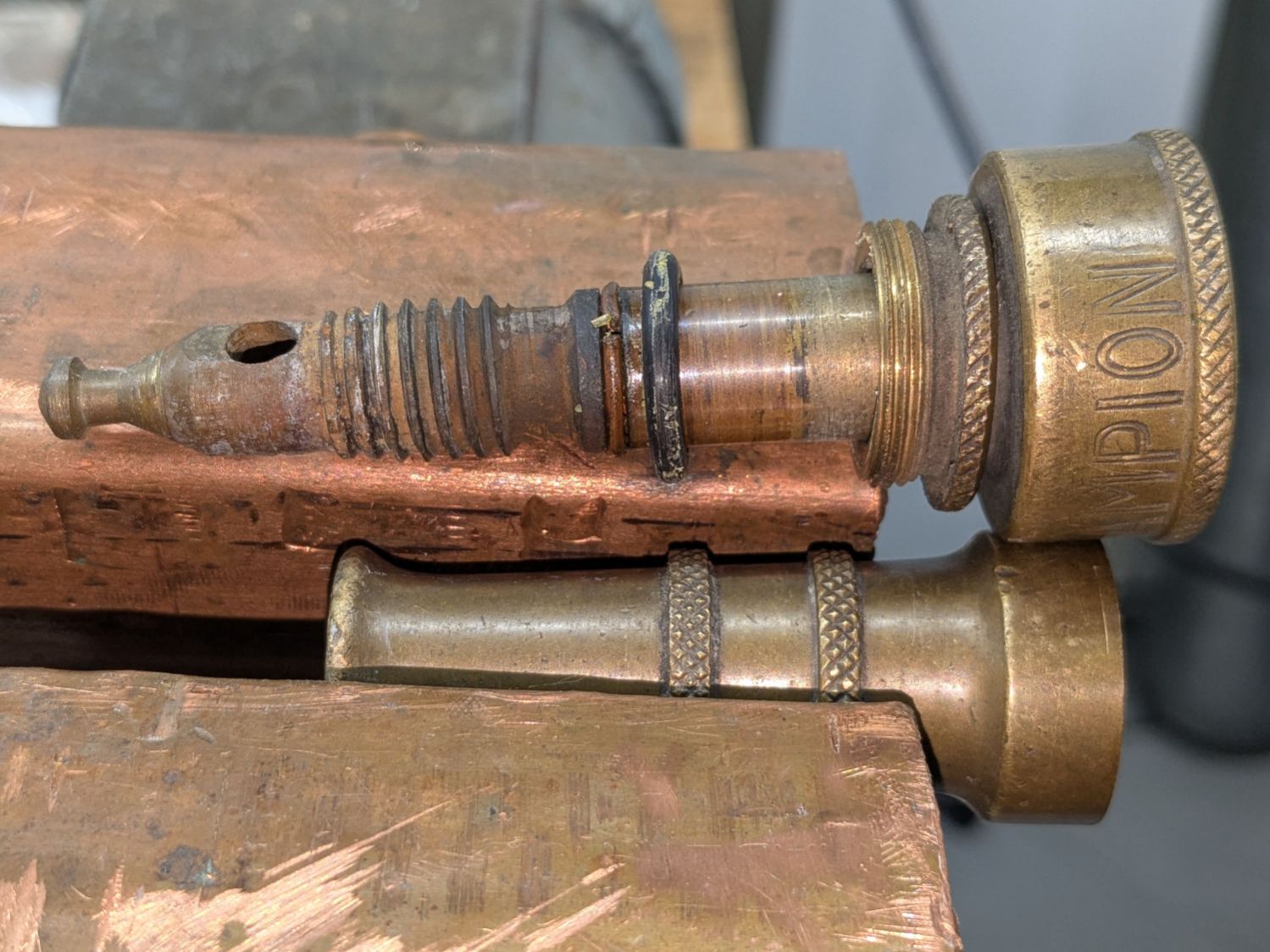

The battered Champion hose nozzle came into play last fall, leaked profusely when turned off, went to a Safe Place for the winter, and recently emerged:

The conical surface (to the right of the tip) must make perfect contact with the edge of a perfect cylindrical hole in the outer shell to shut off the water, which was obviously no longer happening.

