A previous owner used a little too much force on this machinist’s parallel clamp:

It’s been in the bottom of my clamp box forever, so I figured I should either fix it or toss it. Grabbing the butt end in the bench vise and applying some percussive adjustment with a 3 pound hammer straightened it right out:

Done!

Comments

6 responses to “Un-bending a Machinist’s Parallel Clamp Jaw”

Sometimes the BFH is the right tool for the job!

And I didn’t even file to hide or paint to cover!

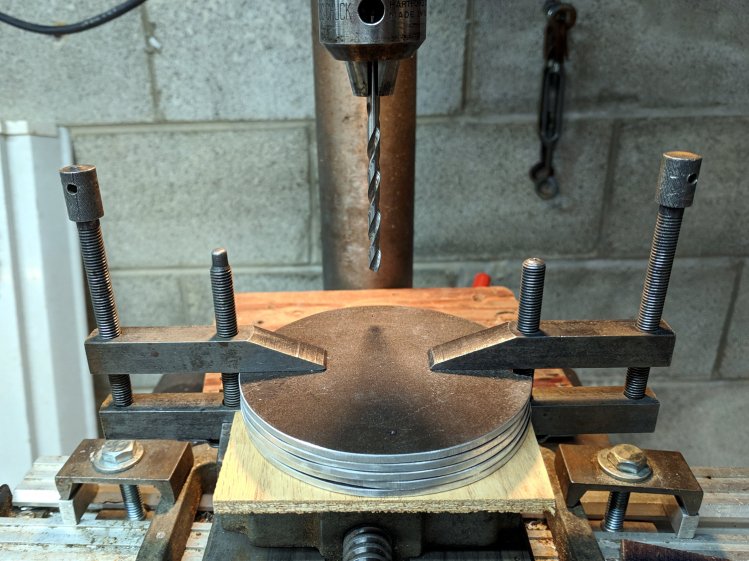

But what is that mystery project on the drill press table?

An aluminum counterweight for the halogen desk lamp rebuild. If the Tiny Bandsaw cut steel, I wouldn’t need nearly so many sheets … [sigh]

Lead automotive wheel weights are often seen at the roadside.

1) Collect some.

2) Break them to remove the steel clip.

3) Drop the lead chunks into an empty steel food can.

4) Use a propane torch to melt the lead. As a caution, do this outdoors and avoid breathing any fumes.

5) Allow to cool.

6) Cut away the steel can.

7) Admire the disk-shaped lead weight thusly created.

8) Congratulate yourself for recycling waste materials to make something useful.

Yes, I have done this.

Part of the shop donation was a bucket full of wheel weights and lead roofing sheets; I’m still kicking myself.