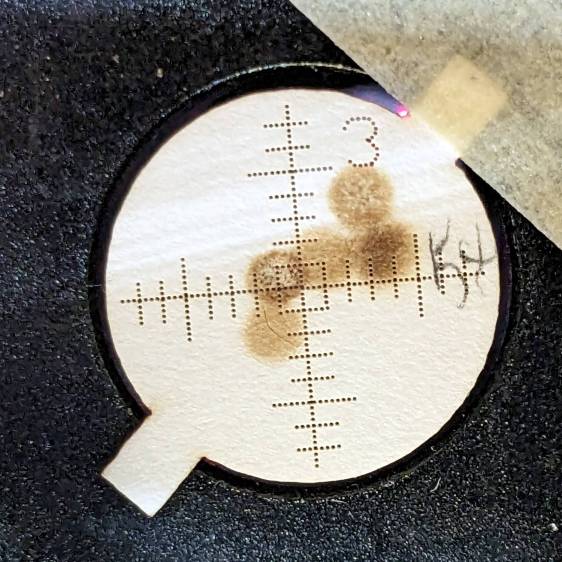

A recent mirror alignment check led to complete failure at the laser head aperture just upstream of Mirror 3:

Those five spots come from the center of the platform and the four corners; they will overlay into a single spot in a properly aligned machine.

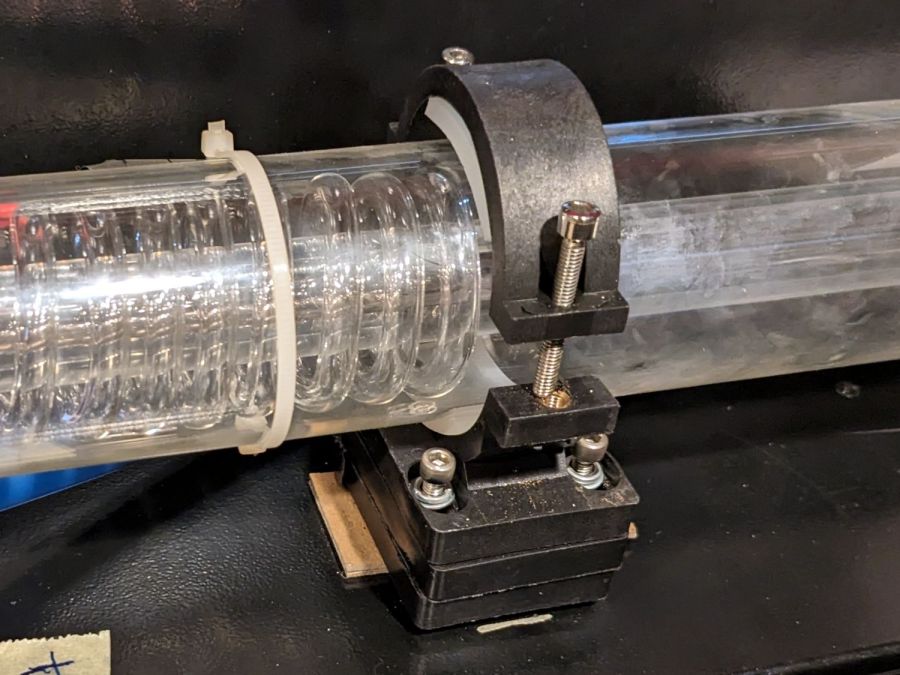

Pondering my options reminded me that I intended to build new laser tube support pads, because the ones shipped inside the machine seemed crudely made:

It’s partly disassembled in preparation for the next step.

The chipboard shims underneath the stack are mine, but the OEM pile was unstable even with the screws tightened. The reason became obvious when I took the stack apart:

The bump in the middle of the upper block surrounds the post of the laser tube cradle. It looks like this from the side:

All of the blocks were crudely molded and could not be stacked into a stable pile. The tech who assembled and aligned the machine tightened the screws so firmly that the washers crushed into saddles:

I can do better than that, if only because I’m not on the clock.

