The Z-axis switch on the Makergear M2 put Z=0 on the surface of the BuildTak platform and a quick leveling got the TerraCycle tires printed, but a more thorough alignment seemed in order.

I wanted to align the magnetic base plate first, but it has a lot of magnets and steel tools just weren’t going to work:

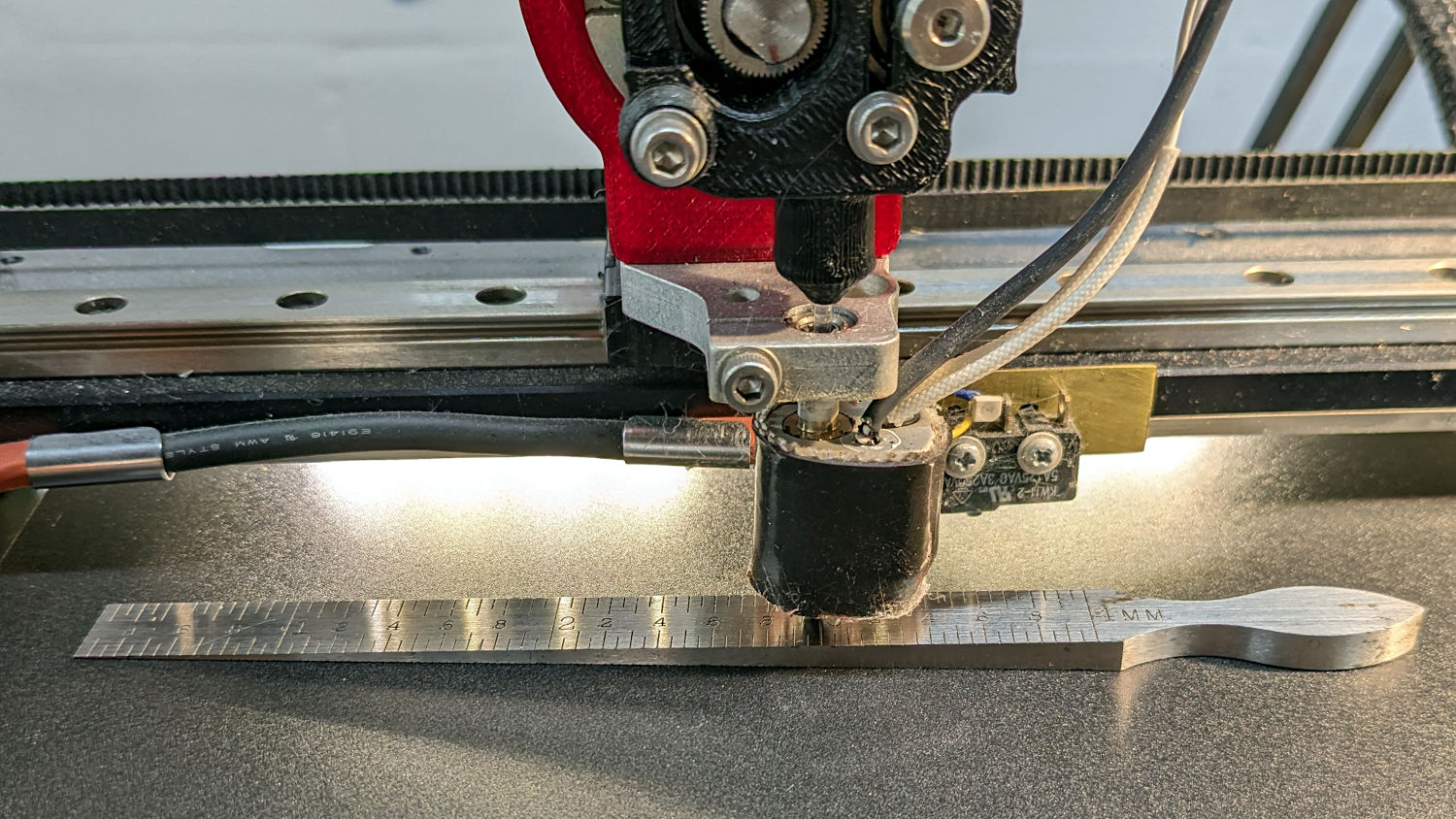

So I put the BuildTak FlexPlate on top and deployed the taper gauge, with all the magnetic fields held safely inside the steel sheet below the surface:

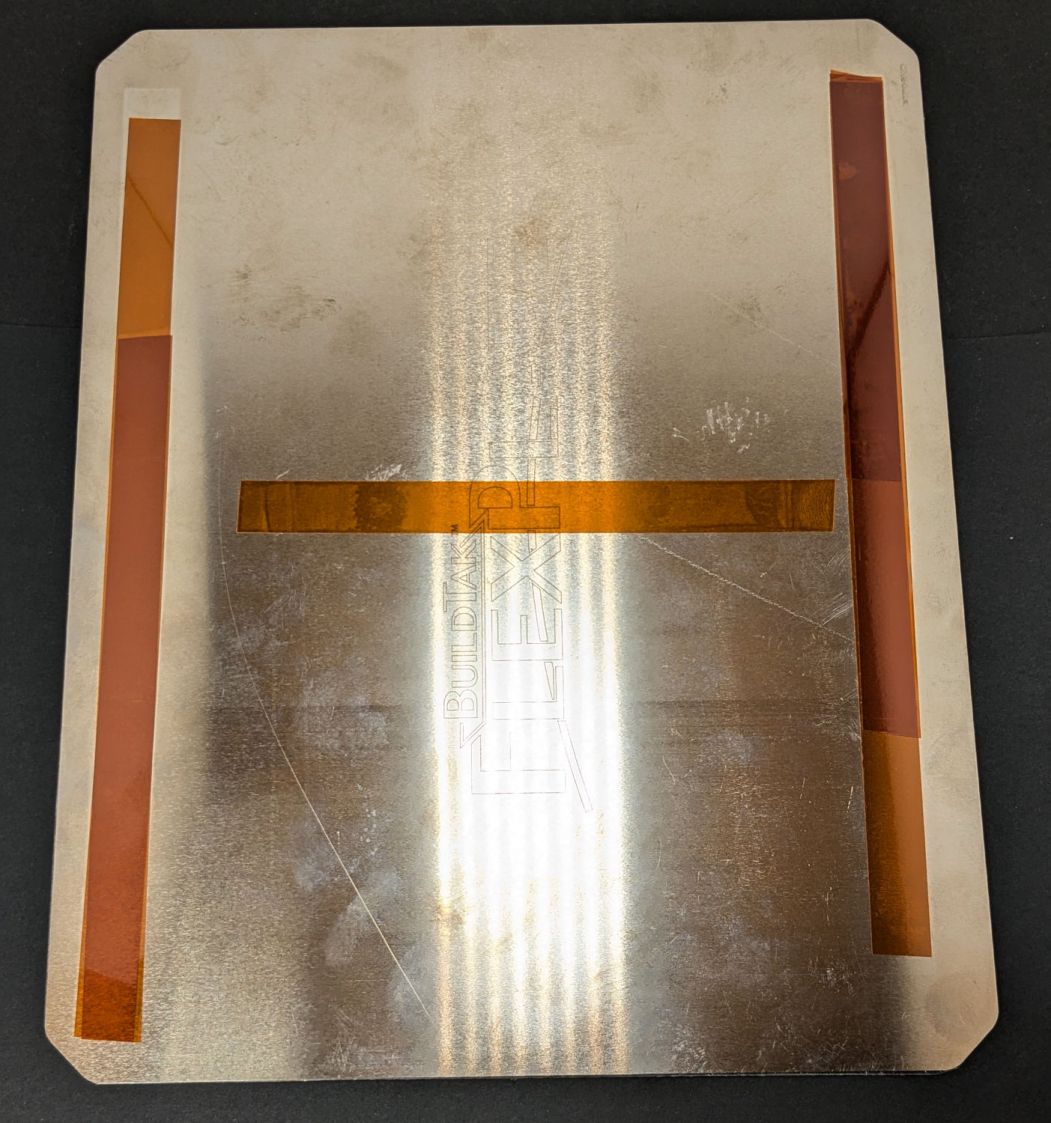

The plate turned out to be mostly flat, with two high spots at the center front and back. A few strips / layers of Kapton tape raised the lowest spots along the sides and middle enough to get the whole surface Close Enough™:

That’s really thick 4 mil = 0.1 mm tape, not puny 1 mil stuff. Two layers added enough height to very slightly warp the steel plate when held down by all those magnets.

The final result was flat within ±0.05 mm across the entire plate, with those two high spots reduced to +0.2 mm.

