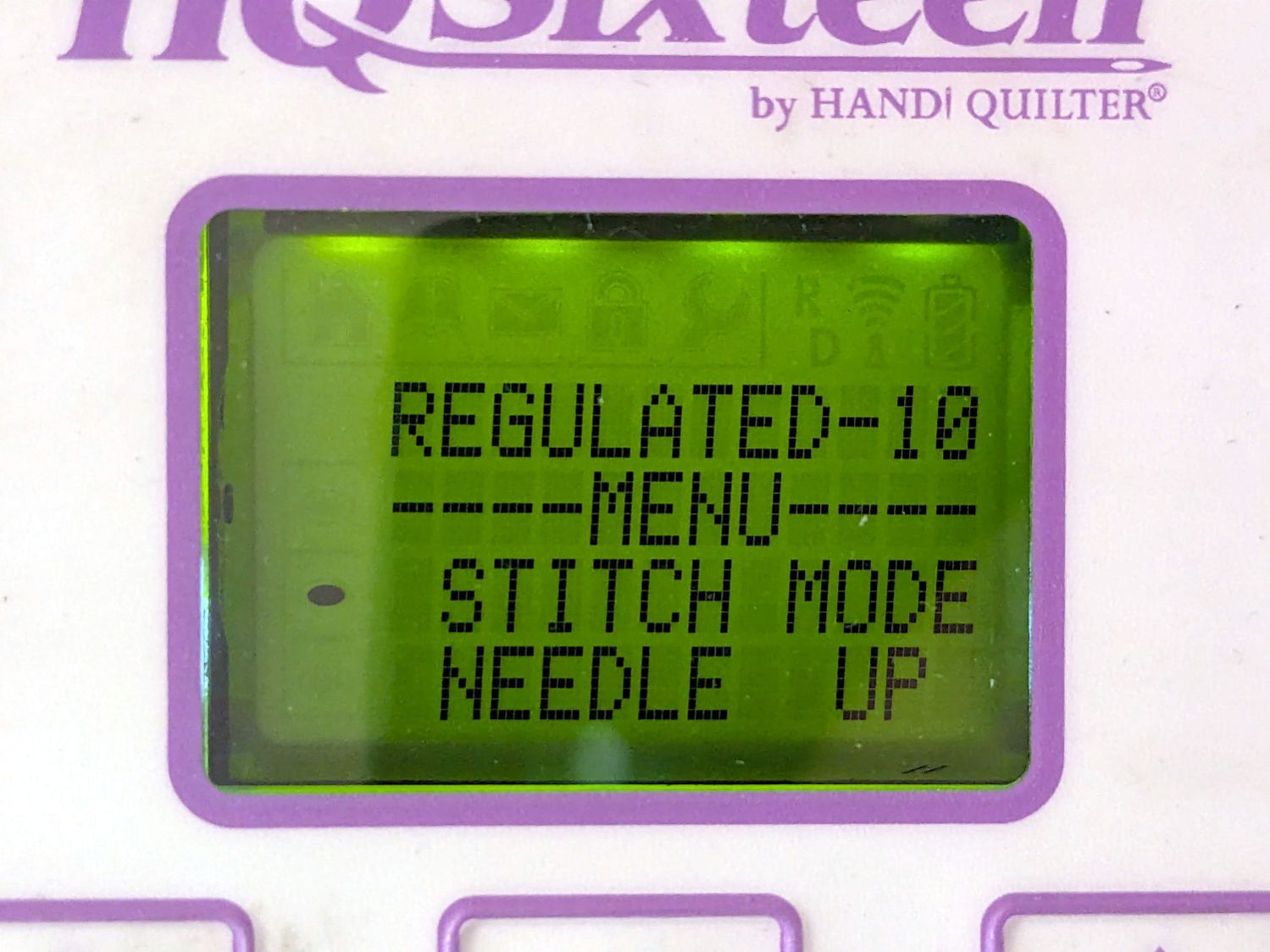

The stitch regulator uses signals from the wheels to measure the distance the machine travels across the fabric and controls the motor speed to produce a fixed number of stitches per inch at that travel speed, as set in the control panel:

Close inspection shows the LCD module came from an early 2000s mobile phone, but there’s no shame in repurposing cheap & readily available hardware.

