One of the soaker hoses in Mary’s Vassar Farms garden split lengthwise near one end:

Although the hose is fully depreciated, I thought it’d be worthwhile to cut off the damaged end and conjure an end cap to see if a simple plug can withstand 100 psi water pressure.

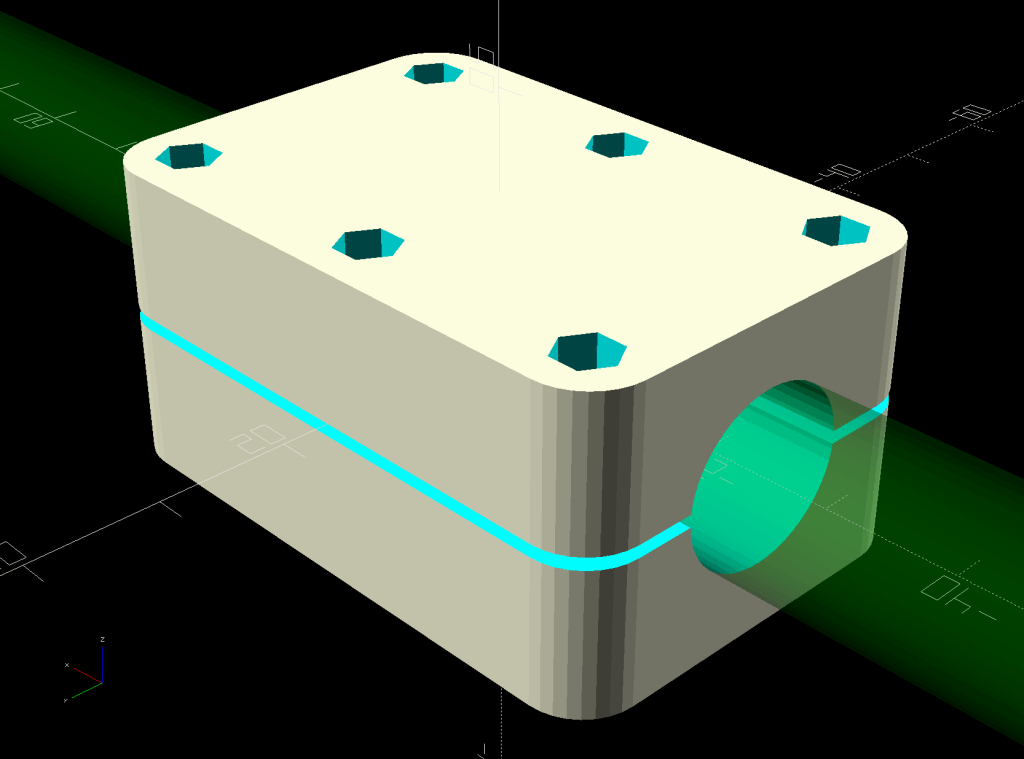

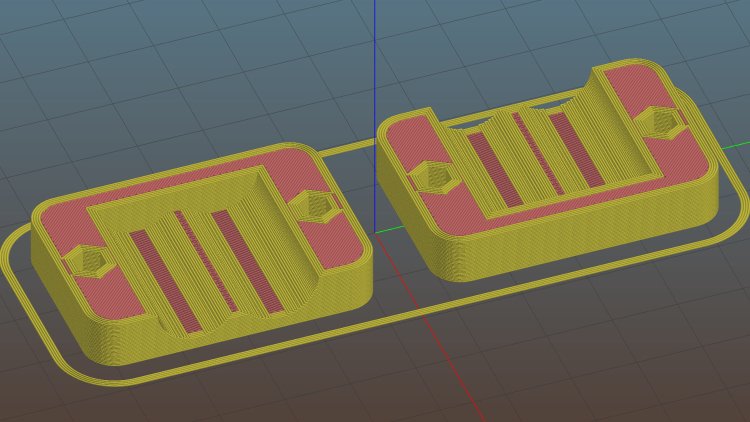

A pair of Delrin (because I have it) plugs with serrations fill the hose channels, with the outer clamp squishing the hose against them:

In real life, they’ll be pushed completely into the hose, with a generous layer of silicone snot caulk improving their griptivity.

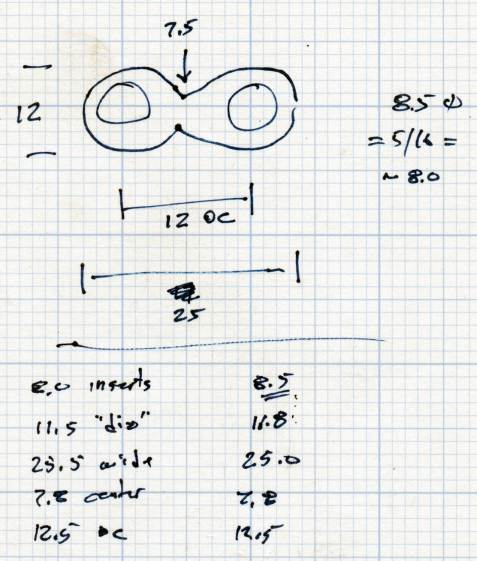

I started with 8 mm plugs, but they didn’t quite fill the channels:

Going to 8.5 mm worked better, although there’s really no way to force the granulated rubber shape into a snug fit around a cylinder:

Fortunately, they need not be leakproof, because leaking is what the hose does for a living. Well, did for a living, back before it died.

