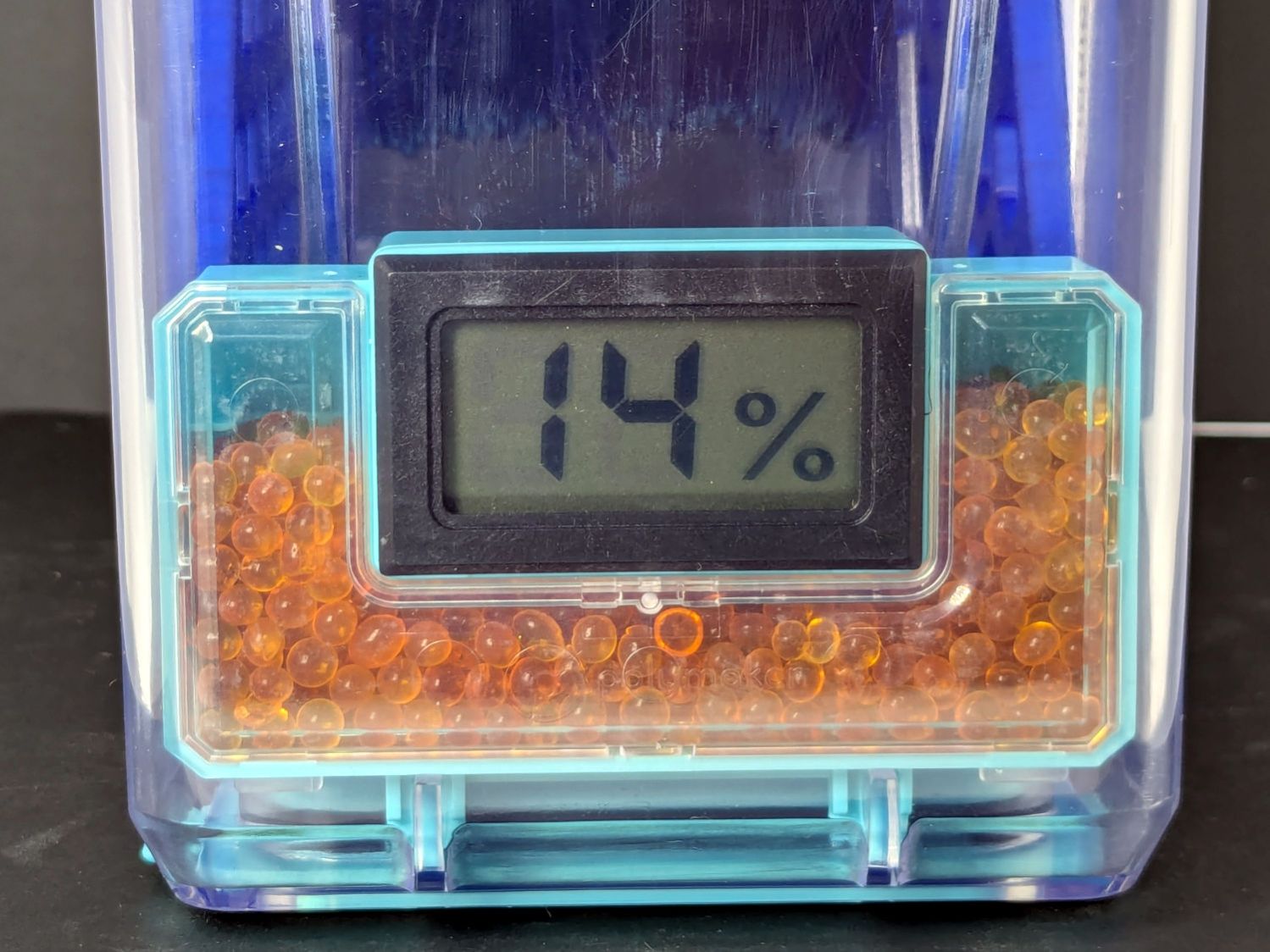

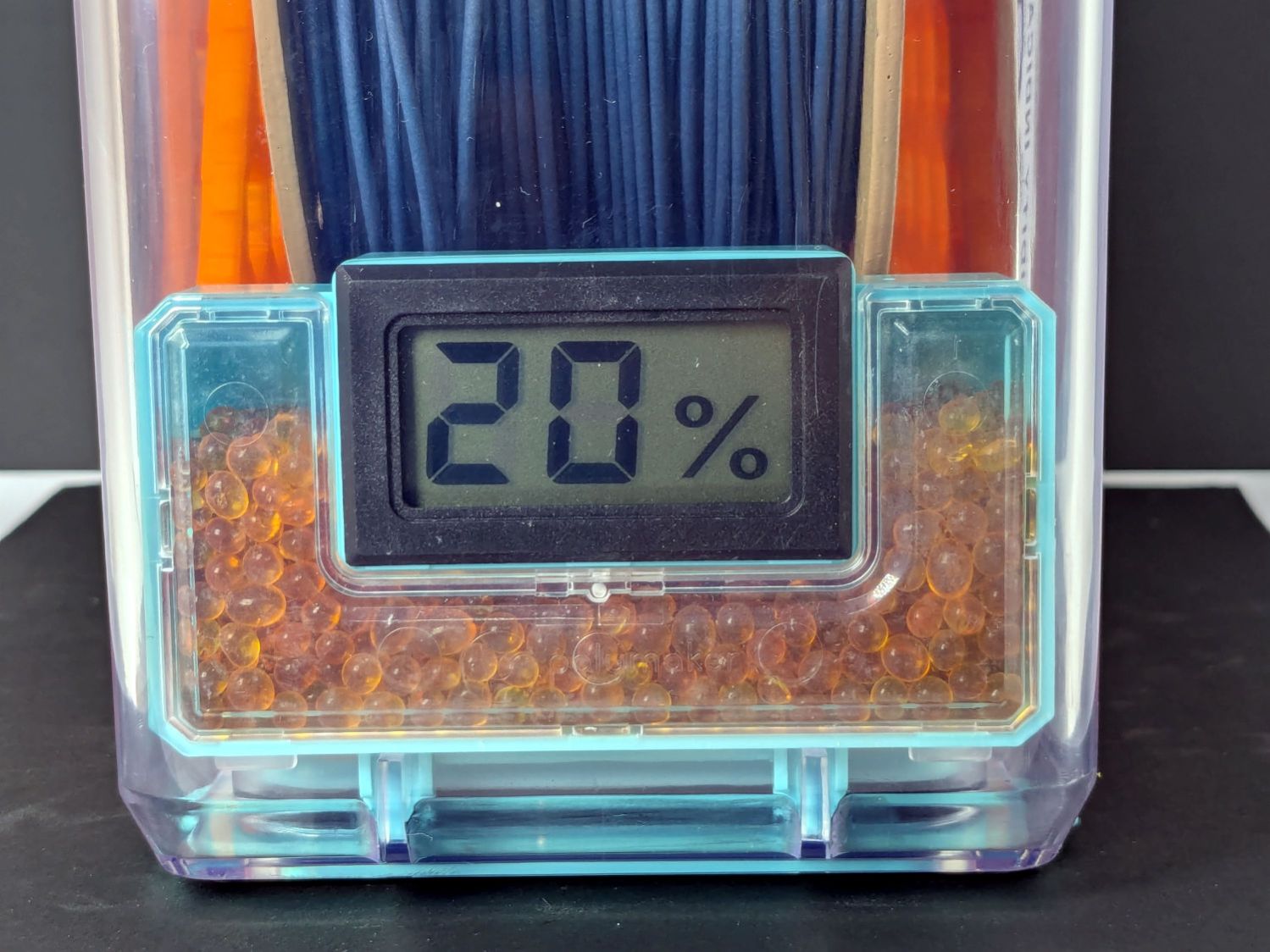

A week after installing 25 g of fresh silica gel, without any outside influence other than using some of the filaments to build things, I recorded the humidity meter reading, the indicator card colors, and the weight gain.

Click on any picture for more dots and to get rid of the captions and their stylin’ photo-blur.

