The kitchen faucet worked its way loose again. Attempting to shut off the water revealed a pair of leaky valves under the sink, so I shut off the house water in the basement, cut the valve pipes below the solder drips, and installed a pair of push-connect shutoffs:

I loves me some good push-connect fitting action, which is new news to me. Back in the Bad Old Days™, I’d be under the sink with a propane torch, trying to solder a pair of wet pipes and failing miserably.

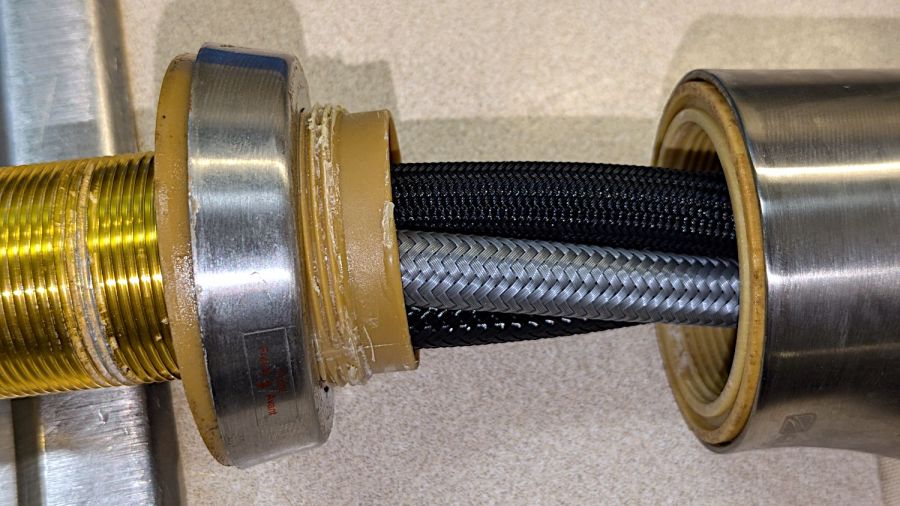

With that out of the way and the faucet dismantled for the first time (by my hands, anyway), the threads holding the base to the spout column may have been damaged during factory assembly:

I thought the gunk was thread lock compound, but it’s shredded plastic from the base fitting threads. The corresponding female threads inside the spout column are undamaged, so I think somebody tried screwing it together with the threads misaligned, backed off, then muscled it together.

It’s worth noting there are no keys or stops fixing the correct orientation of any of these parts. In particular, the trim ring bearing the small Front label (facing you in the picture) has no fixed orientation: whoever assembles the faucet in the factory must position it correctly on the fly as the base screws into the column and jams tight.

So I cleaned up the damaged threads as best I could, flipped the threaded brass tube end-for-end to put the cleanest part into the base, and reassembled everything with careful attention to starting the threads correctly:

Tightening the base fitting into the column is much easier with everything on the kitchen counter, although centering the label on the molded opening required several tries.

Protip: a pair of grippy gloves and rubber sheets help a lot.

I want to find out how secure the original design, properly tightened and aligned, will be, so I did not apply any threadlocker.

Comments

3 responses to “Home Depot Glacier Bay Kitchen Faucet: Round 2”

Those fittings are like magic. I’ve never seen them before. One question. I looked and the ones I could find don’t seem to have that little cap for draining one end of the pipe (like for a pipe to an outside spigot that you want to drain in the winter). Do those exist or why not?

I really hope they’re not like aluminum house wiring: seemed like a good idea until a decade later when houses started burning down. In this case, we’re depending on a little O-ringy-thingy to maintain a seal forever more in a valve that can rotate around the pipe.

There’s a drain-down push-connect valve on the source end of the PEX line going to the back of the house, in a position where it cannot possibly drain that entire droopy run of flexy pipe. I installed ordinary non-drain valves on the hose bib end because I was using those fancy freeze-proof valves that drain themselves.

Probably no drain-down valves for 1/2 inch push-connect → 3/8 inch compression, because who’d ever want to avoid emptying the faucet tubes into a towel under the sink? :grin:

[…] a bit more than half a century, the rubber washer in the cold water shutoff valve for the kitchen sink had […]