It turns out my all-time favorite Pilot Precise V5 Extra Fine stick pen also comes in a clicky-top retractable version:

The cartridge is a nice 6 mm cylinder, eminently transformable into a plotter pen:

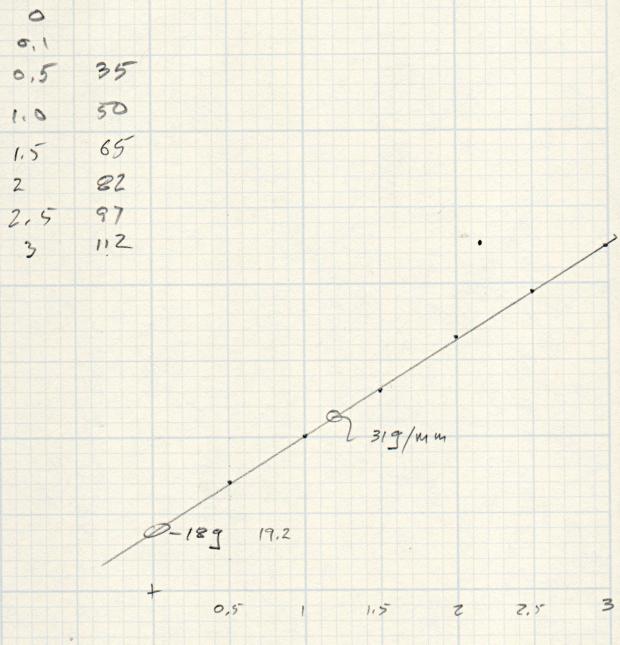

A few minutes with a caliper provides key measurements for a snout surrounding the business end:

The green letters & numbers give the nearest drill sizes. The “T” values along the bottom are the tailstock turns (at 1.5 mm/turn) required to poke the drills to the indicated depths, eyeballed when the body just enters the hole.

Having recently decomissioned the Thing-O-Matic and harvested its organs parts, I have a vast collection of 3/8 inch = 9.52 mm shafts and matching bronze bushings:

Bronze bushings have low stiction, at least when they’re co-axial, and are much shorter than linear ball bearings.

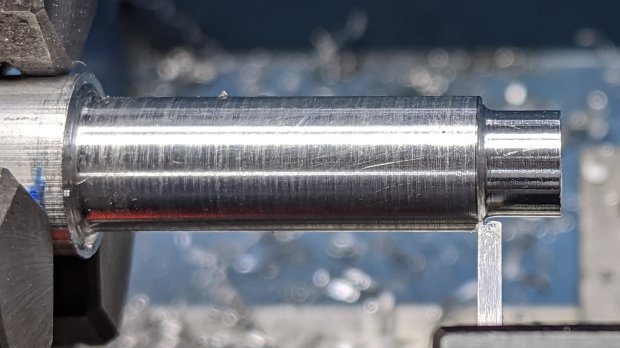

I chopped off a 70 mm length of shaft and faced the raw end:

The other end had a maker’s logo, but I don’t recognize it:

I really wanted an 8 mm bore around the snout, but it just didn’t work out. The ring around the 7.5 mm counterbore shows where the larger drill just … stopped:

A trial fit with the pen cartridge:

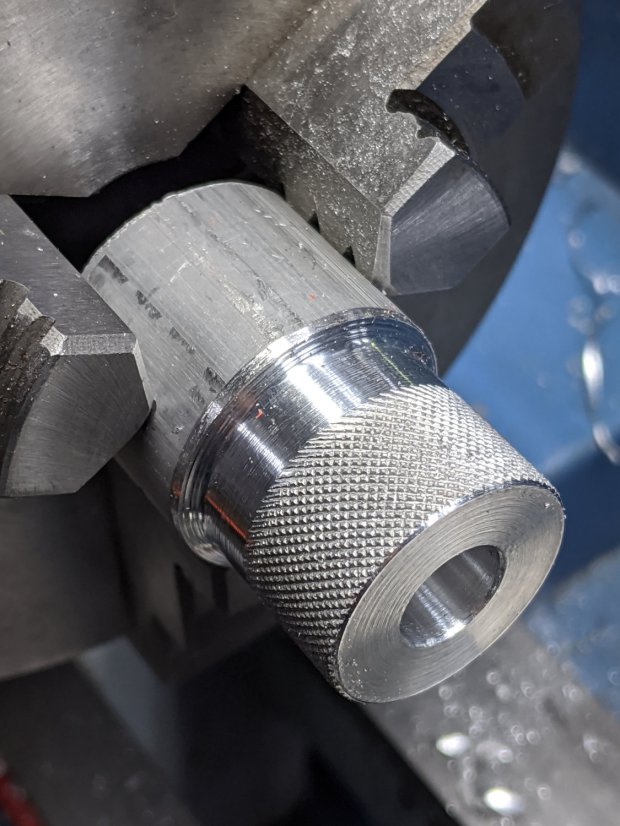

The top of the shaft gets a somewhat longer knurled ring for the 3 mm SHCS holding the cartridge in place:

The screw bears on a split collar turned and drilled from a Delrin rod:

The “split” came from a simple saw cut across one side and I milled a flat spot in the knurling to seat the screw. As usual, the knurled ring got epoxied to the shaft.

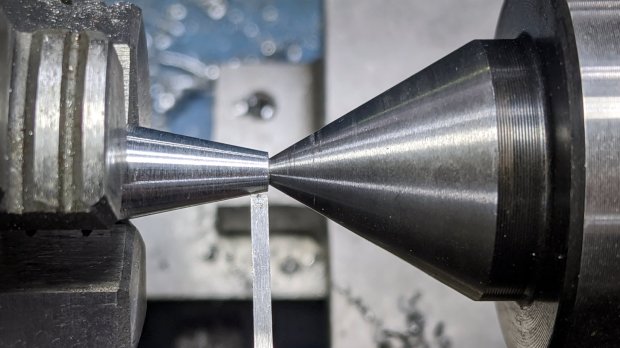

The snout started as a 3/8 inch aluminum rod, drilled as shown in the sketch, with a (scant) 7.5 mm section to fit the shaft. The carbide insert left a nicely rounded shoulder that required trimming to fit snugly into the shaft:

The compound can handle the shallow angle required to shape the snout:

A trial fit showed the snout was a bit too long for comfort:

Making something shorter doesn’t pose much of a challenge:

Another trial fit shows it’s spot on:

The critical part is having the snout support the plastic around the pen tip to prevent wobbulation.

Epoxy the whole thing together, add a suitable spring, tighten the screws & nuts for the reaction plate, and it’s all good. I write with about 50 g of force for these pens, so a light preload seemed in order:

If I’d weighed the full-up shaft + snout + collar + cartridge, I’d know if the Y intercept matches that weight. It seems a little lighter, but I’m not taking the thing apart to find out.

