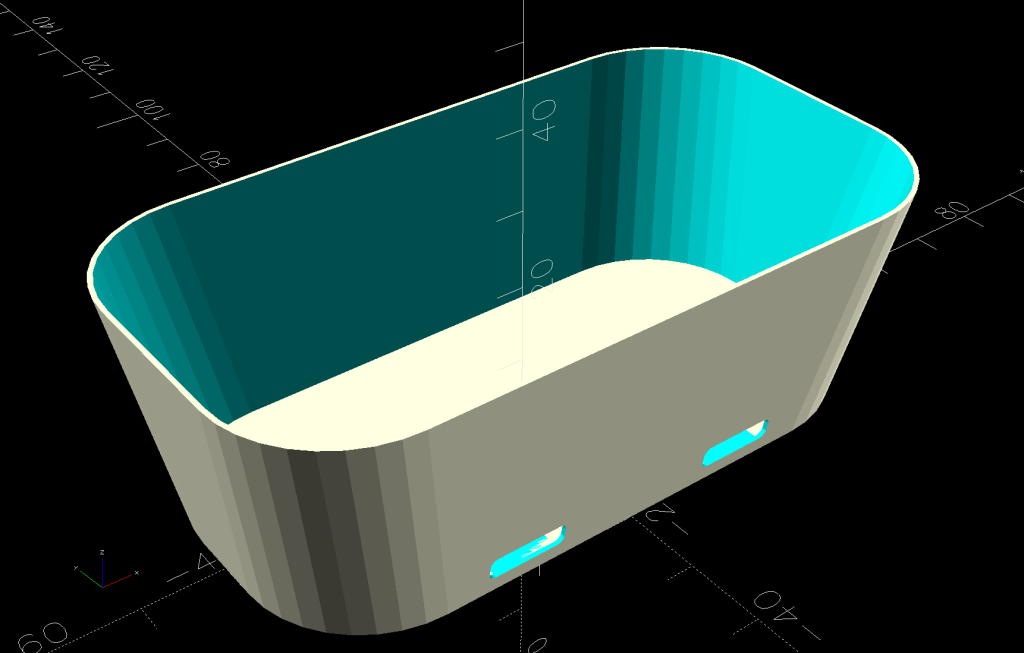

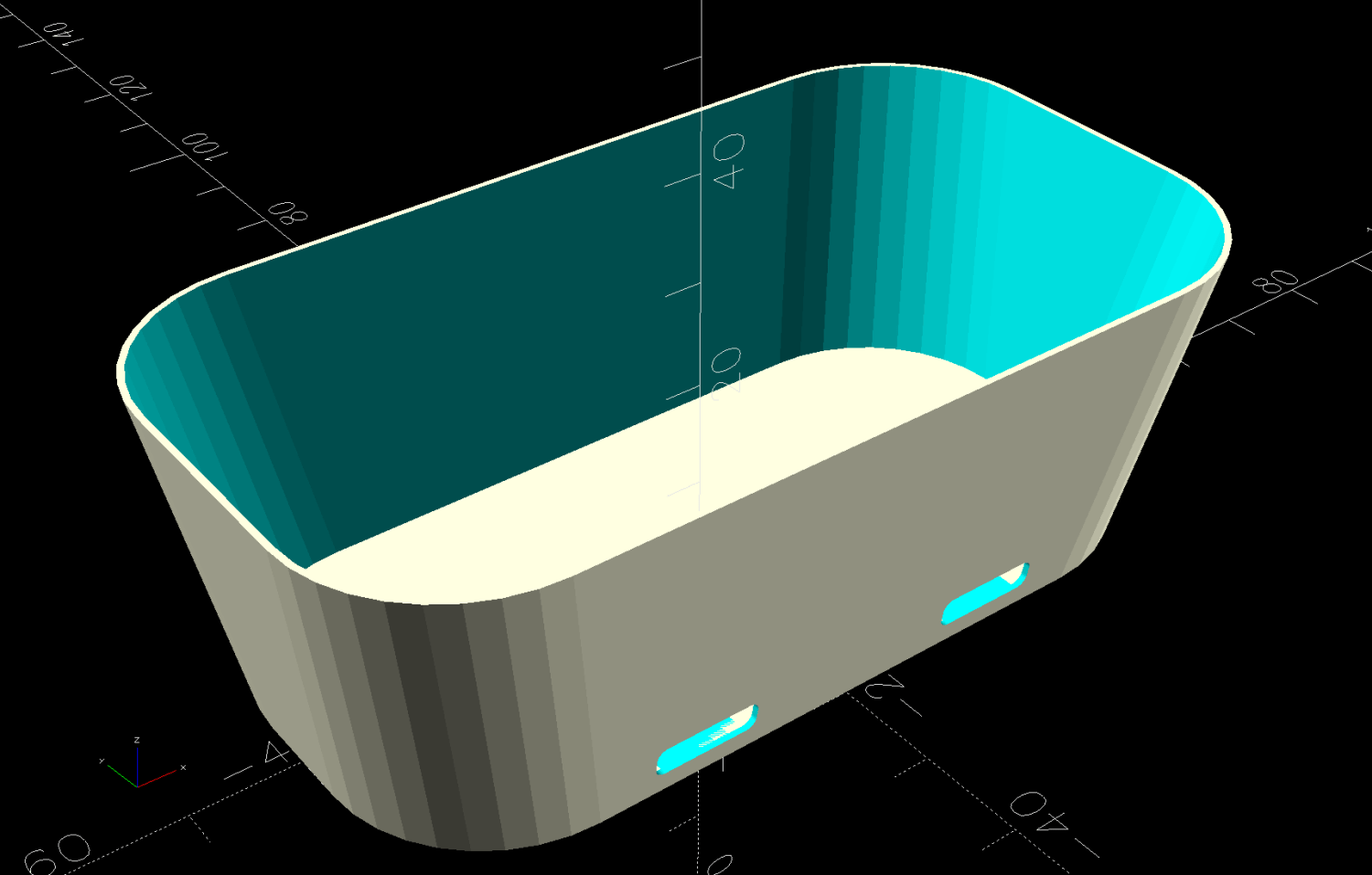

A brace of cheap HD USB cameras may improve the scenery around here during video meetings. They were $16, marked down from an absurd $130:

Some poor schlubs certainly dropped more than twice the price of a Genuine Logitech camera on these critters, but a nearly total lack of demand must have had some effect.

They do take their stylin’ cues from Logitech, although the speckled pattern on a shiny plastic sheet is amusing:

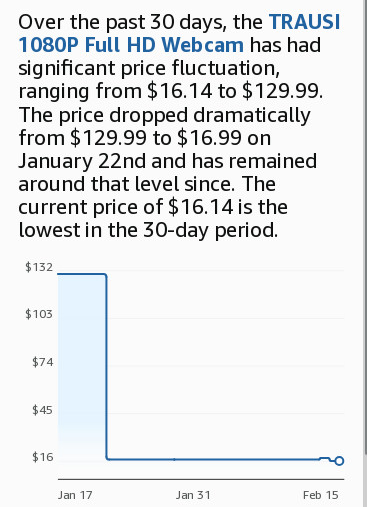

Unsurprisingly, the lens is fixed / manual focus. What looked like focus rings were in different positions on the two cameras:

It turns out the rings were not glued in place, perhaps because they have absolutely no effect on the camera’s focus. Maybe there’s another camera model where they rotate the lens in a threaded socket, but this ain’t that.

The front panel has three pores:

- A red

PowerLED is always on when it’s plugged in - A green

On the airLED lights up when the camera is selected; I have no idea what the WiFi-ish glyph is supposed to represent - The “advanced noise canceling microphone” sits behind a pore offscreen left; the claim seems dubious.

