After five years and one cleaning, the PTT button on Mary’s Tour Easy became increasingly intermittent, both failing to activate solidly and sticking closed (there being nothing quite like a hot mic during a good hill climb), so it’s time for an autopsy:

The snap dome is much more scarred at the central contact:

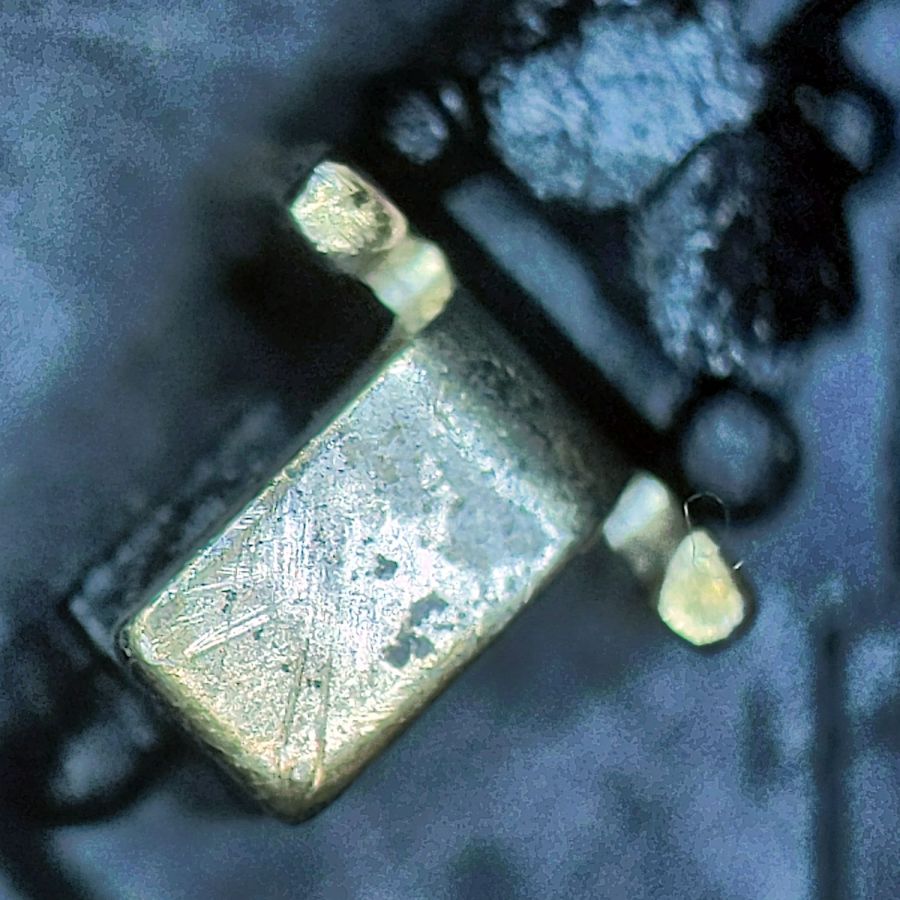

That might be a gold flash coating, but it’s pretty well worn away where it hits the central contact:

Those scratches surely happened during the previous cleaning pass, as I don’t see any way for the dome to create them.

The corner contact also shows some scuffs, along with a scar where the dome corner pivots:

All in all, though, it worked quite well.

The replacement switch, also intended for indoor use on a keypad or some such device, pivots around the front edge and may be easier for her fingertip to activate:

Hot melt glue seems vastly underrated for how wonderful a structural material it is.

If this one lasts five years, I’ll be perfectly happy.

Comments

4 responses to “Tour Easy: PTT Button Replacement”

Regarding hot-melt glue. I recently watched a youtube video that showed using 3d-printed injection molds and hot-melt glue to provide over-molded strain-reliefs to frayed cables. It seemed to work really well. They used vegetable oil for mold release which a first failed attempt showed was necessary.

I like it!

Holt melt glue isn’t wonderful as a structural material, but molding it seems easier than 3D printing a bendy strain relief out of, say, TPU.

Crystalfontz once made an overmolded display:

https://www.crystalfontz.com/product/xe634bktfbku

It was super rugged and waterproof. The overmolding rep said their compound was low pressure, low temperature — then mentioned hot glue :-)

When they worked, they were super rugged. You could use them on their edge as a rubber hammer. Swing them around by the cord and slam them into concrete – not a failure. Unfortunately, production molding prep was labor intensive – lots of RTV to seal behind the display. And about 25% would die in the molding process :-(

Then they changed their formula and about a month after receiving them they would form massive (~3mm) cracks in the overmold just sitting on the shelf. That finally killed the product.

“Then they changed their formula” is the requiem for so many products. :sigh: