All of the Bafang BBS02 displays have a compression clamp intended for more-or-less standard 22.2 mm handlebars, as found on typical upright BMX-ish bikes suitable for conversion to e-bikes and, oddly, our Tour Easy recumbents. My friend’s bike has drop-bar handlebars with a 25.4 mm (yes, exactly 1 inch) center section that just isn’t going to fit through that hole.

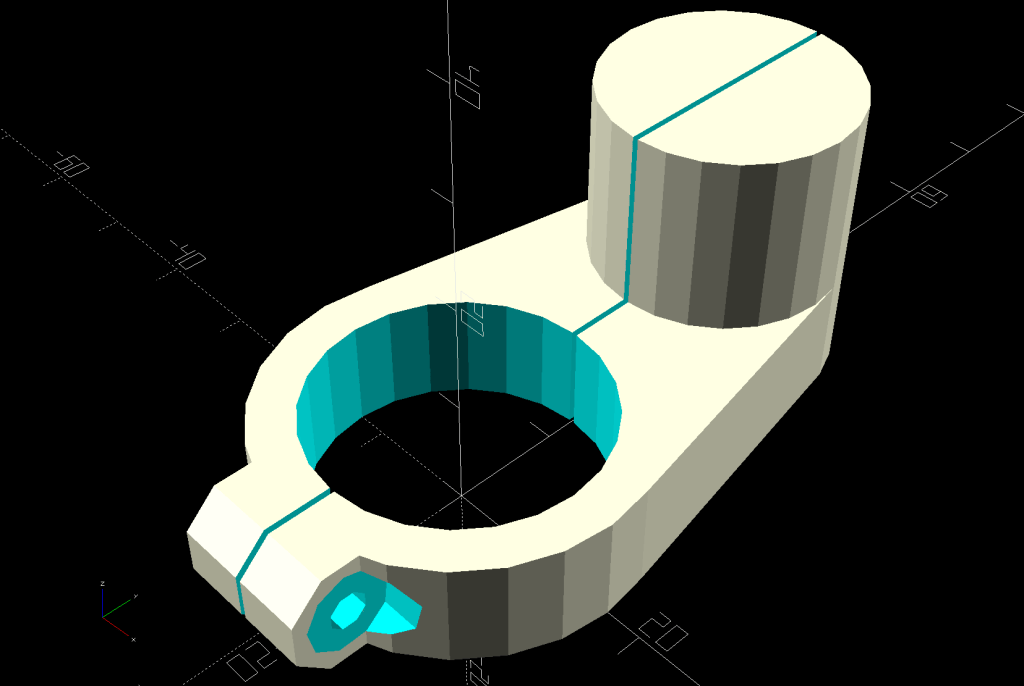

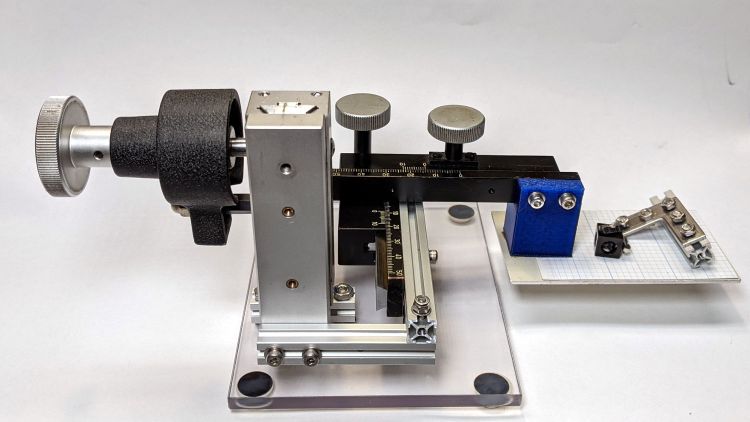

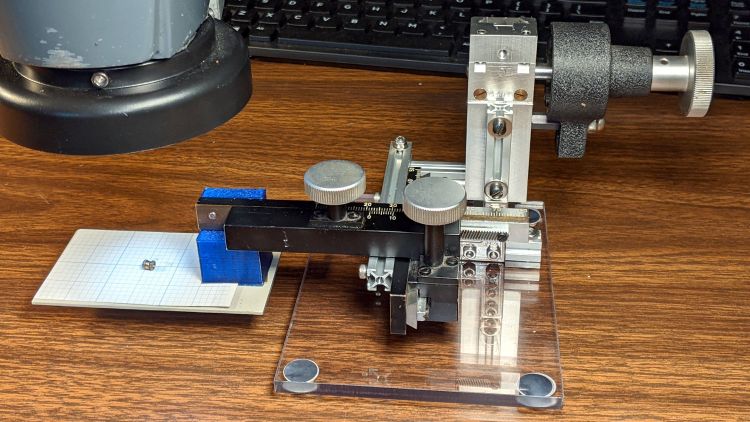

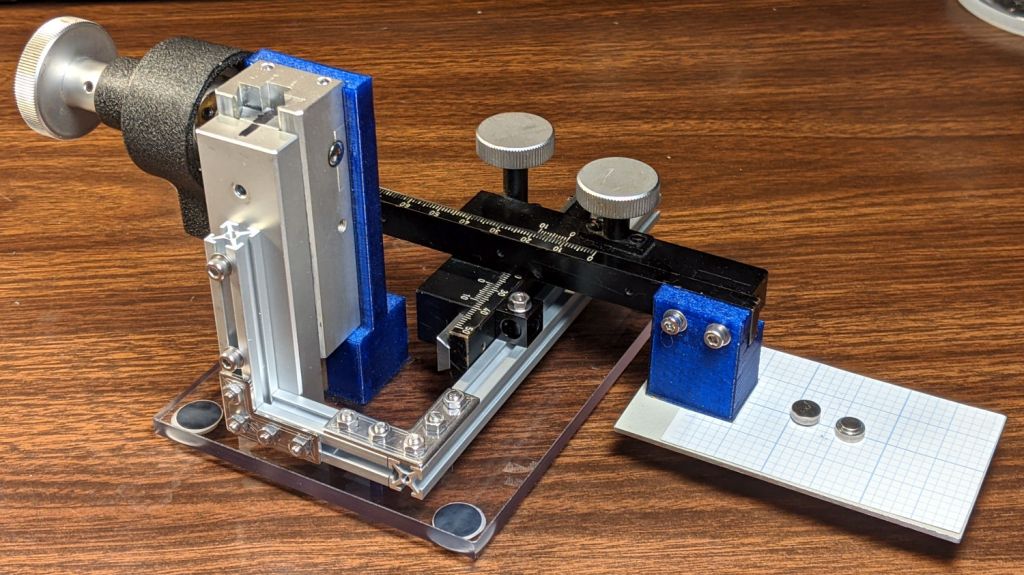

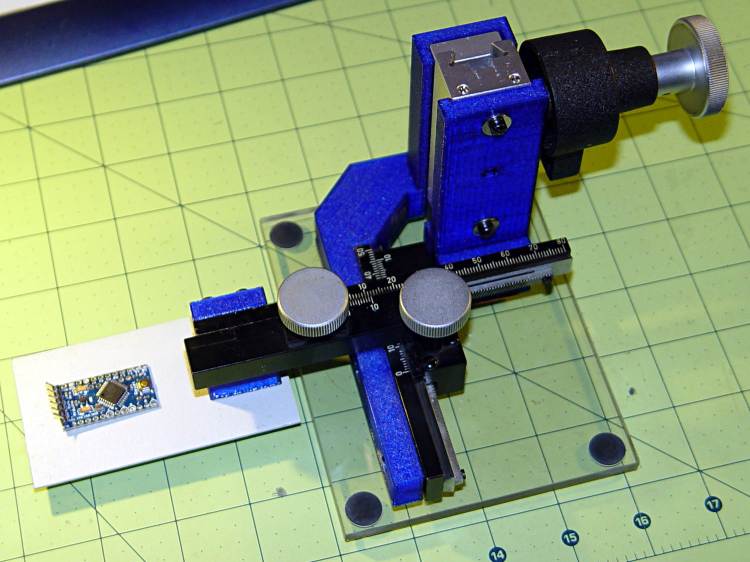

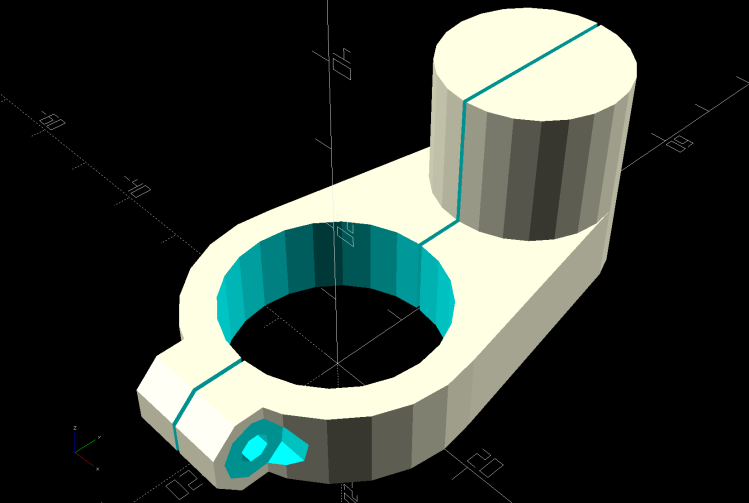

The least awful solution involved summoning an adapter from the vasty digital deep:

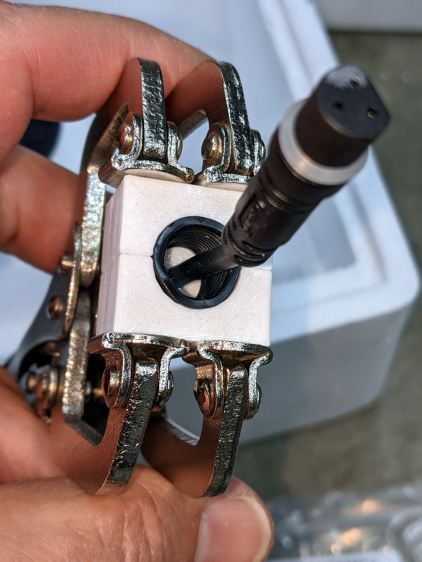

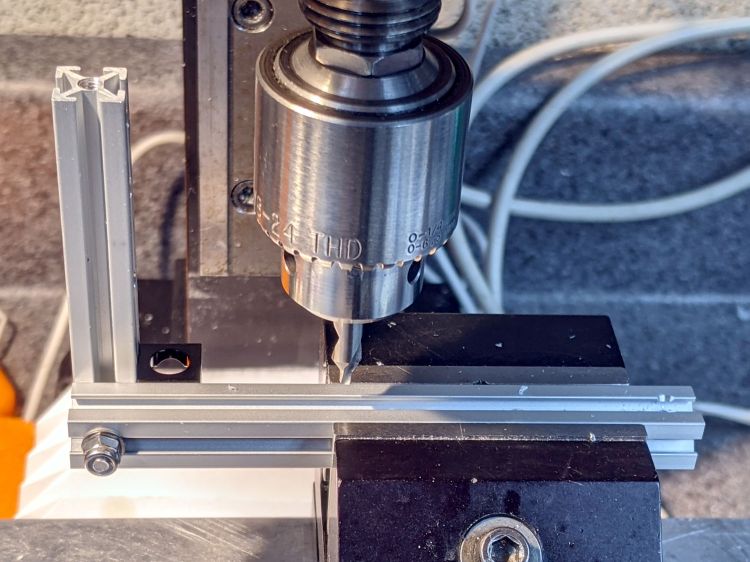

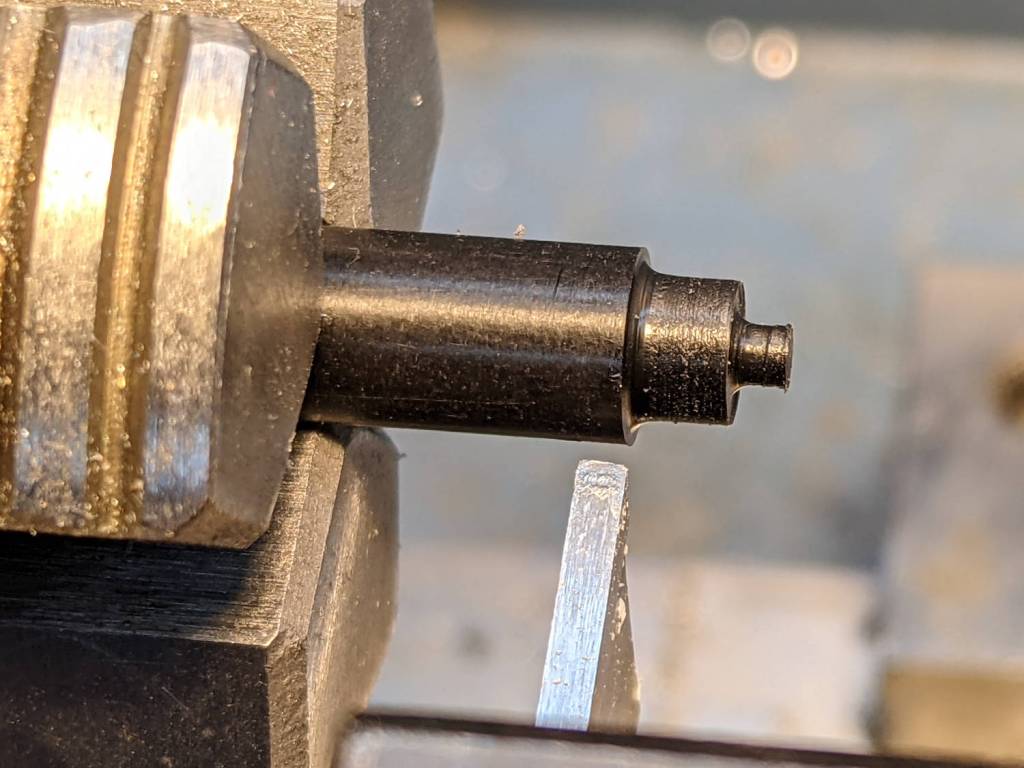

The hole clamps around the handlebar with an M3 SHCS pulling it snug and the display clamps