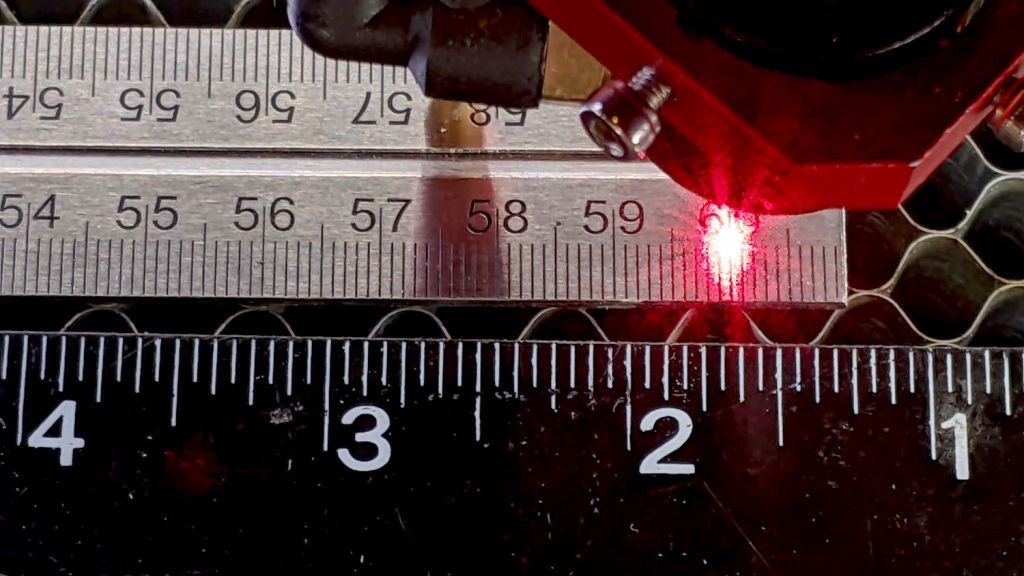

It seems two months of sunlight will fade laser charred MDF down to its original state:

That’s through a thick layer of indoor urethane sealant slathered over MDF without any surface prep. Obviously, not removing the char had no effect on the outcome. On the upside, the urethane did a great job of protecting the MDF from rainfall.

So. Back to the shop.

