Part of the Autumn festivities around here involves blowing leaves into piles, then shredding them into garden mulch. Given that I have a plug-in electric leaf blower / wind stick, I use this as an excuse to exercise the emergency generator (similar to that one) with a (relatively) short extension cord.

As with all small gasoline engines, I fire a shot of starting fluid into the air cleaner to reduce the number of engine-start yanks, which means I must remove the generator’s side panel and unscrew the filter cover. For years I have sworn mighty oaths on the bones of my ancestors to knobify that screw, thus eliminating fiddling with a screwdriver.

Finally:

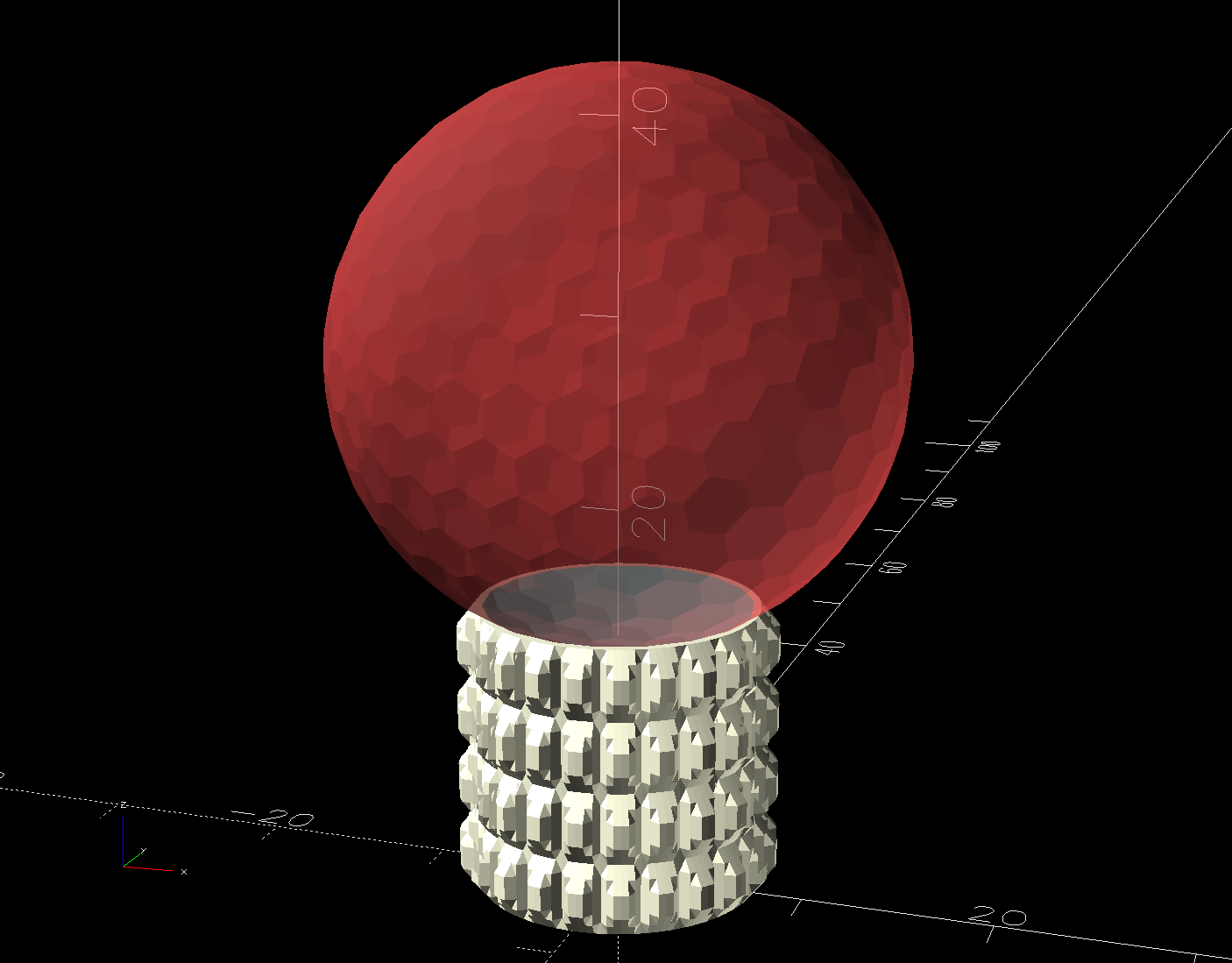

A dozen minutes of printing and a snippet of good double-sided tape later:

The knob sticks out far enough to push into the foam “sound deadening” liner on the cover, so it won’t vibrate loose.

The OpenSCAD source code:

include <BOSL2/std.scad>

/* [Hidden] */

HoleWindage = 0.2;

Protrusion = 0.1;

// Screw head dome

HeadHeight = 2.0;

HeadOD = 14.75;

DomeRadius = (HeadHeight^2 + (HeadOD^2)/4) / (2*HeadHeight);

echo(DomeRadius=DomeRadius);

KnobOD = HeadOD;

KnobLength = 15.0;

RimFudge = 0.3; // ensures a printable edge

// Build it

difference() {

cyl(h=KnobLength, r=KnobOD/2,anchor=BOTTOM,texture="trunc_pyramids",tex_size=[2.0,KnobLength/4]);

# up(KnobLength - HeadHeight + RimFudge)

spheroid(r=DomeRadius,circum=true,style="icosa",anchor=BOTTOM);

}

The cover has robust plastic latches, so I haven’t ever bothered to tighten those screws.

Spam comments get trashed, so don’t bother. Comment moderation may cause a delay.