White PETG, gain 0.6 g:

Black PETG, gain 0.8 g:

Orange PETG, gain 1.0 g:

Blue PETG, gain 0.4 g:

Blue PETG-CF, gain 1.3 g:

Black PETG-CF, gain 2.1 g:

Gray PETG-CF, gain 2.1 g:

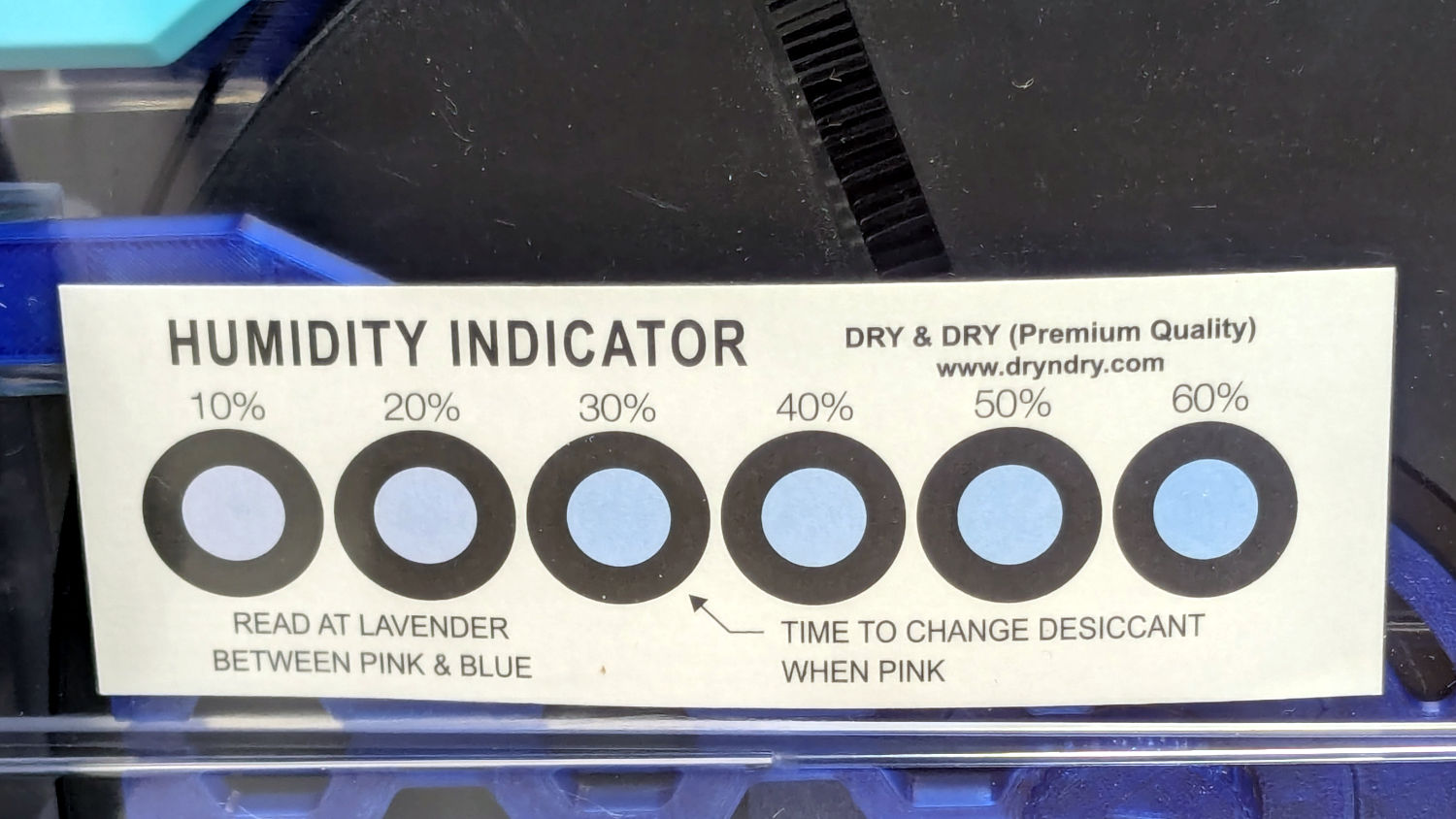

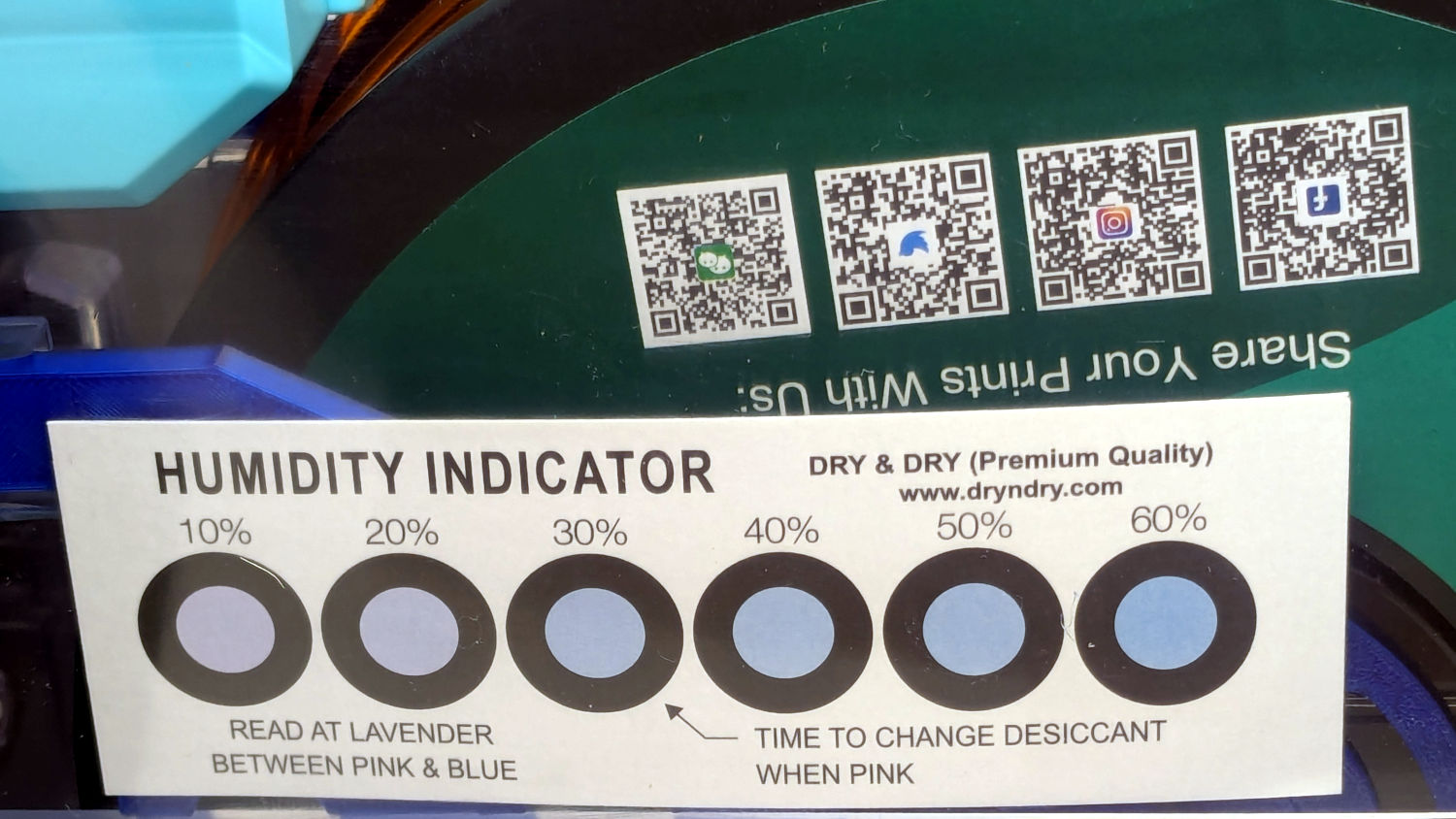

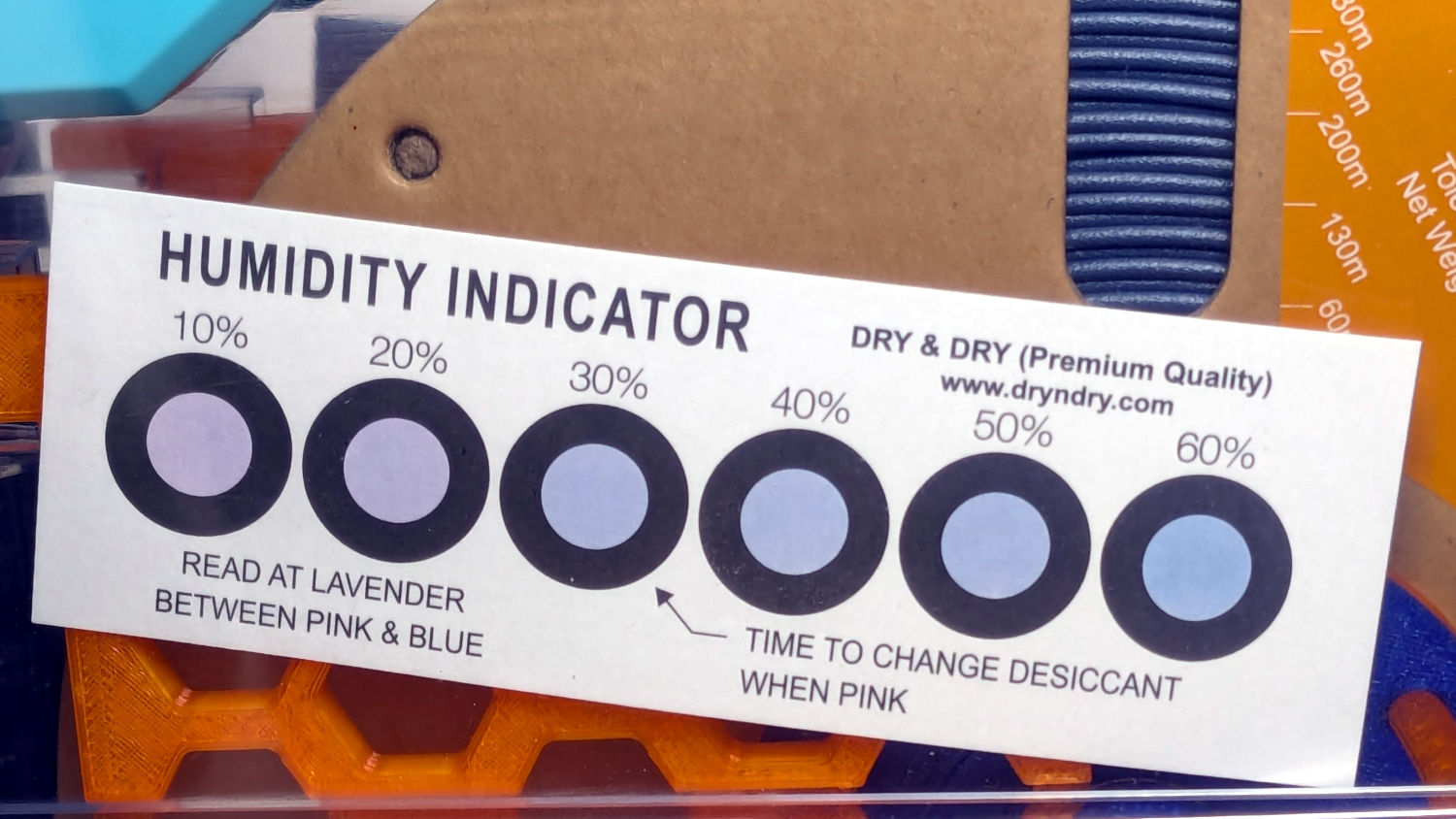

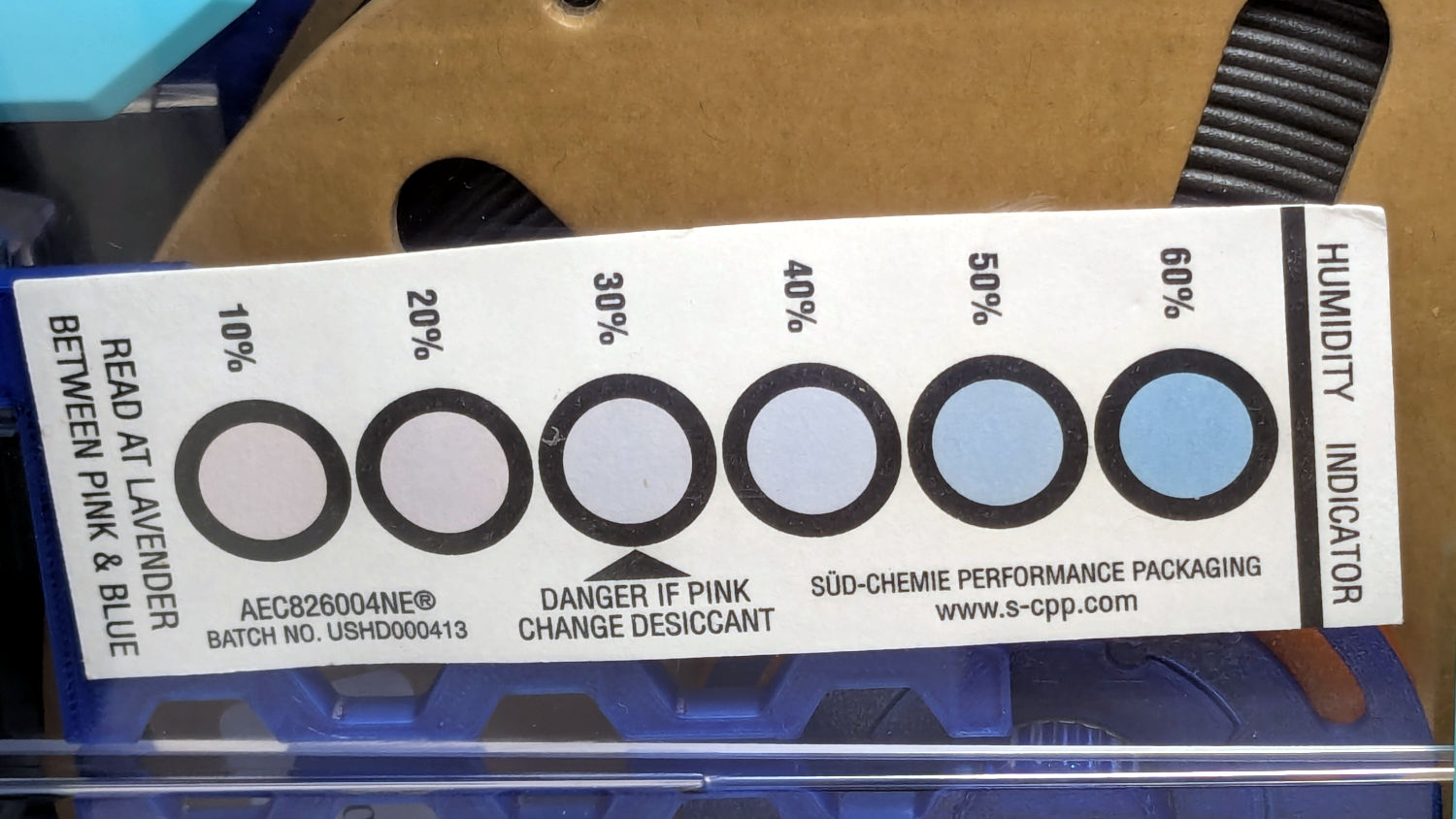

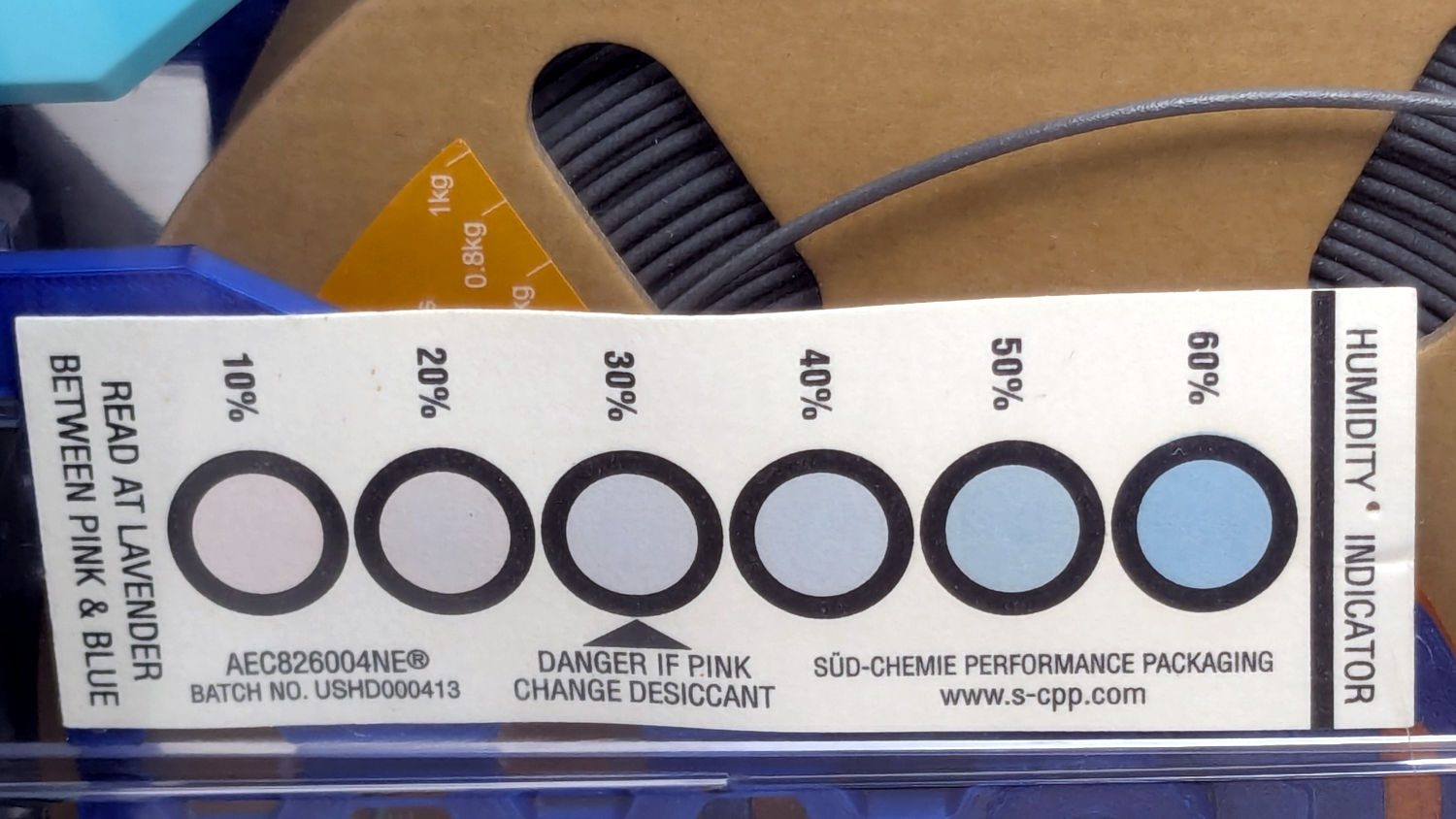

The (newer) indicator cards with the smaller dots / larger black borders