Although I’d thought of a Mu-metal shield, copper foil tape should be easier and safer to shape into a simple shield. The general idea is to line the interior with copper tape, solder the joints together, cover with Kapton tape to reduce the likelihood of shorts, then stick it in place with some connector pin-and-socket combinations. Putting the tape on the outside would be much easier, but that would surround the circuitry with a layer of plastic that probably carries enough charge to throw things off.

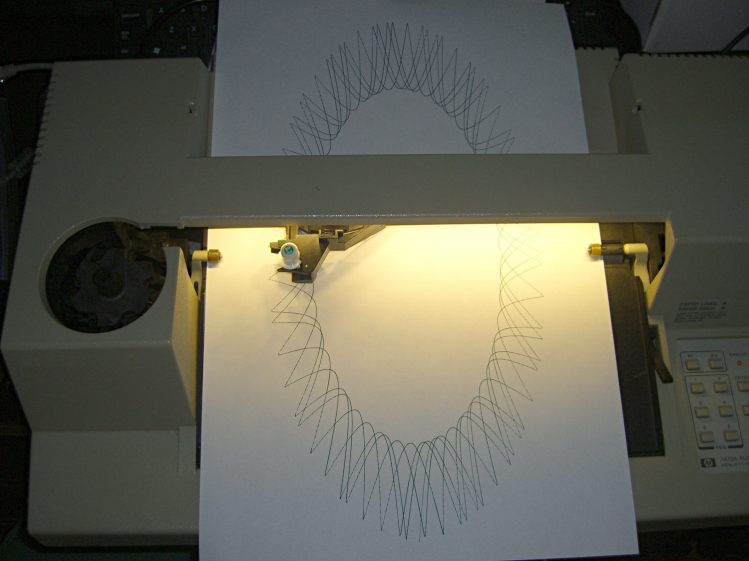

Anyhow, the hexagonal circuit board model now sports a hexagonal cap to support the shield:

The ad-hoc openings fit various switches, wires, & twiddlepots:

Ya gotta start somewhere.

The OpenSCAD source code:

// Victoreen 710-104 Ionization Chamber Fittings

// Ed Nisley KE4ZNU July 2015

Layout = "Show";

// Show - assembled parts

// Build - print can parts + shield

// BuildShield - print just the shield

// CanCap - PCB insulator for 6-32 mounting studs

// CanBase - surrounding foot for ionization chamber

// CanLid - generic surround for either end of chamber

// PCB - template for cutting PCB sheet

// PCBBase - holder for PCB atop CanCap

// Shield - electrostatic shield shell

//- Extrusion parameters must match reality!

// Print with 2 shells and 3 solid layers

ThreadThick = 0.25;

ThreadWidth = 0.40;

HoleWindage = 0.2;

Protrusion = 0.1; // make holes end cleanly

AlignPinOD = 1.75; // assembly alignment pins = filament dia

inch = 25.4;

function IntegerMultiple(Size,Unit) = Unit * ceil(Size / Unit);

//- Screw sizes

Tap4_40 = 0.089 * inch;

Clear4_40 = 0.110 * inch;

Head4_40 = 0.211 * inch;

Head4_40Thick = 0.065 * inch;

Nut4_40Dia = 0.228 * inch;

Nut4_40Thick = 0.086 * inch;

Washer4_40OD = 0.270 * inch;

Washer4_40ID = 0.123 * inch;

//----------------------

// Dimensions

OD = 0; // name the subscripts

LENGTH = 1;

Chamber = [91.0 + HoleWindage,38]; // Victoreen ionization chamber dimensions

Stud = [ // stud welded to ionization chamber lid

[6.5,IntegerMultiple(0.8,ThreadThick)], // flat head -- generous clearance

[4.0,9.5], // 6-32 screw -- ditto

];

NumStuds = 3;

StudSides = 6; // for hole around stud

BCD = 2.75 * inch; // mounting stud bolt circle diameter

PlateThick = 3.0; // layer atop and below chamber ends

RimHeight = 4.0; // extending up along chamber perimeter

WallHeight = RimHeight + PlateThick;

WallThick = 5.0; // thick enough to be sturdy & printable

CapSides = 8*6; // must be multiple of 4 & 3 to make symmetries work out right

PCBFlatsOD = 85.0; // hex dia across flats + clearance

PCBClearance = ThreadWidth; // clearance on each flat

PCBThick = 1.1;

