The measurements:

| 2025-12-29 | ||||

| Filament | %RH | Weight – g | Wt gain – g | Gain % |

| PETG White | 18 | 53.8 | 3.8 | 7.6% |

| PETG Black | 18 | 53.8 | 3.8 | 7.6% |

| PETG Orange | 22 | 52.3 | 2.3 | 4.6% |

| PETG Natural | 22 | 53.4 | 3.4 | 6.8% |

| PETG-CF Blue | 18 | 54.1 | 4.1 | 8.2% |

| PETG-CF Gray | 23 | 54.1 | 4.1 | 8.2% |

| PETG-CF Black | 18 | 53.8 | 3.8 | 7.6% |

| PETG Blue | 10 | 52.9 | 2.9 | 5.8% |

| TPU Clear | 18 | 54.4 | 4.4 | 8.8% |

| TPU Black | 18 | 55.1 | 5.1 | 10.2% |

I used to think there was some correlation between the indicated humidity and the amount of water adsorbed by the silica gel, with the humidity rising as the gel absorbed more water. That is obviously not the case.

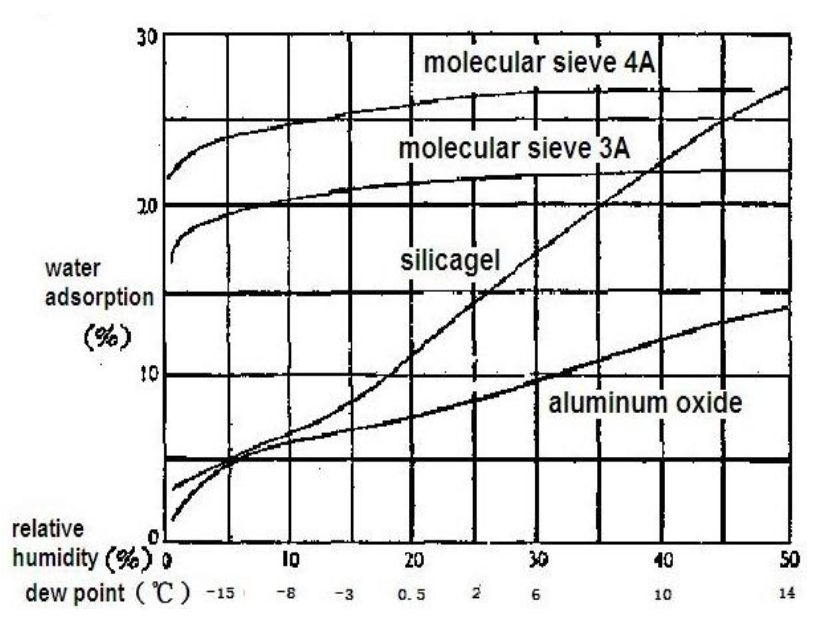

AFAICT, I’d been reading the chart wrong:

Instead of the adsorption being a function of the equilibrium humidity, it’s the other way around. With the humidity held constant (by adding water vapor), the silica gel will adsorb thus-and-so percentage of its weight and equilibrate at that humidity. If the filament was an infinite reservoir of dampness, then the equilibrium humidity would indicate how much the silica gel had coped with.

At least I think that’s how it goes. I have been wrong before.

Anyhow, IMO the right way to proceed is to just replace the silica gel every month and be done with it.

Also true: the humidity meters aren’t particularly accurate at the low humidity values in those boxes.

Spam comments get trashed, so don’t bother. Comment moderation may cause a delay.