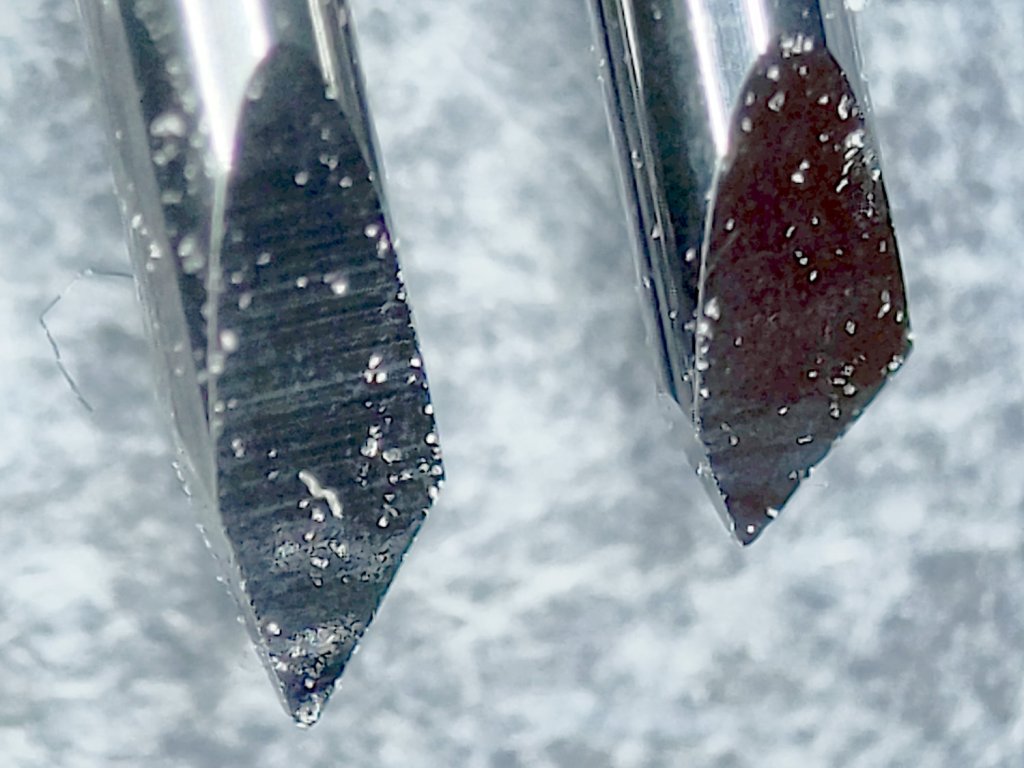

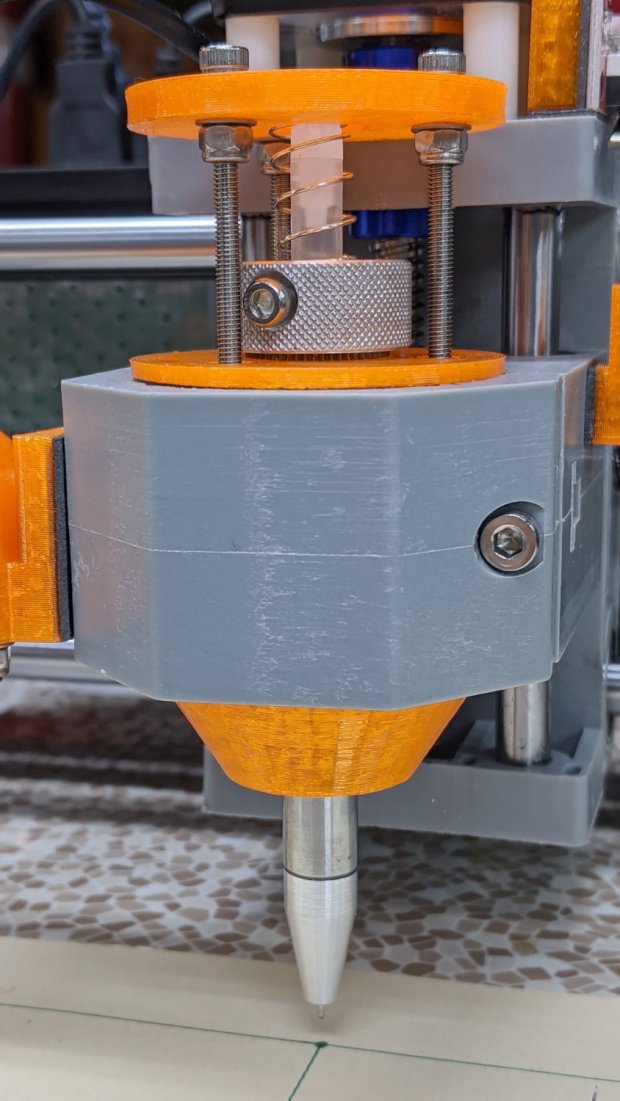

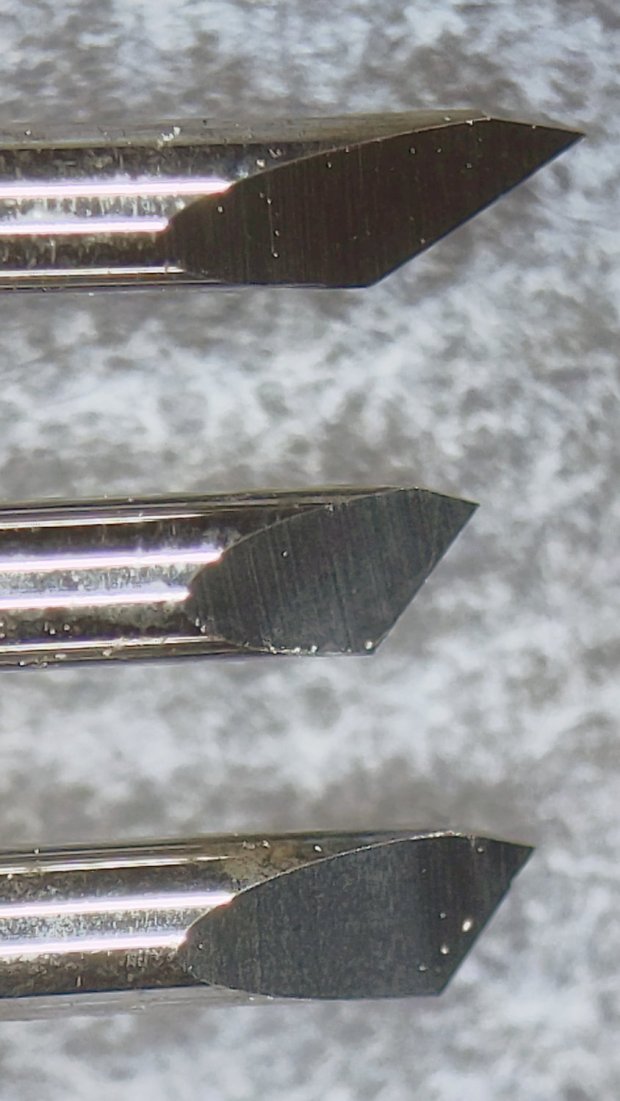

Having used the same two drag knife blades intermittently over the last three-ish years, I wondered just how worn they’d gotten:

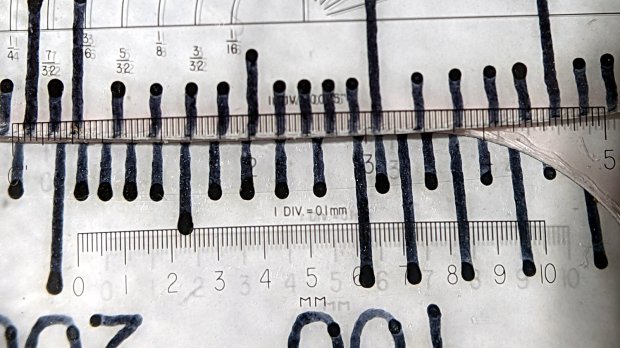

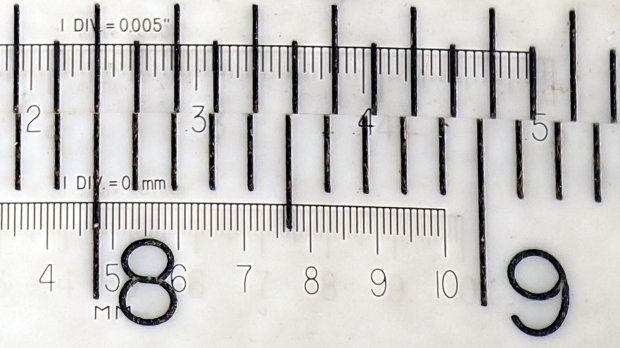

For scale, the cylindrical part of the blade is 1.0 mm OD.

The blade with the longer face (left above and bottom below) has seen the most use and is definitely rounded at the tip:

Three unused blades have sharp tips:

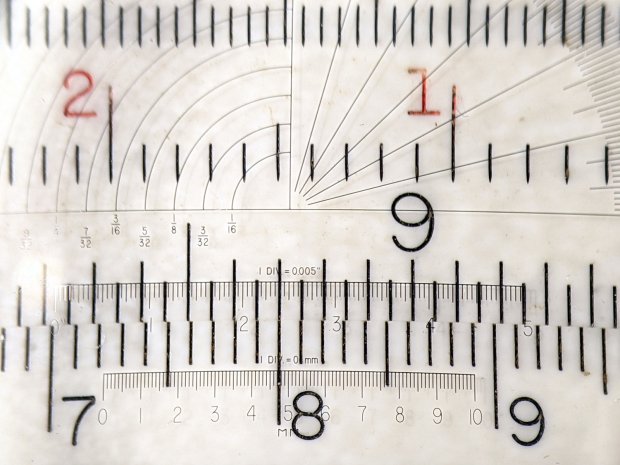

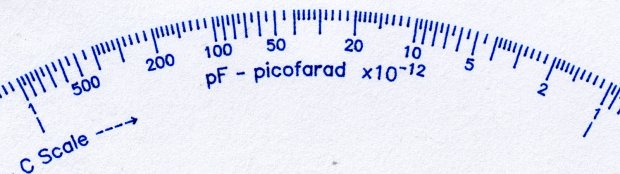

From the top, the (nominal) blade angles are 60°, 45°, and 30°, generally indicated by yellow, red, and blue plastic caps. However, various eBay sellers disagree on how to measure the angle (up from surface / outward from axis) and which cap colors correspond to which angles.

The unused 45° blade bracketed by the two used blades:

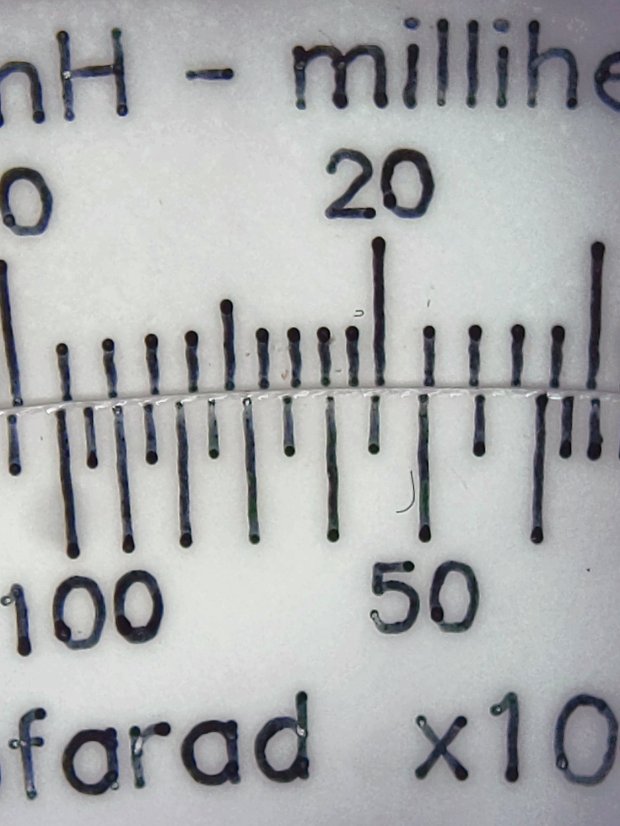

The two lower blades have angles somewhere between 30° and 45°, suggesting slack grinder and QC tolerances. If the actual angle matters to you, buy an assortment (from one seller!), measure what you get, and don’t be surprised when the results aren’t anything in particular.

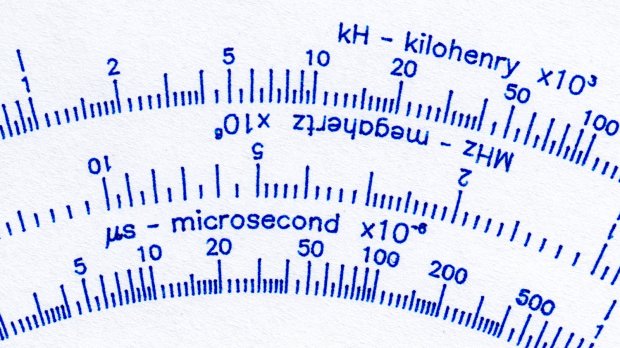

Perhaps, with careful attention to alignment in a non-pivoting / collet holder, one might scribe exceedingly narrow lines.

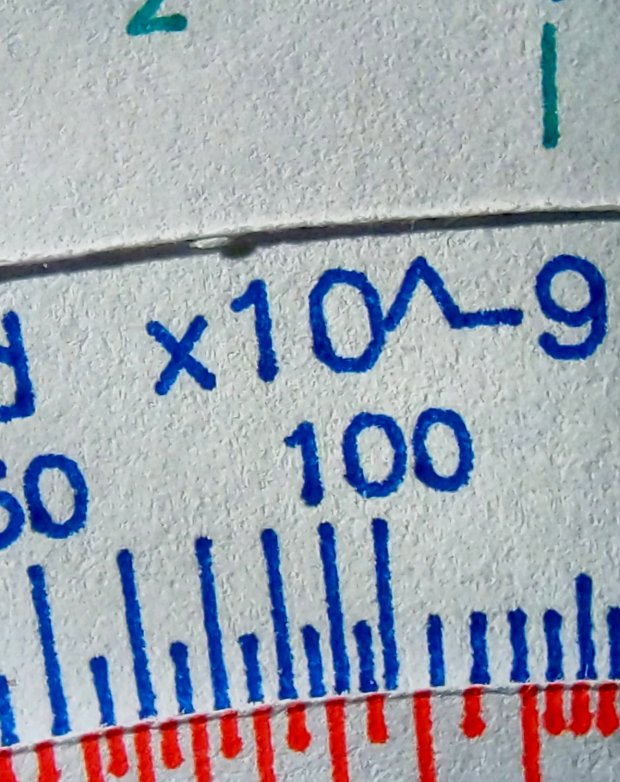

That’s the back of a sheet of carbon paper (remember carbon paper?), which is deep dark gray in normal light. It’s sitting on the sheet of 100 mil grid paper providing scale for small objects, atop the microscope stage positioner, with cold white illumination from an LED ring light.

Protip: even worn blades remain lethally sharp …