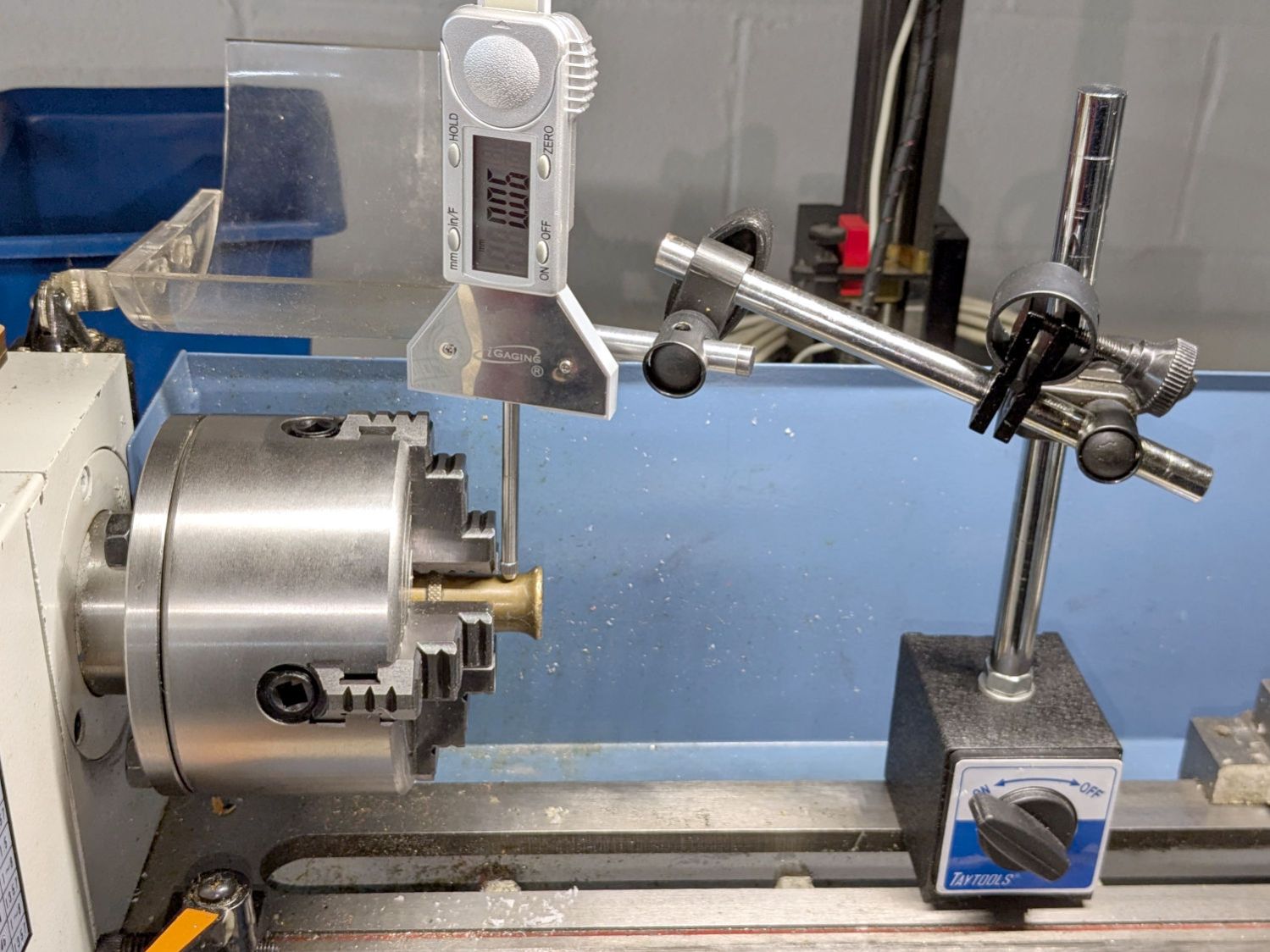

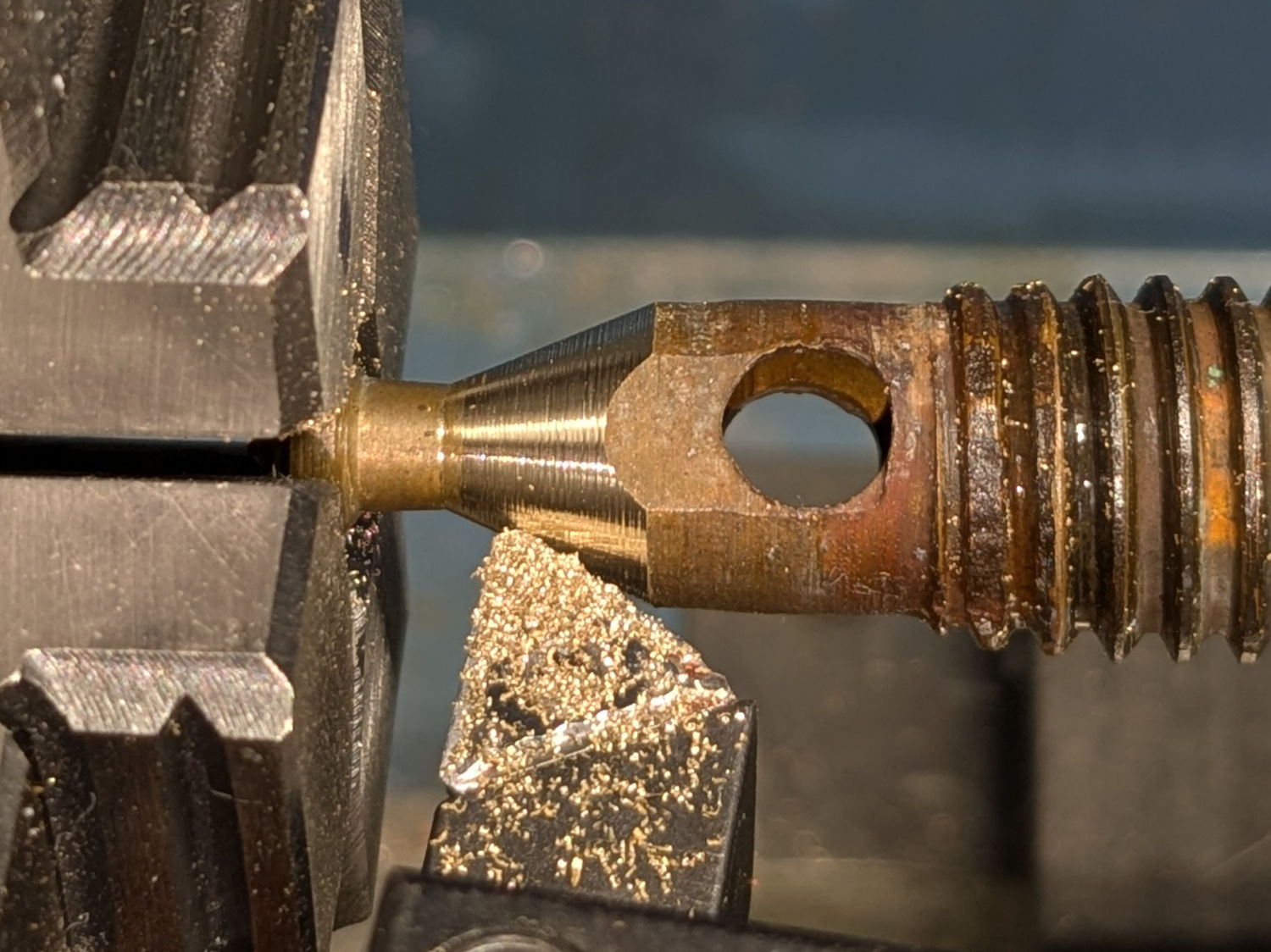

There is no reason why that hole should still be concentric with the outside of the shell, but centering the latter in the four-jaw chuck put the hole within about 0.2 mm of where it should be:

I defined that to be Close Enough™ and made the hole smooth & concentric with a teeny boring bar and sissy cuts. A drill would likely have worked well enough, too.