around the peg to hold everything together:

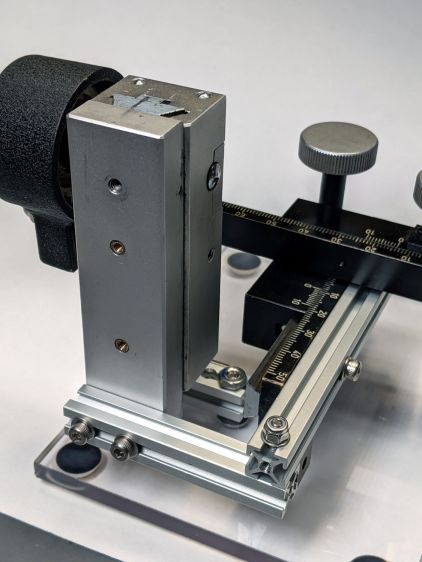

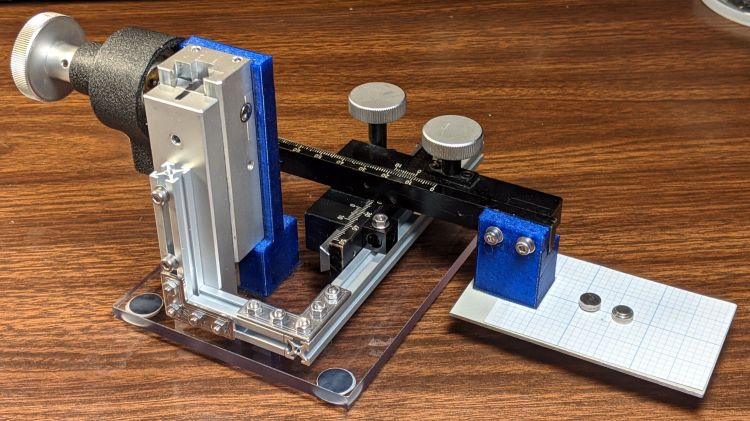

There’s not much to see from the side:

Those scuffs arrived on the protective plastic film!

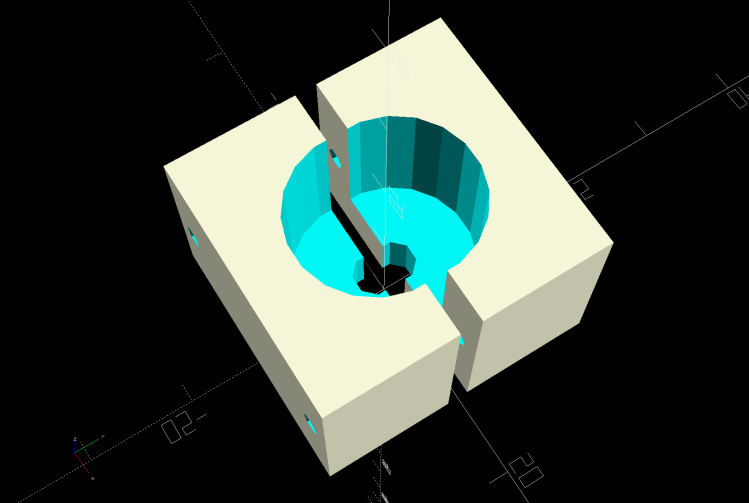

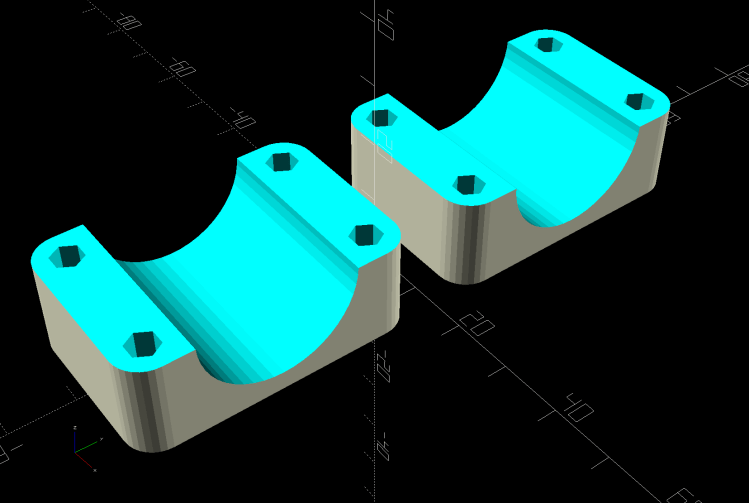

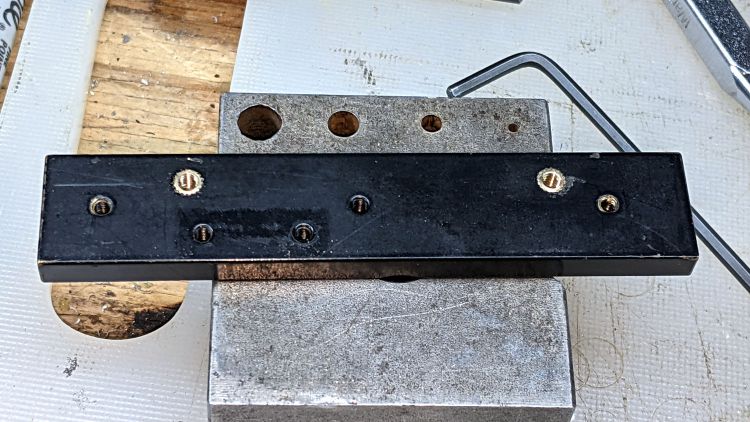

The OpenSCAD source code includes some cruft from an idea that didn’t work out quite right:

HandlebarMax = 1*inch; // middle handlebar diameter

HandlebarMin = 24.0; // .. tape section

BafangClampID = 22.3; // new handlebar diameter

… snippage …

// Handlebar mount for controller

module DispMount() {

ClampRing = [HandlebarMax,HandlebarMax + 2*WallThick,10.0];

ClampOffset = (HandlebarMax + BafangClampID)/2 + 6.0;

DispStudLenth = 16.5;

NumSides = 24;

Tilt = 0*atan2((ClampRing[OD] - BafangClampID)/2,ClampOffset);

echo(str("Tilt: ",Tilt));

difference() {

union() {

hull() {

cylinder(d=ClampRing[OD],h=ClampRing[LENGTH],$fn=NumSides);

translate([0,ClampOffset,0])

cylinder(d=BafangClampID,h=ClampRing[LENGTH],$fn=NumSides);

}

translate([0,ClampOffset,0])

cylinder(d=BafangClampID,h=ClampRing[LENGTH] + DispStudLenth,$fn=NumSides);

translate([-ClampRing[ID]/4,-(ClampRing[OD]/2),ClampRing[LENGTH]/2])

rotate([0,90,0]) rotate(180/8)

cylinder(d=ClampRing[LENGTH]/cos(180/8),h=ClampRing[ID]/2,$fn=8);

}

cube([Kerf,4*ClampOffset,4*DispStudLenth],center=true);

translate([0,0,-Protrusion])

cylinder(d=ClampRing[ID],h=ClampRing[LENGTH] + 2*Protrusion,$fn=NumSides);

translate([-ClampRing[ID]/2,-(ClampRing[OD]/2),ClampRing[LENGTH]/2])

rotate([0,90,0]) rotate(180/8)

PolyCyl(Screw3[ID],ClampRing[ID],8);

for (i=[-1,1])

translate([i*ClampRing[ID]/4,-(ClampRing[OD]/2),ClampRing[LENGTH]/2])

rotate([0,i*90,0]) rotate(180/8)

PolyCyl(Washer3[OD],ClampRing[ID],$fn=8);

translate([-5,25,EmbossDepth/2 - Protrusion/2])

rotate(Tilt)

cube([4.5,21.5,EmbossDepth + Protrusion],center=true);

}

translate([-5,25,0])

linear_extrude(height=EmbossDepth)

rotate(90 + Tilt) mirror([0,1,0])

text(text="KE4ZNU",size=3.3,spacing=1.05,font="Bitstream Vera Sans:style=Bold",

halign="center",valign="center");

}

It’s rock-solid stable: pushing the buttons doesn’t budge it in the least.