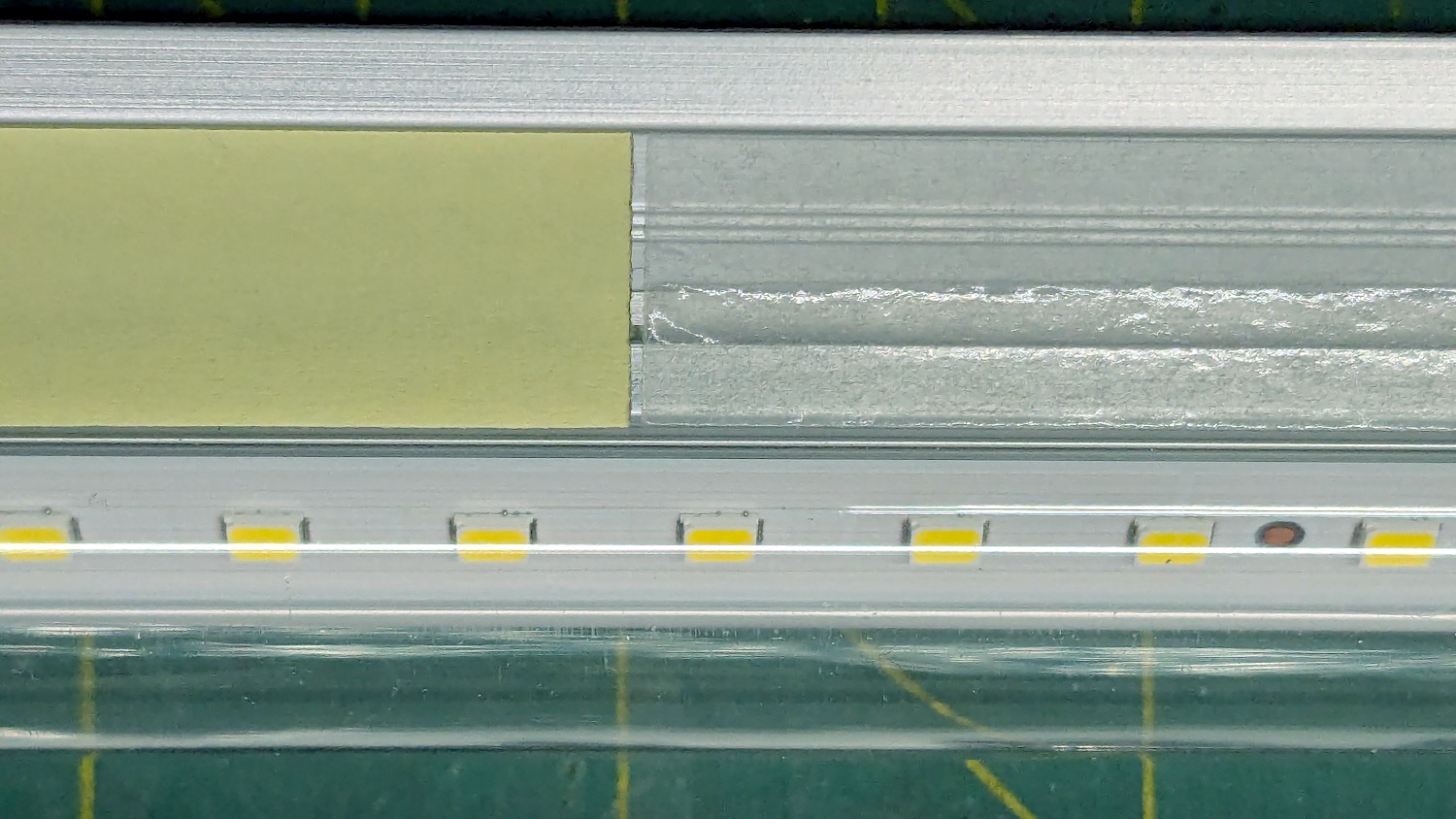

This is a quick-and-ugly test to see how well aluminized Mylar will work as a reflective shade for some LED light bars eventually washing the Living / Sewing room ceiling with enough light to brighten the Sewing Table:

The key question: how well adhesive adheres Mylar to the pleasantly warm aluminum extrusion serving as the heatsink for 40 W of LEDs:

Perhaps surprisingly, those ½ inch strips come from an A4 sheet by way of a paper cutter.

