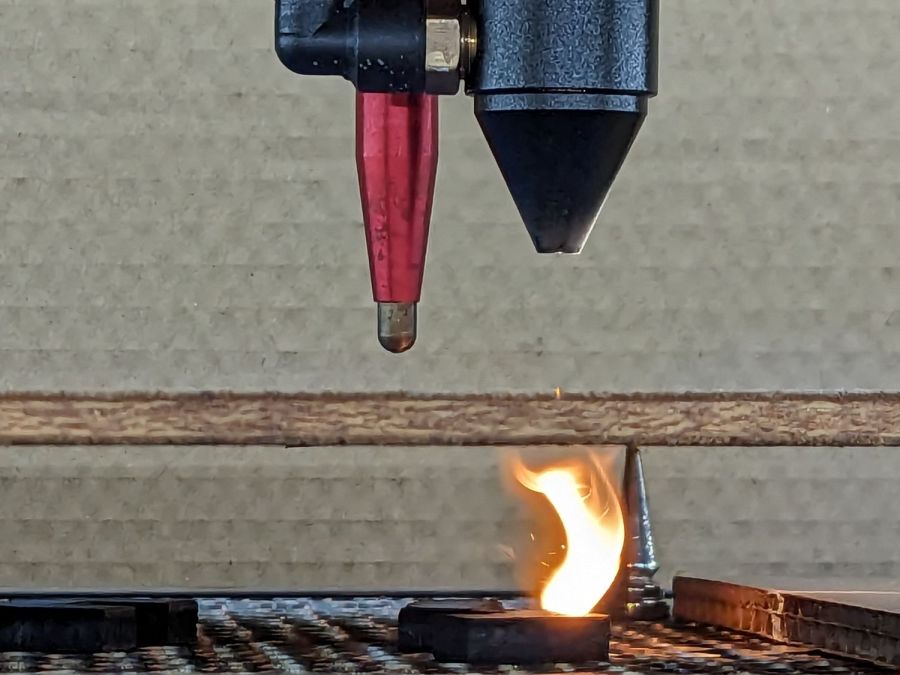

While cutting some oak plywood, I managed to get some interesting (to me, anyhow) pictures of how the assist air interacts with the laser kerf:

The air flow is about 12 l/min from the pump in the bottom of the laser cabinet and is pushing most of the fumes through the kerf, where they ignite and burn merrily.

The plywood is up on magnetic punk spikes to give the fumes plenty of room to disperse without making too much of a mess on the bottom surface. Unfortunately, the flame can blowtorch the cut parts after they fall through onto the honeycomb.

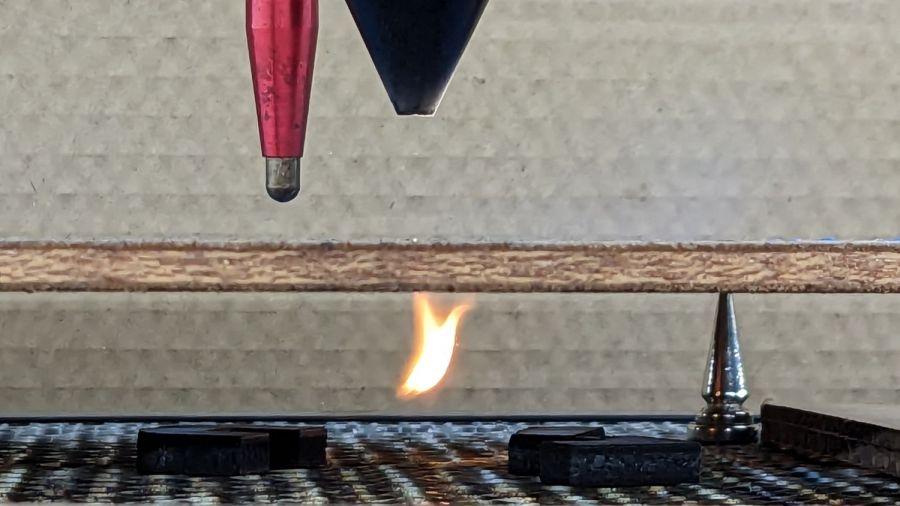

Another view shows some smoke doesn’t make it through the kerf:

The bulk of the flame seems to trail behind the beam as it cuts through the wood, which isn’t surprising:

Just like acrylic flame, it’s kinda pretty, but should serve as another reminder why you must never, ever run your laser unattended.