Although the laser ramp test fixture looked good, Brent wondered what a real test box would reveal about the Prusa MK4’s Input Shaper resonance control.

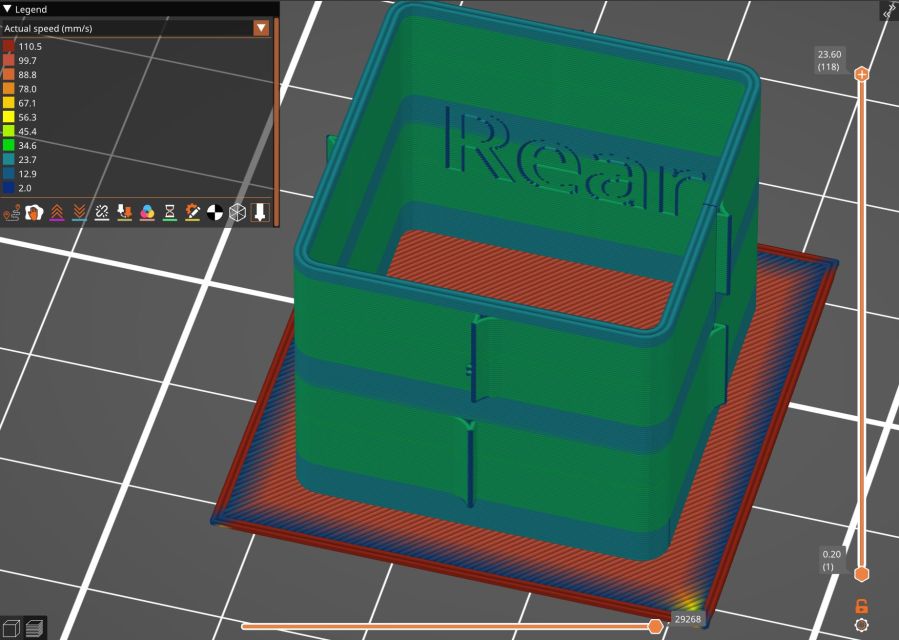

Loading the STL into PrusaSlicer, adding a text label to remind me which way it printed, then slicing with my PETG-CF profile shows the “Actual Speed”, which seems to take acceleration into consideration:

The colors in the legend don’t quite match the colors on the model, but the greenish layers with the jolts trundle along in the mid-20 mm/s range and the blue-ish straight-through layers at 30-ish mm/s.