PCBActual = [PCBFlatsOD/cos(30),PCBThick];

PCBCutter = [(PCBFlatsOD + 2*PCBClearance)/cos(30),PCBThick - ThreadThick]; // OD = tip-to-tip dia with clearance

echo(str("Actual PCB across flats: ",PCBFlatsOD));

echo(str(" ... tip-to-tip dia: ",PCBActual[OD]));

echo(str(" ... thickness: ",PCBActual[LENGTH]));

HolderHeight = 11.0 + PCBCutter[LENGTH]; // thick enough for PCB to clear studs

HolderShelf = 2.0; // shelf under PCB edge

PinAngle = 15; // alignment pin angle on either side of holder screw

echo(str("PCB holder across flats: ",PCBCutter[OD]*cos(30)));

echo(str(" ... height: ",HolderHeight));

ShieldInset = 1.0; // shield inset from actual PCB flat

ShieldWall = 2.0; // wall thickness

Shield = [(PCBFlatsOD - 2*ShieldInset)/ cos(30),35.0]; // electrostatic shield shell shape

//----------------------

// Useful routines

module PolyCyl(Dia,Height,ForceSides=0) { // based on nophead's polyholes

Sides = (ForceSides != 0) ? ForceSides : (ceil(Dia) + 2);

FixDia = Dia / cos(180/Sides);

cylinder(r=(FixDia + HoleWindage)/2,

h=Height,

$fn=Sides);

}

//- Locating pin hole with glue recess

// Default length is two pin diameters on each side of the split

module LocatingPin(Dia=AlignPinOD,Len=0.0) {

PinLen = (Len != 0.0) ? Len : (4*Dia);

translate([0,0,-ThreadThick])

PolyCyl((Dia + 2*ThreadWidth),2*ThreadThick,4);

translate([0,0,-2*ThreadThick])

PolyCyl((Dia + 1*ThreadWidth),4*ThreadThick,4);

translate([0,0,-Len/2])

PolyCyl(Dia,Len,4);

}

module ShowPegGrid(Space = 10.0,Size = 1.0) {

RangeX = floor(100 / Space);

RangeY = floor(125 / Space);

for (x=[-RangeX:RangeX])

for (y=[-RangeY:RangeY])

translate([x*Space,y*Space,Size/2])

%cube(Size,center=true);

}

//-----

module CanLid() {

difference() {

cylinder(d=Chamber[OD] + 2*WallThick,h=WallHeight,$fn=CapSides);

translate([0,0,PlateThick])

PolyCyl(Chamber[OD],Chamber[1],CapSides);

}

}

module CanCap() {

difference() {

CanLid();

translate([0,0,-Protrusion]) // central cutout

rotate(180/6)

cylinder(d=BCD,h=Chamber[LENGTH],$fn=6); // ... reasonable size

for (i=[0:(NumStuds - 1)]) // stud clearance holes

rotate(i*360/NumStuds)

translate([BCD/2,0,0])

rotate(180/StudSides) {

translate([0,0,(PlateThick - (Stud[0][LENGTH] + 2*ThreadThick))])

PolyCyl(Stud[0][OD],2*Stud[0][LENGTH],StudSides);

translate([0,0,-Protrusion])

PolyCyl(Stud[1][OD],2*Stud[1][LENGTH],StudSides);

}

for (i=[0:(NumStuds - 1)], j=[-1,1]) // PCB holder alignment pins

rotate(i*360/NumStuds + j*PinAngle + 60)

translate([Chamber[OD]/2,0,0])

rotate(180/4 - j*PinAngle)

LocatingPin(Len=2*PlateThick - 2*ThreadThick);

}

}

module CanBase() {

difference() {

CanLid();

translate([0,0,-Protrusion])

PolyCyl(Chamber[OD] - 2*5.0,Chamber[1],CapSides);

}

}

module PCBTemplate() {

difference() {

cylinder(d=PCBActual[OD],h=max(PCBActual[LENGTH],3.0),$fn=6); // actual PCB size, overly thick

translate([0,0,-Protrusion])

cylinder(d=10,h=10*PCBActual[LENGTH],$fn=12);

