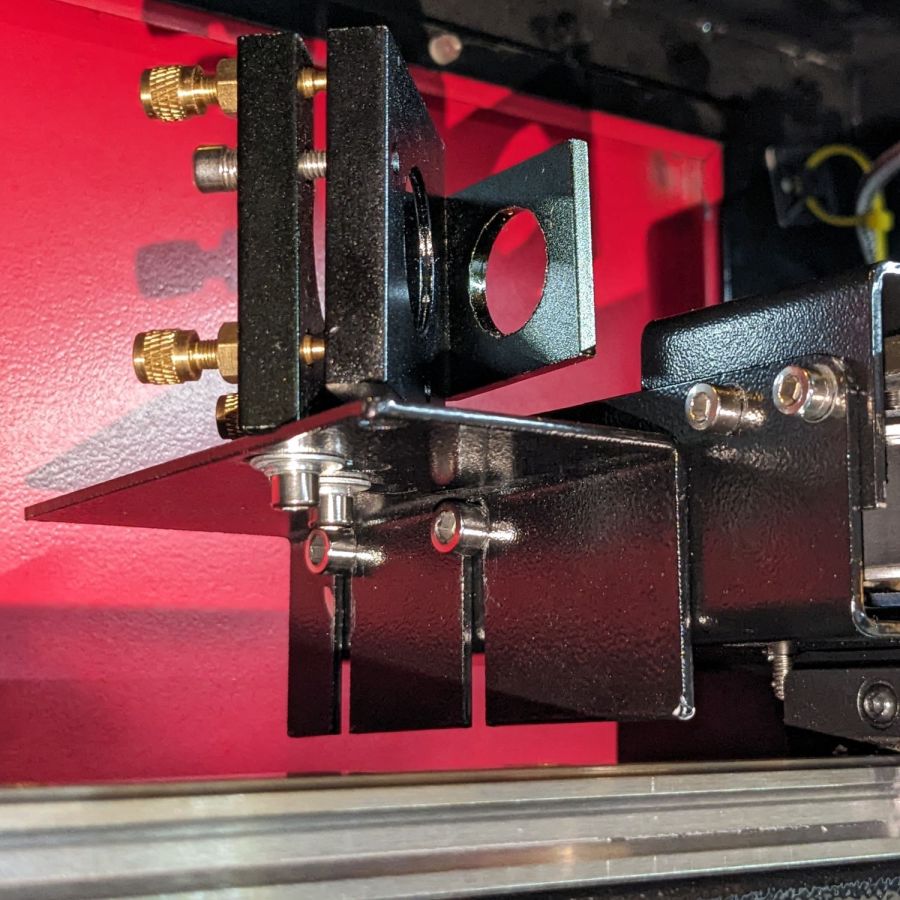

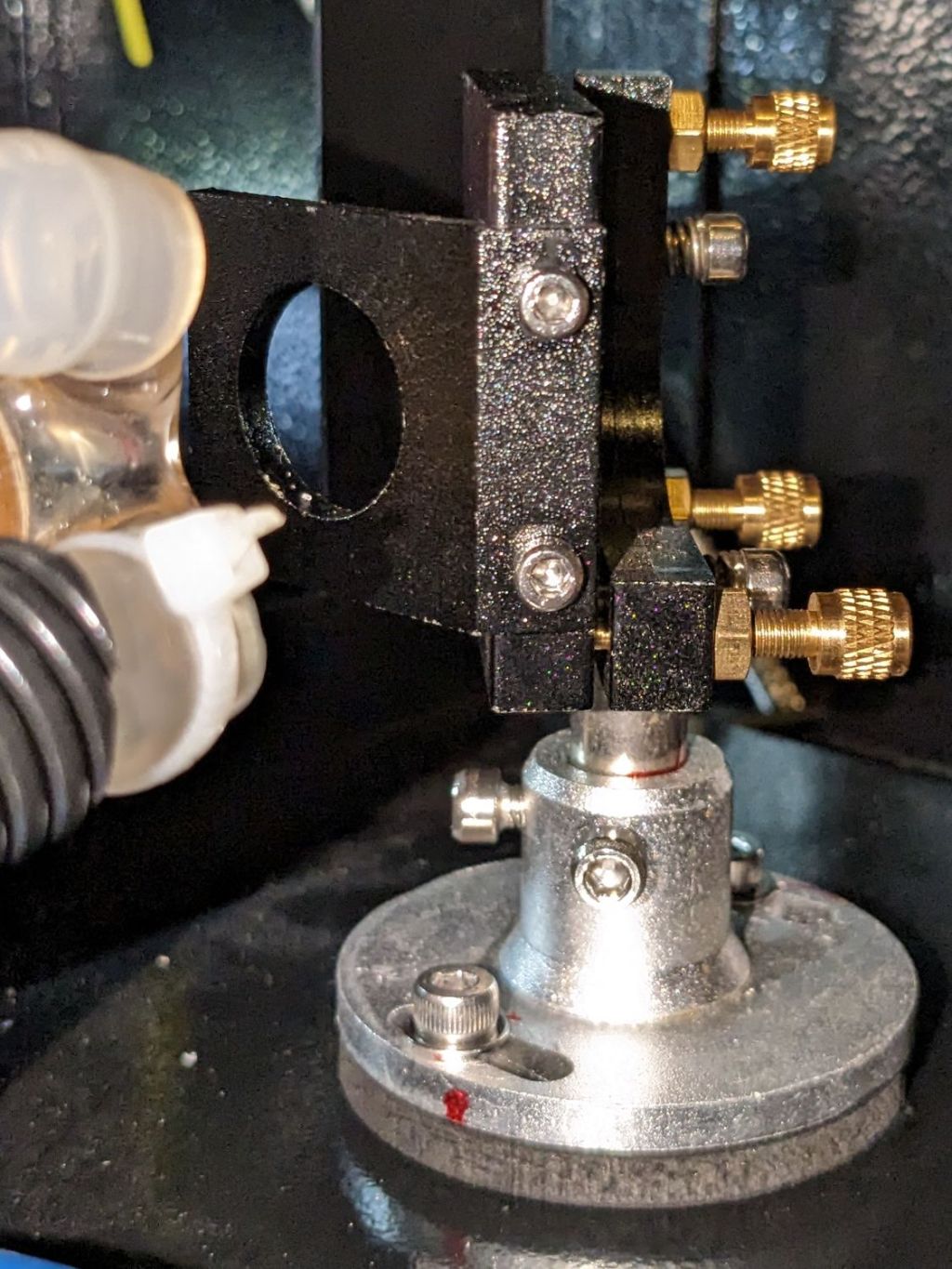

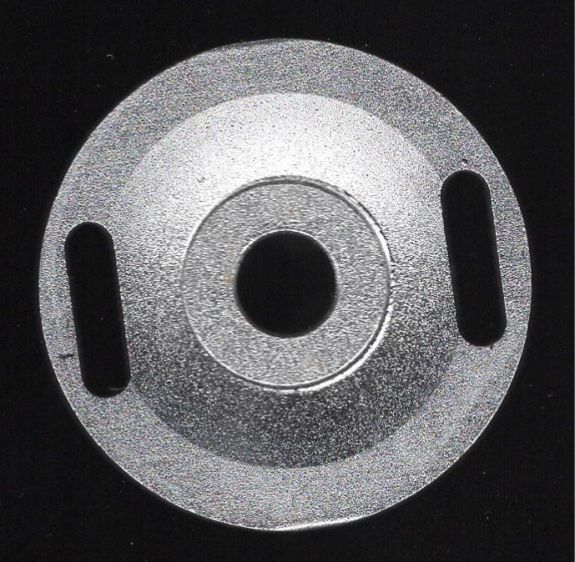

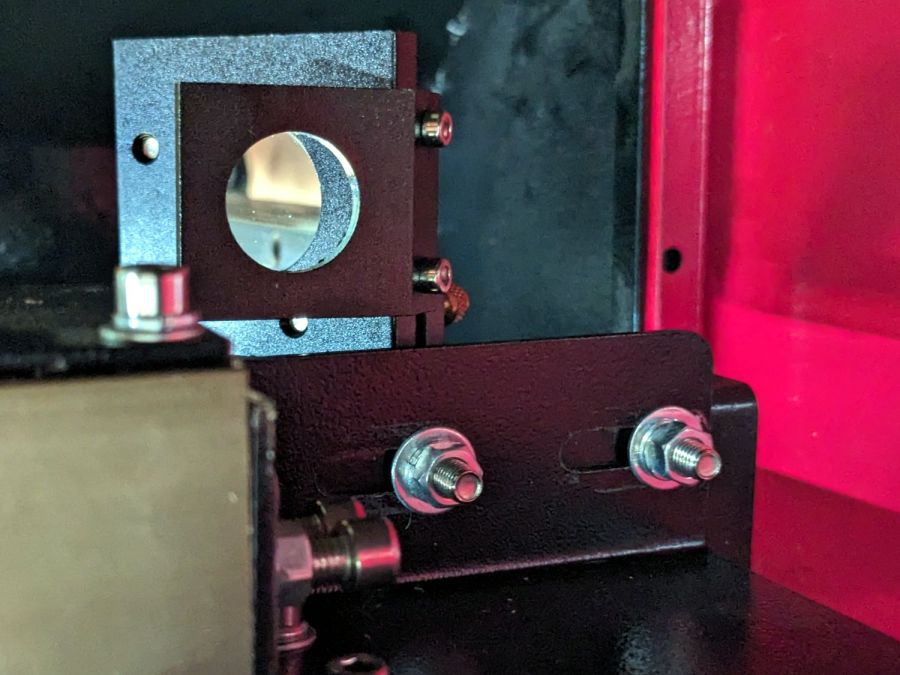

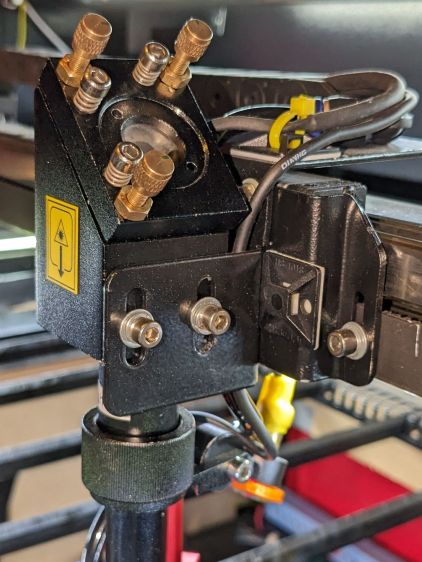