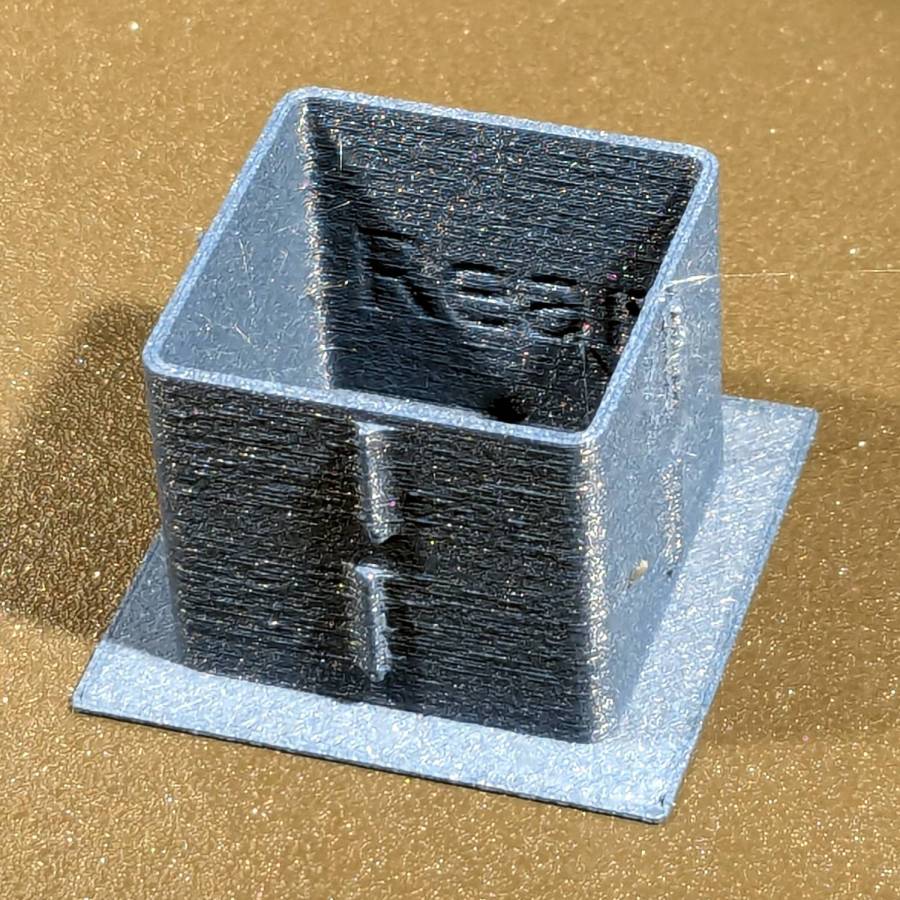

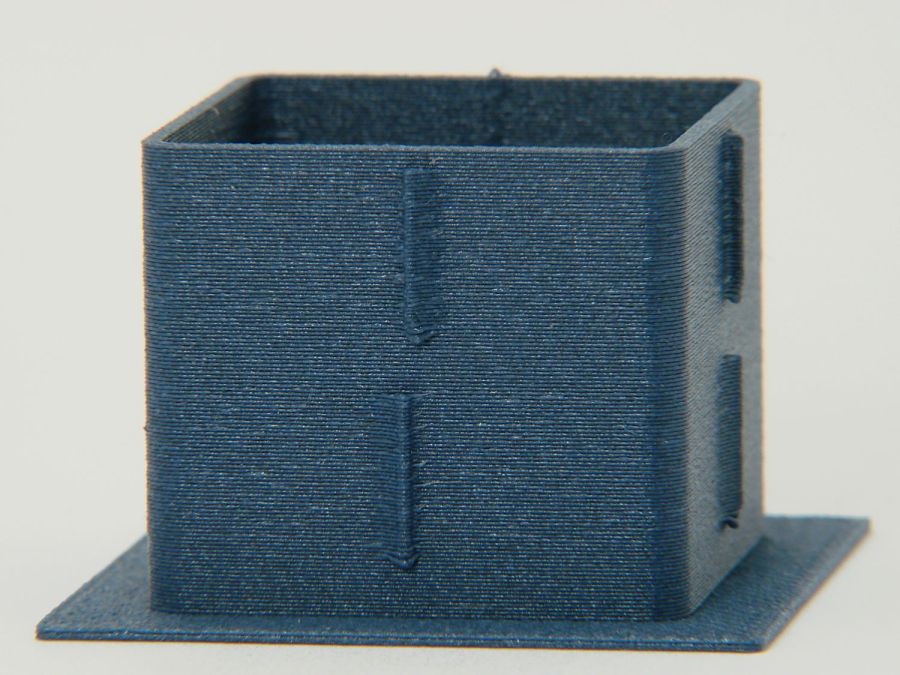

Eryone PETG-CF has a somewhat fuzzy appearance that seems not characteristic of other brands, so I’ll try something else when these spools run out:

The right side of the box (as oriented on the platform) got all the layer retractions and came out festooned with PETG hairs:

You can check my labels by tracking the small retraction zit sticking up from the top layer; I got it wrong the first time. Open the images in a new tab to see more pixels.

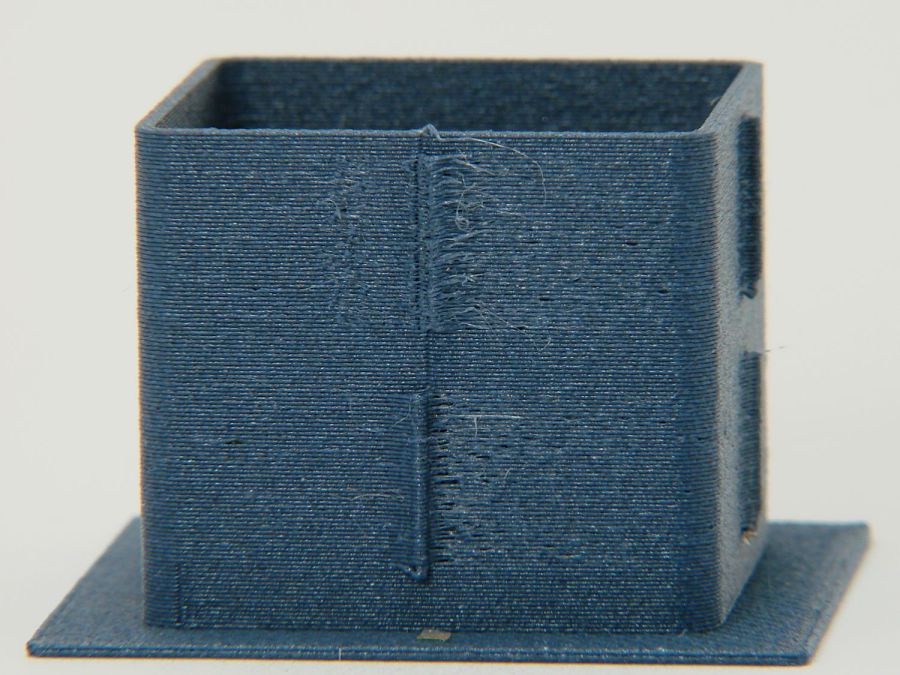

The front:

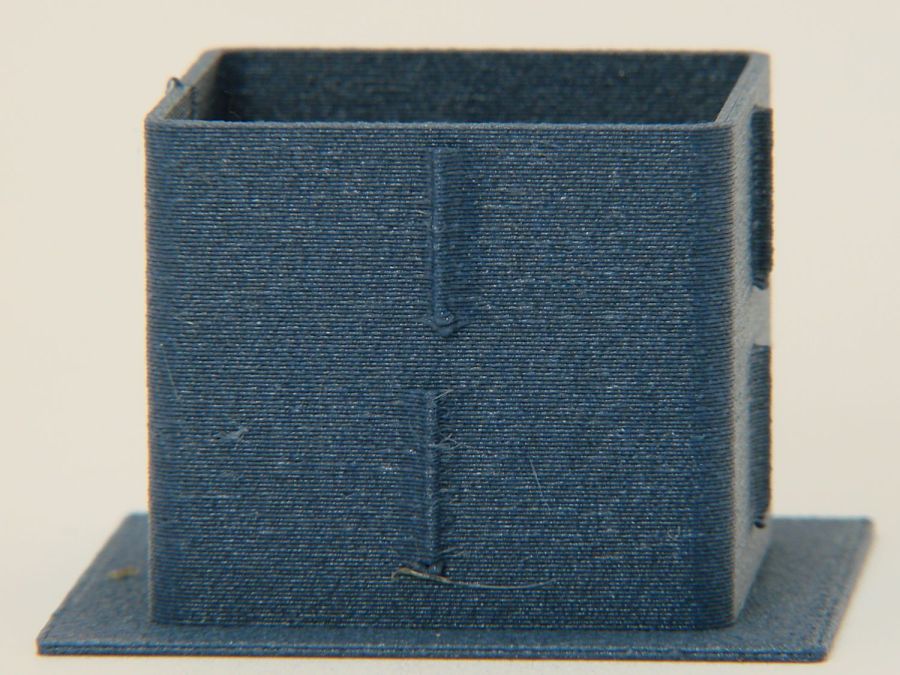

The left:

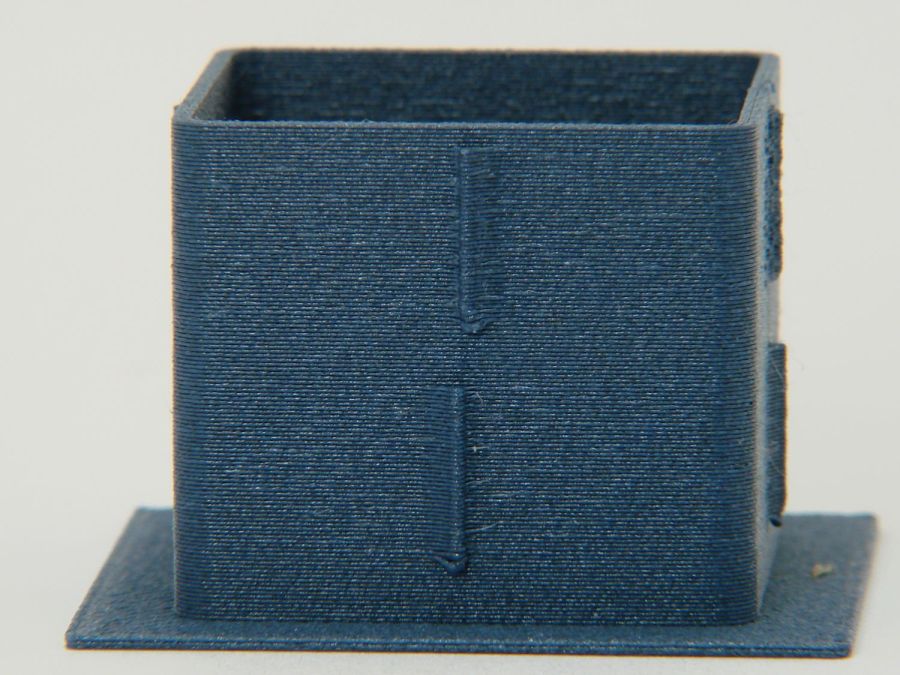

And the rear:

You can barely see the shadow of the “Rear” text on the surface, even though the wall is two threads thick and the text is indented by 0.2 mm, about half the thread width.

As far as I can tell, the MK4 Input Shaper compensation does a great job of suppressing resonance or wobble in all directions.

Looks good to me!

Comments

2 responses to “Prusa MK4 Input Shaper vs. Resonance Test Box”

They have come a long way since the MakerBot Cupcake. You had one, right?

I’m still rockin’ my decade old M2. Finicky and cranky, but still occasionally gets it done. A bit more like me than I might want to admit.

I do think of resurrecting my old Cupcake, because after I enclosed it it would print ABS like a champ. I have never had any success with the M2 and ABS. I did like being able to print in ABS for temperature resistance, strength and (this is big) the ability to easily glue it with full-strength joints.

The big enclosed Prusa with a multi-material upgrade us enticing. Not sure if it is worth nearly $2k (assembled, extended warranty, etc) of enticing.

I tore the old Thing-o-Matic apart a while ago, figuring I’d never use it again and the pieces take up less space than the box.

At some point I must find out if the M2 will print TPU, so I can make bendy things. Word has it the MK4 / MMU3 doesn’t handle TPU without bypassing the MMU3, which would introduce a whole bunch of awkward.

Also, I’ve read the XL is basically a dead end, with the MK4 line continuing to accrue new features. Having separate extruders definitely make multi-material objects with vastly different filaments more tractable; the MK4 / MMU3 takes a long time to change temperatures and downward changes can freeze the higher-temperature filament in the nozzle.

But, on the whole, living in the future is wonderful!