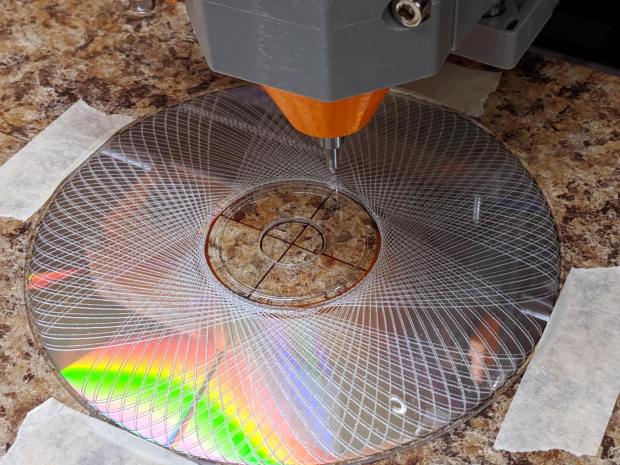

Diamond drag engraving doesn’t put much sideways force on the platters, so taping the CD in place suffices to hold it:

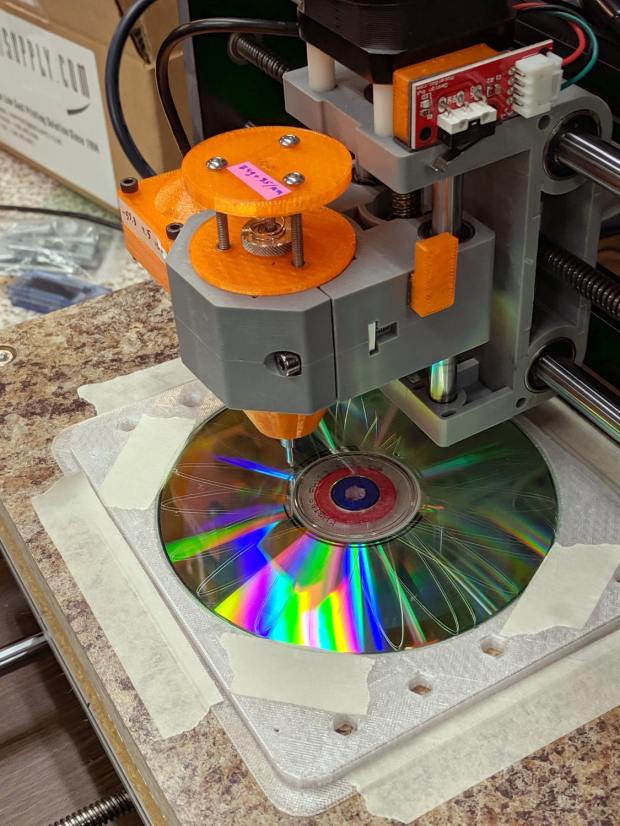

Wrapping a flange around the screw-down platter fixture provides plenty of surface area for tape:

Which looks exactly as you think it would in real life:

Admittedly, masking tape doesn’t look professional, but it’s low-profile, cheap and works perfectly. Blue painter’s tape for the “permanent” hold-down strips on the platform would be a colorful upgrade.

It’s centered on the platform at the XY=0 origin in the middle of the XY travel limits, with edges aligned parallel to the axes. Homing the 3018 and moving to XY=0 puts the tool point directly over the center of the CD without any fussy alignment.

The blue-and-red rings around the center hole assist probe camera alignment, whenever that’s necessary.

The OpenSCAD source code as a GitHub Gist:

| // Machining fixtures for CD and hard drive platters | |

| // Ed Nisley KE4ZNU February … September 2016 | |

| // 2019-08 split from tube base models | |

| PlatterName = "CD"; // [3.5inch,CD] | |

| CNCName = "3018"; // [3018,Sherline] | |

| TapeFlange = true; // Generate tape attachment | |

| PlateThick = 5.0; // [3.0,5.0,10.0,15.0] | |

| RecessDepth = 4.0; // [0.0,2.0,4.0] | |

| //- Extrusion parameters must match reality! | |

| /* [Hidden] */ | |

| ThreadThick = 0.25; | |

| ThreadWidth = 0.40; | |

| HoleWindage = 0.2; | |

| Protrusion = 0.1; // make holes end cleanly | |

| inch = 25.4; | |

| function IntegerMultiple(Size,Unit) = Unit * ceil(Size / Unit); | |

| module PolyCyl(Dia,Height,ForceSides=0) { // based on nophead's polyholes | |

| Sides = (ForceSides != 0) ? ForceSides : (ceil(Dia) + 2); | |

| FixDia = Dia / cos(180/Sides); | |

| cylinder(d=(FixDia + HoleWindage),h=Height,$fn=Sides); | |

| } | |

| ID = 0; | |

| OD = 1; | |

| LENGTH = 2; | |

| //———————- | |

| // Dimensions | |

| P_NAME = 0; // platter name | |

| P_ID = 1; // … inner diameter | |

| P_OD = 2; // … outer diameter | |

| P_THICK = 3; // … thickness | |

| PlatterData = [ | |

| ["3.5inch", 25.0, 95.0, 1.75], | |

| ["CD", 15.0, 120.0, 1.20], | |

| ]; | |

| PlatterSides = 3*4*5; // polygon approximation | |

| B_NAME = 0; // machine name | |

| B_OC = 1; // … platform screw OC, use small integer for slot | |

| B_STUD = 2; // … screw OD clearance | |

| BaseData = [ | |

| ["3018", [5.0, 45.0], 6.0], // slots along X axis | |

| ["Sherline", [1.16*inch,1.16*inch], 5.0], // tooling plate | |

| ]; | |

| PlateRound = 10.0; // corner radius | |

| FlangeSize = [5.0,5.0,3*ThreadThick]; // all-around tape flange | |

| //– calculate values based on input parameters | |

| PI = search([PlatterName],PlatterData,1,0)[P_NAME]; // get platter index | |

| echo(str("Platter: ",PlatterName)); | |

| Platter = [PlatterData[PI][P_ID], | |

| PlatterData[PI][P_OD], | |

| PlatterData[PI][P_THICK]]; | |

| BI = search([CNCName],BaseData,1,0)[B_NAME]; // get base index | |

| echo(str("Machine: ",CNCName)); | |

| AlignOC = IntegerMultiple(Platter[OD],10); | |

| echo(str("Alignment pip offset: ±",AlignOC/2)); | |

| AlignSlot = [3*ThreadWidth,10.0,3*ThreadThick]; | |

| StudClear = BaseData[BI][B_STUD]; // … clearance | |

| StudOC = [IntegerMultiple(AlignOC + 2*StudClear,BaseData[BI][B_OC].x), // … screw spacing | |

| BaseData[BI][B_OC].y]; | |

| echo(str("Stud spacing: ",StudOC)); | |

| NumStuds = [2,1 + 2*floor(Platter[OD] / StudOC.y)]; // holes only along ±X edges | |

| echo(str("Stud holes: ",NumStuds)); | |

| BasePlate = [(20 + StudOC.x*ceil(Platter[OD] / StudOC.x)), | |

| (10 + AlignOC), | |

| PlateThick]; | |

| echo(str("Plate: ",BasePlate)); | |

| Flange = [BasePlate.x + 2*FlangeSize.x,BasePlate.y + 2*FlangeSize.y,FlangeSize.z]; | |

| echo(str("Flange: ",Flange)); | |

| //———————- | |

| // Drilling fixture for disk platters | |

| module PlatterFixture() { | |

| difference() { | |

| union() { | |

| hull() // basic plate shape | |

| for (i=[-1,1], j=[-1,1]) | |

| translate([i*(BasePlate.x/2 – PlateRound),j*(BasePlate.y/2 – PlateRound),0]) | |

