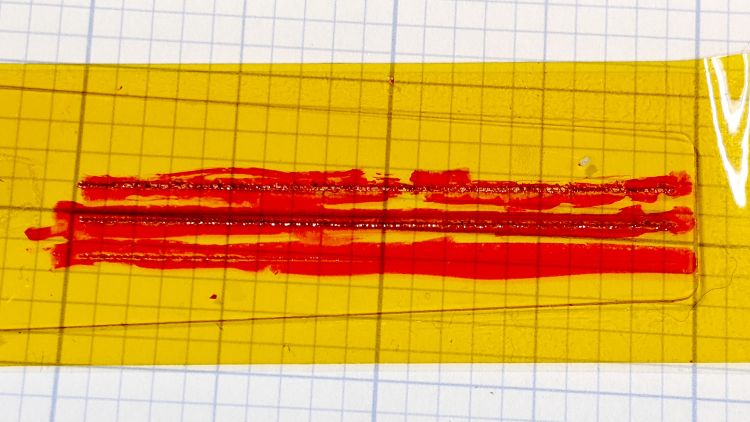

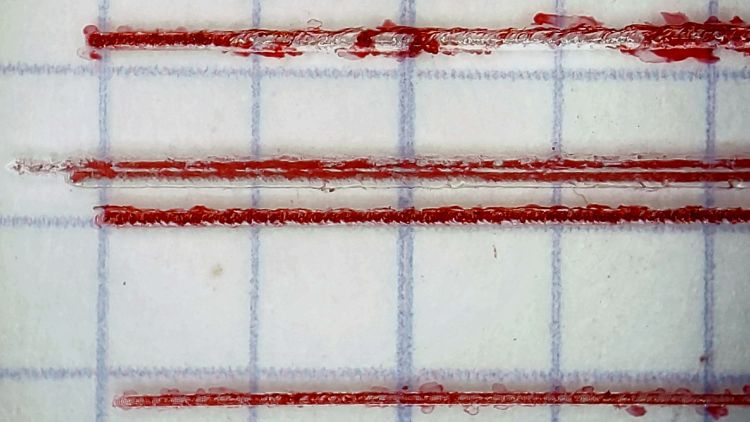

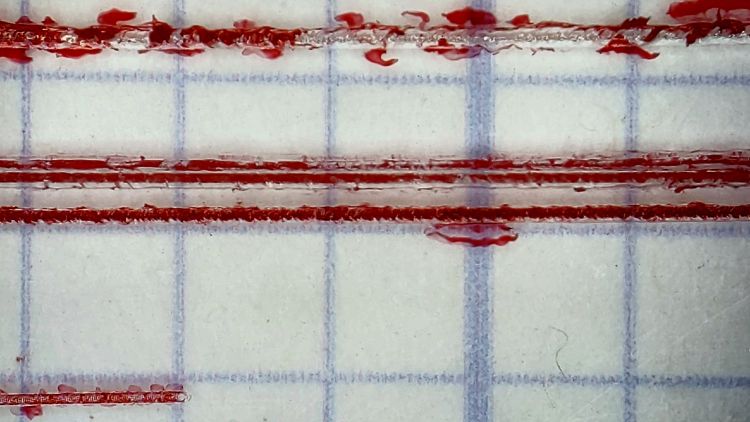

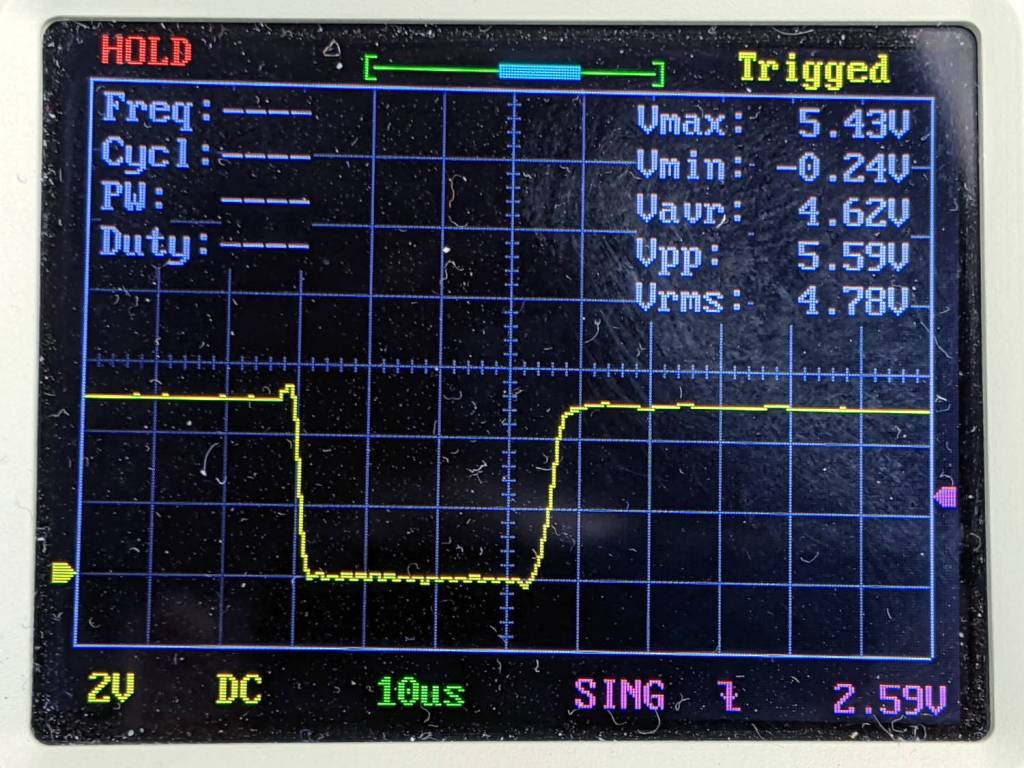

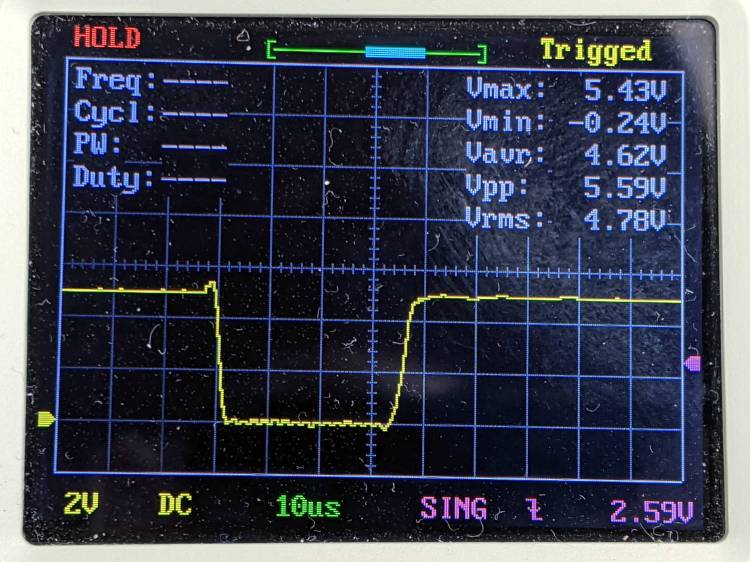