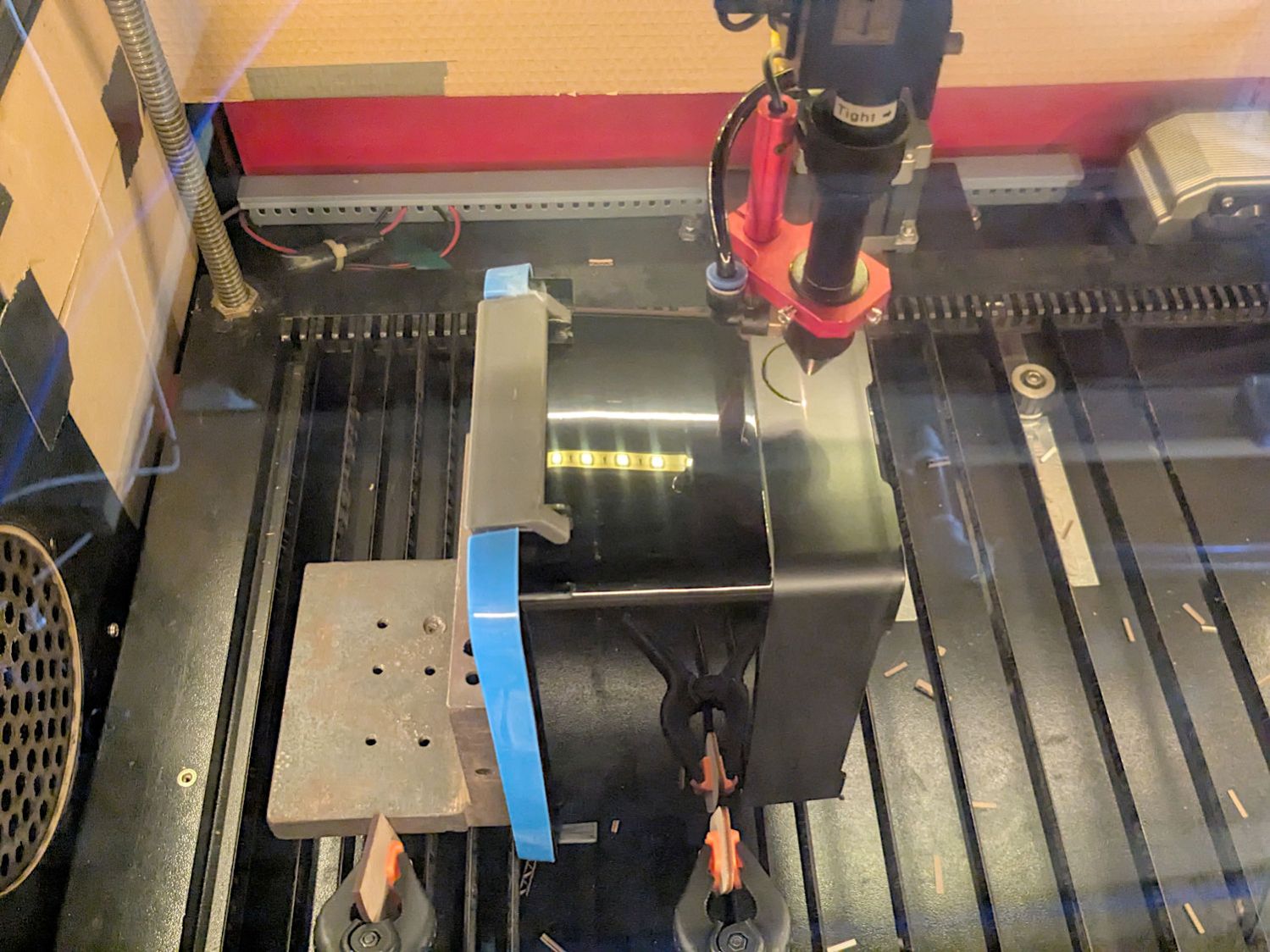

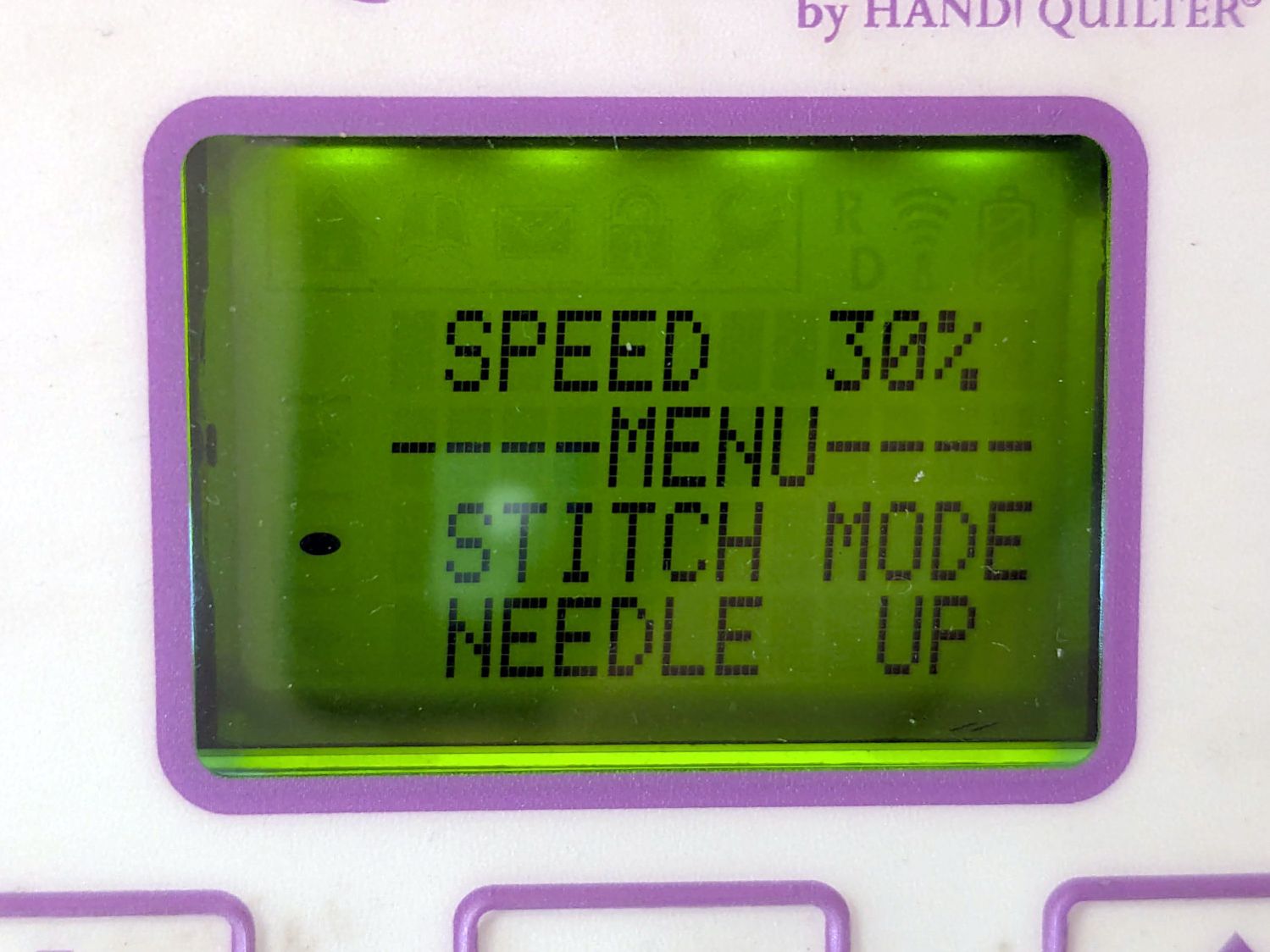

When the stitch regulator is not active, the machine runs at a fixed speed set on the control panel:

The controller can set the speed between 100% to 10% of the motor’s 1500 stitch/min full speed, with 1% steps that seem too large on the low end and too small for the high end. Aiming my laser tachometer at a retroreflective tape snippet on the handwheel shows the machine runs at the correct fractions of its actual 1492 stitch/min = RPM.

The stitch regulator uses the same motor speed range, which sets corresponding limits on the maximum and minimum speeds across the fabric, with the ratio set by the stitch/inch value.

At the 10 stitch/inch setting Mary has been using, the travel speed range is:

15 inch/min = (150 stitch/min) / (10 stitch/inch)150 inch/min = (1500 stitch/min) / (10 stitch/inch)

When you stop moving the machine, the controller will shut off the motor after a few stitches in the same place, which turns out to be convenient for tying off the end of a stitched line on a quilt. When you move too fast, the machine will top out at 1500 stitch/min while producing too-long stitches until the travel speed drops below 150 inch/min.

What’s not obvious is how slow those speeds are:

- 0.25 inch/s = 15 inch/min

- 2.5 inch/s = 150 inch/min

As an exercise, fire up the metronome app on your phone at one tick per second, then try drawing intricate patterns within those speed limits. You will inevitably move too fast, even without the soundtrack of a frantically accelerating motor topping out at 1500 RPM.

We think the surprisingly low upper speed limit accounts for much of the trouble Mary’s compadres report while using the stitch regulator.

