The CNC 3018-Pro doesn’t absolutely need home switches, but (in principle) they let you install a workholding fixture at a known position, home the axes, pick a preset coordinate system for the fixture, and not have to touch off the axes before making parts.

Having used Makerbot-style endstop switch PCBs for the MPCNC, this was straightforward:

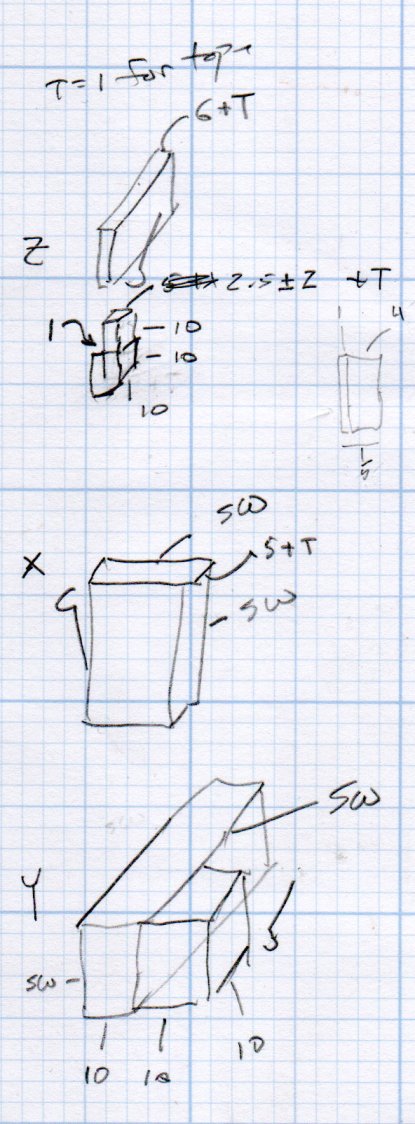

The X and Z axis switches simply press against the appropriate moving parts:

The little tab stuck on the tool clamp provides a bit of clearance around the upper part of the X axis assembly.

The Y axis switch needed a slightly tapered tab to extend the bearing holder:

It’s made from a random scrap of clear plastic, hand-filed to suit, and stuck on the bearing to trigger the switch in exactly the right spot.

You can find elaborate switch mounts on Thingiverse, but I’ve become a big fan of genuine 3M outdoor-rated foam tape for this sort of thing: aggressive stickiness, no deterioration, possible-but-not-easy removal.

The switches need +5 V power, so add a small hack to the CAMTool V3.3 control board to let the connectors plug right in:

The solid models borrow their central depression around the switch terminals from the MPCNC blocks:

The OpenSCAD source code as a GitHub Gist:

| // 3018-Pro Mount for Makerbot Endstop PCB | |

| // Ed Nisley KE4ZNU – 2019-07 | |

| /* [Build Options] */ | |

| Layout = "Show"; // [Build, Show] | |

| /* [Hidden] */ | |

| ThreadThick = 0.25; // [0.20, 0.25] | |

| ThreadWidth = 0.40; // [0.40] | |

| function IntegerMultiple(Size,Unit) = Unit * ceil(Size / Unit); | |

| Protrusion = 0.01; // [0.01, 0.1] | |

| HoleWindage = 0.2; | |

| ID = 0; | |

| OD = 1; | |

| LENGTH = 2; | |

| //- Shapes | |

| // Basic PCB with hole for switch pins | |

| // origin at switch actuator corner, as seen looking at component side | |

| SwitchClear = [15.0,5.0,2.0]; // clearance around switch pins | |

| SwitchOffset = [12.5,9.0,0.0]; // center of switch pins from actuator corner | |

| PCB = [26.0,16.4,2*SwitchClear.z]; // switch PCB beyond connector, pin height | |

| XBlock = [PCB.x,PCB.y,5.0]; | |

| module XMount() { | |

| difference() { | |

| cube(XBlock,center=false); | |

| translate(SwitchOffset + [0,0,XBlock.z – SwitchClear.z/2]) | |

| cube(SwitchClear + [0,0,Protrusion],center=true); | |

| } | |

| } | |

| YBlock = [PCB.x + 10.0,PCB.y,20.0]; | |

| module YMount() { | |

| difference() { | |

| translate([-10.0,0,0]) | |

| cube(YBlock,center=false); | |

| translate([0,-Protrusion,10.0]) | |

| cube(YBlock + [0,2*Protrusion,0],center=false); | |

| translate(SwitchOffset + [0,0,10.0 – SwitchClear.z/2]) | |

| cube(SwitchClear + [0,0,Protrusion],center=true); | |

| } | |

| } | |

| ZBlock = [PCB.x,PCB.y,6.0]; | |

| ZPin = [20.0,10.0,5.5]; | |

| module ZMount() { | |

| difference() { | |

| cube(ZBlock,center=false); | |

| translate(SwitchOffset + [0,0,ZBlock.z – SwitchClear.z/2]) | |

| cube(SwitchClear + [0,0,Protrusion],center=true); | |

| } | |

| translate([0,-ZBlock.y,0]) | |

| difference() { | |

| cube(ZPin,center=false); | |

| translate([ZPin.x/2,-Protrusion,4.0]) | |

| cube(ZPin + [0,2*Protrusion,0],center=false); | |

| } | |

| } | |

| //- Build things | |

| if (Layout == "Show") { | |

| translate([0,YBlock.y,0]) | |

| XMount(); | |

| translate([0,-YBlock.y/2]) | |

| YMount(); | |

| translate([0,-(ZBlock.y + YBlock.y)]) | |

| ZMount(); | |

| } |

The dimension doodles:

Comments

3 responses to “CNC 3018-Pro: Home Switches”

[…] the Camtool V3.3 board and ran well enough, although it accelerated very slowly. After installing Home switches, figuring out the travel limits, and trying different speeds & accelerations, it runs much […]

[…] platform solves the repeatability problem by putting the CD at a fixed location relative to the machine’s Home coordinates. The next step puts the XY=0 coordinate origin at the exact center of the platter, so the pattern […]

[…] are absolute machine coordinates, with Y and Z pulled off home by 1 mm. I set one of bCNC’s buttons to emit G28 and park the tool carrier over there, out of the […]