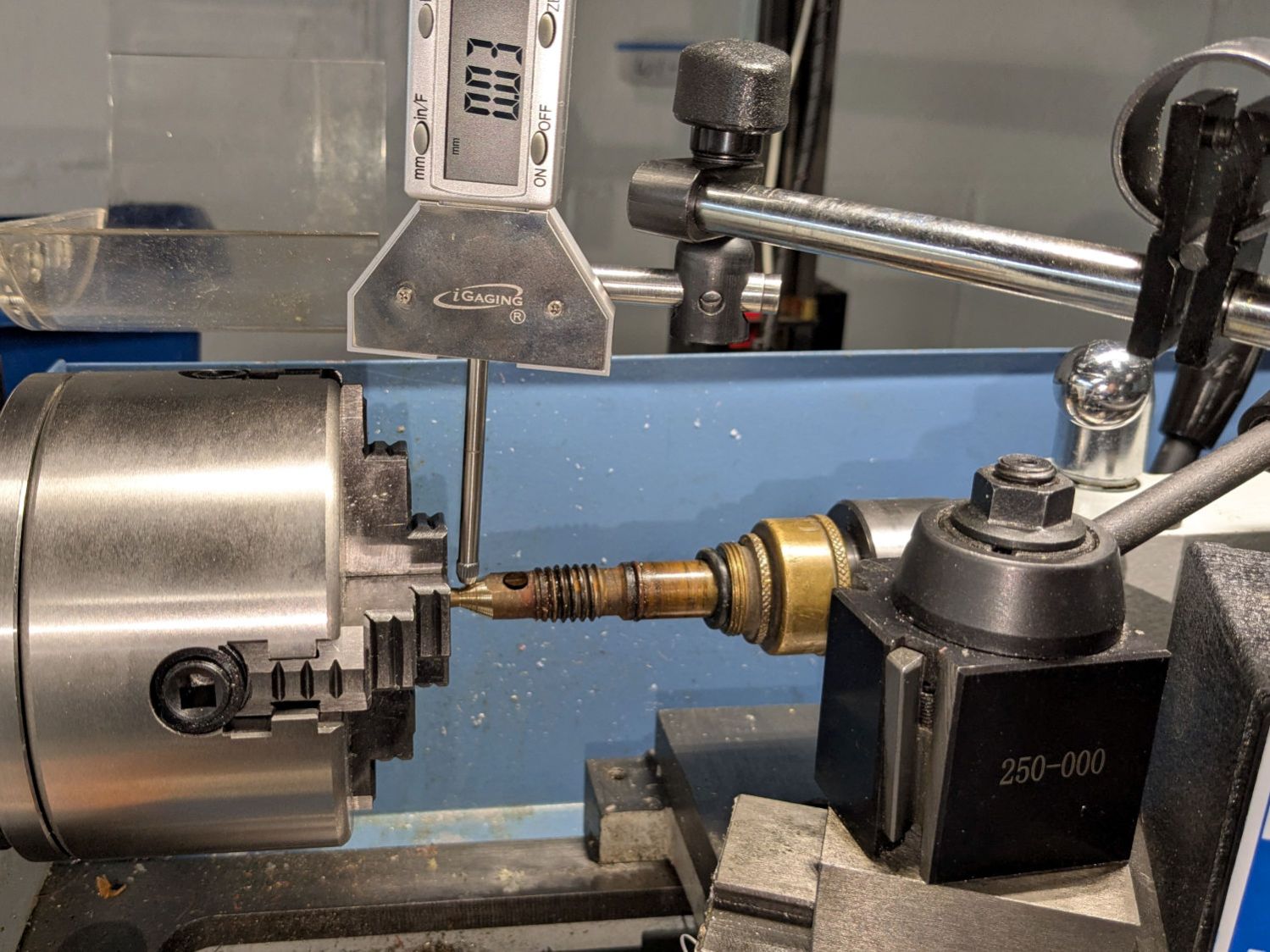

Gently filing the nastiness off the cone showed it wouldn’t suffice, so center it while noting the irregular diameter all around:

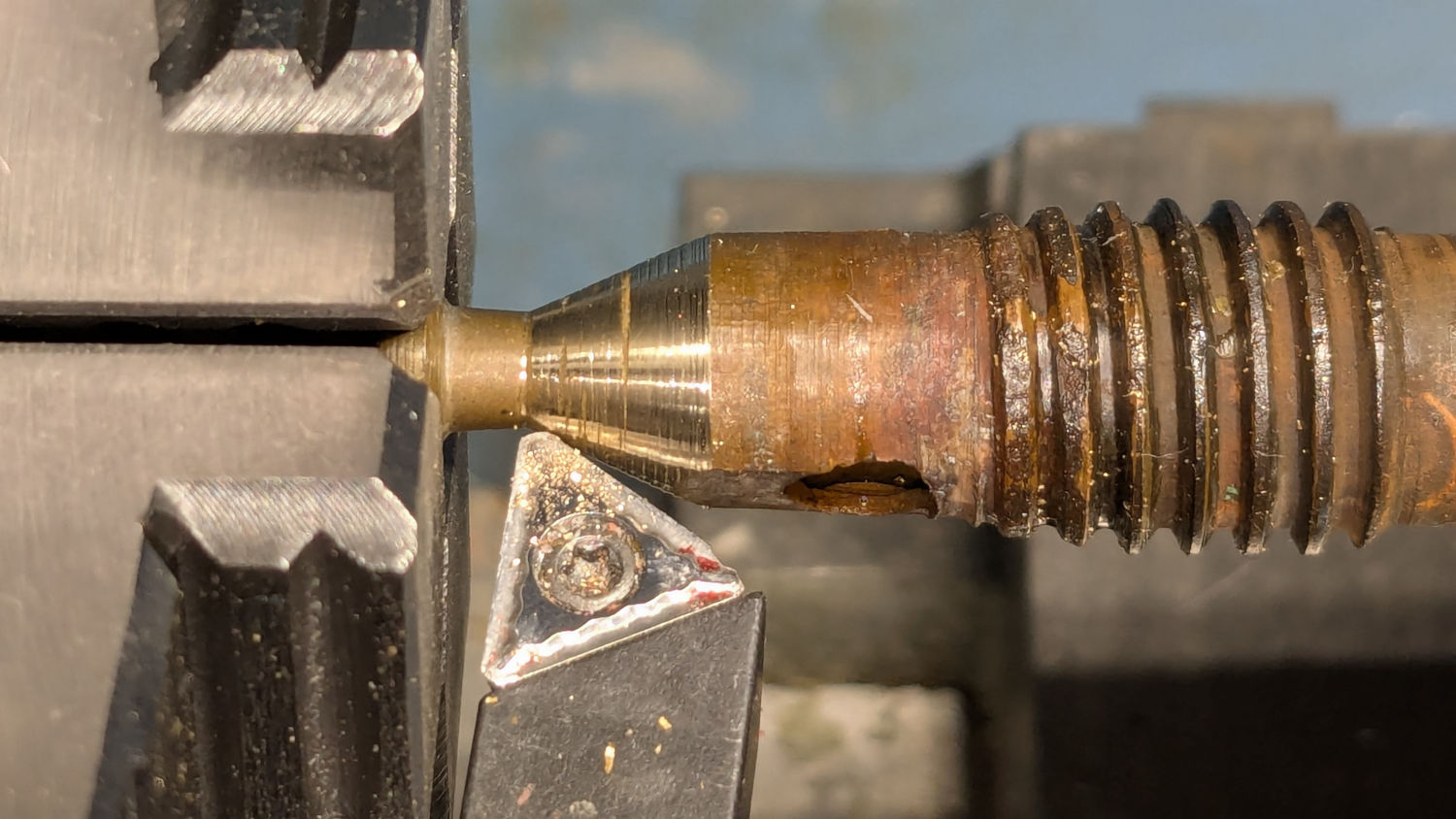

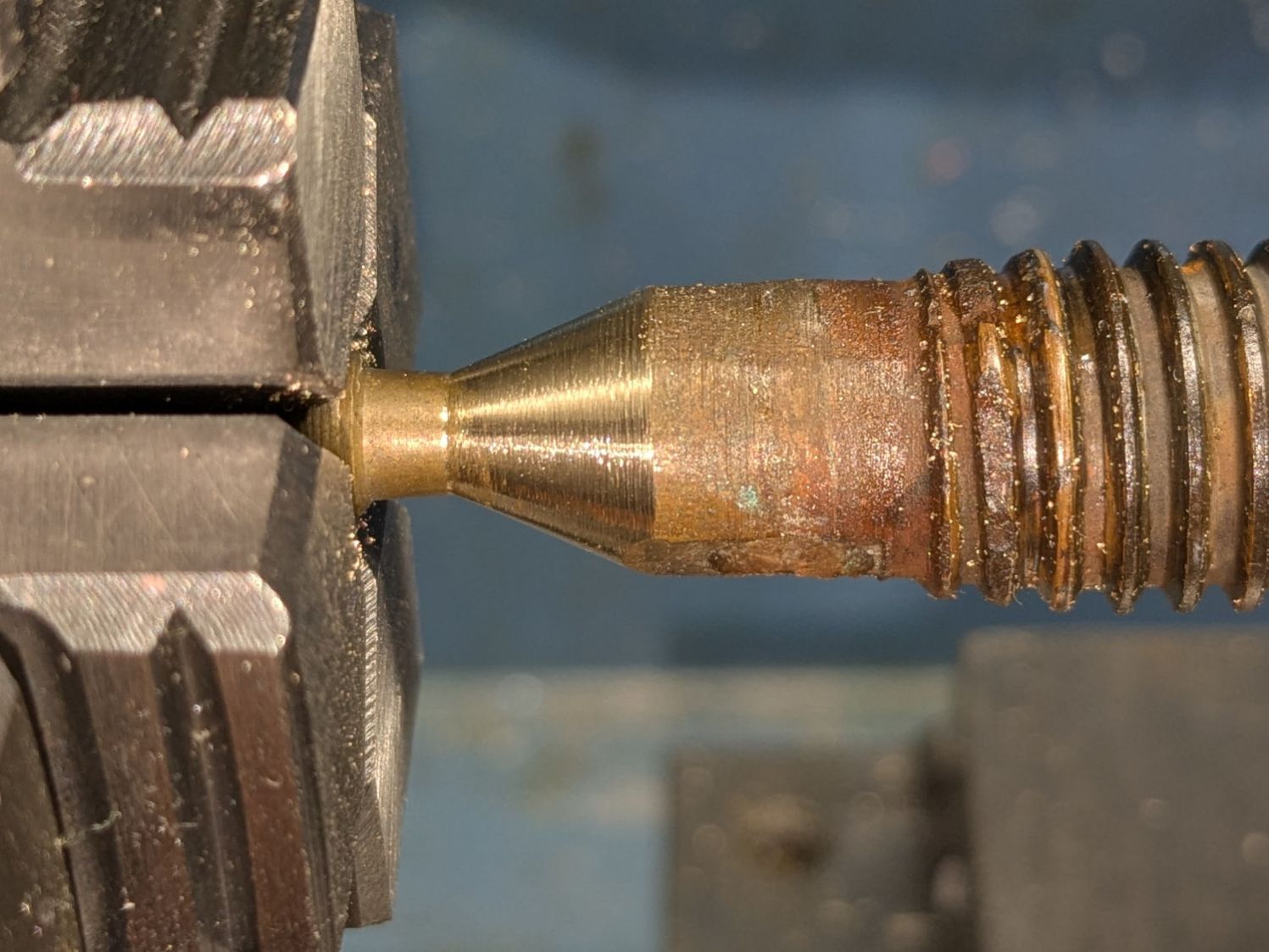

A skim cut revealed the need for more attention:

Another tenth of a millimeter improved its disposition:

Gentle touchup with a fine file reserved for special occasions may have been a further improvement:

Add a dollop of silicone grease to encourage the shell to turn much more easily on the O-ring, reassemble in reverse order, and top it off with a new hose washer.

A quick test on a reasonably warm day showed the cone met the cylinder poorly enough to consign this nozzle to the brass recycling box.

It was fun trying, though …

Comments

7 responses to “Champion Hose Nozzle: Refreshed Seal Attempt”

this is interesting……..I think mine still seals, but I have an alternate valve on the end of the hose, with a quick disconnect on the nozzle and showerhead for flower watering.

If I didn’t find a similar nozzle in the Hydraulics Box, I’d definitely be rooting around in there for a shutoff valve. :grin:

Some thoughts (assuming WP finally allows me access!)

Just my 2c…!

That thread looks like it started out awful and time has done it no favors!

The O-ring keeps water from flowing from the back of the nozzle, which it does reasonably well. The silicone grease definitely improved its slipperiness, but it seems to be just slightly the wrong size and the nozzle turns too firmly.

