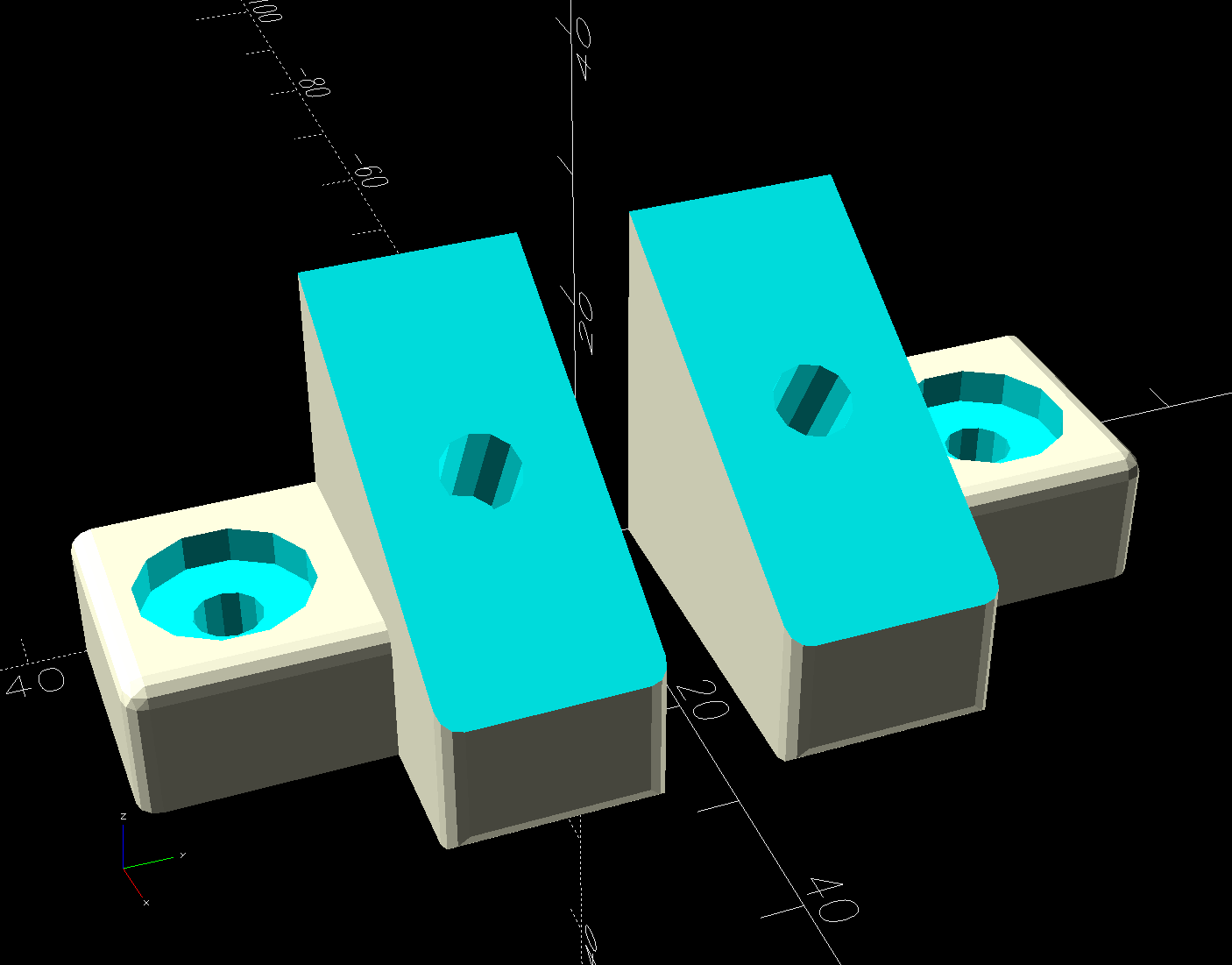

The object of the game being to tilt the LED strip lights at (maybe) 30° to put more light higher on the wall and further out on the ceiling, with the overriding constraint of no visible holes. Given their eventual home atop the window moulding along the front wall of the Living Sewing Room, these seemed adequate:

The hole on the angled part fits an M4 brass insert and the recessed holes capture the washer-like head of a sharp-point lath screw.