| cylinder(r=PlateRound,h=BasePlate.z,$fn=4*4); | |

| if (TapeFlange) | |

| hull() | |

| for (i=[-1,1], j=[-1,1]) | |

| translate([i*(Flange.x/2 – PlateRound), | |

| j*(Flange.y/2 – PlateRound), | |

| 0]) | |

| cylinder(r=PlateRound,h=FlangeSize.z,$fn=4*4); | |

| } | |

| for (i=[-1,0,1], j=[-1,0,1]) // origin pips | |

| translate([i*AlignOC/2,j*AlignOC/2,BasePlate.z – 2*ThreadThick]) | |

| cylinder(d=4*ThreadWidth,h=1,$fn=6); | |

| for (i=[-1,1], j=[-1,1]) { // alignment slots | |

| translate([i*(AlignOC + AlignSlot.x)/2, | |

| j*Platter[OD]/4, | |

| (BasePlate.z – AlignSlot.z/2 + Protrusion/2)]) | |

| cube(AlignSlot + [0,0,Protrusion],center=true); | |

| translate([i*Platter[OD]/4, | |

| j*(AlignOC + AlignSlot.x)/2, | |

| (BasePlate.z – AlignSlot.z/2 + Protrusion/2)]) | |

| rotate(90) | |

| cube(AlignSlot + [0,0,Protrusion],center=true); | |

| } | |

| for (i=[-1,1], j=[-floor(NumStuds.y/2):floor(NumStuds.y/2)]) // mounting stud holes | |

| translate([i*StudOC.x/2,j*StudOC.y/2,-Protrusion]) | |

| rotate(180/6) | |

| PolyCyl(StudClear,BasePlate.z + 2*Protrusion,6); | |

| translate([0,0,-Protrusion]) // center clamp hole | |

| rotate(180/6) | |

| PolyCyl(StudClear,BasePlate.z + 2*Protrusion,6); | |

| translate([0,0,BasePlate.z – Platter[LENGTH]]) // disk locating recess | |

| rotate(180/PlatterSides) | |

| linear_extrude(height=(Platter[LENGTH] + Protrusion),convexity=2) | |

| difference() { | |

| circle(d=(Platter[OD] + 2*HoleWindage),$fn=PlatterSides); | |

| circle(d=Platter[ID] – HoleWindage,$fn=PlatterSides); | |

| } | |

| translate([0,0,BasePlate.z – RecessDepth]) // drilling recess | |

| rotate(180/PlatterSides) | |

| linear_extrude(height=(RecessDepth + Protrusion),convexity=2) | |

| difference() { | |

| circle(d=(Platter[OD] – 10),$fn=PlatterSides); | |

| circle(d=(Platter[ID] + 10),$fn=PlatterSides); | |

| } | |

| } | |

| } | |

| //———————- | |

| // Build it | |

| PlatterFixture(); | |

Comments

6 responses to “CNC 3018-Pro: Tape-Down Platter Fixture”

For what it’s worth, there’s a chance mail costs from the usual eBay suspects might go up: https://www.freightwaves.com/news/us-to-leave-global-postal-union-next-month

Apparently, US subsidies for foreign shipping have been out of line, and this could impact parcel post rates for small packages.

If it helps get rid of the absolute bottom dollar sellers, I’m all for it.

I’ve been paying a few bucks more to “US Sellers”, which seem to be US-based front offices / reshippers of Chinese sources: the eBay seller name (a friendly ‘Murrican string) rarely matches the PayPal biller name (generally a set of Chinese characters).

Tracking down the physical mailing addresses suggests they’re parceling a containerload of assorted stuff, so foreign-postage increases may not matter.

Tariffs, on the other paw, should definitely apply and, if the eBay / Aliexpress pool get vacuumed, I’ll call ’em a net win.

[…] CNC 3018-Pro: Tape-Down Platter Fixture Schwalbe Marathon Plus and Michelin Protek vs. Glass Chip […]

[…] Makes the outer circle exactly 15.0 mm in diameter to match the CD hub ring ID: […]

[…] Taping the CD fixture to the CNC 3018-Pro’s raised platform solves the repeatability problem by putting the CD at a fixed location relative to the machine’s Home coordinates. The next step puts the XY=0 coordinate origin at the exact center of the platter, so the pattern comes out exactly centered on the disc: […]

[…] variation on the CD fixture produces a 3.5 inch hard drive platter […]