The HQ Sixteen has been running at higher speeds as Mary practices using its stitch regulator and the vibrations shook several of the table shims (blocks, whatever) onto the floor. I hope a layer of EVA foam provides enough compliance to keep them in place:

The foam is 2 mm thick, so subtracting that from the nominal thickness makes the new blocks come out right.

A short module extracts the footprint for export as an SVG image to laser-cut both the foam and the adhesive sheet required to stick it in place:

module ShimPad(Thickness = PadThick) {

if (Thickness)

linear_extrude(height=Thickness)

projection(cut=true)

ShimBlock();

else

projection(cut=true)

ShimBlock();

}

It turns out linear_extrude() chokes on a zero height.

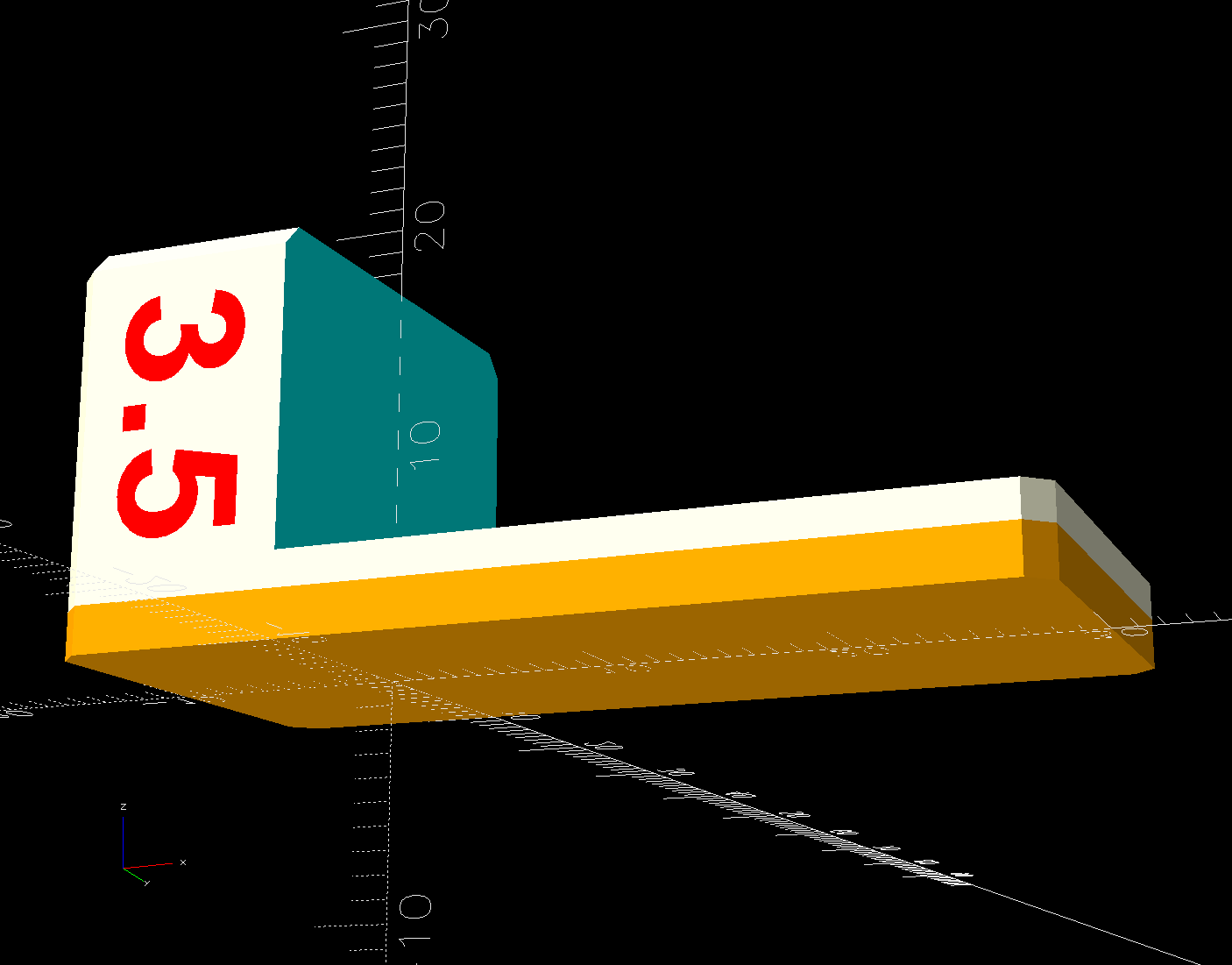

When handed a nonzero Thickness, the code generates a simulated foam sheet:

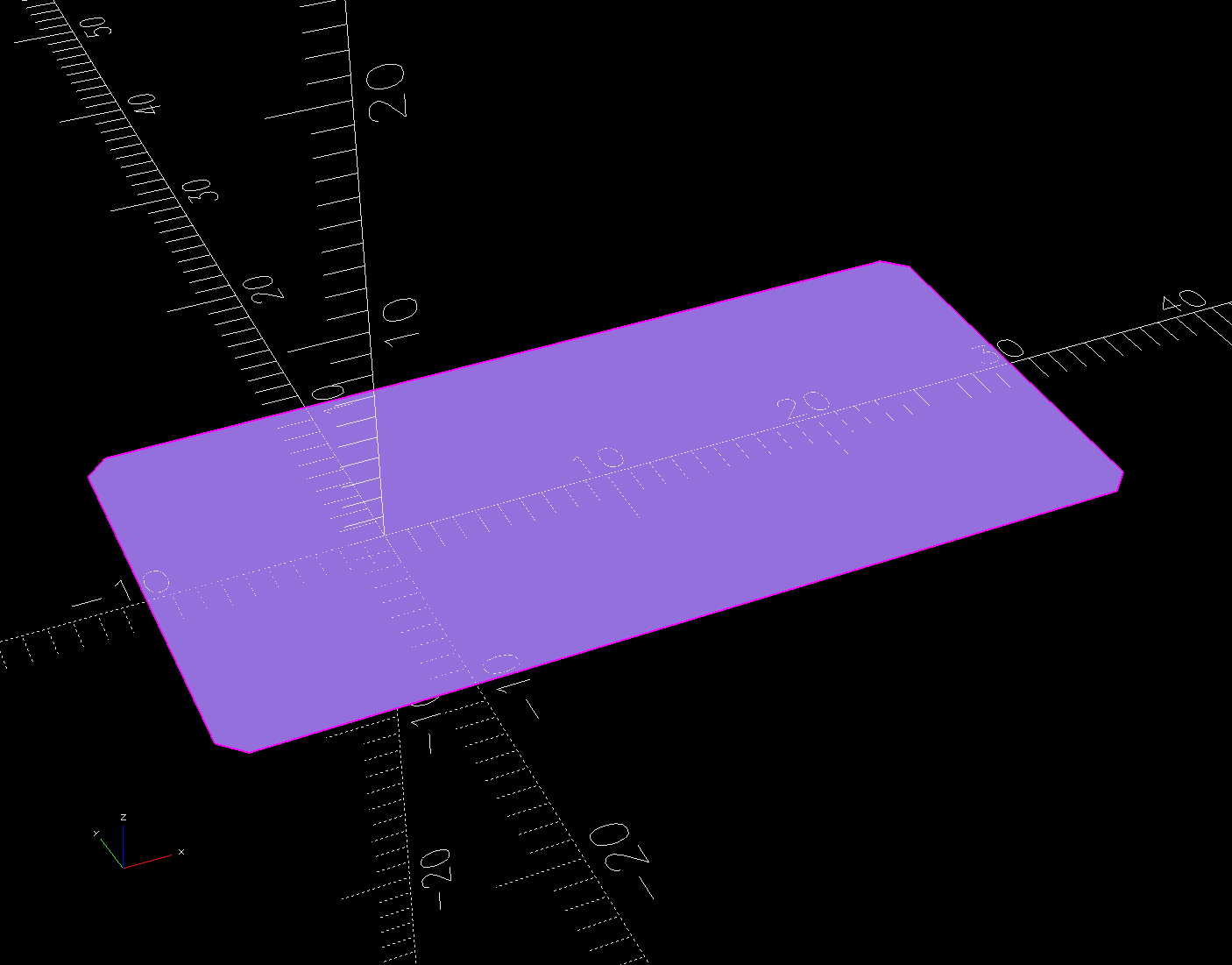

The footprint looks about like you’d expect:

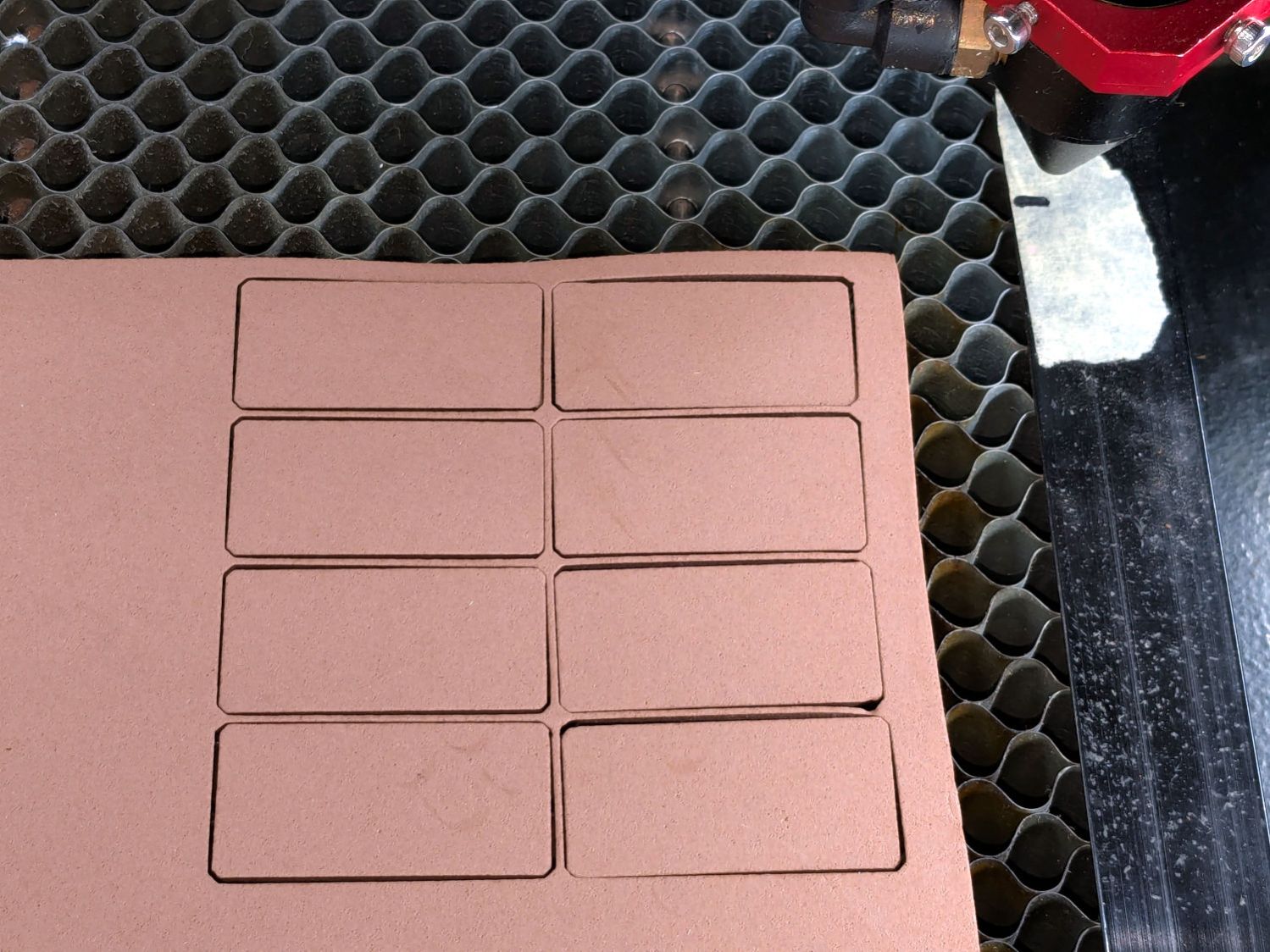

Import into LightBurn, duplicate it sufficiently, set the speed & power & kerf for EVA foam, then cut ’em out:

Ditto for the adhesive, stick together, and upgrade the fleet.

If these shake loose, snippets of adhesive film will stick them firmly to the underside of the table panels.

Update: Yeah, they needed sticky snippets. Whole lotta shakin’ goin’ on with that machine!