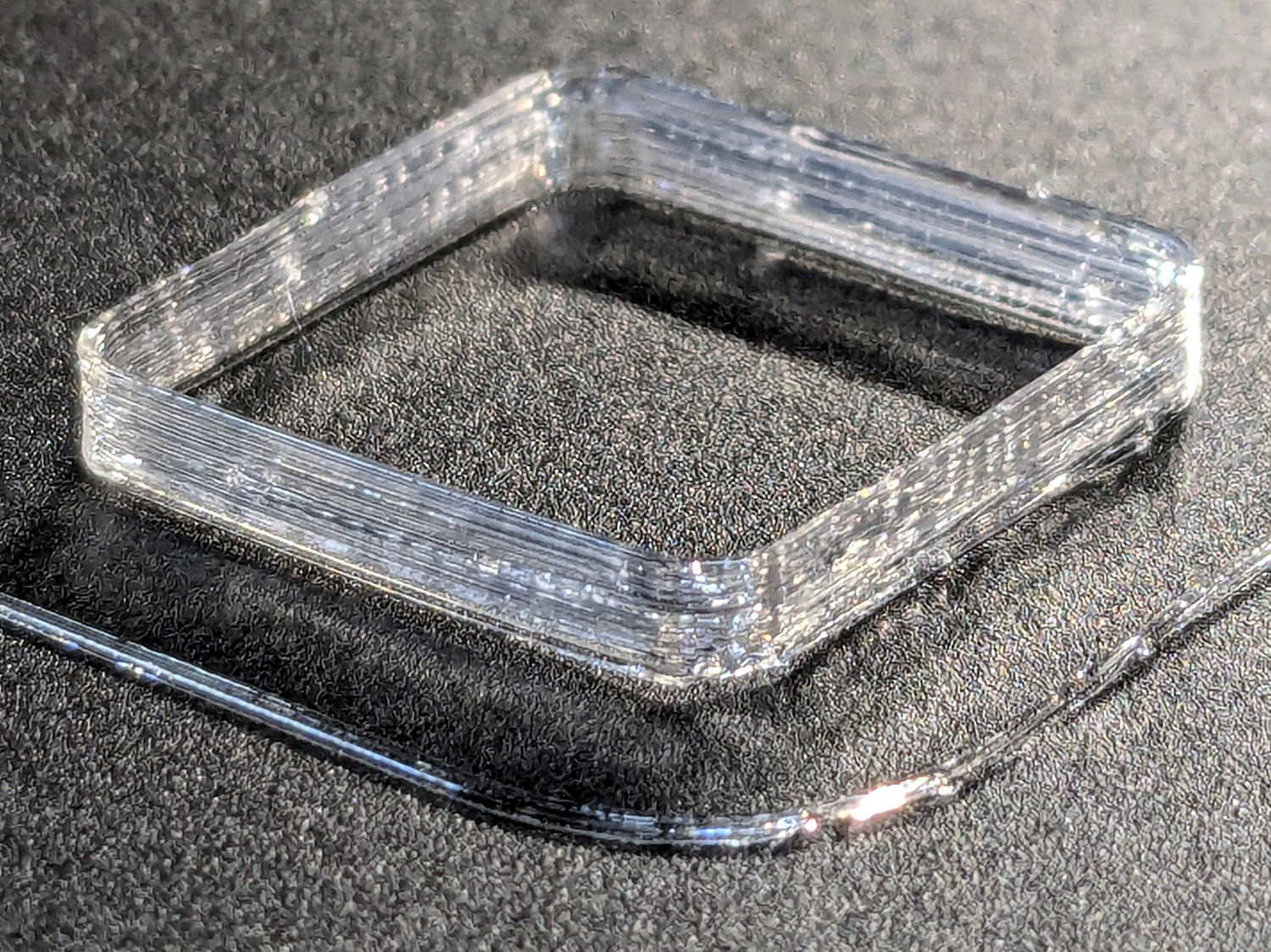

At which point, an array of thinwall calibration boxes came out perfectly:

The high spots lie outside the skirt at the front & rear of the plate, where they should be easy to avoid with most models I can imagine building in TPU. Stipulated: I have a stunted imagination.

TPU boxes are bendy little things with 0.45 mm walls:

After I got the plate flattened, even a single-thread wall of TPU sticks to BuildTak like it was glued there.

I had PrusaSlicer print them sequentially to avoid excessive back-and-forth, although combining 2 mm Retraction with Avoid crossing perimeters has eliminated much of the previous stringing:

I modified the startup G-Code to purge & wipe the nozzle at the right-front corner of the plate:

If I’d done that at the start, the BuildTak surface wouldn’t have a small divot melted into the center front edge where the previous G-Code paused the nozzle at the edge of the glass plate while heating. Pausing a millimeter off the diagonal seems to isolate the hot nozzle from the plastic surface.

The revised startup G-Code, with the earlier clearing motions commented out:

;-- PrusaSlicer Start G-Code for M2 starts --

; Ed Nisley KE4NZU

; Makergear V4 hot end

; Origin at platform center, set by MANUAL_X_HOME_POS compiled constants

; Z-min switch at platform, must move nozzle to X=135 to clear

; 2025-08-29 tweak priming spot to avoid scorching BuildTak surface

G90 ; absolute coordinates

G21 ; millimeters

M83 ; relative extrusion distance

M104 S[first_layer_temperature] ; start extruder heating

M140 S[first_layer_bed_temperature] ; start bed heating

M17 ; enable steppers

G4 P500 ; ... wait for power up

G92 Z0 ; set Z to zero, wherever it might be now

G0 Z10 F1000 ; move platform downward to clear nozzle; may crash at bottom

G28 Y ; home Y to clear plate, offset from compiled constant

G28 X ; home X, offset from M206 X, offset from compiled constant

G0 X135 Y0 F15000 ; move off platform to right side, center Y

G28 Z ; home Z to platform switch, offset from M206 Z measured

G0 Z2.0 F1000 ; get air under switch

;G0 Y-126 F10000 ; set up for priming, zig around corner

;G0 X0 ; center X

;G0 Y-125.5 ; just over platform edge

G0 Y-121 F15000 ; set up for priming

G0 X96 ; diagonally beyond trimmed corner of BuildTak plate

G0 Z0 F500 ; exactly at platform

M190 S[first_layer_bed_temperature] ; wait for bed to finish heating

M109 S[first_layer_temperature] ; set extruder temperature and wait

G1 E25 F200 ; prime to get pressure, generate blob on edge

;G0 Y-123 F5000 ; shear off blob

;G0 X15 F15000 ; jerk away from blob, move over surface

;G4 P500 ; pause to attach

;G1 X45 F500 ; slowly smear snot to clear nozzle

G0 X94 Y-119 F5000 ; shear off blob

G0 X90 F15000 ; jerk away

G4 P500 ; pause

G1 X50 Y-124 F500 ; smear snot

G1 Z1.0 F2000 ; clear bed for travel