The clamps have a solid endstop, although it’s more to tidy the end than to hold the plugs in place:

The clamps need aluminum backing plates to distribute the stress evenly across their flat sides:

Those are 8-32 stainless steel screws. The standard 1 inch length worked out exactly right through no fault of my own.

The OpenSCAD source code as a GitHub Gist:

| // Rubber Soaker Hose End Plug | |

| // Ed Nisley KE4ZNU June 2019 | |

| // 2020-05 Two-channel hose end plug | |

| Layout = "Hose"; // [Hose,Block,Show,Build] | |

| //- Extrusion parameters must match reality! | |

| /* [Hidden] */ | |

| ThreadThick = 0.25; | |

| ThreadWidth = 0.40; | |

| HoleWindage = 0.2; | |

| Protrusion = 0.1; // make holes end cleanly | |

| inch = 25.4; | |

| function IntegerMultiple(Size,Unit) = Unit * ceil(Size / Unit); | |

| //———- | |

| // Dimensions | |

| // Hose lies along X axis | |

| HoseTubeOD = 12.0; // water tube diameter | |

| HoseTubeOC = 12.5; // .. spacing | |

| HoseWebThick = 7.8; // center joining tubes | |

| Hose = [100,25.0,HoseTubeOD]; // X=very long, Y=overall width, Z=thickness | |

| HoseSides = 12*4; | |

| PlugLength = 25.0; // plugs in hose channels | |

| PlateThick = 5.0; // end block thickness | |

| WallThick = 2.0; // overall minimum thickness | |

| Kerf = 0.75; // cut through middle to apply compression | |

| ID = 0; | |

| OD = 1; | |

| LENGTH = 2; | |

| // 8-32 stainless screws | |

| Screw = [4.1,8.0,3.0]; // OD = head LENGTH = head thickness | |

| Washer = [4.4,9.5,1.0]; | |

| Nut = [4.1,9.7,6.0]; | |

| CornerRadius = Washer[OD]/2; | |

| ScrewOC = Hose.y + Washer[OD]; | |

| echo(str("Screw OC: ",ScrewOC)); | |

| BlockOAL = [PlugLength + PlateThick,ScrewOC + Washer[OD],2*WallThick + Hose.z]; // overall splice block size | |

| echo(str("Block: ",BlockOAL)); | |

| //———————- | |

| // Useful routines | |

| module PolyCyl(Dia,Height,ForceSides=0) { // based on nophead's polyholes | |

| Sides = (ForceSides != 0) ? ForceSides : (ceil(Dia) + 2); | |

| FixDia = Dia / cos(180/Sides); | |

| cylinder(d=(FixDia + HoleWindage),h=Height,$fn=Sides); | |

| } | |

| // Hose shape | |

| module HoseProfile() { | |

| rotate([0,-90,0]) | |

| translate([0,0,-Hose.x/2]) | |

| linear_extrude(height=Hose.x,convexity=4) | |

| union() { | |

| for (j=[-1,1]) // outer channels | |

| translate([0,j*HoseTubeOC/2]) | |

| circle(d=HoseTubeOD,$fn=HoseSides); | |

| translate([0,0]) | |

| square([HoseWebThick,HoseTubeOC],center=true); | |

| } | |

| } | |

| // Outside shape of splice Block | |

| // Z centered on hose rim circles, not overall thickness through center ridge | |

| module SpliceBlock() { | |

| difference() { | |

| hull() | |

| for (i=[-1,1], j=[-1,1]) // rounded block | |

| translate([i*(BlockOAL.x/2 – CornerRadius),j*(BlockOAL.y/2 – CornerRadius),-BlockOAL.z/2]) | |

| cylinder(r=CornerRadius,h=BlockOAL.z,$fn=4*8); | |

| for (j=[-1,1]) // screw holes | |

| translate([0, | |

| j*ScrewOC/2, | |

| -(BlockOAL.z/2 + Protrusion)]) | |

| PolyCyl(Screw[ID],BlockOAL.z + 2*Protrusion,6); | |

| cube([2*BlockOAL.x,2*BlockOAL.y,Kerf],center=true); // slice through center | |

| } | |

| } | |

| // Splice block less hose | |

| module ShapedBlock() { | |

| difference() { | |

| SpliceBlock(); | |

| translate([(-Hose.x/2) + (BlockOAL.x/2) – PlateThick,0,0]) | |

| HoseProfile(); | |

| } | |

| } | |

| //———- | |

| // Build them | |

| if (Layout == "Hose") | |

| HoseProfile(); | |

| if (Layout == "Block") | |

| SpliceBlock(); | |

| if (Layout == "Show") { | |

| ShapedBlock(); | |

| translate([(-Hose.x/2) + (BlockOAL.x/2) – PlateThick,0,0]) | |

| color("Green",0.25) | |

| HoseProfile(); | |

| } | |

| if (Layout == "Build") { | |

| SliceOffset = 0; | |

| intersection() { | |

| translate([SliceOffset,0,BlockOAL.z/4]) | |

| cube([4*BlockOAL.x,4*BlockOAL.y,BlockOAL.z/2],center=true); | |

| union() { | |

| translate([0,0.6*BlockOAL.y,BlockOAL.z/2]) | |

| ShapedBlock(); | |

| translate([0,-0.6*BlockOAL.y,BlockOAL.z/2]) | |

| rotate([0,180,0]) | |

| ShapedBlock(); | |

| } | |

| } | |

| } |

The original doodle, with dimensions vaguely related to the final model:

There is, as far as I can tell, no standardization of dimensions or shapes across manufacturers, apart from the threaded hose fittings.