A reader asked how the M20 camera mount on my bike works with respect to the camera’s clock; this description explains a few things missing from the original writeup.

Do you have to set the time & date at start of every ride?

The internal clock shuts down about ten seconds after you pull the battery. If-and-only-if you swap batteries fast enough, it’ll keep time forever. Screw up once and it snaps back to Epoch Zero.

“Car mode” automagically begins recording when USB power goes on, but the manual advises:

TIP: When using your camera as a dashcam, use a car charger cable and remove the internal battery to make sure it does not die out while you travel.

That’s because the M20 continues to run from its internal battery when USB power drops. After recording an hour of a parking lot or your garage wall, the battery dies and so does the clock.

Of course, without the internal battery, the clock dies ten seconds after you turn off the car.

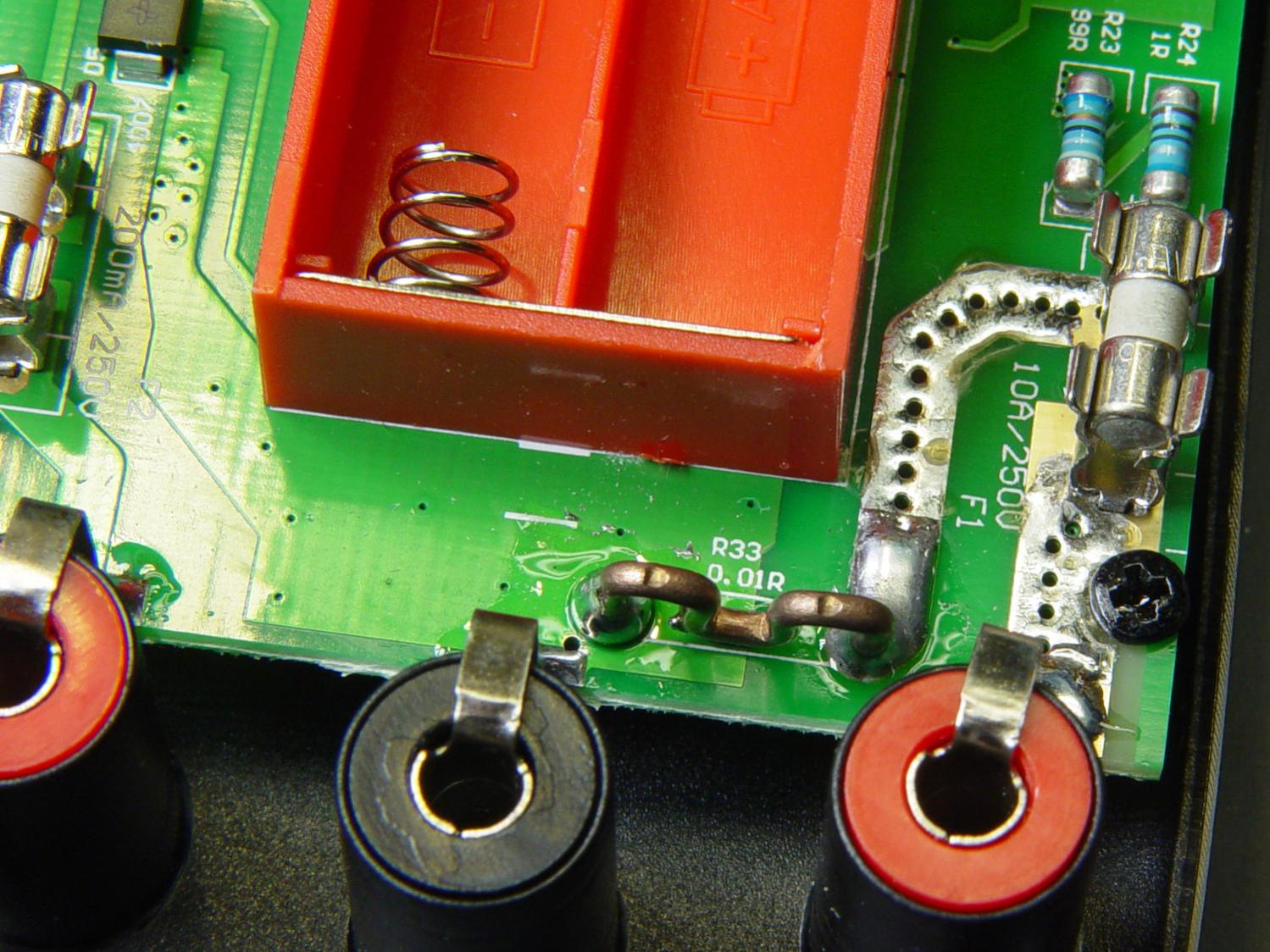

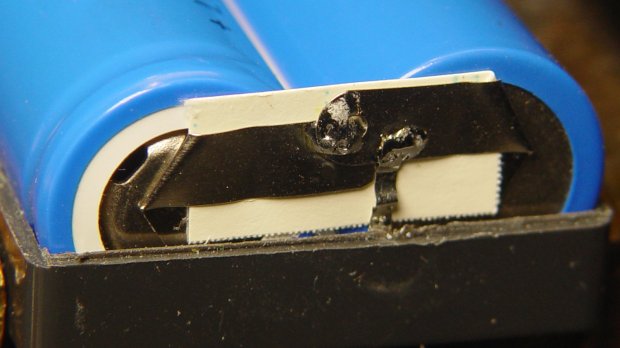

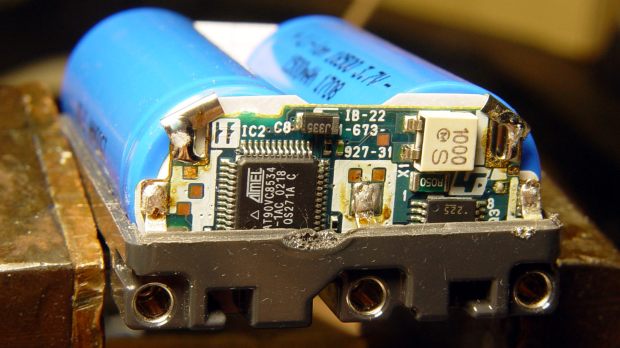

The internal battery has many days of capacity with the camera turned off (whew!), so I conjured the case & PowerCore battery tray to handle our normal rides. The internal battery keeps the clock alive overnight and during the rain we’ve had for the last week, the PowerCore supplies juice during the ride, and I recharge the PowerCore every few weeks.

The M20 doesn’t draw charging current when I turn it on, but poking the PowerCore’s status button also turns on its outputs, whereupon the M20 decides it should begin charging and, bonus, draw power from the PowerCore during the entire ride. The M20 finishes charging while we ride, but the PowerCore continues supplying power and, when I turn the M20 off, the PowerCore sees no current draw and shuts itself off.

Only a geek could love a lashup like that, but it works around the M20’s broken clock and removes its battery maintenance hassle.