With Mirror 1 and Mirror 2 aligned, the next step is positioning the laser head to put the beamline at the center of both the aperture and Mirror 3 inside:

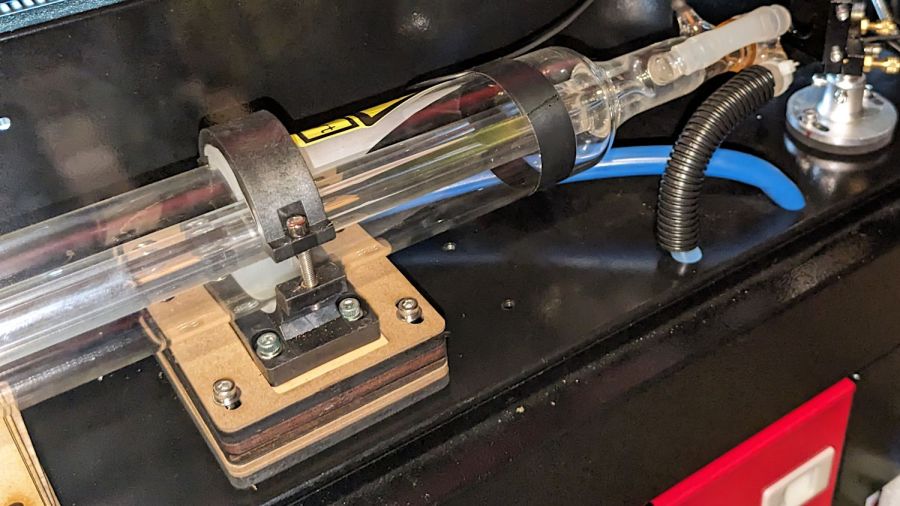

Raising the laser tube by 5 mm put the head’s Z axis screws in the middle of their slots. This had the additional benefit of letting me rotate the head slightly around the X axis to make it perpendicular with the bed, thus fixing its mysterious from-the-factory misalignment.

