Setting up the Makergear M2 to print TPU (eSun 95A) involved a cold pull to get the remaining PETG out of the nozzle, some manual flushing, then printing test cubes to figure out a reasonable speed / temperature combination:

A 10 mm solid cube came out overstuffed and the first 20 mm cube lacked enough infill to hold its top up, but the third cube looked surprisingly good at 230 °C and 30 mm/s with 15% 3D Honeycomb infill:

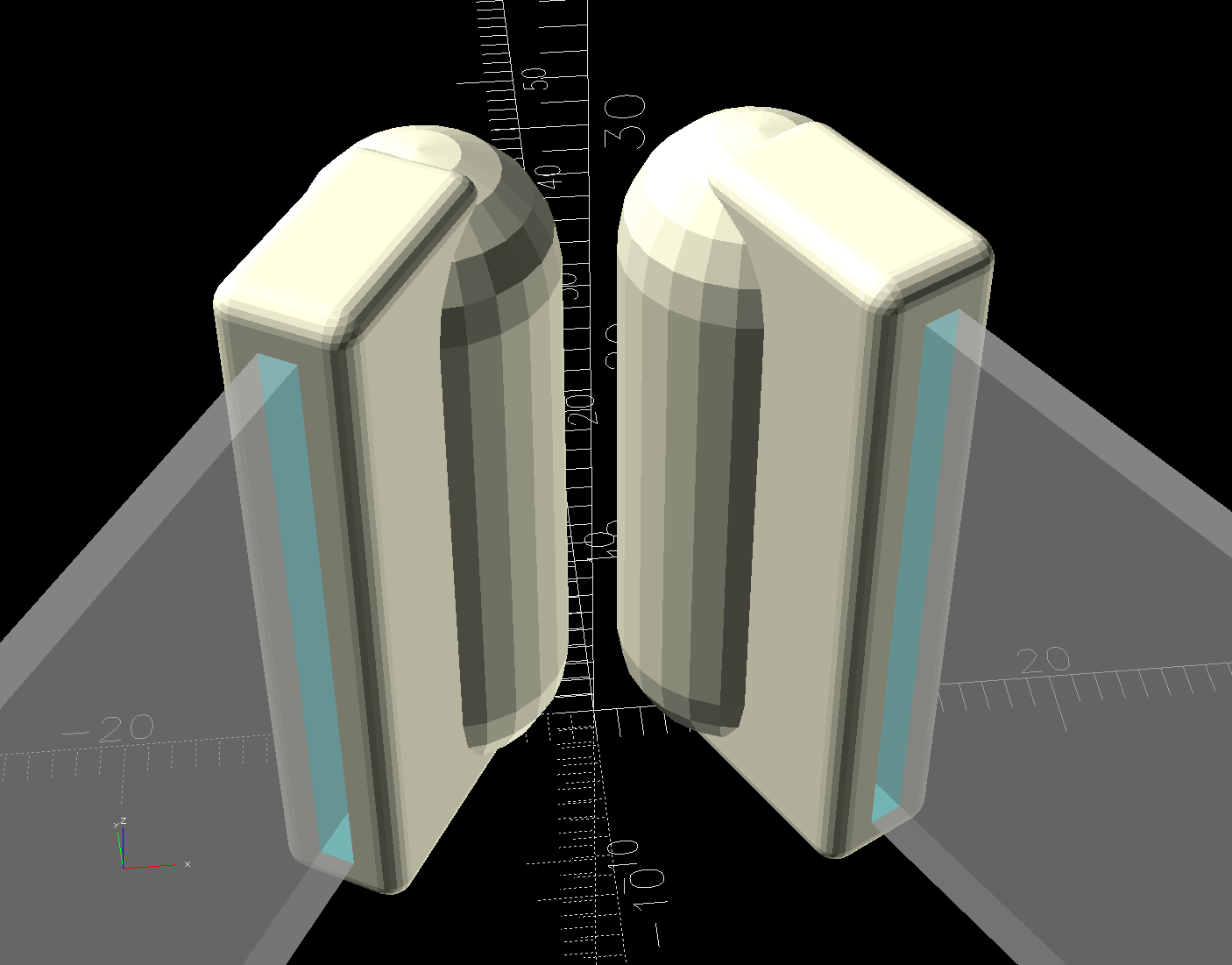

With that settled, I conjured pairs of soft (-ish) jaw pads for the far-too-many metal spring clamps having worn out their vinyl pads:

Those were the first attempt and worked well enough to suggest nicely rounded endcaps instead of flat cylinders:

Unlike the first version, they now build standing on their rectangular clamp jaw opening:

Those two groups have different lengths (1 inch and 1-⅛ inch) with PrusaSlicer combining the OpenSCAD program’s output.

The as-built pads are essentially un-photographable:

TPU is tough enough to make the single-layer brim un-tearable, but they’re easy enough to separate & trim with scissors. Even the 5 mm brim has a tenuous grip on glass + Suave hair “spray” applied from a dropper bottle, so I should try a BuildTak sheet that’s been on the to-do pile for far too many years.

Similarly, TPU is flexy enough to make a precise fit unnecessary: push firmly to force the pads onto the jaws and you’re done.

The OpenSCAD source code as a GitHub Gist:

| // Spring clamp replacement jaw pad | |

| // Ed Nisley – KE4ZNU | |

| // 2025-04-26 | |

| include <BOSL2/std.scad> | |

| Layout = "Show"; // [Show,Build,Clamp] | |

| Ends = "Round"; // [Flat,Round] | |

| Sets = 1; | |

| /* [Hidden] */ | |

| HoleWindage = 0.2; | |

| Protrusion = 0.1; | |

| NumSides = 2*3*4; | |

| WallThick = 2.0; | |

| CushionOD = 10.0; | |

| CushionStem = 10.0; | |

| JawAngle = 60/2; // just for Show | |

| JawWidth = 1.000*INCH; // clamps are hard-inch sizes: 1.0 and 1.125 | |

| Jaw = [1.5,50,JawWidth]; // roughly one jaw | |

| Gap = 2.0; | |

| $fn = 2*3*4; | |

| //———- | |

| // Define objects | |

| //—– | |

| // Clamp jaw | |

| module Clamp() { | |

| up(WallThick) | |

| cuboid(Jaw,anchor=BOTTOM+BACK); | |

| } | |

| module Pad() { | |

| difference() { | |

| union() { | |

| cyl(d=CushionOD,h=Jaw.z + 2*WallThick,anchor=BOTTOM, | |

| rounding = (Ends == "Flat") ? 0 : CushionOD/2); | |

| cuboid([Jaw.x + 2*WallThick,CushionStem,Jaw.z + 2*WallThick], | |

| rounding=WallThick/2,anchor=BOTTOM+BACK); | |

| } | |

| Clamp(); | |

| } | |

| } | |

| //———- | |

| // Build things | |

| if (Layout == "Clamp") { | |

| Clamp(); | |

| } | |

| if (Layout == "Show") { | |

| for (i = [-1,1]) | |

| right(i*(CushionOD + Gap)/2) | |

| zrot(i*JawAngle) { | |

| Pad(); | |

| color("Silver",0.5) | |

| Clamp(); | |

| } | |

| } | |

| if (Layout == "Build") { | |

| for (n = [0:(Sets – 1)]) | |

| for (i = [-1,1]) | |

| right(i*((CushionOD + Gap)/2 + n*(CushionOD + Gap))) | |

| up(CushionStem) back(Jaw.z/2) xrot(90) | |

| Pad(); | |

| } |

Comments

One response to “Metal Spring Clamp: TPU Jaw Pads”

[…] TPU extrusion parameters on the Makergear M2, as holes smaller than about 2 mm vanish, even though the block’s outside dimensions are spot on. This application wasn’t too critical, so I sharpened the wire ends and stabbed them into the […]