|

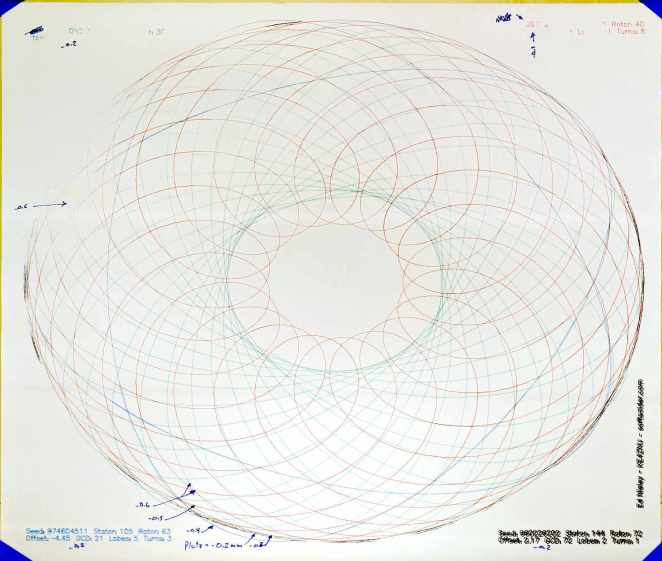

// Spirograph simulator for MPCNC used as plotter |

|

// Ed Nisley KE4ZNU – 2017-12-23 |

|

|

|

// Spirograph equations: |

|

// https://en.wikipedia.org/wiki/Spirograph |

|

// Loosely based on GCMC cycloids.gcmc demo: |

|

// https://gitlab.com/gcmc/gcmc/tree/master/example/cycloids.gcmc |

|

|

|

// Required command line parameters: |

|

|

|

// -D Pen=n pen selection for tool change and legend position |

|

// -D PaperSize=[x,y] overall sheet size: [17in,11in] |

|

// -D PRNG_Seed=i non-zero random number seed |

|

|

|

include("tracepath.inc.gcmc"); |

|

include("engrave.inc.gcmc"); |

|

|

|

//—– |

|

// Greatest Common Divisor |

|

// https://en.wikipedia.org/wiki/Greatest_common_divisor#Using_Euclid's_algorithm |

|

// Inputs = integers without units |

|

|

|

function gcd(a,b) { |

|

local d=0; |

|

|

|

if (!isnone(a) || isfloat(a) || !isnone(b) || isfloat(b)) { |

|

warning("Values must be dimensionless integers"); |

|

} |

|

|

|

while (!((a | b) & 1)) { // remove and tally common factors of two |

|

a >>= 1; |

|

b >>= 1; |

|

d++; |

|

} |

|

|

|

while (a != b) { |

|

if (!(a & 1)) {a >>= 1;} // discard non-common factor of 2 |

|

elif (!(b & 1)) {b >>= 1;} // … likewise |

|

elif (a > b) {a = (a – b) >> 1;} // gcd(a,b) also divides a-b |

|

else {b = (b – a) >> 1;} // … likewise |

|

} |

|

|

|

local GCD = a*(1 << d); // form gcd |

|

|

|

// message("GCD: ",GCD); |

|

return GCD; |

|

|

|

} |

|

|

|

//—– |

|

// Max and min functions |

|

|

|

function max(x,y) { |

|

return (x > y) ? x : y; |

|

} |

|

|

|

function min(x,y) { |

|

return (x < y) ? x : y; |

|

} |

|

|

|

//—– |

|

// Pseudo-random number generator |

|

// Based on xorshift: |

|

// https://en.wikipedia.org/wiki/Xorshift |

|

// http://www.jstatsoft.org/v08/i14/paper |

|

// Requires initial state from calling script |

|

// -D "PRNG_Seed=$(date +%N)" |

|

|

|

function XORshift() { |

|

|

|

local x = PRNG_State; |

|

|

|

x ^= x << 13; |

|

x ^= x >> 17; |

|

x ^= x << 5; |

|

|

|

PRNG_State = x; |

|

return x; |

|

} |

|

|

|

//—– |

|

// Spirograph tooth counts mooched from: |

|

// http://nathanfriend.io/inspirograph/ |

|

// Stators has both inside and outside counts, because we're not fussy |

|

|

|

Stators = [96, 105, 144, 150]; |

|

Rotors = [24, 30, 32, 36, 40, 45, 48, 50, 52, 56, 60, 63, 64, 72, 75, 80, 84]; |

|

|

|

//—– |

|

// Start drawing things |

|

// Set these variables from command line |

|

|

|

comment("PRNG seed: ",PRNG_Seed); |

|

|

|

PRNG_State = PRNG_Seed; |

|

|

|

// Define some useful constants |

|

|

|

AngleStep = 2.0deg; |

|

|

|

Margins = [0.5in,0.5in] * 2; |

|

|

|

comment("Paper size: ",PaperSize); |

|

|

|

PlotSize = PaperSize – Margins; |

|

comment("PlotSize: ",PlotSize); |

|

|

|

//—– |

|

// Set up gearing |

|

|

|

s = (XORshift() & 0xffff) % count(Stators); |

|

StatorTeeth = Stators[s]; |

|

comment("Stator ",s,": ",StatorTeeth); |

|

|

|

r = (XORshift() & 0xffff) % count(Rotors); |

|

RotorTeeth = Rotors[r]; |

|

comment("Rotor ",r,": ",RotorTeeth); |

|

|

|

GCD = gcd(StatorTeeth,RotorTeeth); // reduce teeth to ratio of least integers |

|

comment("GCD: ",GCD); |

|

StatorN = StatorTeeth / GCD; |

|

RotorM = RotorTeeth / GCD; |

|

|

|

L = to_float((XORshift() & 0x3ff) – 512) / 100.0; // normalized pen offset in rotor |