}

}

module PCBBase() {

difference() {

cylinder(d=Chamber[OD] + 2*WallThick,h=HolderHeight,$fn=CapSides); // outer rim

rotate(30) {

translate([0,0,-Protrusion]) // central hex

cylinder(d=(PCBActual[OD] - HolderShelf/cos(30)),h=2*HolderHeight,$fn=6);

translate([0,0,HolderHeight - PCBCutter[LENGTH]]) // hex PCB recess

cylinder(d=PCBCutter[OD],h=HolderHeight,$fn=6);

for (i=[0:NumStuds - 1]) // PCB retaining screws

rotate(i*120 + 30)

translate([(PCBCutter[OD]*cos(30)/2 + Clear4_40/2 + ThreadWidth),0,-Protrusion])

rotate(180/6)

PolyCyl(Tap4_40,2*HolderHeight,6);

for (i=[0:(NumStuds - 1)], j=[-1,1]) // PCB holder alignment pins

rotate(i*360/NumStuds + j*PinAngle + 30)

translate([Chamber[OD]/2,0,0])

rotate(180/4 - j*PinAngle)

LocatingPin(Len=PlateThick);

}

for (i=[0:NumStuds - 1]) // segment isolation

rotate(i*120 - 30)

translate([0,0,-Protrusion]) {

linear_extrude(height=2*HolderHeight)

polygon([[0,0],[Chamber[OD],0],[Chamber[OD]*cos(60),Chamber[OD]*sin(60)]]);

}

}

}

//-- Electrostatic shield

// the cutouts are completely ad-hoc

module ShieldShell() {

CutHeight = 7.0;

difference() {

cylinder(d=Shield[OD],h=Shield[LENGTH],$fn=6);

translate([0,0,-ShieldWall])

cylinder(d=(Shield[OD] - 2*ShieldWall/cos(30)),h=Shield[LENGTH],$fn=6);

translate([Shield[OD]/4 - 20/2,Shield[OD]/2,(CutHeight - Protrusion)/2])

rotate(90)

cube([Shield[OD],20,CutHeight + Protrusion],center=true);

translate([-Shield[OD]/4 + 5/2,Shield[OD]/2,(CutHeight - Protrusion)/2])

rotate(90)

cube([Shield[OD],5,CutHeight + Protrusion],center=true);

translate([-Shield[OD]/2,0,(CutHeight - Protrusion)/2])

cube([Shield[OD],5,CutHeight + Protrusion],center=true);

}

}

//----------------------

// Build it

ShowPegGrid();

if (Layout == "CanLid") {

CanLid();

}

if (Layout == "CanCap") {

CanCap();

}

if (Layout == "CanBase") {

CanBase();

}

if (Layout == "PCBBase") {

PCBBase();

}

if (Layout == "PCB") {

PCBTemplate();

}

if (Layout == "Shield") {

ShieldShell();

}

if (Layout == "Show") {

CanBase();

color("Orange",0.5)

translate([0,0,PlateThick + Protrusion])

cylinder(d=Chamber[OD],h=Chamber[LENGTH],$fn=CapSides);

translate([0,0,(2*PlateThick + Chamber[LENGTH] + 2*Protrusion)])

rotate([180,0,0])

CanCap();

translate([0,0,(2*PlateThick + Chamber[LENGTH] + 5.0)])

PCBBase();

color("Green",0.5)

translate([0,0,(2*PlateThick + Chamber[LENGTH] + 7.0 + HolderHeight)])

rotate(30)

PCBTemplate();

translate([0,0,(2*PlateThick + Chamber[LENGTH] + 15.0 + HolderHeight)])

rotate(30)

ShieldShell();}

if (Layout == "Build") {

translate([-0.50*Chamber[OD],-0.60*Chamber[OD],0])

CanCap();

translate([0.55*Chamber[OD],-0.60*Chamber[OD],0])

rotate(30)

translate([0,0,Shield[LENGTH]])

rotate([0,180,0])

ShieldShell();

translate([-0.25*Chamber[OD],0.60*Chamber[OD],0])

CanBase();

translate([0.25*Chamber[OD],0.60*Chamber[OD],0])

PCBBase();

}

if (Layout == "BuildShield") {

translate([0,0,Shield[LENGTH]])

rotate([0,180,0])

ShieldShell();

}