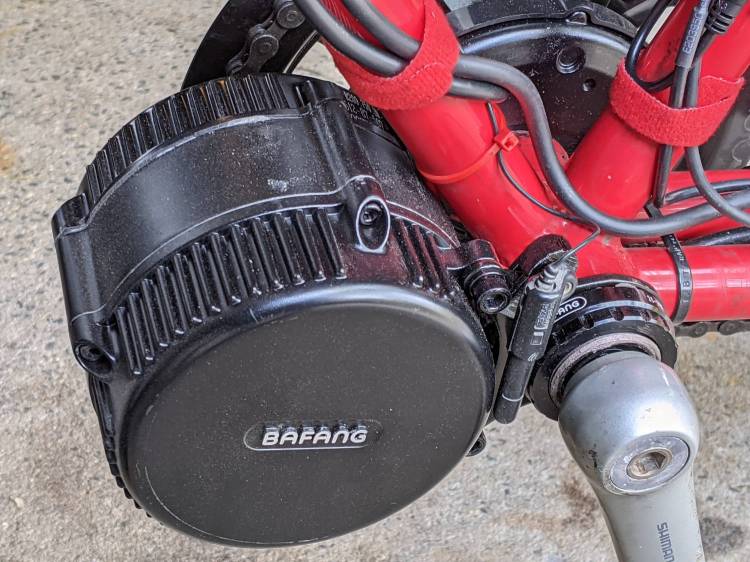

The Bafang BBS02 motor claims a 750 W power output, although I suspect that’s measured at the instant before it flings its guts across the test lab:

With a nominal 48 V battery supplying the motor’s nominal 24 A (some say 25 A) current, it dissipates well over 1100 W, although that’s obviously a short-term thing. With 750 W calling for 15-ish A, most likely it will (ideally) suffer thermal shutdown long before the battery runs out.

Torque being more-or-less proportional to current, its nominal 160 N·m torque at 24 A scales downward by the same factor as the current, for 100 N·m at 15 A.

The as-received Bafang BBS02 motor controller configuration provided far too much torque for our riding style; I think it’s intended for much younger folks tackling off-road trails on what used to be called mountain bikes, rather than assisting us with normal street riding.

For example, the default maximum current was 24 A and the first step of pedal assistance was 28% = 6.7 A → 45 N·m: a pretty hefty shove right off the starting line. The Tour Easy was pretty much uncontrollable in the driveway, which is a Bad Sign.

I started with the “Limitless” configuration (wherein the assistance for all steps continues up to the 20 mph overall speed limit) and reduced the maximum current to 15 A.

The first assistance step of 5% = 0.8 A → 5 N·m now compensates for the additional weight of the Bafang motor + battery and feels like the unloaded bike.

The second step was 37% = 8.9 A → 59 N·m and is now 7% = 1 A → 7 N·m, so Mary can ride along with a little oomph for minor hills.

The third step was 46% = 11 A → 74 N·m and is now 16% = 2.4 A → 16 N·m, enough for the admittedly gentle hills along Vassar Road.

The throttle uses the ninth step setting (100% = 15 A → 100 N·m) to provide a “get out of Dodge” boost at intersections.

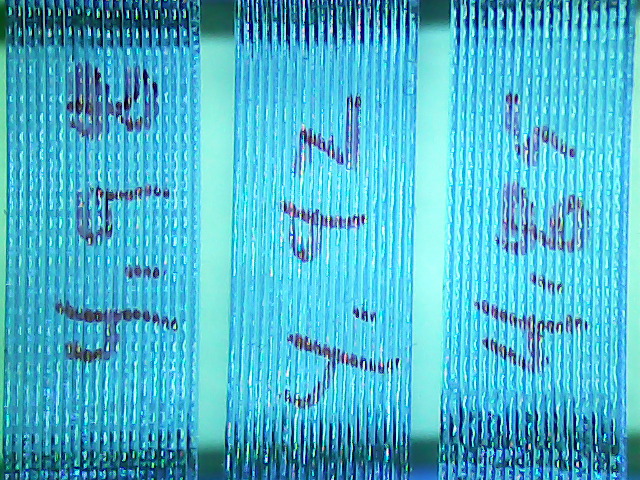

So far, the BBS02 configuration file looks like this:

[Basic]

LBP=42

LC=15

ALC0=0

ALC1=5

ALC2=7

ALC3=16

ALC4=25

ALC5=37

ALC6=51

ALC7=67

ALC8=85

ALC9=100

ALBP0=0

ALBP1=100

ALBP2=100

ALBP3=100

ALBP4=100

ALBP5=100

ALBP6=100

ALBP7=100

ALBP8=100

ALBP9=100

WD=12

SMM=0

SMS=1

[Pedal Assist]

PT=3

DA=0

SL=0

SSM=3

WM=0

SC=10

SDN=5

TS=10

CD=8

SD=1

KC=100

[Throttle Handle]

SV=11

EV=42

MODE=1

DA=10

SL=0

SC=10

Mary says she’s getting entirely enough exercise and, frankly, so am I. We have yet to try faster paces and steeper hills.