|

comment("Offset: ", L); |

|

|

|

sgn = sign((XORshift() & 0xff) – 128); |

|

K = sgn*to_float(RotorM) / to_float(StatorN); // normalized rotor dia |

|

comment("Dia ratio: ",K); |

|

|

|

Lobes = StatorN; // having removed all common factors |

|

Turns = RotorM; |

|

|

|

comment("Lobes: ", Lobes); |

|

comment("Turns: ", Turns); |

|

|

|

//—– |

|

// Crank out a list of points in normalized coordinates |

|

|

|

Path = {}; |

|

Xmax = 0.0; |

|

Xmin = 0.0; |

|

Ymax = 0.0; |

|

Ymin = 0.0; |

|

|

|

for (a=0.0deg ; a <= Turns*360deg ; a += AngleStep) { |

|

x = (1 – K)*cos(a) + L*K*cos(a*(1 – K)/K); |

|

if (x > Xmax) {Xmax = x;} |

|

elif (x < Xmin) {Xmin = x;} |

|

|

|

y = (1 – K)*sin(a) – L*K*sin(a*(1 – K)/K); |

|

if (y > Ymax) {Ymax = y;} |

|

elif (y < Ymin) {Ymin = y;} |

|

|

|

Path += {[x,y]}; |

|

} |

|

|

|

//message("Max X: ", Xmax, " Y: ", Ymax); |

|

//message("Min X: ", Xmin, " Y: ", Ymin); // min will always be negative |

|

|

|

Xmax = max(Xmax,-Xmin); // odd lobes can cause min != max |

|

Ymax = max(Ymax,-Ymin); // … need really truly absolute maximum |

|

|

|

//—– |

|

// Scale points to actual plot size |

|

|

|

PlotScale = [PlotSize.x / (2*Xmax), PlotSize.y / (2*Ymax)]; |

|

comment("Plot scale: ", PlotScale); |

|

|

|

Points = scale(Path,PlotScale); // fill page, origin at center |

|

|

|

//—– |

|

// Set up pen |

|

|

|

if (Pen > 0) { |

|

comment("Tool change: ",Pen); |

|

toolchange(Pen); |

|

} |

|

|

|

//—– |

|

// Plot the curve |

|

|

|

feedrate(3000.0mm); |

|

|

|

safe_z = 1.0mm; |

|

plot_z = -1.0mm; |

|

|

|

tracepath(Points, plot_z); |

|

|

|

//—– |

|

// Put legend in proper location |

|

|

|

feedrate(500mm); |

|

TextSize = [3.0mm,3.0mm]; |

|

TextLeading = 1.5; // line spacing as multiple of nominal text height |

|

MaxPen = 4; |

|

|

|

line1 = typeset("Seed: " + PRNG_Seed + " Stator: " + StatorTeeth + " Rotor: " + RotorTeeth,FONT_HSANS_1); |

|

line2 = typeset("Offset: " + L + " GCD: " + GCD + " Lobes: " + Lobes + " Turns: " + Turns,FONT_HSANS_1); |

|

|

|

maxlength = TextSize.x * max(line1[-1].x,line2[-1].x); |

|

|

|

textpath = line1 + (line2 – [-, TextLeading, -]); // undef – n -> undef to preserve coordinates |

|

|

|

if (Pen == 1 || Pen > MaxPen ) { // catch and fix obviously bogus pen selections |

|

textorg = [PlotSize.x/2 – maxlength,-(PlotSize.y/2 – TextLeading*TextSize.y)]; |

|

} |

|

elif (Pen == 2) { |

|

textorg = [-PlotSize.x/2,-(PlotSize.y/2 – TextLeading*TextSize.y)]; |

|

} |

|

elif (Pen == 3) { |

|

textorg = [PlotSize.x/2 – maxlength, PlotSize.y/2 – TextSize.y]; |

|

} |

|

elif (Pen == 4) { |

|

textorg = [-PlotSize.x/2, PlotSize.y/2 – TextSize.y]; |

|

} |

|

else { |

|

Pen = 0; // squelch truly bogus pens |

|

textorg = [0mm,0mm]; // just to define it |

|

} |

|

|

|

if (Pen) { // Pen = 0 suppresses legend |

|

placepath = scale(textpath,TextSize) + textorg; |

|

comment("Legend begins"); |

|

engrave(placepath,safe_z,plot_z); |

|

} |

|

|

|

if (Pen == 1) { // add attribution along right margin |

|

attrpath = typeset("Ed Nisley – KE4ZNU – softsolder.com",FONT_HSANS_1); |

|

attrpath = rotate_xy(attrpath,90deg); |

|

attrorg = [PlotSize.x/2,5*TextLeading*TextSize.y – PlotSize.y/2]; |

|

placepath = scale(attrpath,TextSize) + attrorg; |

|

comment("Attribution begins"); |

|

engrave(placepath,safe_z,plot_z); |

|

} |

|

|

|

goto([-,-,25.0mm]); |