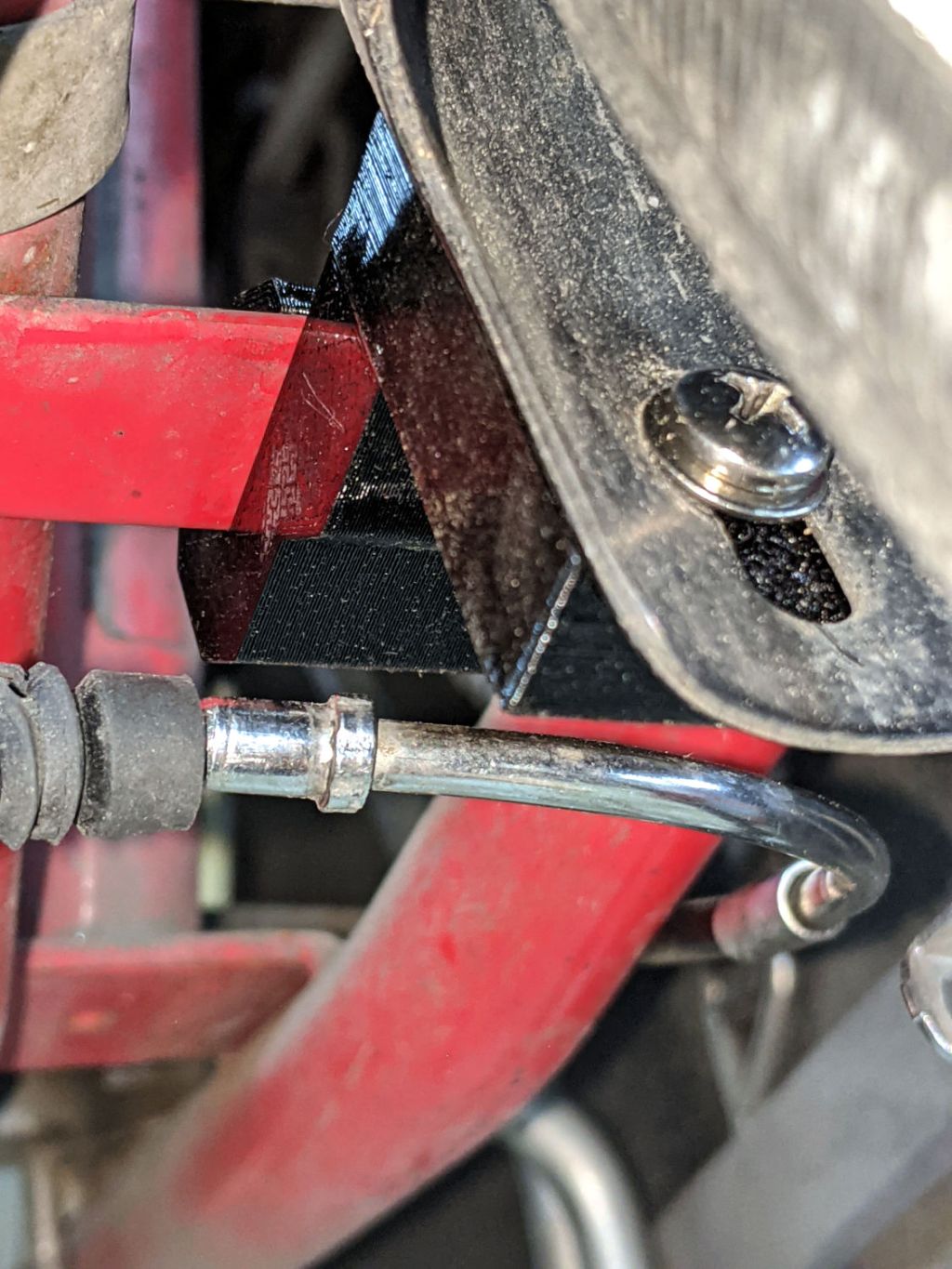

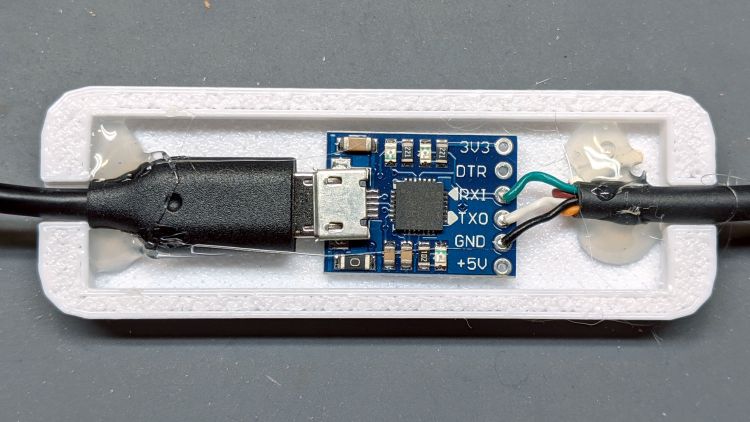

The last view before sticking the lid in place with hot melt glue:

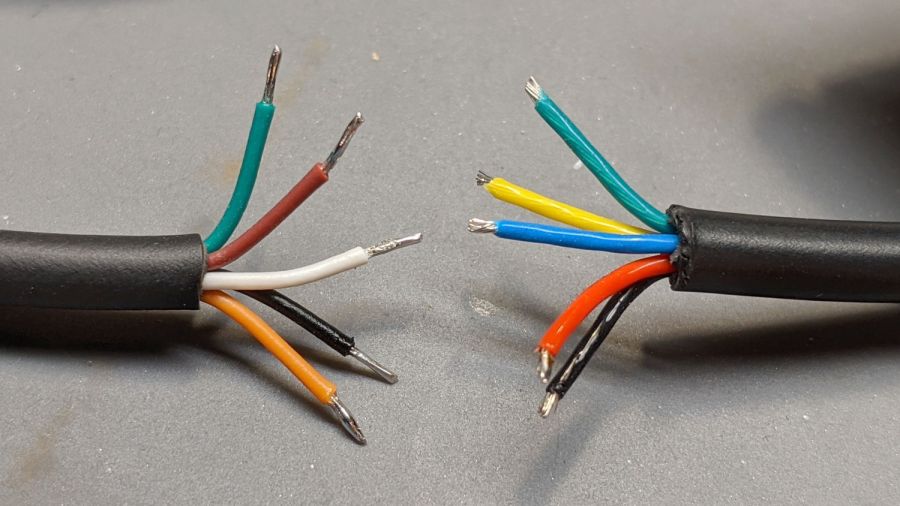

The cable on the right goes to the motor controller through the display pigtail cable, sporting colors from a parallel universe.

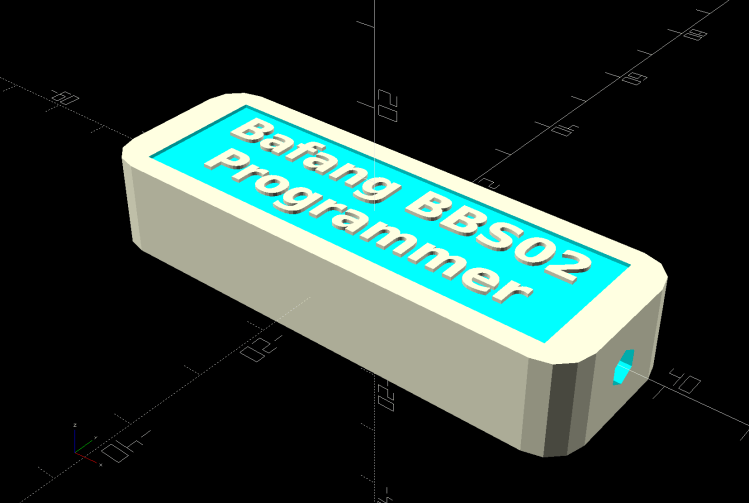

A (possibly not counterfeit) CP2102 USB-to-serial adapter allows a slightly smaller case than one with the known-fake FTDI adapter and added some identification:

It splits along the midline for printing, of course.

The OpenSCAD source code replaces the previous version:

// Programming cable case

ProgCavity = [60.0,18.0,7.0];

ProgBlock = [70.0,24.0,13.0];

ProgCableOD = 4.0;

module ProgrammerCase() {

difference() {

hull() {

for (i=[-1,1], j=[-1,1])

translate([i*(ProgBlock.x/2 - CornerRadius),j*i*(ProgBlock.y/2 - CornerRadius),-ProgBlock.z/2])

cylinder(r=CornerRadius,h=ProgBlock.z,$fn=12);

}

translate([-ProgBlock.x,0,0])

rotate([0,90,0])

PolyCyl(ProgCableOD,3*ProgBlock.x,6);

cube(ProgCavity,center=true);

translate([0,0,ProgBlock.z/2 + ProgCavity.z/2 - EmbossDepth])

cube(ProgCavity,center=true);

translate([0,0,-(ProgBlock.z/2 + ProgCavity.z/2 - EmbossDepth)])

cube(ProgCavity,center=true);

}

translate([0,4,ProgBlock.z/2 - EmbossDepth])

linear_extrude(height=EmbossDepth)

text(text="Bafang BBS02",

size=5,spacing=1.00,font="Bitstream Vera Sans:style=Bold",

halign="center",valign="center");

translate([0,-4,ProgBlock.z/2 - EmbossDepth])

linear_extrude(height=EmbossDepth)

text(text="Programmer",

size=5,spacing=1.00,font="Bitstream Vera Sans:style=Bold",

halign="center",valign="center");

translate([0,4,-ProgBlock.z/2])

linear_extrude(height=EmbossDepth)

mirror([1,0])

text(text="Ed Nisley",

size=5,spacing=1.00,font="Bitstream Vera Sans:style=Bold",

halign="center",valign="center");

translate([0,-4,-ProgBlock.z/2])

linear_extrude(height=EmbossDepth)

mirror([1,0])

text(text="softsolder.com",

size=5,spacing=1.00,font="Bitstream Vera Sans:style=Bold",

halign="center",valign="center");

}

// Half case sections for printing

module HalfCase(Section = "Upper") {

intersection() {

translate([0,0,ProgBlock.z/4])

cube([2*ProgBlock.x,2*ProgBlock.y,ProgBlock.z/2],center=true);

if (Section == "Upper")

ProgrammerCase();

else

translate([0,0,ProgBlock.z/2])

ProgrammerCase();

}

}

// .. snippage ..

translate([0,2*Block.x/2 * gap,0]) {

translate([gap*ProgBlock.x/2,0,ProgBlock.z/2])

rotate([180,0,0])

HalfCase("Upper");

translate([-gap*ProgBlock.x/2,0,0])

HalfCase("Lower");

}

My friend rides about the same way we do, except from a much higher perch, so I’ll start her off with a configuration similar to the one we settled on for Mary’s Tour Easy.