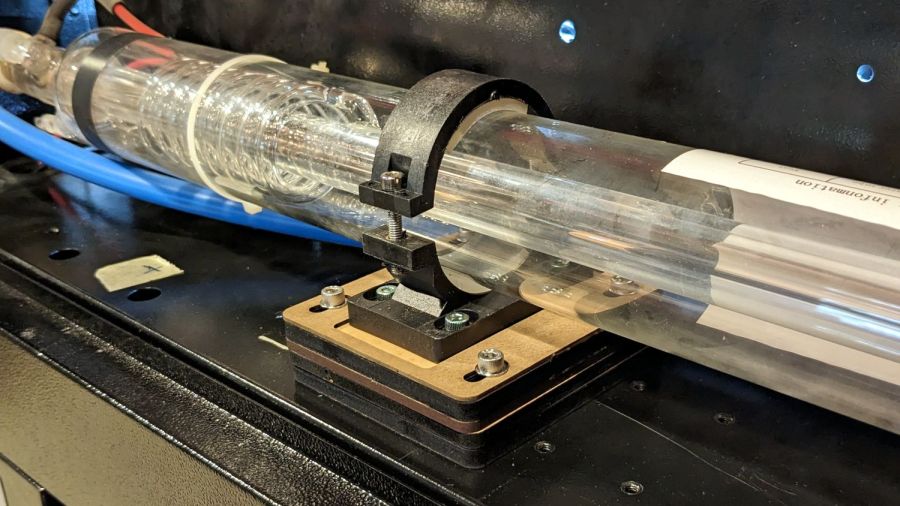

The tube support on the right end (toward the beam outlet) screwed into a nice set of threaded inserts brazed onto the floor of the laser compartment.

As far as I can tell, the laser cabinet was intended for a real 60 W tube measuring 1200 mm that would stick out into a box on the side of the cabinet, but would allow the left tube support base (shown above) to screw into a similar quartet of threaded inserts. Instead, it has an overdriven 50 W tube measuring 1050 mm with the left support screwed into four crudely hand-drilled and -tapped holes so far off the centerline as to jam the screws against the front end of their slots in order to get the tube barely into alignment, with the screws on the output side jammed against the rear end of their slots.

To answer a question you may have: the commercial tube supports one might buy from a reputable supplier (or, for that matter, Amazon) are either exactly as wide as the compartment (thus eliminating one degree of freedom) or obviously unsteady, and would surely require drilling more holes in awkward locations.

So, we begin.

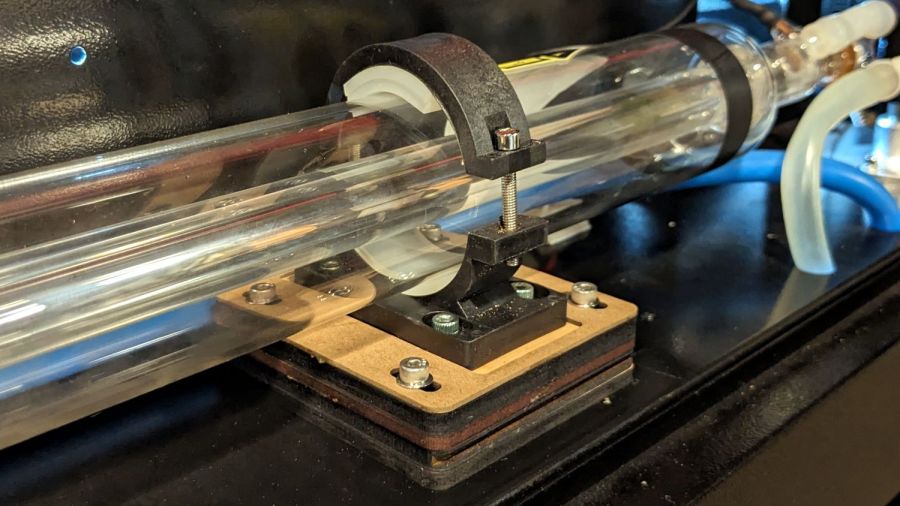

The general idea is to make a larger set of blocks fitting another quartet of holes with threaded inserts on the right side of the compartment floor:

On the right, I stuck the bottom block to the shelf with double-sided tape:

Because I was unwilling to:

- Drill and tap holes with the tube in place or

- Remove the tube to get safer access

The alert reader will note the four tapped holes immediately to the right of the new blocks. Those were evidently intended for a center tube support for the longer tube, because the crudely hand-drilled holes hide just out of view to the left of the new blocks.

At the far left of that picture, beyond the two holes probably intended for coolant tubes, you can see one of the four holes with tapped inserts that would match longer tubes, where the 50 W tube has its anode and coolant connections.

