The little red shift indicator tab in the SRAM X.9 rear shifter on Mary’s bike snapped:

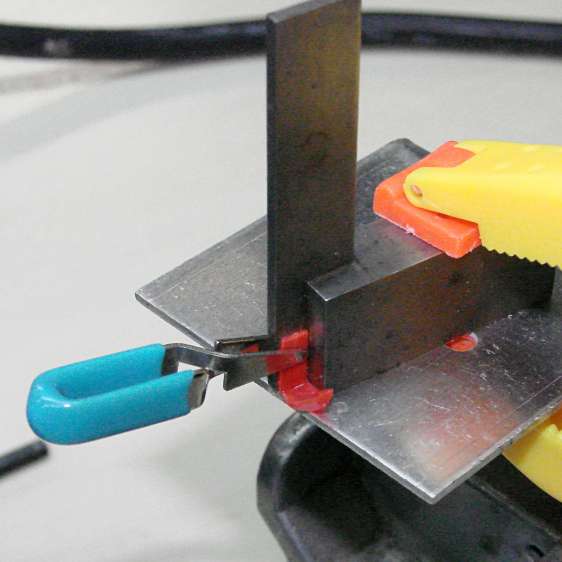

In a triumph of hope over experience, I tried gluing the pieces with a bit of fixturing and a dab of IPS #3 solvent:

Didn’t work any better than the last time, of course. Every gear shift snap must apply 1000 G to that poor little tab…

What’s new & different: one can now obtain Official Repair Kits consisting of the indicator tab, the plastic cover, and the two screws for $6.47 delivered from eBay.

Done!

Comments

11 responses to “SRAM Shift Indicator: Repair FAIL”

I looked at the title and was thinking “Static RAM? What sort of shift is being indicated?”

Abacus, perhaps?

I’ve never much understood why you’d need the indicator anyway. As far as I can tell, bike gears come in two positions: too high and too low, and you can’t tell either from the red pointer…

We’ve discovered that night riding makes us faster: we can’t see the shift indicators, so we just pedal in crazy-high gears. Weird, but true.

Obviously we need illuminated digital readouts! Maybe on our next bikes…

Either that or automatic gear shifters. Now that would be a project :)

About once a decade, somebody decides an automatic transmission would be a great idea. Fast forward a year and the project vanished without a trace. An omen for he who would be admonished, sez I.

What I really want: a cogged belt, Shimano Alfine in the back, and Schlumpf Mountain Drive up front. Neither of those work with a belt, alas.

It seems to me that at least the Alfine will in fact: http://www.gatescarbondrive.com/~/media/cds/documents/gates-tech-bulletin-di2.pdf?la=en … sounds like a fun project!

Eee-lectronic internal shifting and belt drive: fire the torch!

You devil…

Then you can embed your tach, torque, and gear into APRS packets!

I’ve had good luck lately with using my hot air soldering tool to “weld” plastics back together. The trick seems to be getting the temp up, and just as it hits the molten stage, to use a knife blade or screwdriver to smear some of the plastic from each piece to t’other, otherwise surface tension will cause them to ball up and pull away from the break.

Probably depends highly on the plastic, and tricky on small pieces like this, but might be handy someday…

Another reason to get a hot air soldering tool!

I’d surely reduce that little tab to a puddle, but that wouldn’t be much of a loss. Next time around, I’ll give that a try.

Thanks for the suggestion!