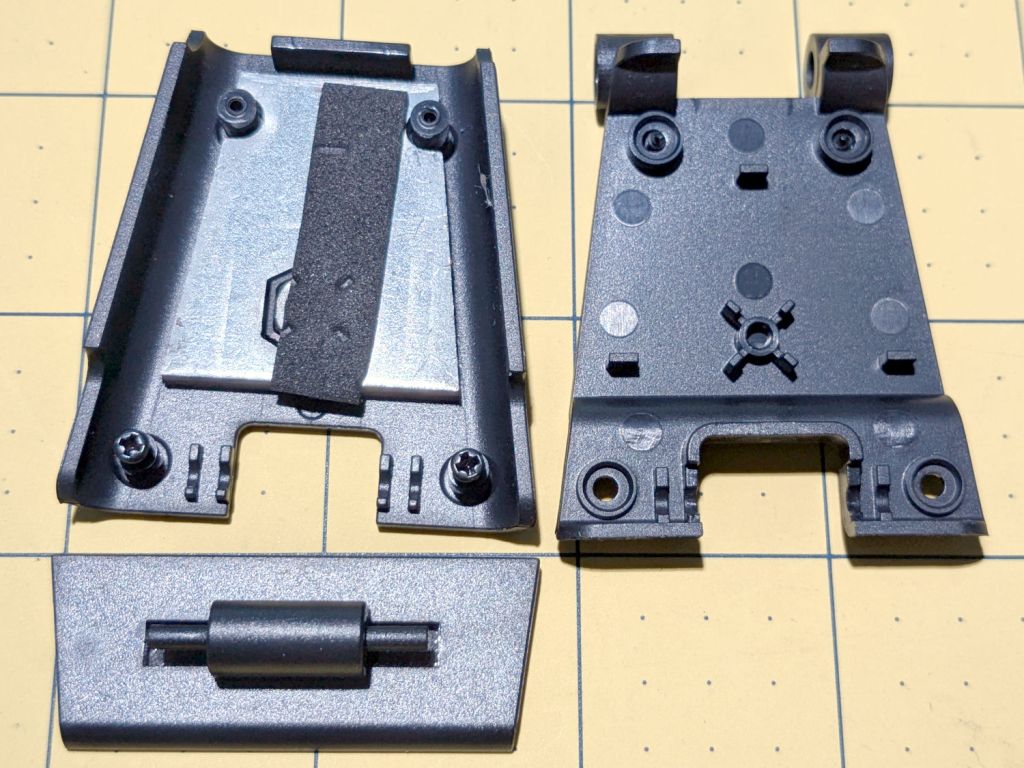

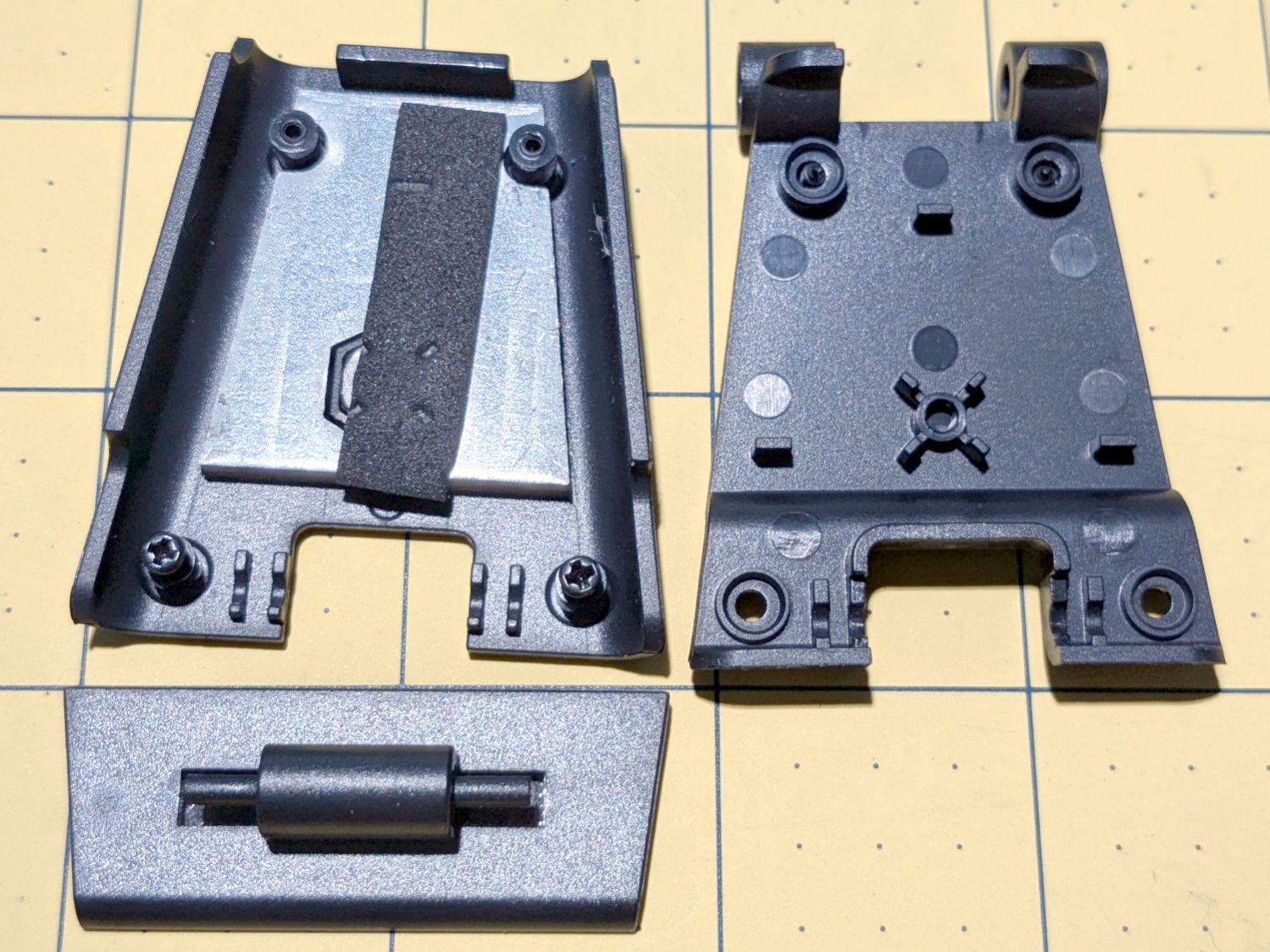

Because these may go into smaller spaces, I dismantled the base to see what was involved. Most of the screws lie underneath thin foam sheets:

The lower plate has a tripod mount and a folding bracket:

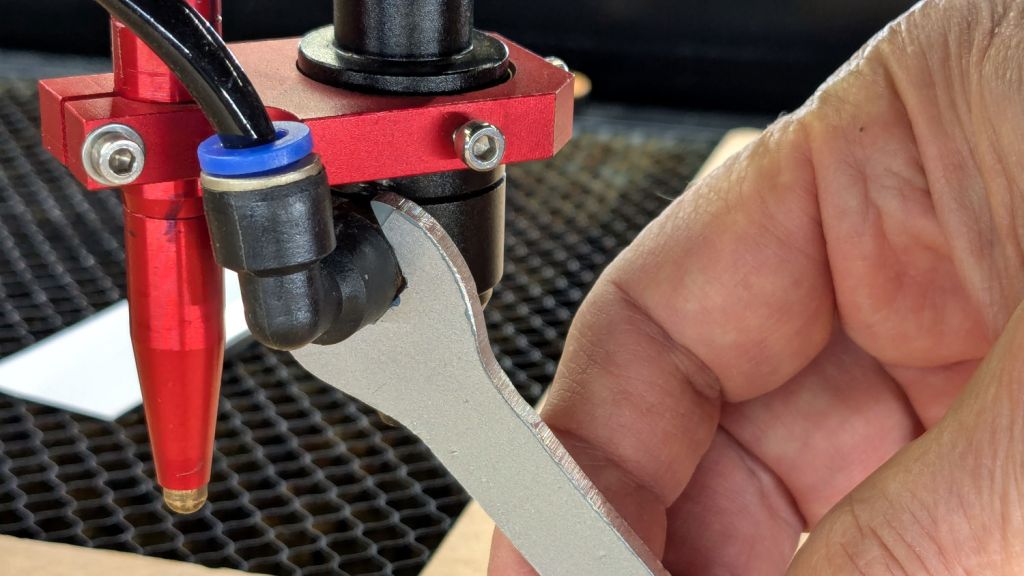

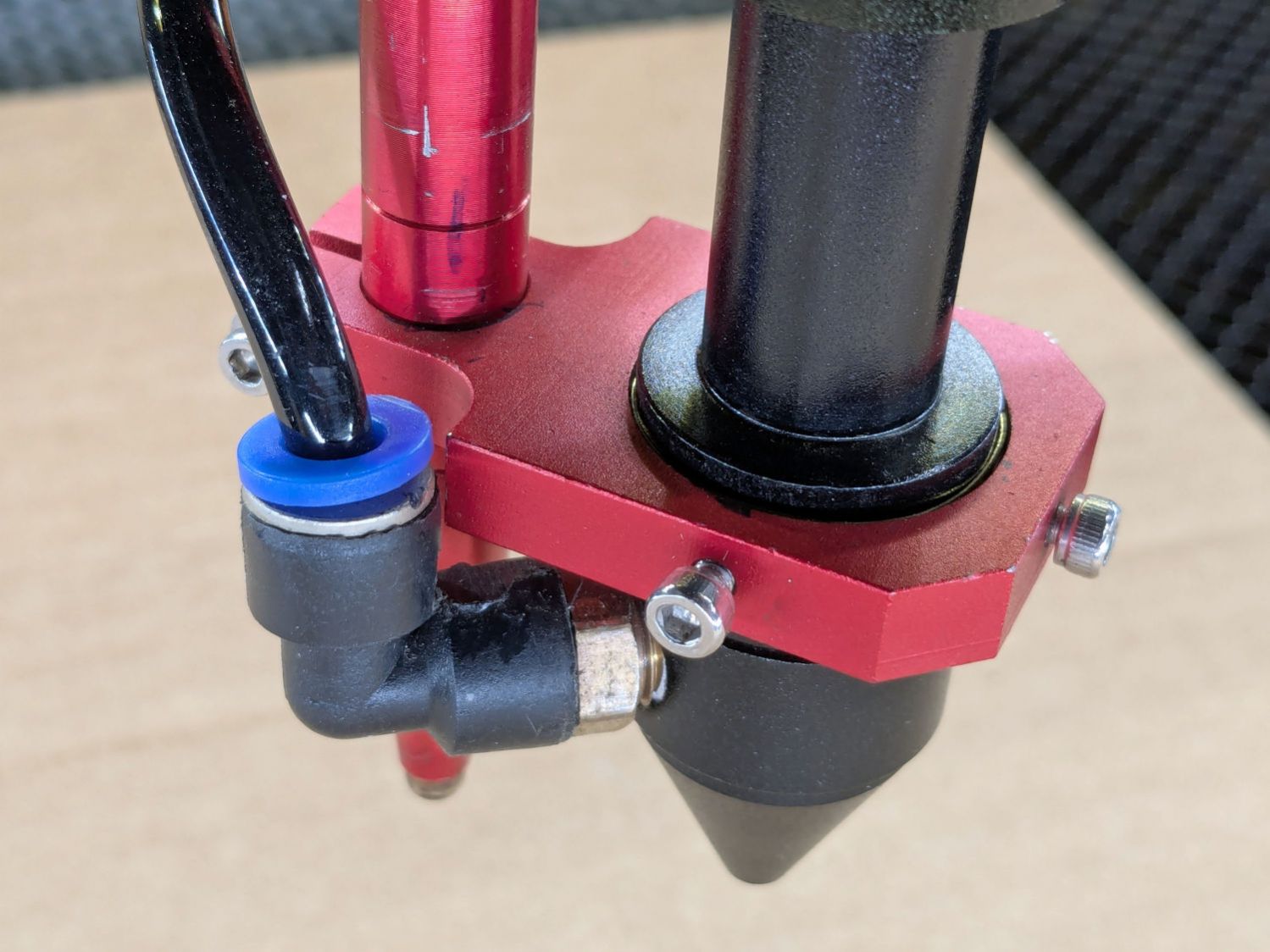

