With the microwave back in operation, I thought I might learn something about the failed gas sensor:

Given that much information, finding the datasheet for a Figaro TGS880 sensor didn’t require much effort. In case you were wondering, the replacement sensor has no trace of branding or identification.

The sensor element has a resistance varying with gas concentration, for a variety of test gases I hope our kitchen never contains in such abundance:

The measurement circuit:

I betcha the microwave waits for an order-of-magnitude resistance drop from whatever the starting value might be, then calls it done.

The belly band holding the steel mesh to the plastic base is no match for a Dremel slitting wheel:

As the saying goes, Sensoria est omnis divisa in partes tres:

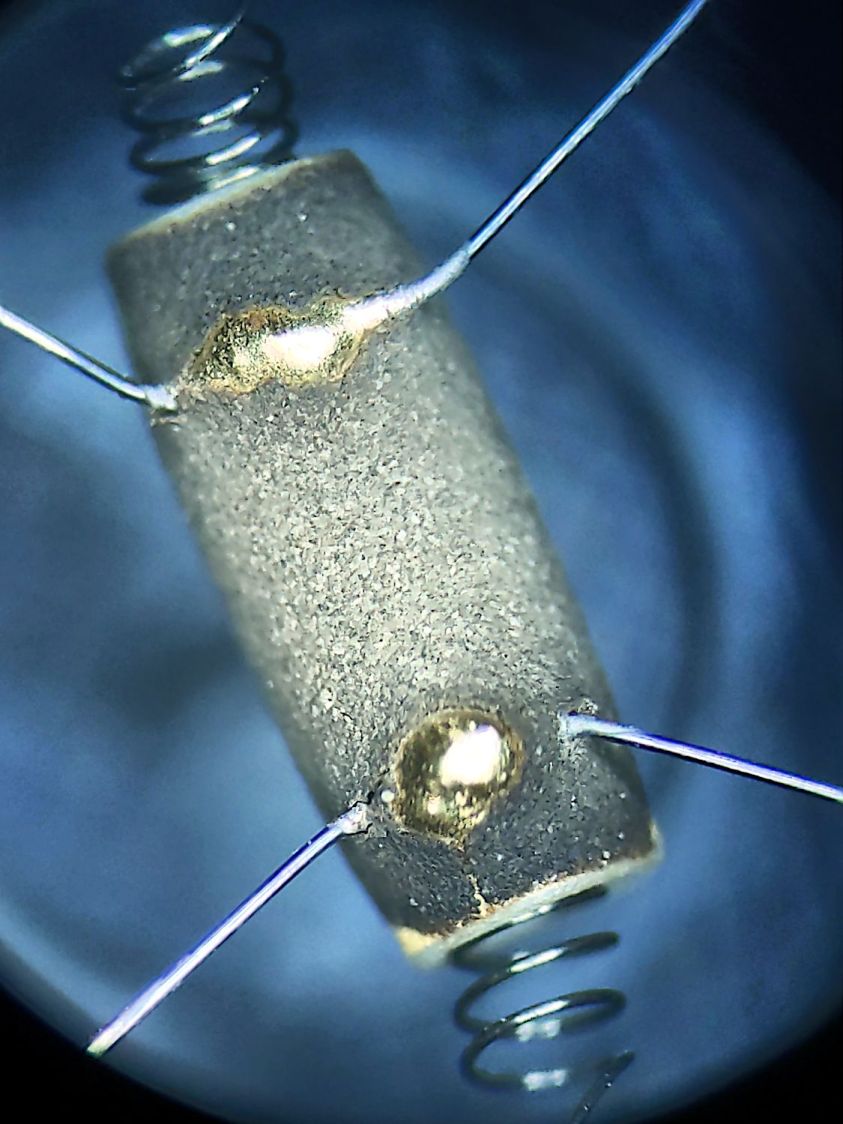

A closer look at the sensor element:

The granular surface does not get along well with the 5× digital zoom required to fill the phone’s sensor, but you get the general idea:

The heater measured 30 Ω on the dot and the sensor was an open circuit on the 100 MΩ range. Connecting the heater to a 5 V supply dropped the sensor resistance to 800 kΩ @ 50 %RH and a warm breath punched it to about 2 MΩ. That’s with an ohmmeter because I haven’t yet unpacked the Electronics Bench, but seems far above the spec of 20-70 kΩ in air.

So it’s still a sensor, even if it’s not within spec.

The WordPress AI-generated image for this post is … SFnal:

My pictures apparently aren’t up to contemporary blog standards …

Comments

5 responses to “Samsung Microwave Gas Sensor Teardown”

The inside of the sensor was milled? Or the marks are from the mold that made it?

They look like mold marks, but it’s definitely the least-awful surface finish they could get away with.

Sometimes only a Dremel can do the job. Take care, the cutting disks are fragile.

As Eks taught me, you can take anything apart with a Dremel slitting disk. I bought a generous supply of disks and the bottom of the tube is becoming visible, so it’s getting on time for a resupply.

[…] Check out the full teardown in the post here. […]