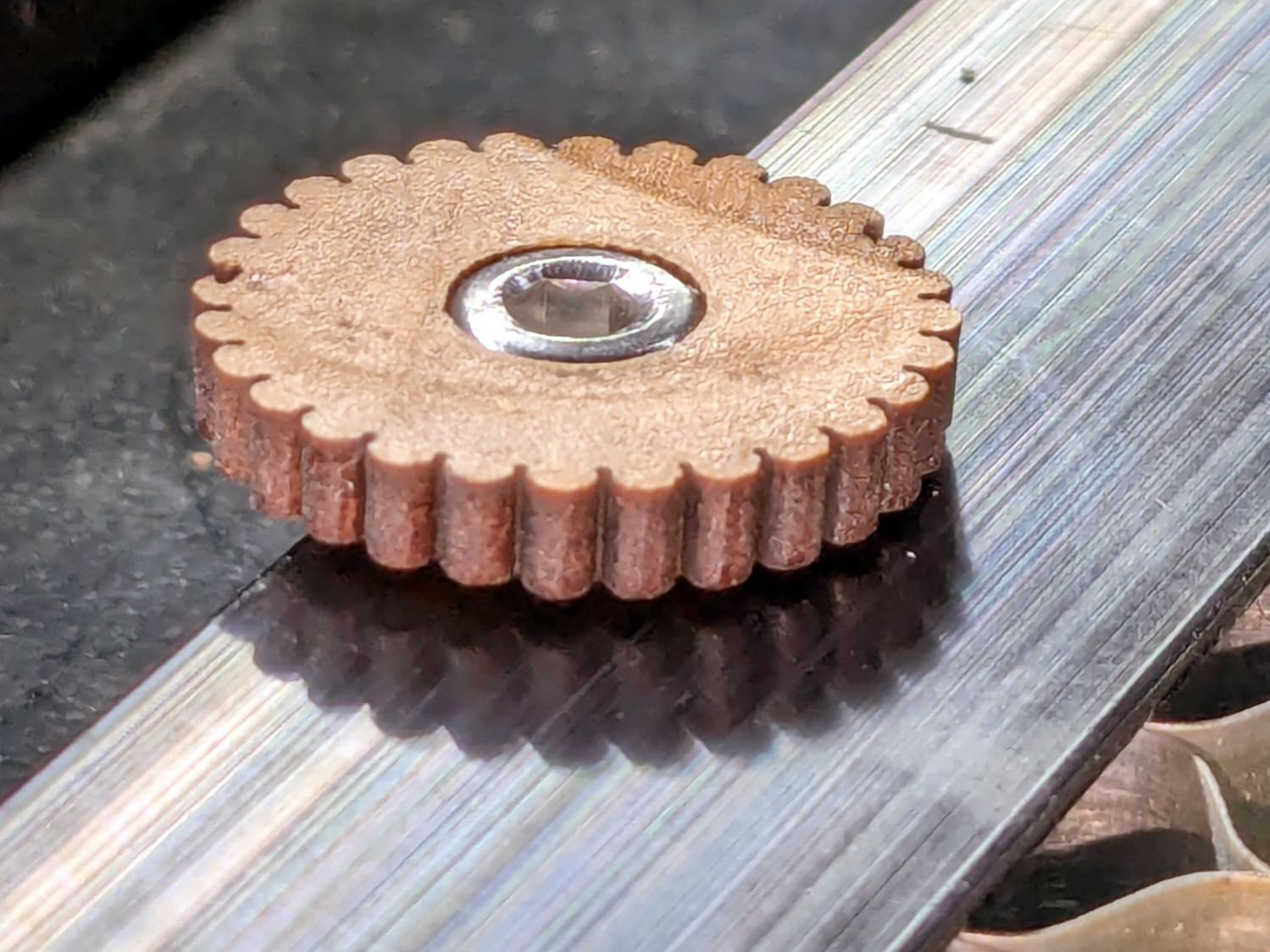

A nubbly knob on the M4 screws securing the honeycomb to the laser’s platform:

Leveling feet for the HQ Sixteen long-arm machine’s table for the high side of the floor:

And 12 mm taller on the low side:

Both of those “projects”, which may be too grand a term, went from “I need a thing” to having one in hand over the course of a few minutes yesterday. Neither required a great deal of thought, having previously worked out the proper speed / power settings to cut 3 mm MDF and 1 mm cork.

Other folks may lead you to believe lasers are all about fancy artwork and elaborate finished products. Being the type of guy who mostly fixes things, I’d say lasers are all about making small and generally simple parts, when and where they’re needed, to solve a problem nobody else has.

Perhaps I should devote more attention to using fancy wood with a hand-rubbed wax finish, but MDF fills my simple needs.

With a laser and a 3D printer, shop tools have definitely improved since the Bad Old Days!

Comments

One response to “Trivial Laser Projects”

[…] devoted considerable effort to smoothing the HQ Sixteen’s path across the table, with commensurate improvement, Mary […]