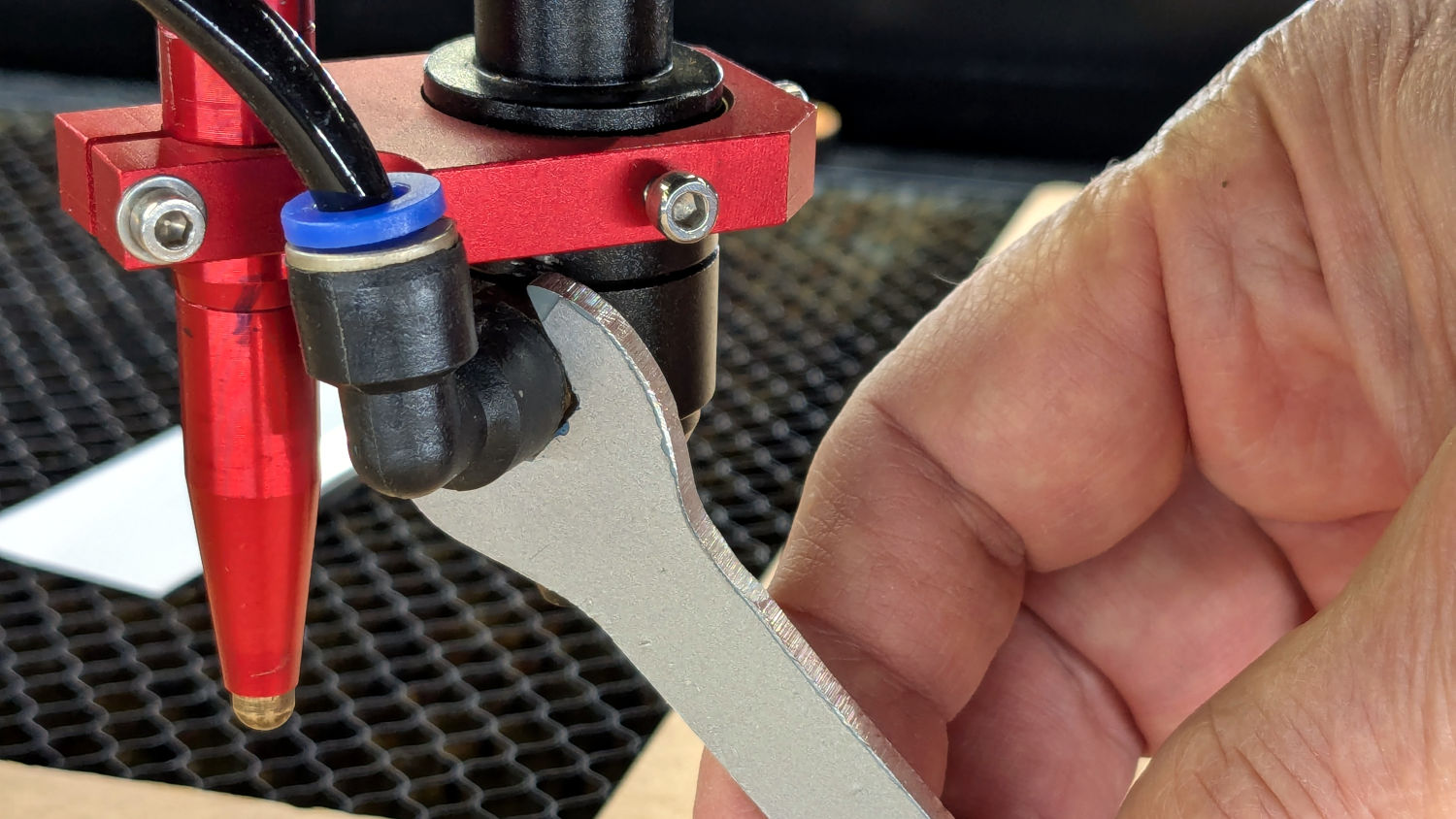

The camera body has a ball mount with a few degrees of movment:

