Making the clothes dryer vent filter snout from TPU did not work nearly as well as I expected:

I think that’s the result of applying heat to a slightly compressed rear wall made of bendy plastic.

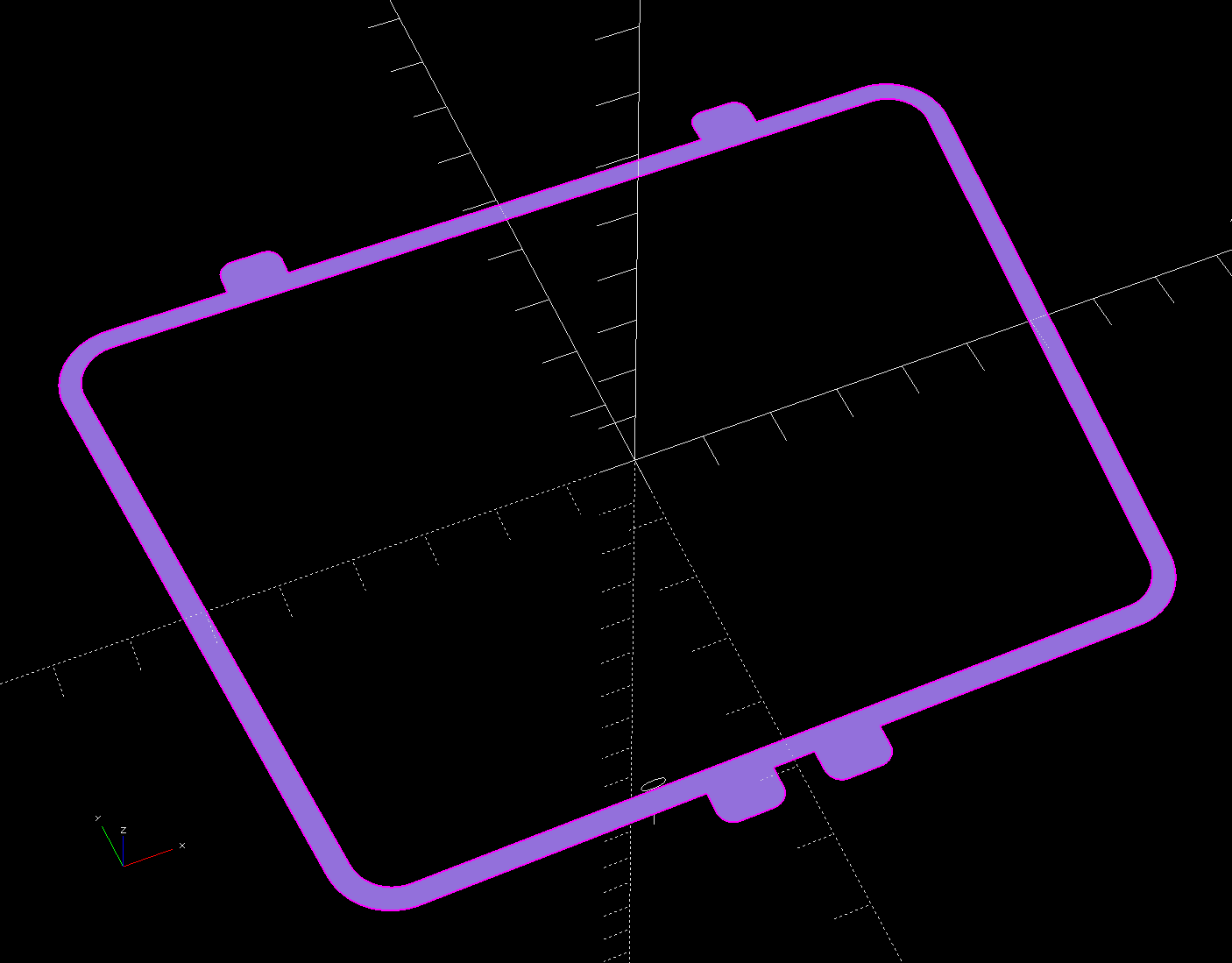

Making it from much stiffer white PETG required moving the front mounting tabs to the middle to allow enough bendiness to snap them into the vent:

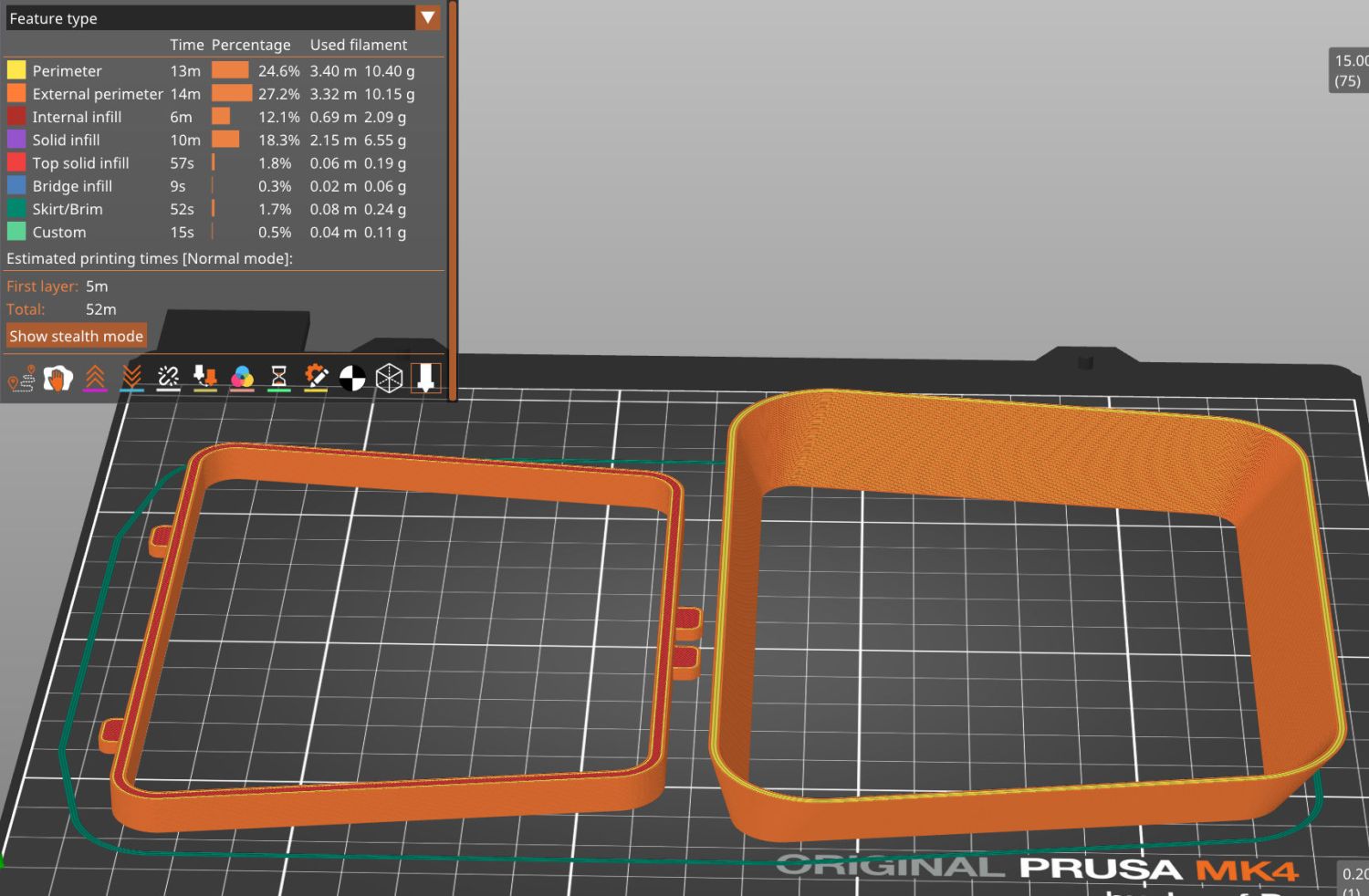

Although both pieces barely fit on the MK4’s platform, I made the upper ring first to verify the fit:

If I ever make another, it’ll print as a single top-side-down unit, because the dimensions are now spot on.

From outside, it looks just like the TPU version:

The snood is a cheesecloth tube with shock cord holding it to the snout.

Spam comments get trashed, so don’t bother. Comment moderation may cause a delay.