;-- PrusaSlicer Start G-Code ends --

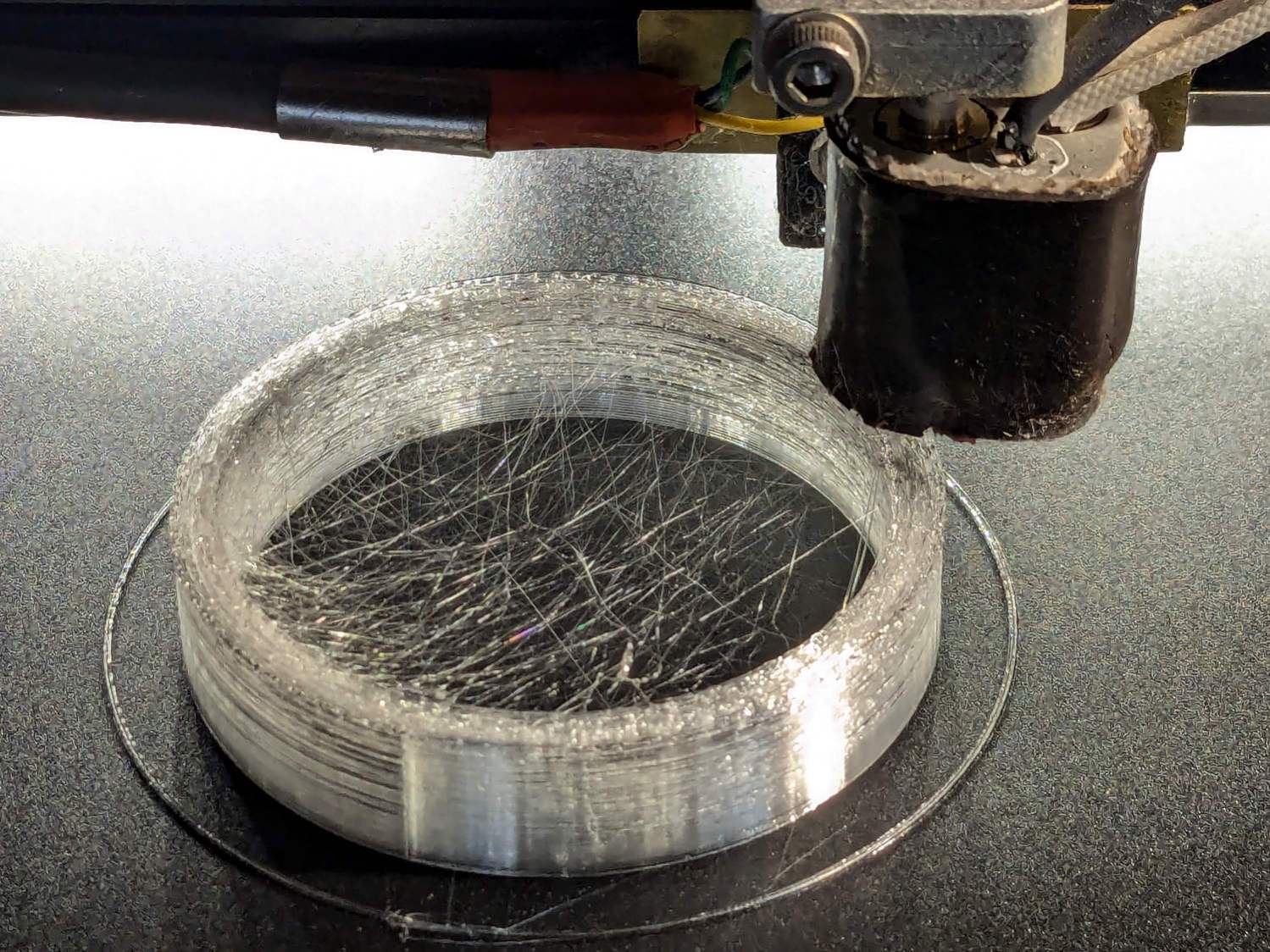

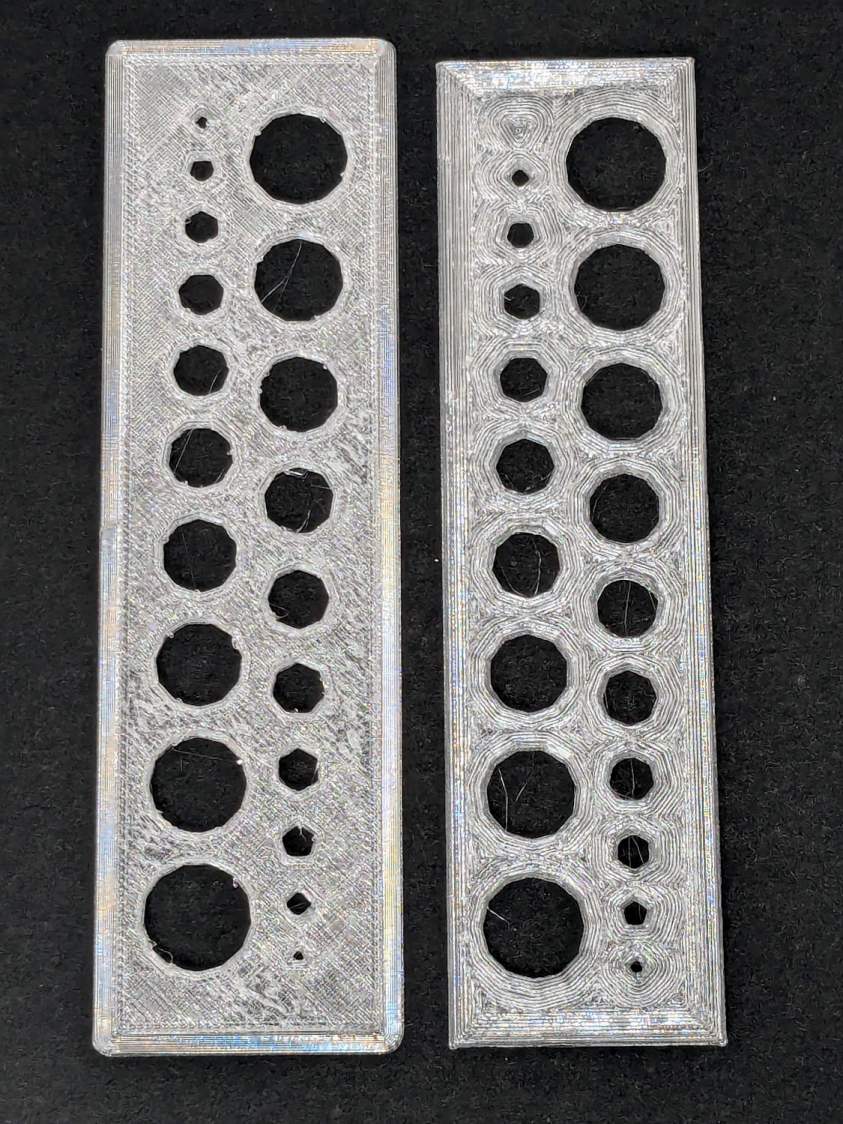

With all that done, the Small Hole Gauge came out much better:

The one on the left came from the M2’s glass plate (with a brim barely improving its adhesion) and the one on the right was on BuildTak after all the fussing; I just noticed I laid them out in opposite directions.

An edge view shows the fuzzy surface on the left:

The tiniest holes in both are undersized, but AFAICT you could ram a screw through that bendy sheet without much effort.

The BuildTak sheet works well enough that I have not tried the PEI-covered FlexPlate, which I’m sure will require similar shimming to get a level surface.

And, no, I am not going to install a surface probe on the M2’s hot end.

Leave a reply to brentatedsblog Cancel reply