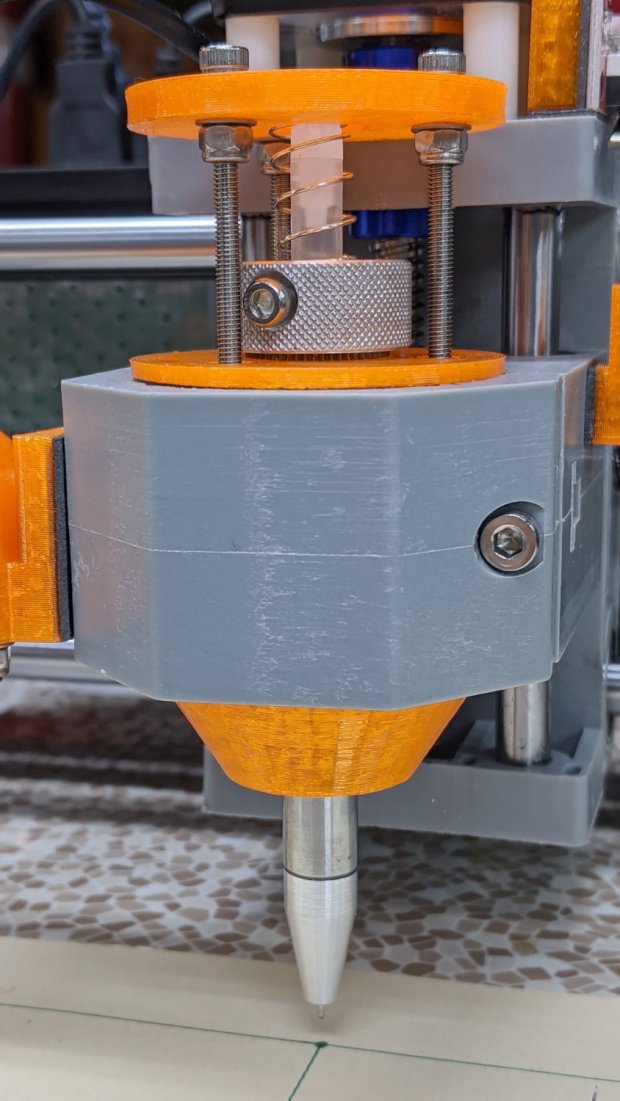

The first version of the 3D printed holder (shown above) is a straightforward modification of the LM12UU diamond drag bit holder, but, after building enough of these things, I realized the circular reaction plate should be triangular to get more clearance in front of the Z-axis stepper motor when installing & removing the holder:

It also has a recess for the serrated top of the bearing, to prevent the knurled collar from clicking annoyingly as the Z-axis rises at the end of each stroke.

Now, to see how well it draws!

The OpenSCAD source code as a GitHub Gist:

| // Diamond Scribe in linear bearings for CNC3018 | |

| // Ed Nisley KE4ZNU – 2019-08-9 | |

| Layout = "Build"; // [Build, Show, Base, Mount, Plate] | |

| /* [Hidden] */ | |

| ThreadThick = 0.25; // [0.20, 0.25] | |

| ThreadWidth = 0.40; // [0.40, 0.40] | |

| /* [Hidden] */ | |

| Protrusion = 0.1; // [0.01, 0.1] | |

| HoleWindage = 0.2; | |

| inch = 25.4; | |

| function IntegerMultiple(Size,Unit) = Unit * ceil(Size / Unit); | |

| ID = 0; | |

| OD = 1; | |

| LENGTH = 2; | |

| //- Adjust hole diameter to make the size come out right | |

| module PolyCyl(Dia,Height,ForceSides=0) { // based on nophead's polyholes | |

| Sides = (ForceSides != 0) ? ForceSides : (ceil(Dia) + 2); | |

| FixDia = Dia / cos(180/Sides); | |

| cylinder(r=(FixDia + HoleWindage)/2,h=Height,$fn=Sides); | |

| } | |

| //- Dimensions | |

| PenOD = 6.1; // pen refill shaft, max OD | |

| Bearing = [(3.0/8.0)*inch,16.0,10.6]; // linear bearing body, ID = shaft diameter | |

| BearingFlange = [Bearing[OD],17.2,1.0]; // flange around end of bearing | |

| Spring = [8.5,9.5,15.5]; // compression spring around shaft, LENGTH = uncompressed | |

| SpringRecess = 4*ThreadThick; | |

| WallThick = 4.0; // minimum thickness / width | |

| Screw = [3.0,6.75,25.0]; // holding it all together, OD = washer | |

| Insert = [3.0,4.2,7.9]; // brass insert | |

| //Insert = [3.0,5.0,8.0]; | |

| //Insert = [4.0,6.0,10.0]; | |

| Clamp = [43.2,44.0,34.0]; // tool clamp ring, OD = clearance around top | |

| LipHeight = IntegerMultiple(2.0,ThreadThick); // above clamp for retaining | |

| BottomExtension = 15.0; // below clamp to reach workpiece | |

| MountOAL = LipHeight + Clamp[LENGTH] + BottomExtension; // total mount length | |

| echo(str("Mount OAL: ",MountOAL)); | |

| Plate = [PenOD + 4*ThreadWidth,Clamp[ID] – 0*2*WallThick,WallThick]; // spring reaction plate | |

| echo(str("Screw length: ",Spring[LENGTH] + Plate[LENGTH] + Insert[LENGTH])); | |

| NumScrews = 3; | |

| ScrewBCD = Bearing[OD] + Insert[OD] + 2*WallThick; | |

| echo(str("Retainer max OD: ",ScrewBCD – Screw[OD])); | |

| NumSides = 9*4; // cylinder facets (multiple of 3 for lathe trimming) | |

| // Basic mount shape | |

| module CNC3018Base() { | |

| translate([0,0,MountOAL – LipHeight]) | |

| cylinder(d=Clamp[OD],h=LipHeight,$fn=NumSides); | |

| translate([0,0,MountOAL – LipHeight – Clamp[LENGTH] – Protrusion]) | |

| cylinder(d=Clamp[ID],h=(Clamp[LENGTH] + 2*Protrusion),$fn=NumSides); | |

| cylinder(d1=Bearing[OD] + 2*WallThick,d2=Clamp[ID],h=BottomExtension + Protrusion,$fn=NumSides); | |