seem less acute than the (older) large-dot cards. The two 28 %RH cards look about right, but the 20 and 21 %RH cards seem more different than the similar humidity would suggest.

Under 20 %RH, all the spots look pretty much the same, but AFAICT any humidity below 20 %RH is Good Enough for 3D printing.

The Blue PETG-CF went directly from its sealed bag into the PolyDryer box, unlike the Black and Gray PETG-CF spools that sat in the 50% RH basement long enough to soak up the ambience. The Blue has outgassed enough water to suggest spools do not arrive “bone dry” from the factory, although the Black and Gray prove the Basement Shop is wetter than the factory.

All of the silica gel together weighed 184.2 on the same scale I originally measured the 25 g quantities that should have totalled 175 g, but the individual measurements total 183.3 g. I don’t trust the scale to be better than ±0.1 g on any measurement, so half a percent is likely as good as it gets.

The silica gel weighed 187 g on the kitchen scale, sweated down to 179 g after 7 minutes in the microwave being defrosted like 1.5 pounds of fish, and, depending on which numbers you believe, released 8 to 10 g of water in the process.

Microwaving something containing so little water means the silica gel absorbs very little of the energy: the dish, glass turntable, and metal walls got absurdly hot. I think using the induction cooktop and cast iron pan makes more sense, even if it takes longer.

With fresh silica gel in place, perhaps waiting two weeks will produce interesting numbers.

Comments

3 responses to “PolyDryer Humidity: Meter vs. Indicator Cards vs. Adsorption”

[…] Which looks like this: […]

[…] Which looks like this: […]

[…] top cup contains fresh-from-stock dry (regenerated) silica gel beads and the others, left-to-right and top-to-bottom, come from PolyDryer […]