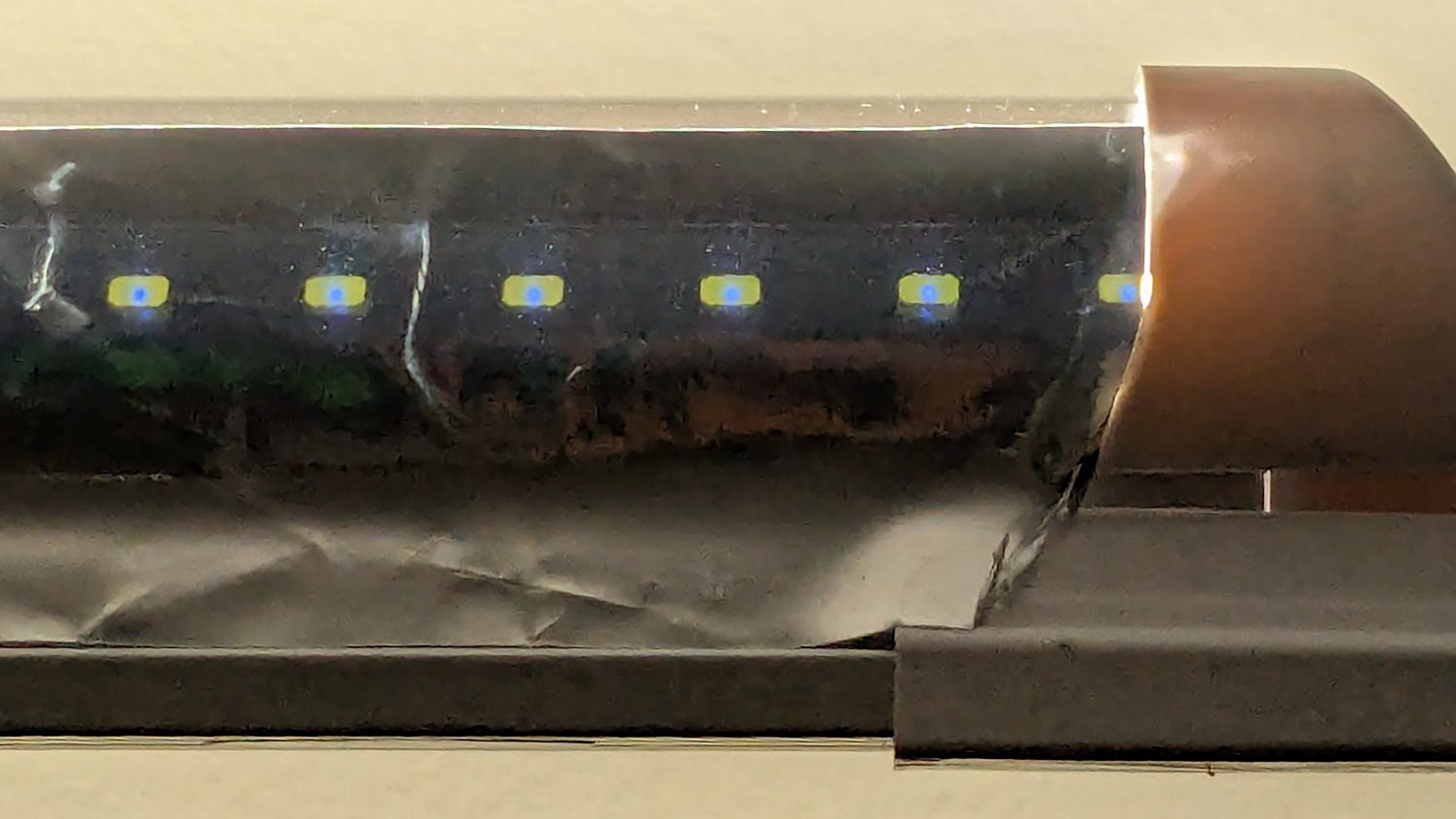

As with the Mylar shades over the COB LED strips in the laser, the LEDs remain through the aluminized layer:

The LED bars will be directly visible, so bouncing the direct light against the wall reduces glare and puts it to good use.

The Mylar strips are 1 inch wide, cut with a utility knife against a straightedge, although ⅞ inch seems adequate. The last LED over on the right sits at the endcap, so I will (try to) tuck the Mylar ends under the caps for a cleaner fit.

The bars have two 4 foot strips of LEDs in series, with a lump of circuitry buried in the aluminum extrusion that seems be a bridge rectifier and a small electrolytic capacitor. There’s not nearly enough capacitance to knock down the 120 Hz flicker and I have an uneasy expectation of stroboscopic effects on the sewing machines.

This is a test. […] This is only a test.

Now, to model angle brackets fitting the strips to the window moulding.

Comments

One response to “LED Strip Lights: Shade Adhesive”

[…] object of the game being to tilt the LED strip lights at (maybe) 30° to put more light higher on the wall and further out on the ceiling, with the […]