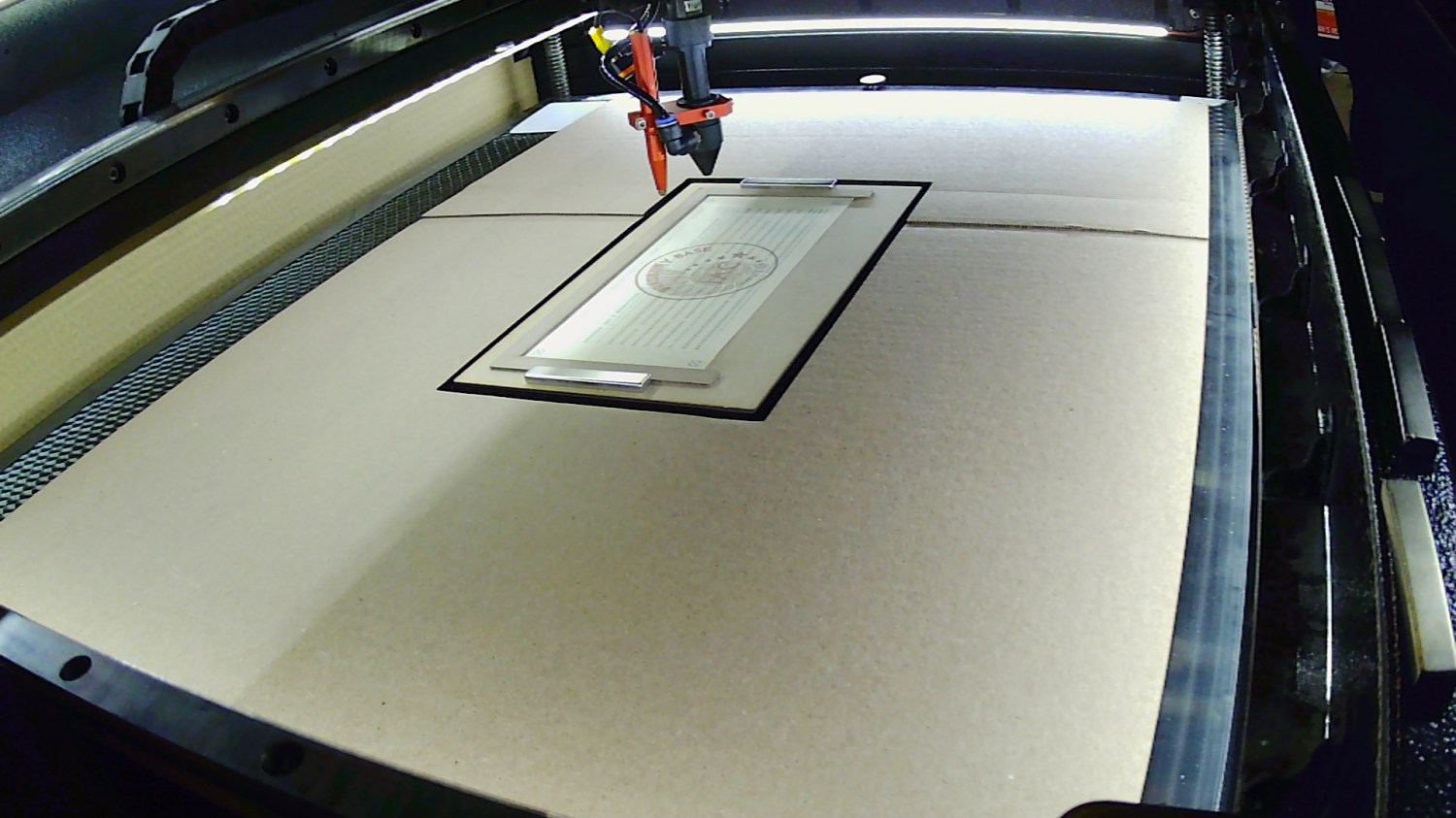

Reassembled and stuck inside the laser cabinet with some good double-sided foam tape, it definitely produces a better image than the previous camera:

Whatever noise cancellation the mic may provide is irrelevant in there: nobody’s listening.