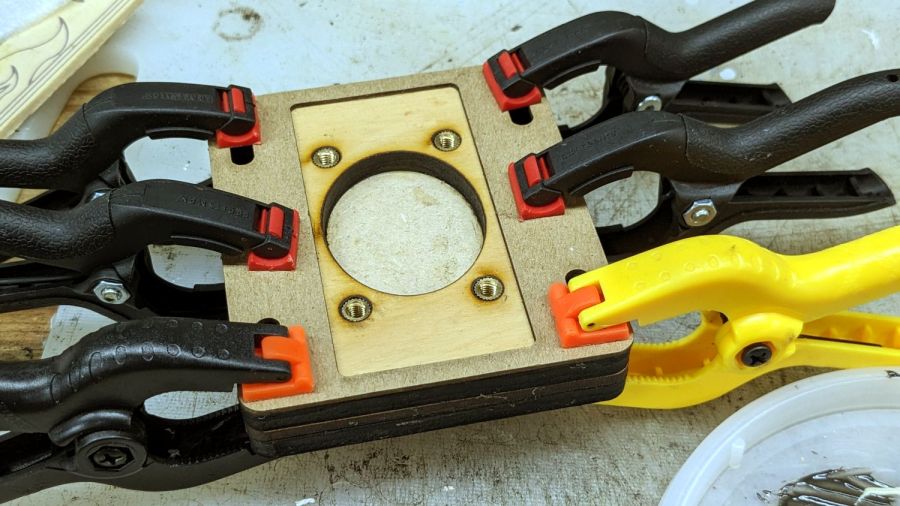

The larger blocks I made have a hole accommodating the bulge in the tube cradle to let it slide back and forth as needed:

That seemed easier and less exciting than attempting to flycut the bottom of the OEM plastic tube cradle.

The chipboard layer serves as a guide to keep the tube cradle lined up, with its now much shorter screws into the brass inserts epoxied into the plywood layer.

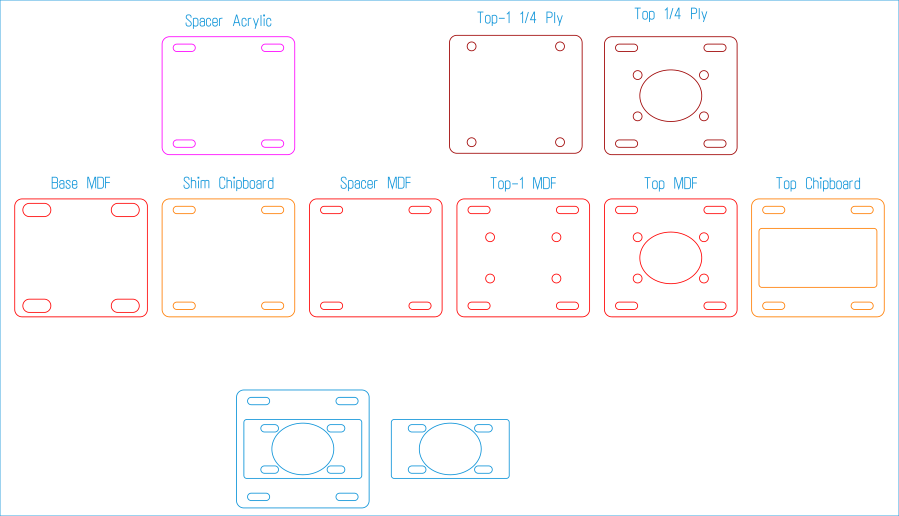

I glued the top layers together to get a rigid assembly, with the lower layers being replaceable shims adding up to the right height, whatever that might be. The LightBurn layout has an assortment of useful pieces, some of which I didn’t need:

If this were a greenfield project, the leftmost Base MDF pad would come in handy, as its slots are large enough to clear the flat side of the 4 mm rivnuts I’d install in the compartment floor.

Thin shims come from paperboard boxes & chipboard:

Thicker spacers come from (scrap) plywood and MDF:

Skipping ahead a few days, the tube & mirror realignment came out much better:

That’s only the four corners of the platform, but it’s OK by me.

If you’re fussy, the scorches are all low by a bit under 2 mm. Fixing that requires raising the tube by 2 mm, which I can certainly do, but I’m going to let this whole affair mellow out for a while.

The LightBurn SVG layout as a GitHub Gist:

Comments

2 responses to “Laser Cutter: Improved Tube Support Pads”

[…] I cut some 5 mm plywood spacers and nerved […]

[…] the laser tube 5 mm required nothing more than cutting and inserting 5 mm spacers and finding slightly longer M4 […]