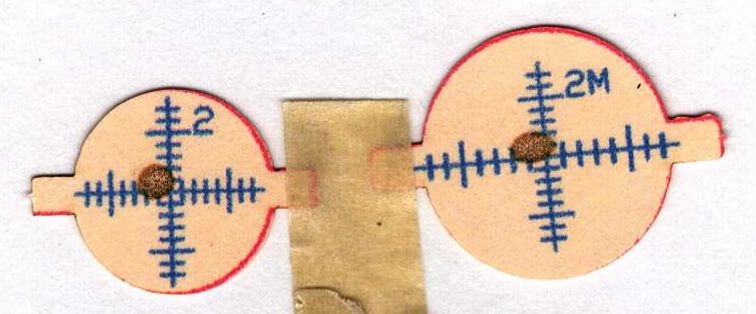

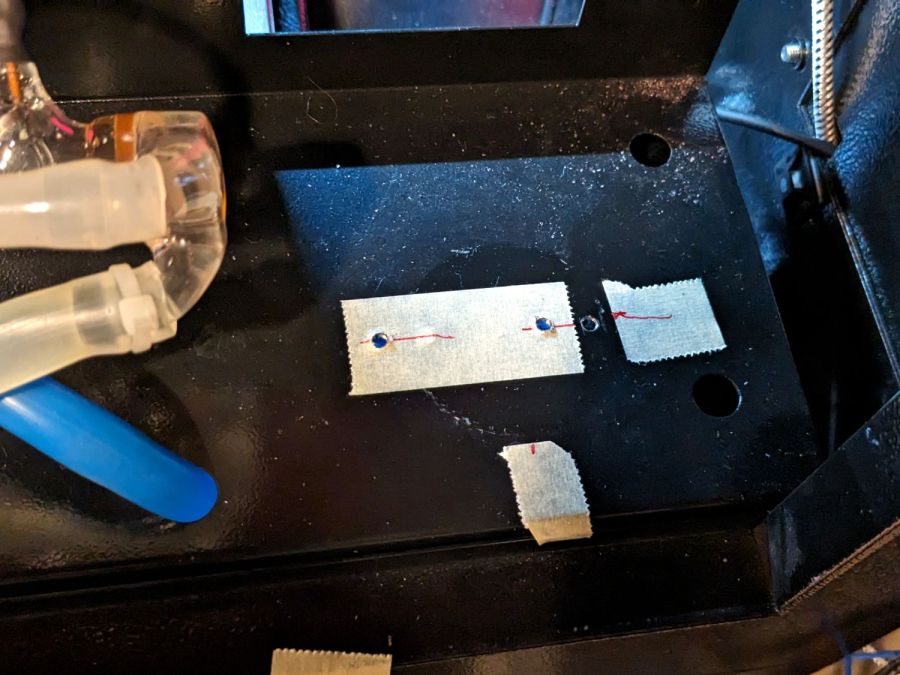

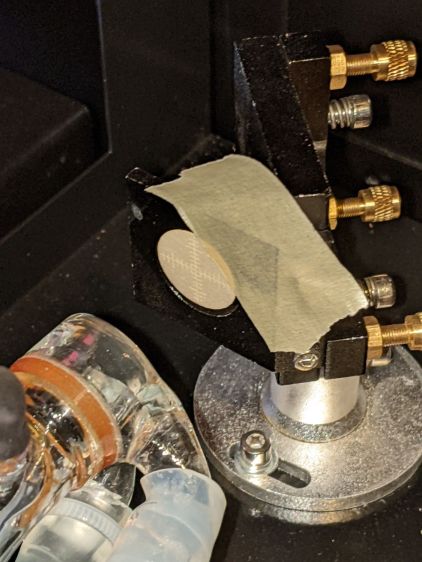

Centering the beamline horizontally required a few iterations of Mirror 2’s position along the Y axis, but eventually produced this result:

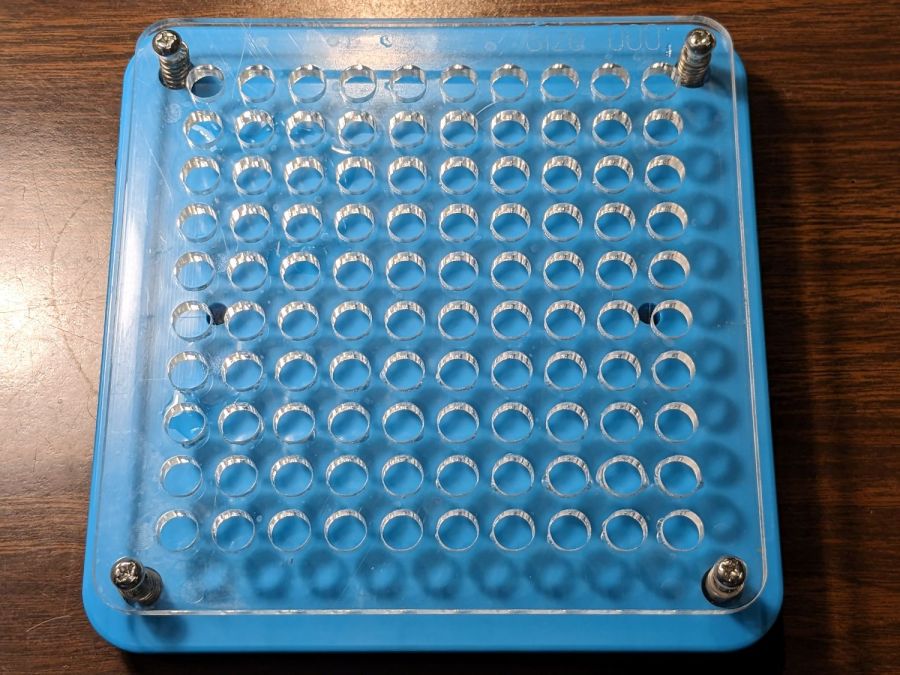

Those are five manual pulses with the head at the corners and center of the platform. I put the 3M target on the mirror rotated 90° from the proper orientation with the stretched scale aligned vertically and parallel to the slightly oval beam mark.

