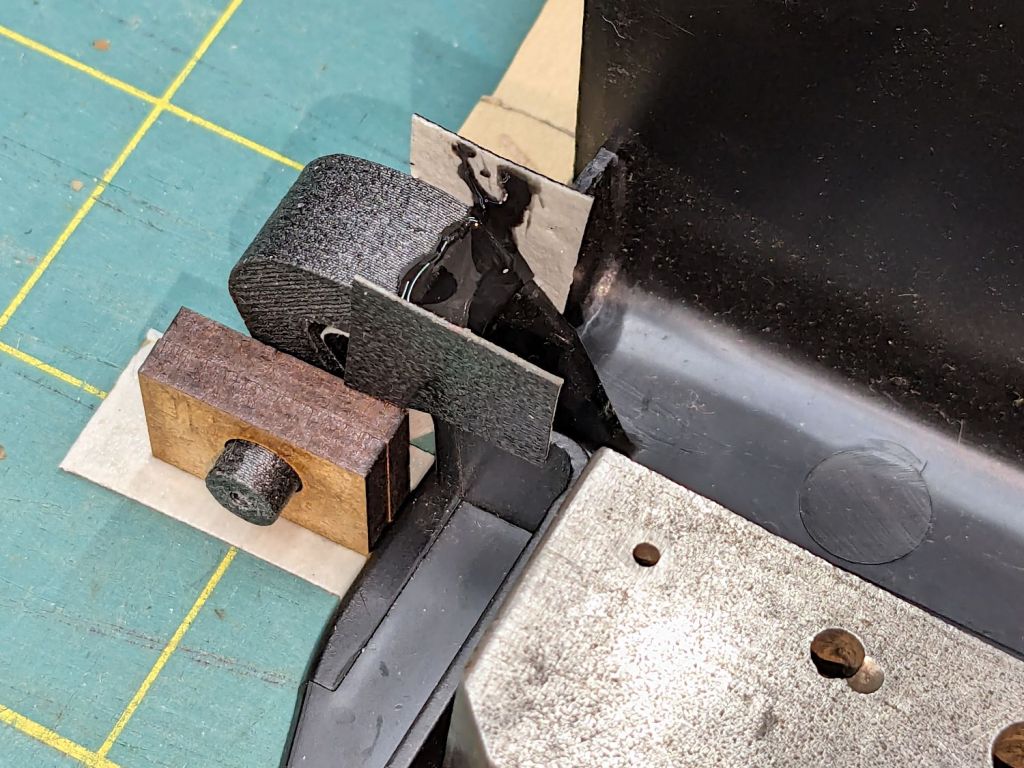

A pair of plant stands from a friend’s collection ended up in Mary’s care and cried out for feet to keep their welded steel wire legs from scratching the floor:

Admittedly, it’s not the prettiest stand you can imagine, but the sentimental value outweighs all other considerations.

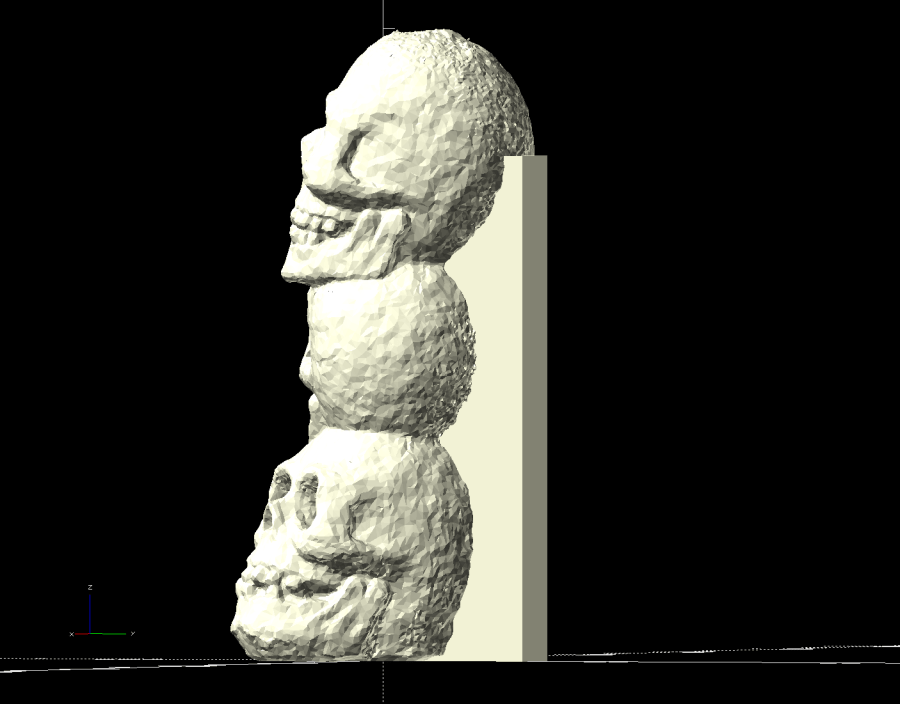

The feet are shrink-wrapped around the legs with enough curviness to look good:

With a drain hole in the bottom to prevent water from rusting the wires any more than they already are:

I briefly considered a flat bottom at the proper angle to sit on the floor, but came to my senses; it would never sit at the proper angle.