I think the slop in the threads is intended to allow the cone to center itself against the end of the cylindrical hole, so the entire seal depends on how well that cone meets the edge of the hole. My boring & filing just aren’t up to spec, not least because I didn’t / can’t remove any corrosion inside the nozzle where the cone meets it.

I vaguely recall a Home Shop Machinist article about making such a spray nozzle from brass bar stock, but those skills (and machine tools!) are aspirational for me. :sigh:

(I think WordPress held your comment because it came from a new / different email address. You’d be depressed to know what else it holds for review, so I’m reluctant to dial that down. Sorry ’bout that.)

Last spring I discovered that draining the hose and leaving the closed nozzle on the loop was insufficient. Somewhere in the low meadow is the part that broke off from freeze damage. I think it was 30 years old.

Found some decent ones on Amazon. The Home Desperate ones use a snap-ring so the nozzle cannot be dismantled. Not fun when the water source to the pump has dead algae and random crud in it. Casual observation of the snapring says it won’t come out without a fight.

The lathe project reminded me of an extremely unsuccessful attempt at doing a new carburetor shaft on a well worn VW Beetle. Some things require far more tooling and patience than I have.

The phrase “Decent ones on Amazon” is a rare sight. :grin:

[…] email discussion suggested the Champion hose nozzle might, once upon a time, have had a washer between the conical and cylindrical […]