Setting up a piece of MDF and hitting the Frame button produced a lightly scorched line around the part perimeter, plus a slightly diagonal track leading from / to the Home position in the far right corner:

Doing another pass with LightBurn’s rubber-band frame produced the faint dotted circle.

Huh. Didn’t useda do that.

The laser should not fire while framing and, having just installed LightBurn’s 1.2.01 update, suspicion instantly fell on the most recently changed thing.

Which turned out not to be the case, as LightBurn’s tech support pointed out:

This is generally an indication of a failed high-voltage power supply, not a software issue.

OMTech’s support requested a video of the equipment bay, which didn’t seem like a useful way to convey the situation. Instead, I sent pix.

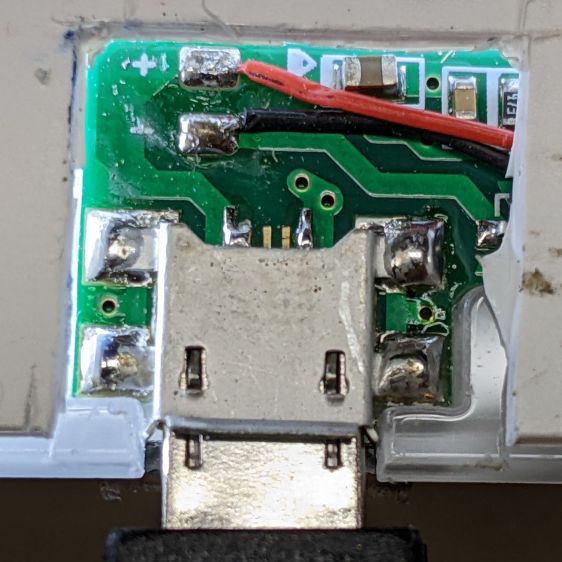

This picture shows the status of the 60 W laser power supply while the laser is incorrectly firing:

The power supply has two LEDs on what looks like, but is not, an Ethernet jack near the bottom:

- Orange P LED: good water flow

- Green L LED: controller’s PWM signal

The LASER orange LED near the top turns on when the HV output is active and the laser should be firing.

In this case, L LED is off and the LCD shows “Laser signal OFF”, but the LASER LED is on and the LCD shows 2 mA beam current: the laser beam is ON, even though the controller has not activated the PWM signal.

Not only that, but I discovered the laser would fire while framing even with the lid up and the “safety interlock” sensor active.

Totally did not expect that.

For comparison, the power supply status during a manual pulse at 49% power:

In that case, the L LED shows the PWM signal is active, the LASER LED is on, and the LCD shows 14 mA of current to the tube. That’s how it should work.

Although the function of the TEST button seems very lightly documented, pressing it did not turn on the output (the LASER LED is off), despite lighting the L LED:

OMTech confirmed my suspicion:

We are afraid that the laser power supply is defective

A replacement should arrive in a few days.

Protip: always practice laser eye safety.