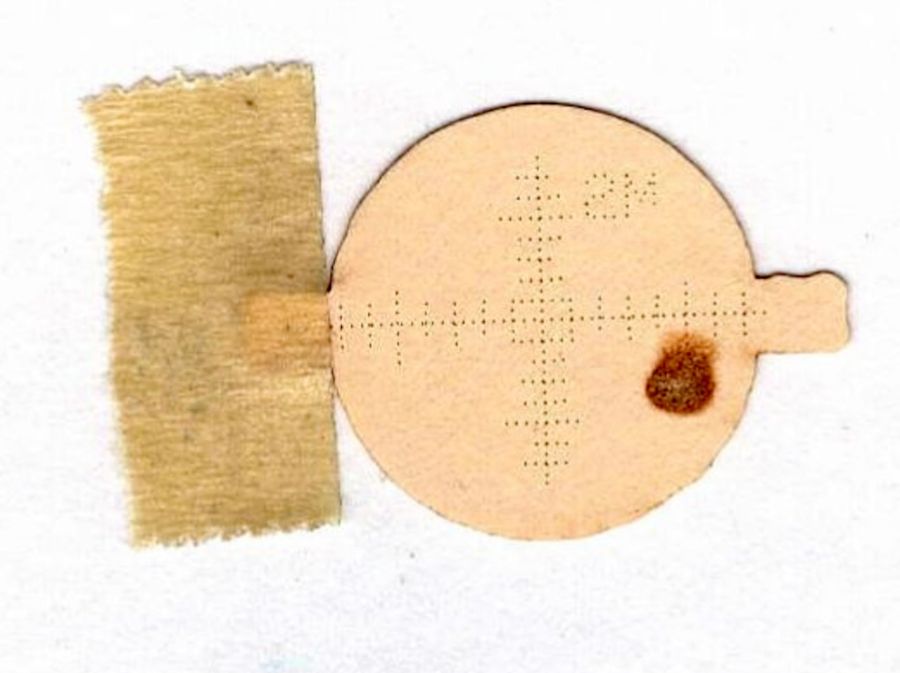

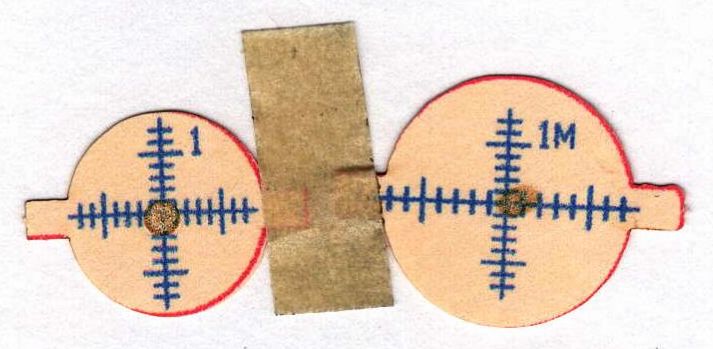

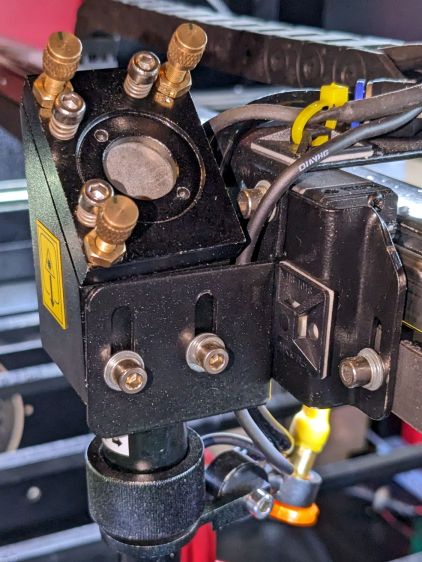

The F target shows the beam position inside the head just above the focus lens:

The little target in the middle gets centered on the nozzle by feel and shows the beam position within a 2 mm circle. The initial position was off against the side of the nozzle, but slight twiddling of the Mirror 3 screws centered it.

I centered the lower F target at the beam position using the red dot aiming pointer, then pulsed the laser to put a pinhole almost exactly at the graticule center. The larger scorch shows the beam size with the platform lowered 10 mm from the focus level. The Z axis leadscrews are not particularly precise and the platform moves by about a millimeter in X and Y as they rotate, so that’s about as good as it gets.

After all that, the laser behaves at least as well as it ever did and I feel better about having the beamline actually travel along the center of the optical path.

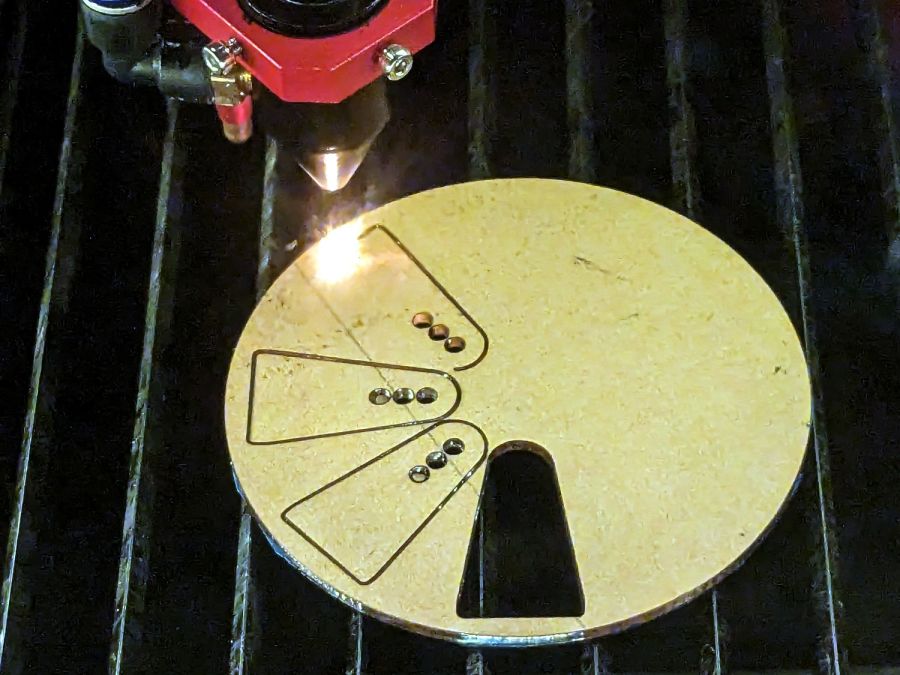

Now, back to cutting out interesting shapes …