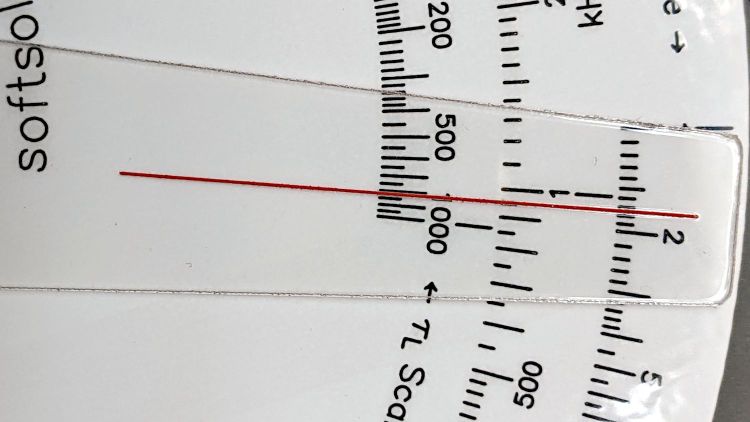

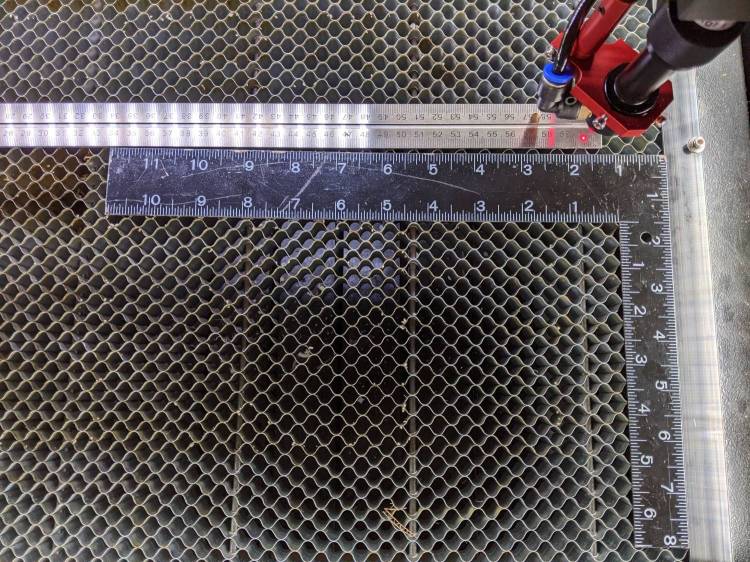

Lacking wider masking tape, two strips of tape laid along a cut-to-suit slab of fresh MDF will serve as a paint mask:

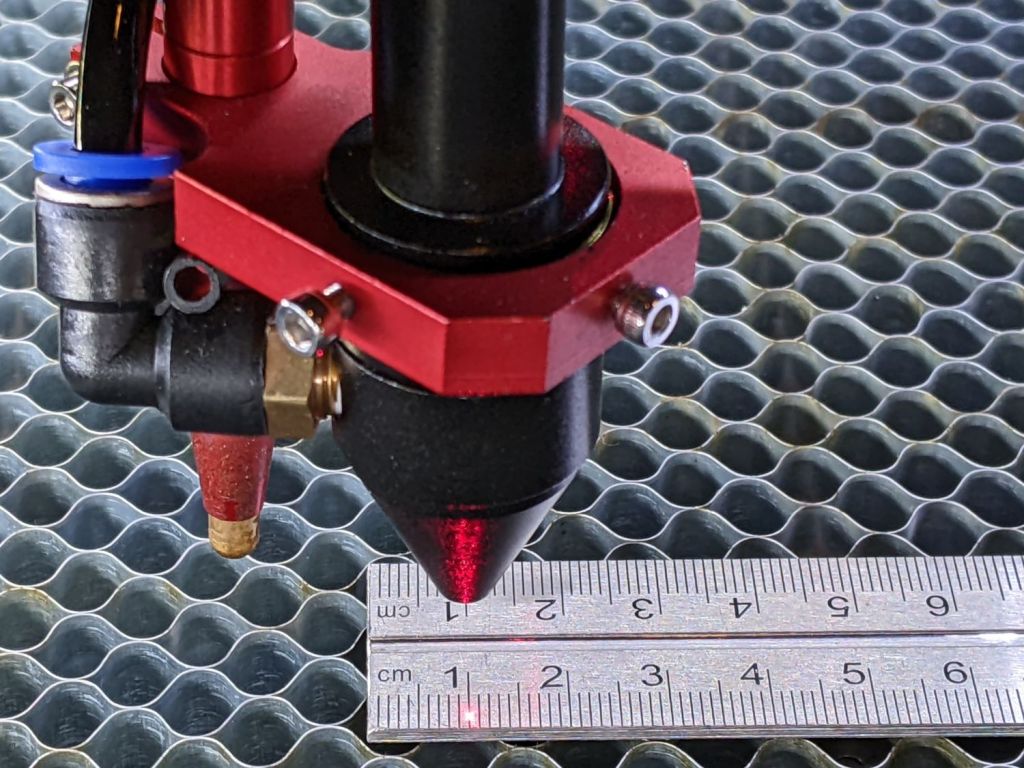

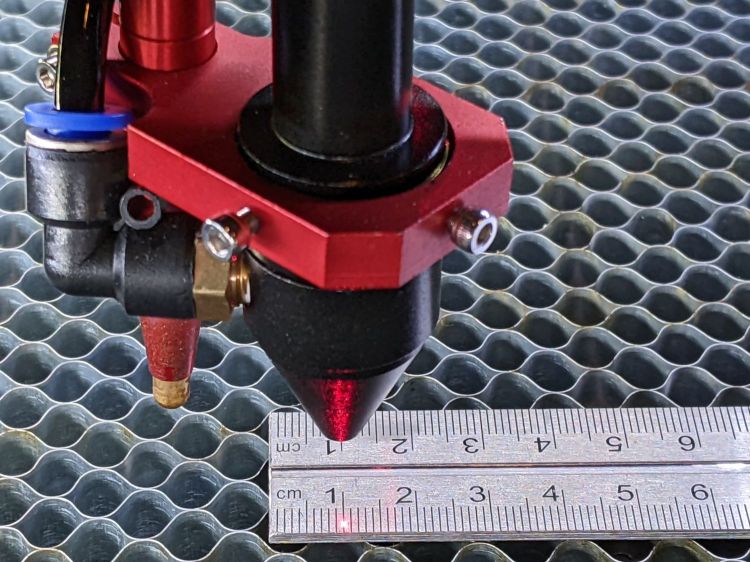

Belatedly I Learned: cut the tape close to the edge, then fold it under so the autofocus pen can’t possibly snag it en passant.

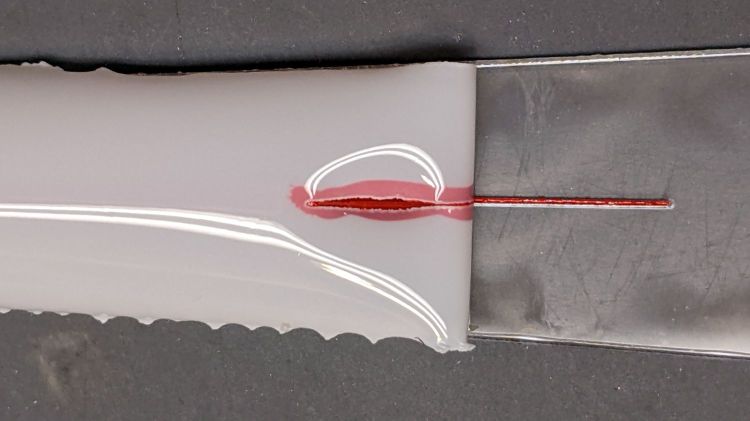

Shoot the entire surface with a couple of black enamel rattlecan coats:

Yes, the engraved areas look reddish, most likely due to another complete lack of surface prep. Perhaps brushing / vacuuming / washing would remove some of the char, but let’s see how it behaves with no further attention.

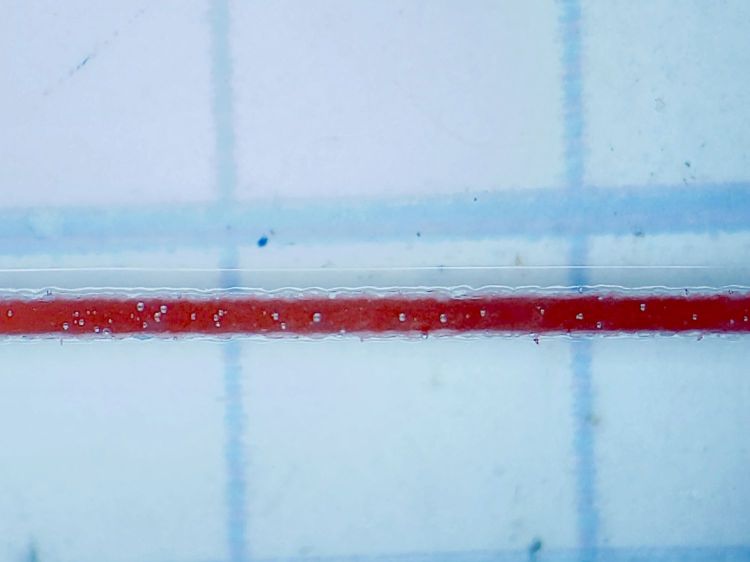

Peel the tape, weed the letters / antlers, slather on a coat of urethane, and it looks downright bold:

Of course, if those two tape strips don’t exactly abut, the paint produces a nasty line:

Should you overlap the strips a wee bit to ensure cleanliness, the engraved surface will then have a noticeable (in person, anyhow) discontinuity due to the laser losing energy in two tape layers, which wouldn’t matter in this application. We defined the few paint lines as Good Enough™ for the purpose; a strip of absurdly wide masking tape is now on hand in anticipation of future need.

Burnishing the tape might have prevented paint bleed around the engraved areas:

But, given that I was painting raw / unfinished MDF with an unsmooth surface, burnishing probably wouldn’t produce a significantly better outcome.

By popular request, the new signs sit a few grids lower on the gates:

Perhaps these will outlast the garden season …