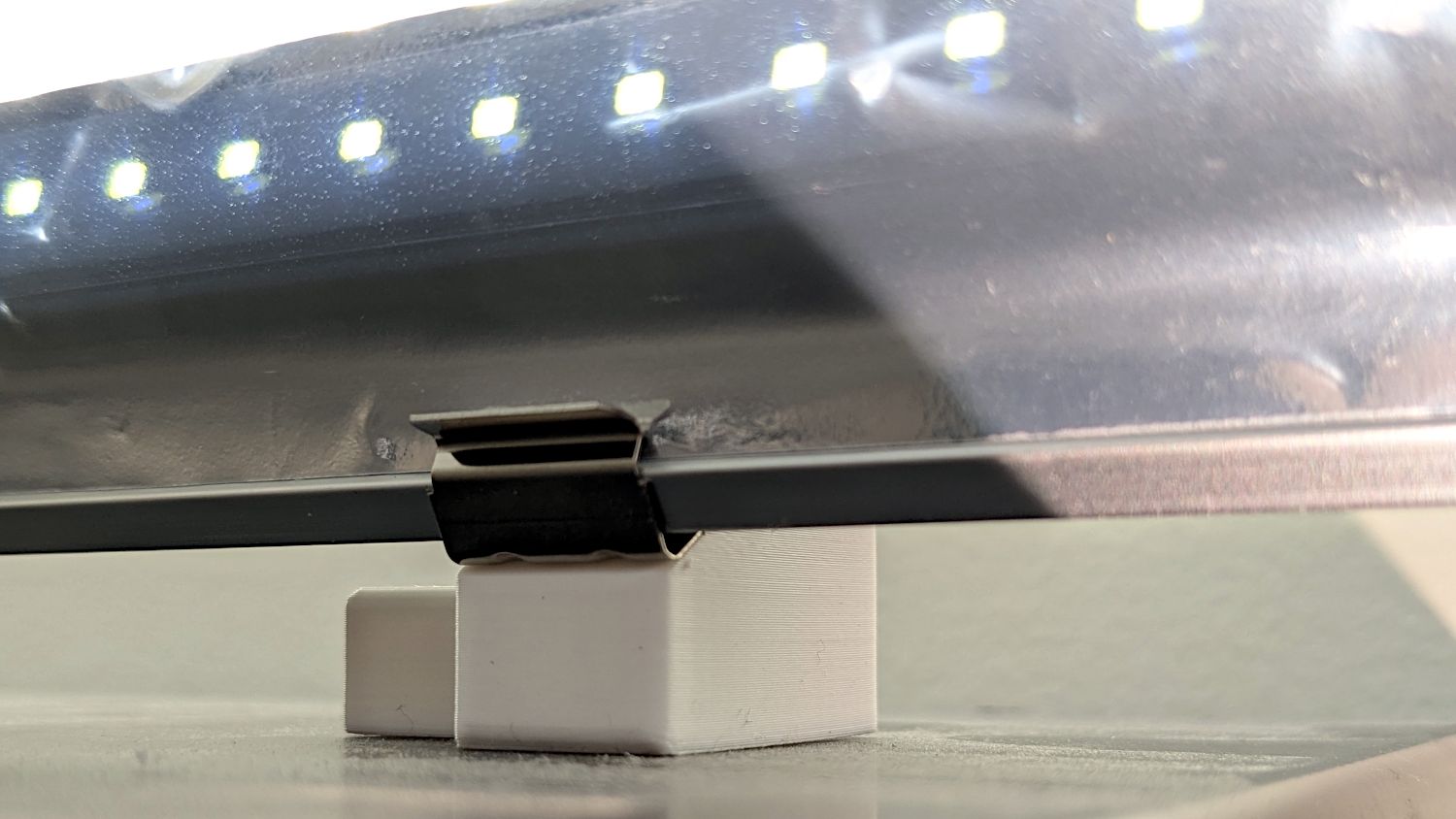

Two pairs applied to the lights sitting atop the Fabric Cabinets served to verify the fit:

They’re held firmly by the aluminum extrusion and don’t need a bigger footprint to remain stable.

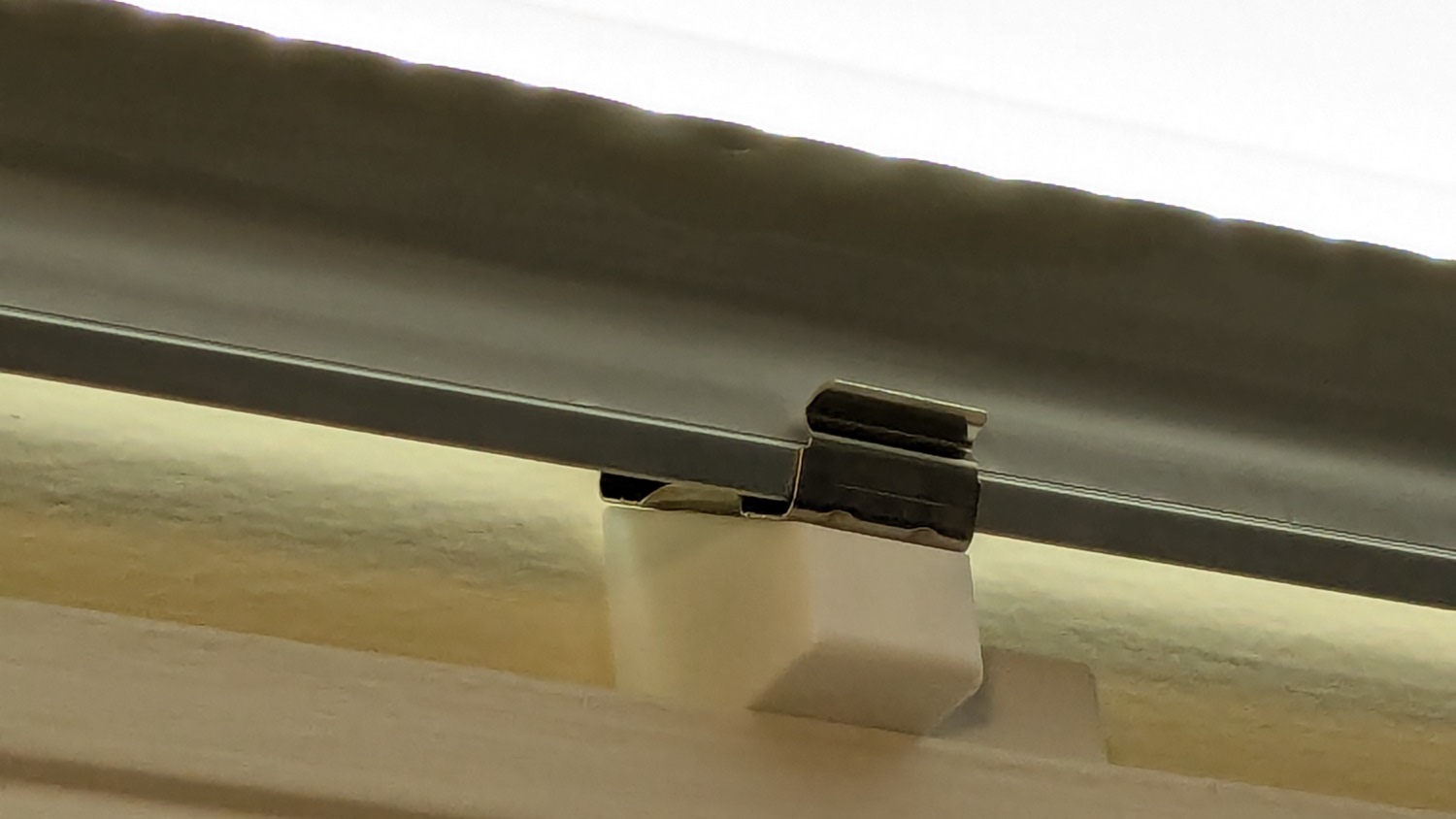

So I made another six, stuck on ⅞ inch strips of aluminized Mylar (cut from a bag in much better condition), and drilled holes where they can’t be seen:

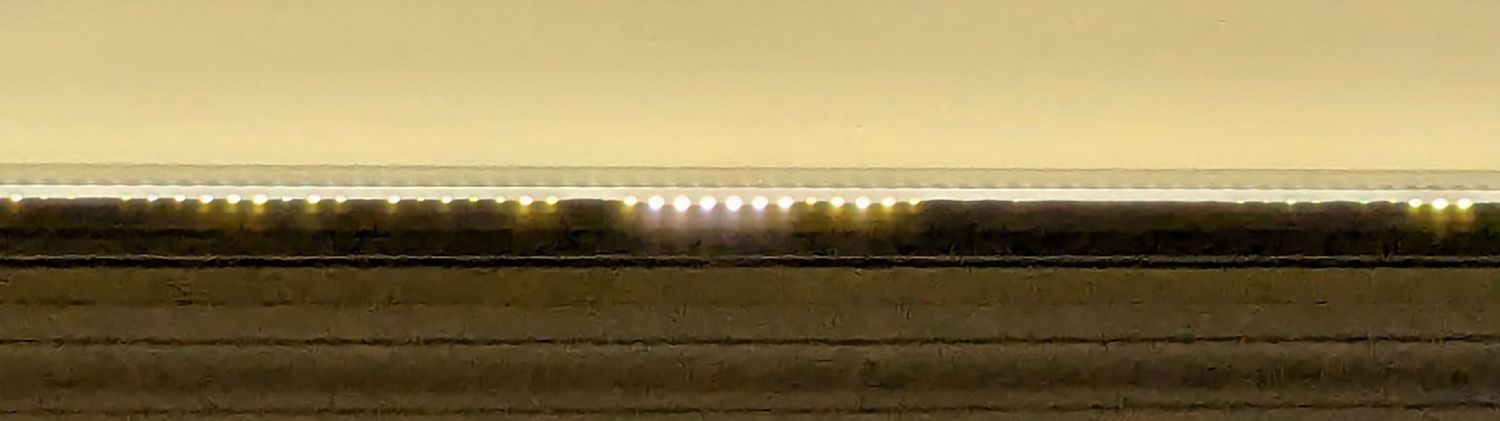

It’s almost too bright in there with 3 × 40 W of LED lights washing the wall and ceiling:

I don’t like the cold 6000 K color temperature, but Mary doesn’t mind it. They fill the Sewing Table with shadowless / glareless light, although that kind of light makes the place look like a store.

I think moving the strip lower and away from the wall could hide the entire mount from view.

Contrary to what I expected, the Mylar reflectors must be at least an inch tall to avoid Baily’s Beads seen from across the room:

With all that in mind, we’ll run these for a while to shake out any other improvements.

The OpenSCAD source code as a GitHub Gist:

| // LED light bar mounts | |

| // Ed Nisley – KE4ZNU | |

| // 2025-03-16 | |

| include <BOSL2/std.scad> | |

| Layout = "Show"; // [Show,Build,ScrewMount,BarMount] | |

| BaseAngle = 30; // [0:50] | |

| /* [Hidden] */ | |

| ID = 0; | |

| OD = 1; | |

| LENGTH = 2; | |

| Protusion = 0.1; | |

| NumSides = 3*4; | |

| Radius = 1.5; | |

| $fn = NumSides; | |

| MouldWidth = 18.0; // nominal (3/4) * INCH, but lots of paint slop | |

| MouldScrew = [4.7,12.0,2.6]; // clearance, head OD, head thick | |

| Insert = [4.0,5.5,6.0 + 3.0]; // heat-set brass without pilot end | |

| BarClip = [33.0,15.0,11.0]; // snaps around led base | |

| ScrewBlockOA = [MouldWidth,MouldScrew[OD] + 2*Radius + 2.0,10.0]; | |

| BarBlockOA = [BarClip.x*cos(BaseAngle),15.0,BarClip.x*sin(BaseAngle) + 2*ScrewBlockOA.z]; | |

| Gap = 2.0 + max(ScrewBlockOA.y,BarBlockOA.y); | |

| //———- | |

| // Define shapes | |

| module ScrewMount() { | |

| difference(){ | |

| cuboid(ScrewBlockOA,anchor=BOTTOM,rounding=Radius,except=[FRONT,BOTTOM,LEFT]); | |

| up(ScrewBlockOA.z – MouldScrew[LENGTH]) | |

| zrot(180/NumSides) | |

| cylinder(d=MouldScrew[OD],h=MouldScrew[LENGTH] + Protusion); | |

| down(Protusion) | |

| cylinder(d=MouldScrew[ID],h=2*ScrewBlockOA.z); | |

| } | |

| } | |

| module BarMount() { | |

| difference() { | |

| cuboid(BarBlockOA,anchor=CENTER,rounding=Radius,edges=RIGHT); | |

| yrot(BaseAngle) | |

| cube([3*BarBlockOA.x,2*BarBlockOA.y,BarBlockOA.z],anchor=BOTTOM); | |

| yrot(BaseAngle) | |

| cylinder(d=Insert[OD],h=2*Insert[LENGTH],anchor=CENTER); | |

| } | |

| } | |

| module Mount() { | |

| union() { | |

| right(ScrewBlockOA.x/2) back(ScrewBlockOA.y/2) | |

| ScrewMount(); | |

| right(BarBlockOA.x/2) fwd(BarBlockOA.y/2) up(BarBlockOA.z/2) | |

| BarMount(); | |

| } | |

| } | |

| //———- | |

| // Build things | |

| if (Layout == "ScrewMount") | |

| ScrewMount(); | |

| if (Layout == "BarMount") | |

| BarMount(); | |

| if (Layout == "Show") | |

| Mount(); | |

| if (Layout == "Build") { | |

| yflip_copy(Gap) Mount(); | |

| } |

Comments

3 responses to “LED Strip Lights: Window Moulding Mounts”

The white-walled workroom in the shop/barn now has 4 shop lights in addition to the 8 bulbs worth of light fixtures, and I have to tone down the lighting if I need to do intensive work with the shop computer.

The bulbs are leftover 23W CFs, and I have some “decorative” “100W equivalent” LEDs, which have a current draw and lumen output compatible with “60W equivalent” bulbs. It’ll be a mix of 5000K and 2700K illumination, but it’s worth trying.

We use 2700K for the house, but the overhead lights in the shop are 5000K. Color issues haven’t been bad, though I have to check to see what the lighting does for resistor color codes.

I continue to be astonished Mary has no trouble with grossly mismatched color temperatures, while she cannot understand why I say a “peach” sweater is “pink”. :grin:

[…] AFAICT, “metallic paper” consists of shiny aluminum film bonded to heavy paper / cardstock, with transparent colored film bonded atop the aluminum. The sheet is, of course, highly reflective, which looks dark unless it’s reflecting a bright surface, like the well-lit Sewing Room ceiling: […]