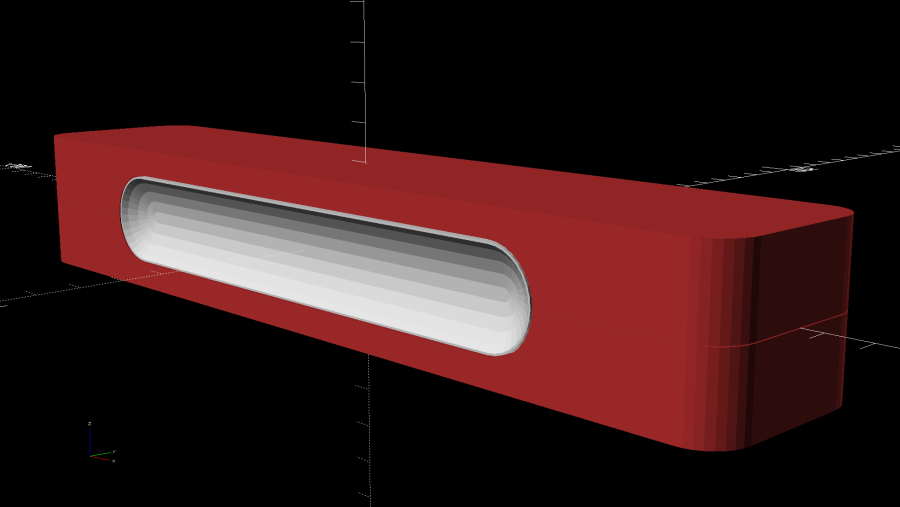

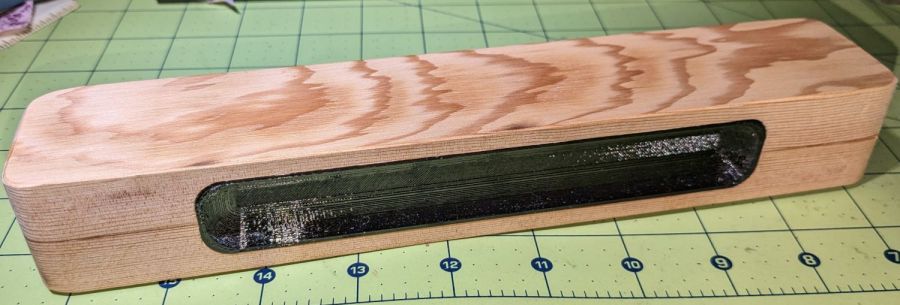

With the pockets milled into the oak blocks, the next step is to insert a pair of comfy 3D printed finger grips:

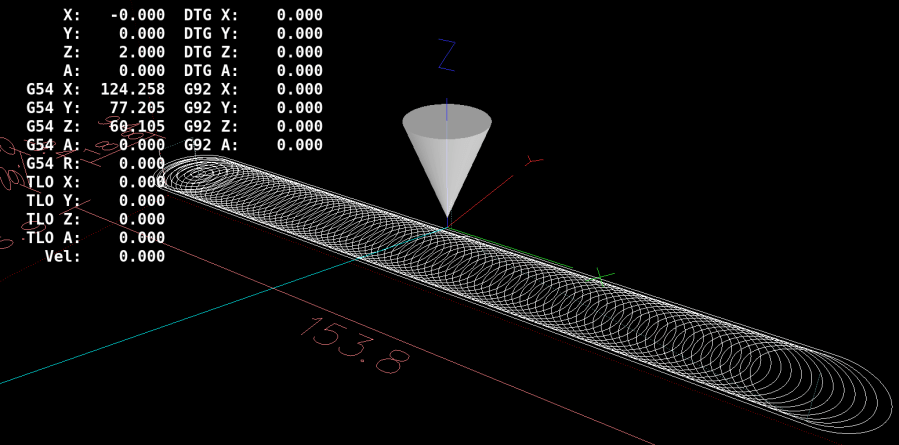

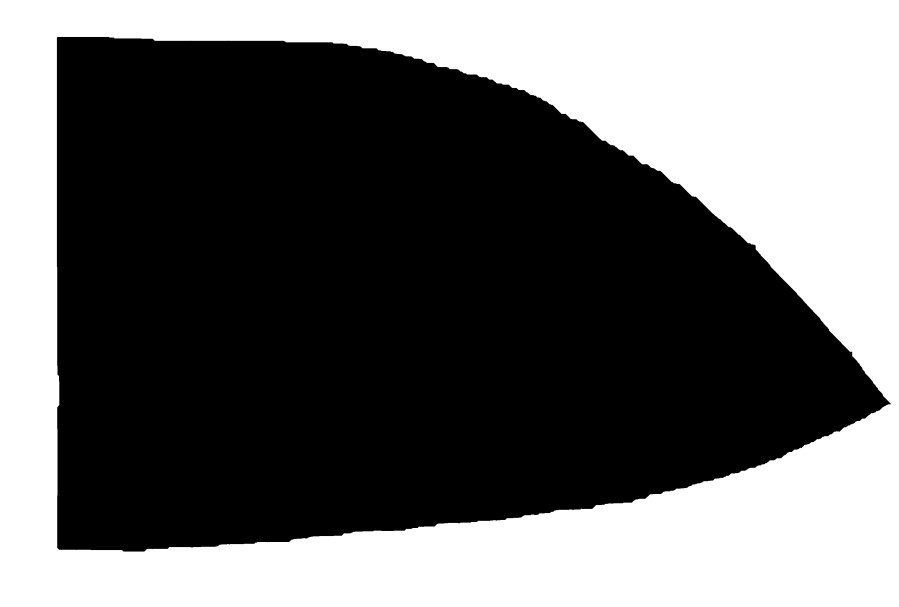

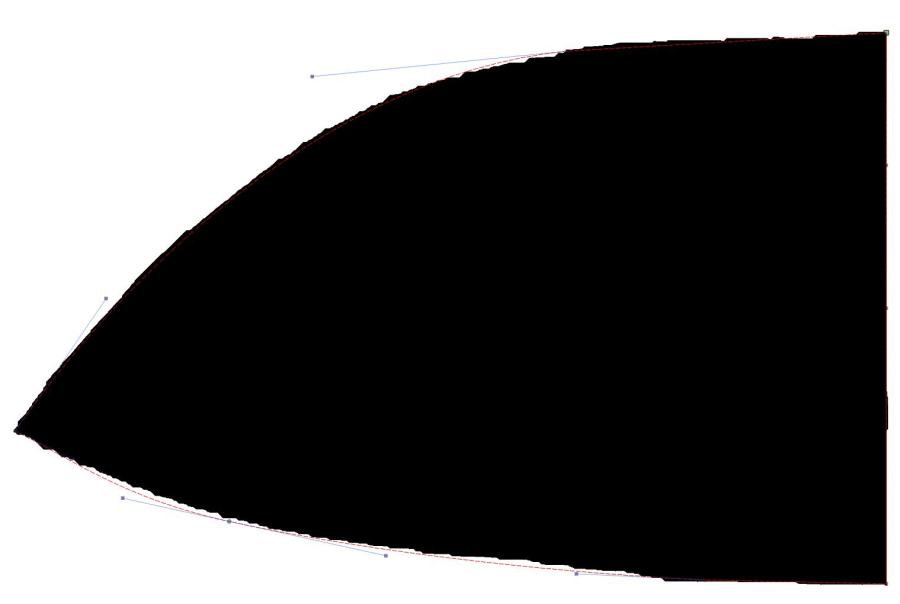

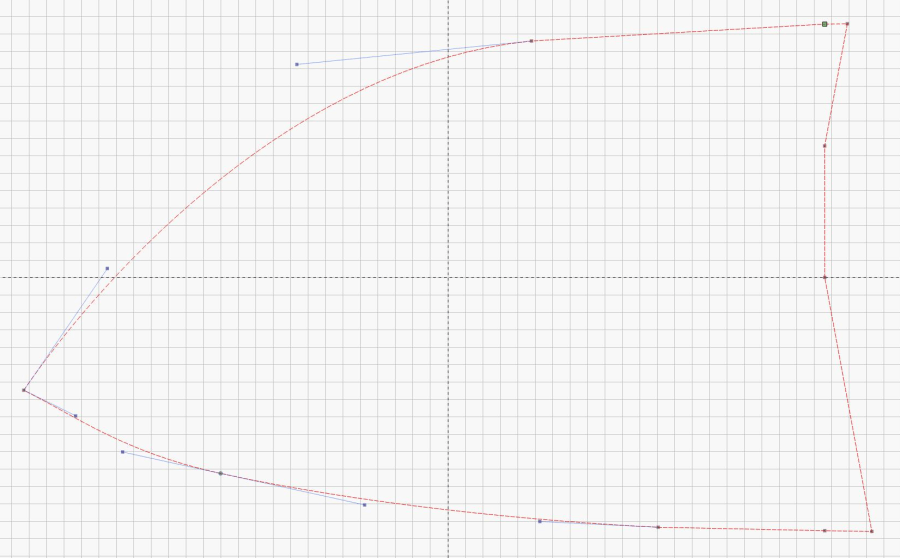

Getting comfy required a bank shot off the familiar chord equation to find the radius of a much larger circle producing the proper depth between the known width. The recess then comes from subtracting a hotdog from a lozenge exactly filling the wood pocket.

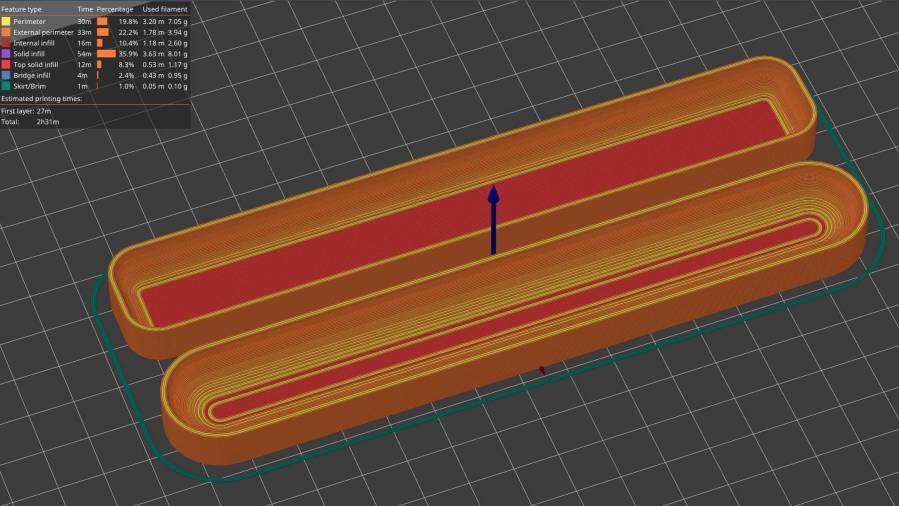

A pair of grips takes just under two hours to print while requiring no attention, which I vastly prefer to tending the Sherline.

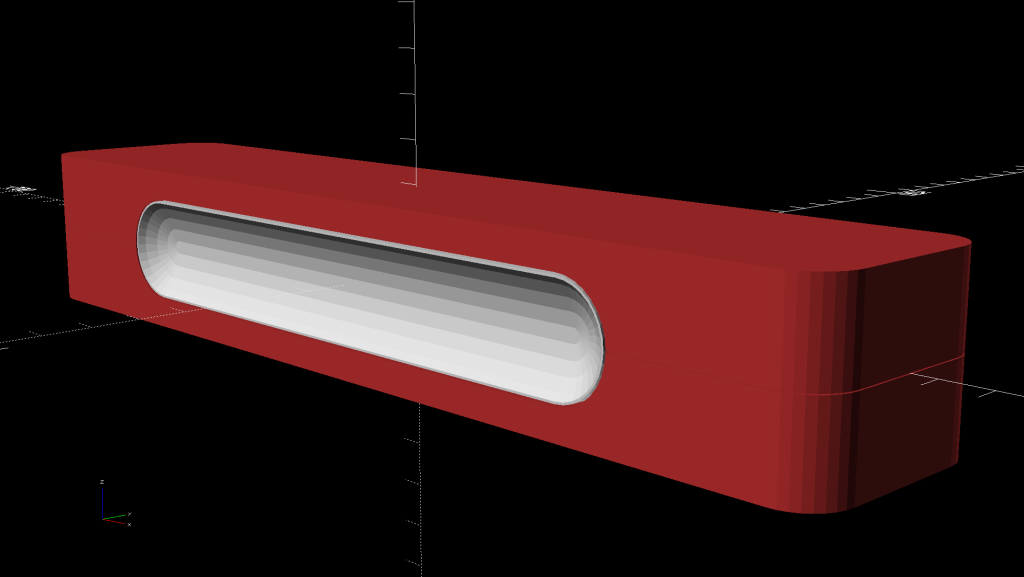

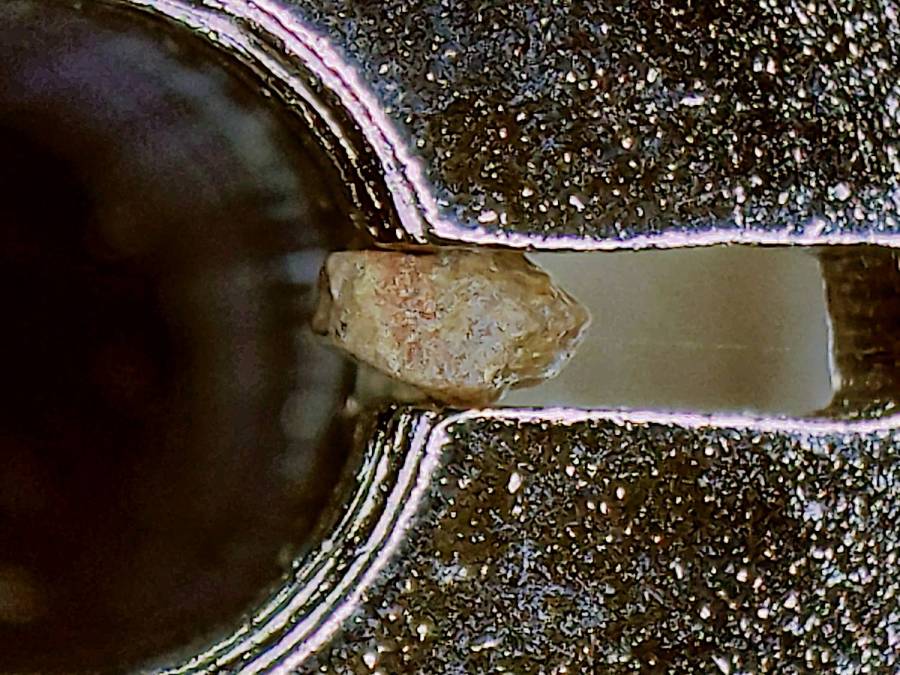

The wood pocket is 7 mm deep and the grips stand 6.5 mm tall, leaving just enough room for three blobs of acrylic adhesive to hold them together. After squishing the grips into their pockets, a pair of right angles aligned everything while the adhesive cured:

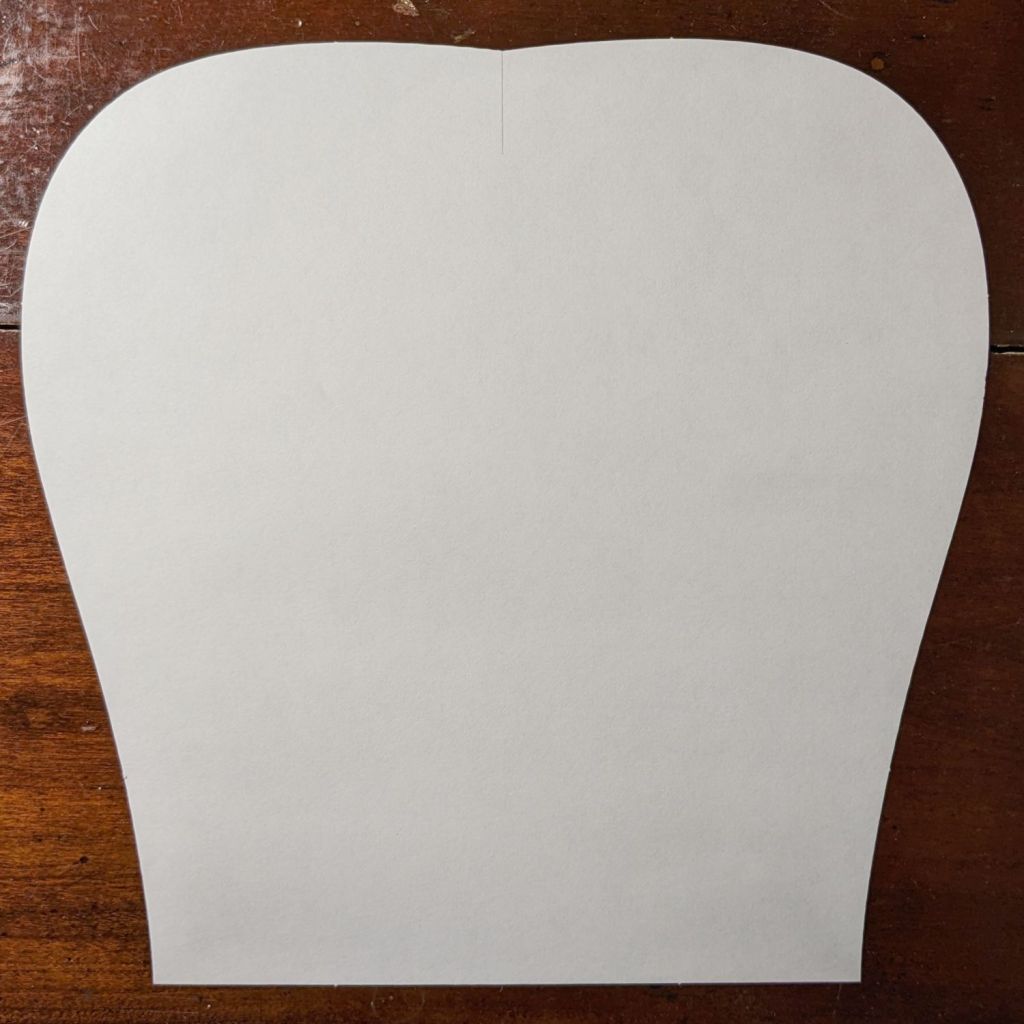

Mary asked for a longer weight for a place mat project, with a slightly narrower block to compensate for the additional length:

The grip and pocket were the same size, so it was just a matter of tweaking the block size and cutting more wood.

All in all, a quick project with satisfying results!

The OpenSCAD source code as a GitHub Gist:

| // Oak ironing weight finger grips | |

| // Ed Nisley KE4ZNU 2023-01 | |

| Layout = "Show"; // [Block,Grip,Show,Build] | |

| //- Extrusion parameters must match reality! | |

| /* [Hidden] */ | |

| ThreadThick = 0.25; | |

| ThreadWidth = 0.40; | |

| HoleWindage = 0.2; | |

| Protrusion = 0.1; // make holes end cleanly | |

| inch = 25.4; | |

| function IntegerMultiple(Size,Unit) = Unit * ceil(Size / Unit); | |

| ID = 0; | |

| OD = 1; | |

| LENGTH = 2; | |

| //———- | |

| // Dimensions | |

| // Length along X axis | |

| Block = [250.0,50.0,39.0]; // overall wood block | |

| BlockRadius = 10.0; | |

| CornerRadius = 10.0; | |

| Kerf = 0.2; | |

| Socket = [160.0,25.0,6.5]; // raw recess into block | |

| SocketRadius = Socket.y/2; | |

| echo(Socket=Socket,SocketRadius=SocketRadius); | |

| WallThick = ThreadWidth; // Thinnest printed wall | |

| Clearance = 0.5; // between grip and recess | |

| GripBlock = Socket – [2*Clearance,2*Clearance,Clearance]; | |

| GripBlockRadius = SocketRadius – Clearance; | |

| echo(GripBlock=GripBlock); | |

| GripDepth = 5.0; // finger grip recess | |

| GripRecess = [GripBlock.x – 2*WallThick,GripBlock.y – 2*WallThick,GripDepth]; | |

| GripRecessRadius = GripBlockRadius – WallThick; | |

| echo(GripRecess=GripRecess,GripRecessRadius=GripRecessRadius); | |

| GripChordRadius = (pow(GripDepth,2) + pow(GripRecess.y,2)/4) / (2*GripDepth); | |

| echo(GripChordRadius=GripChordRadius); | |

| NumSides = 4*8; | |

| //———- | |

| // Shapes | |

| module WoodBlock() { | |

| difference() { | |

| hull() | |

| for (i=[-1,1], j=[-1,1]) // rounded block | |

| translate([i*(Block.x/2 – BlockRadius),j*(Block.y/2 – BlockRadius),-Block.z/2]) | |

| cylinder(r=BlockRadius,h=Block.z,$fn=NumSides); | |

| for (j=[-1,1]) // grip socket | |

| translate([0,j*(Block.y/2 + Protrusion),0]) | |

| rotate([j*90,0,0]) | |

| hull() { | |

| for (i=[-1,1]) | |

| translate([i*(Socket.x/2 – SocketRadius),(Socket.y/2 – SocketRadius),0]) | |

| cylinder(r=SocketRadius,h=Socket.z + Protrusion,$fn=NumSides); | |

| } | |

| cube([2*Block.x,2*Block.y,Kerf],center=true); | |

| } | |

| } | |

| module Grip() { | |

| difference() { | |

| hull() | |

| for (i=[-1,1]) // overall grip block | |

| translate([i*(GripBlock.x/2 – GripBlockRadius),0,0]) | |

| cylinder(r=GripBlockRadius,h=GripBlock.z,$fn=NumSides); | |

| hull() { | |

| for (i=[-1,1]) // grip recess | |

| translate([i*(GripBlock.x/2 – GripRecessRadius – WallThick), | |

| 0, | |

| GripChordRadius + GripBlock.z – GripDepth]) | |

| sphere(r=GripChordRadius,$fn=NumSides); | |

| } | |

| } | |

| } | |

| //———- | |

| // Build them | |

| if (Layout == "Block") | |

| WoodBlock(); | |

| if (Layout == "Grip") | |

| Grip(); | |

| if (Layout == "Show") { | |

| color("Brown") | |

| WoodBlock(); | |

| color("Silver") | |

| for (j=[-1,1]) | |

| translate([0,j*(Block.y/2 – GripBlock.z),0]) | |

| rotate([j*-90,0,0]) | |

| Grip(); | |

| } | |

| if (Layout == "Build") { | |

| for (i=[-1,1]) | |

| translate([i*(Block.y/2 – GripBlock.z),0,0]) | |

| rotate([0,0,90]) | |

| Grip(); | |

| } |