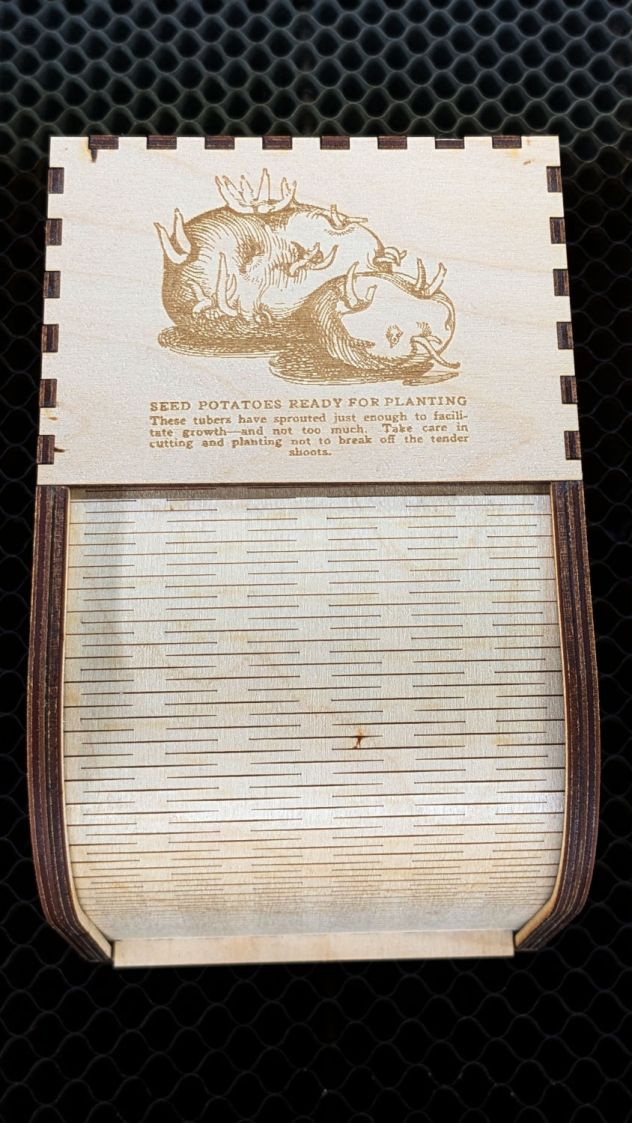

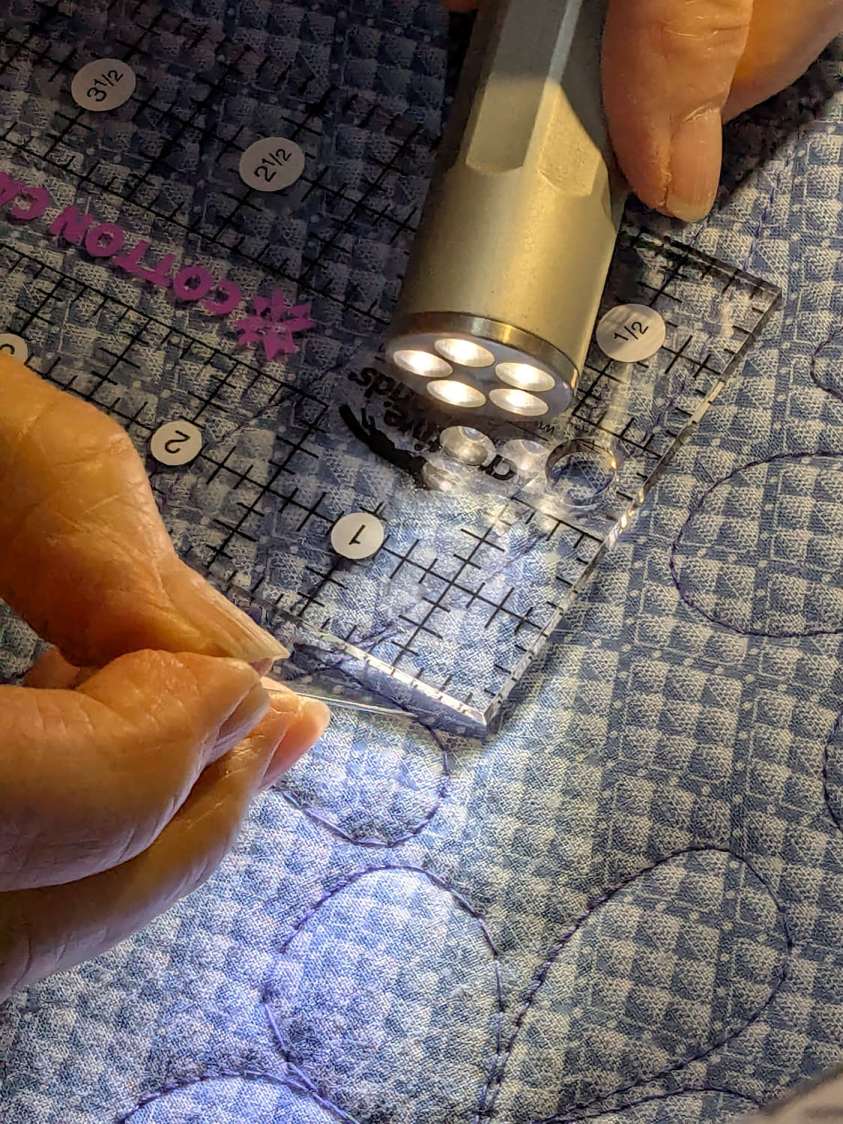

After laying down a few square yards of practice quilt patterns while measuring the results and becoming accustomed to the sound and feel of the machine running at high speeds, Mary’s producing good results:

I definitely hit the knees in gratitude when the stitch regulator Just Worked™ after plugging it in, because that ribbon cable did not inspire any confidence whatsoever.