The end results snapped into place:

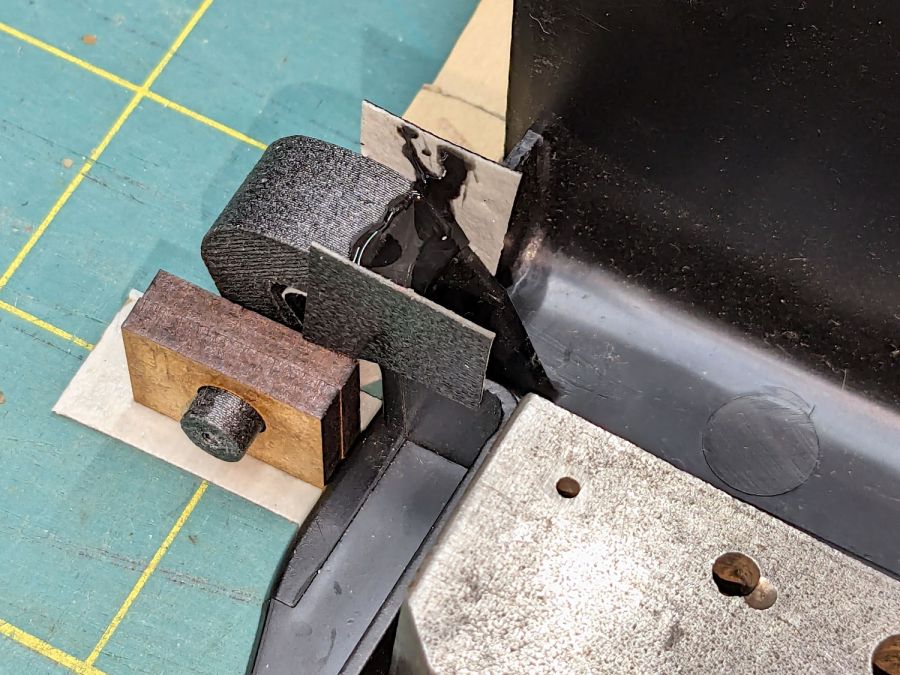

Of course the other stand, at first glance identical to the one above, has a different wire size and slightly different geometry, which I only discovered after printing another trio of feet. Changing the appropriate constants in the OpenSCAD program and waiting an hour produced a better outcome:

Living in the future is good, all things considered.

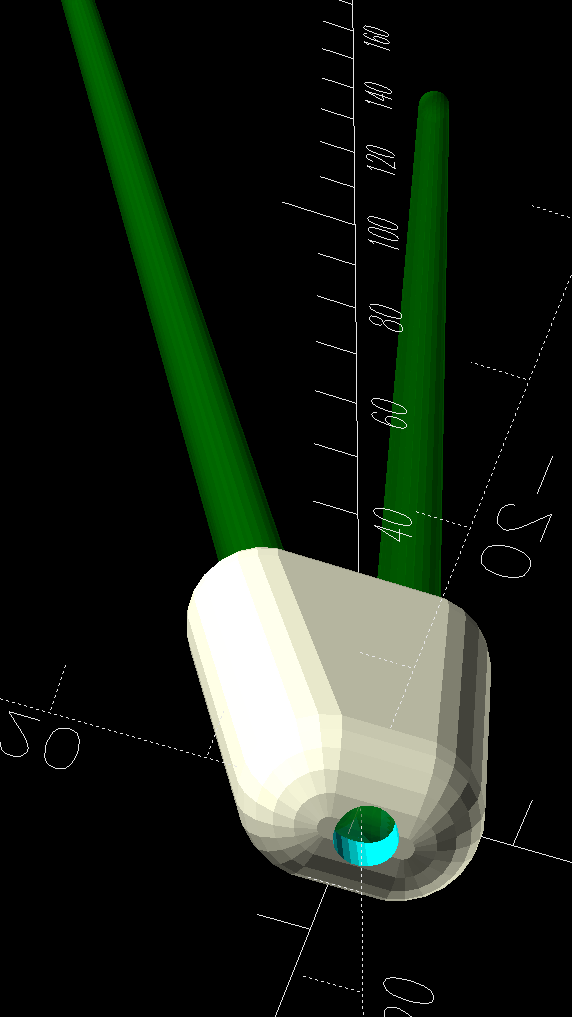

The OpenSCAD code as a GitHub Gist:

| // Wire plant stand feet | |

| // Ed Nisley KE4ZNU | |

| // 2024-11-06 | |

| Layout = "Show"; // [Show,Build,Leg,LegPair,FootShell,Foot,Section] | |

| /* [Hidden] */ | |

| ID = 0; | |

| OD = 1; | |

| LENGTH = 2; | |

| TOP = 0; | |

| BOT = 1; | |

| FootLength = 30.0; // vertical foot length | |

| LegRings = // [255.0,350.0,300.0]; // top dia, bottom dia, vertical height | |

| [260.0,312.0,300.0]; | |

| WireOD = //4.6 + 0.4; // oversize to handle bent legs | |

| 5.7 + 1.0; | |

| DrainOD = 4.0; // drain hole in the bottom | |

| LegWidth = // [65.0,9.7]; // outer width at top & bottom | |

| [95.0, 12.0]; | |

| LegAngle = atan((LegWidth[TOP] – LegWidth[BOT])/(2*LegRings[LENGTH])); | |

| StandAngle = atan((LegRings[TOP] – LegRings[BOT])/(2*LegRings[LENGTH])); | |

| WallThick = 3.0; | |

| FootWidth = 2*[WallThick,WallThick] + | |

| [LegWidth[BOT] + LegWidth[TOP]*FootLength/LegRings[LENGTH],LegWidth[BOT]]; | |

| echo(FootWidth=FootWidth); | |

| NumSides = 2*3*4; | |

| Protrusion = 0.1; | |

| //—– Set up pieces | |

| module Leg() { | |

| hull() | |

| for (k = [0,1]) | |

| translate([0,0,k*LegRings[LENGTH]]) | |

| sphere(d=WireOD,$fn=NumSides); | |

| } | |

| module LegPair() { | |

| for (i = [-1,1]) | |

| translate([i*(LegWidth[BOT] – WireOD)/2,0,0]) | |

| rotate([0,i*LegAngle,0]) | |

| rotate(180/NumSides) | |

| Leg(); | |

| hull() // simulate weld for flat bottom | |

| for (i = [-1,1]) | |

| translate([i*(LegWidth[BOT] – WireOD)/2,0,0]) | |

| rotate([0,i*LegAngle,0]) | |

| rotate(180/NumSides) | |

| sphere(d=WireOD,$fn=NumSides); | |

| } | |

| module FootShell() { | |

| difference() { | |

| hull() { | |

| for (i = [-1,1]) { | |

| translate([i*((FootWidth[BOT] – WireOD)/2 – WallThick),0,0]) | |

| rotate(180/NumSides) | |

| sphere(d=(WireOD + 2*WallThick),$fn=NumSides); | |

| translate([i*((FootWidth[TOP] – WireOD)/2 – WallThick),0,FootLength – WireOD/2]) | |

| rotate(180/NumSides) | |

| sphere(d=(WireOD + 2*WallThick),$fn=NumSides); | |

| } | |

| } | |

| translate([0,0,FootLength + FootLength/2]) | |

| cube([2*FootWidth[TOP],10*WallThick,FootLength],center=true); | |

| rotate(180/NumSides) | |

| cylinder(d=DrainOD,h=4*FootLength,center=true,$fn=NumSides); | |

| } | |

| } | |

| module Foot() { | |

| difference() { | |

| FootShell(); | |

| hull() | |

| LegPair(); | |

| } | |

| } | |

| //—– Build it | |

| if (Layout == "Leg") | |

| Leg(); | |

| if (Layout == "LegPair") | |

| LegPair(); | |

| if (Layout == "FootShell") | |

| FootShell(); | |

| if (Layout == "Foot") | |

| Foot(); | |

| if (Layout == "Section") | |

| difference() { | |

| Foot(); | |

| cube([FootWidth[TOP],(WireOD + 2*WallThick),2*FootLength],center=false); | |

| } | |

| if (Layout == "Show") { | |

| rotate([StandAngle,0,0]) { | |

| Foot(); | |

| color("Green",0.5) | |

| LegPair(); | |

| } | |

| } | |

| if (Layout == "Build") | |

| translate([0,0,FootLength]) | |

| rotate([0*(90-StandAngle),180,0]) | |

| Foot(); |