| } | |

| // Mount with holes & c | |

| module Mount() { | |

| difference() { | |

| CNC3018Base(); | |

| translate([0,0,-Protrusion]) // bearing | |

| PolyCyl(Bearing[OD],2*MountOAL,NumSides); | |

| translate([0,0,-Protrusion]) // bearing flanges | |

| PolyCyl(BearingFlange[OD],BearingFlange[LENGTH] + Protrusion,NumSides); | |

| translate([0,0,MountOAL – 1.5*BearingFlange[LENGTH]]) // sink into surface | |

| PolyCyl(BearingFlange[OD],2*BearingFlange[LENGTH],NumSides); | |

| for (i=[0:NumScrews – 1]) // clamp screws | |

| rotate(i*360/NumScrews) | |

| translate([ScrewBCD/2,0,MountOAL – Clamp[LENGTH]]) | |

| rotate(180/8) | |

| PolyCyl(Insert[OD],Clamp[LENGTH] + Protrusion,8); | |

| } | |

| } | |

| module SpringPlate() { | |

| difference() { | |

| hull() | |

| for (i=[0:NumScrews – 1]) | |

| rotate(i*360/NumScrews) | |

| translate([ScrewBCD/2,0,0]) | |

| cylinder(d=Screw[OD] + 4*ThreadWidth,h=Plate[LENGTH],$fn=24); | |

| translate([0,0,-Protrusion]) | |

| PolyCyl(Plate[ID],2*MountOAL,NumSides); | |

| translate([0,0,Plate[LENGTH] – SpringRecess]) // spring retainer | |

| PolyCyl(Spring[OD] + 4*ThreadWidth,SpringRecess + Protrusion,NumSides); | |

| for (i=[0:NumScrews – 1]) // clamp screws | |

| rotate(i*360/NumScrews) | |

| translate([ScrewBCD/2,0,-Protrusion]) | |

| rotate(180/8) | |

| PolyCyl(Screw[ID],2*MountOAL,8); | |

| } | |

| } | |

| //—– | |

| // Build it | |

| if (Layout == "Base") | |

| CNC3018Base(); | |

| if (Layout == "Mount") | |

| Mount(); | |

| if (Layout == "Plate") | |

| SpringPlate(); | |

| if (Layout == "Show") { | |

| Mount(); | |

| translate([0,0,MountOAL + Plate[LENGTH] + Spring[LENGTH]]) | |

| rotate([180,0,0]) | |

| SpringPlate(); | |

| } | |

| if (Layout == "Build") { | |

| translate([0,-0.75*Clamp[OD],MountOAL]) | |

| rotate([180,0,0]) | |

| Mount(); | |

| translate([0,0.75*Plate[OD],0]) | |

| SpringPlate(); | |

| } |

Comments

10 responses to “CNC 3018XL: Pilot V5RT Pen Holder”

What, no pics of the output? Inquiring minds want to ogle! Also, how do the retracts compare to the traditional as handwriting instruments?

Gotta have some suspense in the story!

Aaaand it took me a while to accumulate the evidence: better paper produces better results. [duh]

[…] « CNC 3018XL: Pilot V5RT Pen Holder […]

[…] Extra Fine Pilot V5 pens have a 0.5 mm ball, in contrast to the 1.0 mm ball in the cheap pens I’ve been using, so they should produce much finer lines. […]

[…] CNC 3018XL with a Pilot V5RT pen draws the deck scales on white […]

[…] Pilot Precise V5RT cartridge on plain paper (20 lb 98 white), also laminated, looks pretty […]

[…] probe camera hovers just over the switch and the Pilot V5RT pen holder is ready for […]

[…] The Pilot V5RT pens use a custom holder: […]

[…] Flushed with success about the MPCNC drag knife locking screw, I installed a similar screw on the V5RT pen holder for the CNC 3018: […]

[…] recently upcycled a 3/8 inch shaft from the Thing-O-Matic into a pen holder for the CNC 3018-XL, I cut off another section with an abrasive wheel, then tried to face it […]