|

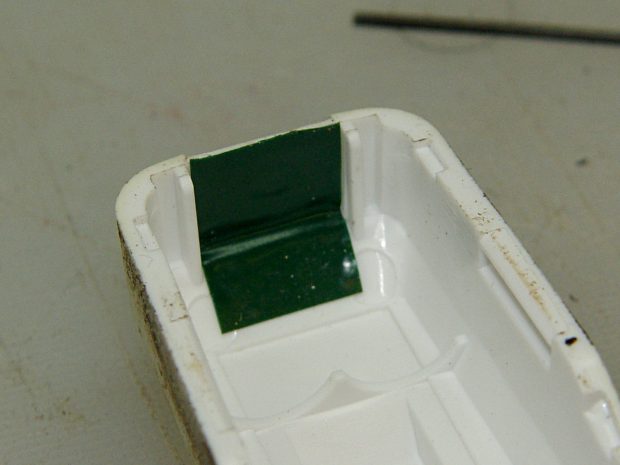

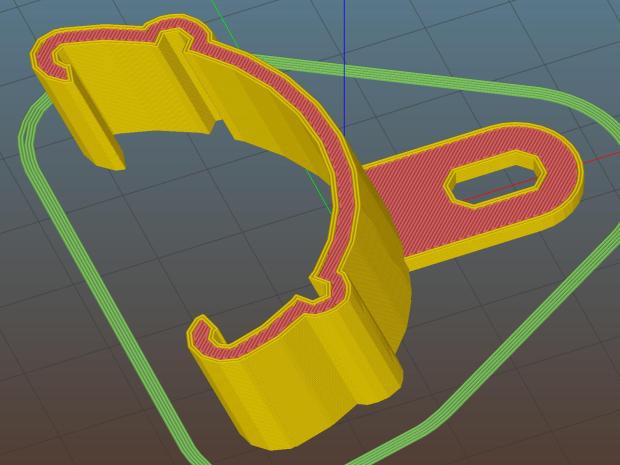

// Tour Easy front fender clip |

|

// Ed Nisley KE4ZNU April 2017 |

|

|

|

Layout = "Clip"; // Build Profile Ferrule Clip |

|

|

|

//- Extrusion parameters must match reality! |

|

|

|

ThreadThick = 0.25; |

|

ThreadWidth = 0.40; |

|

|

|

HoleWindage = 0.2; |

|

|

|

Protrusion = 0.1; // make holes end cleanly |

|

|

|

inch = 25.4; |

|

|

|

function IntegerMultiple(Size,Unit) = Unit * ceil(Size / Unit); |

|

|

|

//———————- |

|

// Dimensions |

|

|

|

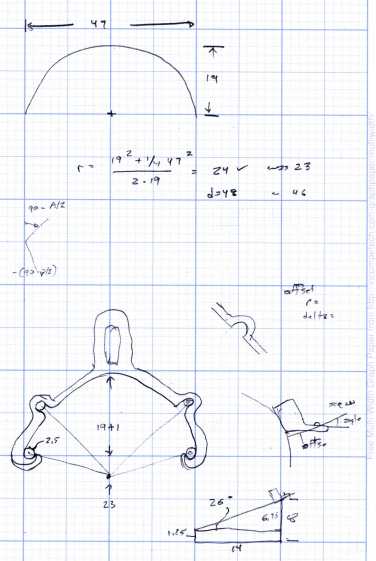

// special case: fender is exactly half a circle! |

|

|

|

FenderC = 51.0; // fender outside width = chord |

|

FenderM = 21.0; // height of chord |

|

|

|

FenderR = (pow(FenderM,2) + pow(FenderC,2)/4) / (2 * FenderM); // radius |

|

echo(str("Fender radius: ", FenderR)); |

|

FenderD = 2*FenderR; |

|

|

|

FenderA = 2 * asin(FenderC / (2*FenderR)); |

|

echo(str(" … arc: ",FenderA," deg")); |

|

|

|

FenderThick = 2.5; // fender thickness, assume dia of edge |

|

|

|

ClipHeight = 15.0; // top to bottom, ignoring rakish tilt |

|

ClipThick = 3.0; // thickness of clip around fender |

|

ClipD = FenderD; // ID of clip against |

|

ClipSides = 4 * 8; // polygon sides around clip circle |

|

|

|

BendReliefD = 2.5; // bend arch diameter |

|

BendReliefA = 2/3 * FenderA/2; // … angle from dead ahead |

|

BendReliefCut = 1.0; // factor to thin outside of bend |

|

|

|

ID = 0; |

|

OD = 1; |

|

LENGTH = 2; |

|

|

|

StayDia = 3.3; // fender stay rod diameter |

|

StayOffset = 23.0; // stay-to-fender distance |

|

StayAngle = -5; // angle from stay to fender |

|

|

|

FerruleSides = 2*4; |

|

Ferrule = [StayDia,3*FenderThick/cos(180/FerruleSides),6*StayDia + StayOffset]; // ID = stay rod OD |

|

|

|

//———————- |

|

// Useful routines |

|

|

|

module PolyCyl(Dia,Height,ForceSides=0) { // based on nophead's polyholes |

|

|

|

Sides = (ForceSides != 0) ? ForceSides : (ceil(Dia) + 2); |

|

|

|

FixDia = Dia / cos(180/Sides); |

|

|

|

cylinder(r=(FixDia + HoleWindage)/2, |

|

h=Height, |

|

$fn=Sides); |

|

} |

|

|

|

//———————- |

|

// Clip profile around fender |

|

// Centered on fender arc |

|

|

|

module Profile(HeightScale = 1) { |

|

|

|

linear_extrude(height=HeightScale*ClipHeight,convexity=5) { |

|

difference() { |

|

offset(r=ClipThick) // outside of clip |

|

union() { |

|

circle(d=ClipD,$fn=ClipSides); |

|

for (i=[-1,1]) |

|

rotate(i*BendReliefA) { |

|

translate([ClipD/2 + BendReliefD/2,0,0]) |

|

circle(d=BendReliefD,$fn=6); |

|

} |

|

} |

|

union() { // inside of clip |

|

circle(d=ClipD,$fn=ClipSides); |

|

for (i=[-1,1]) |

|

rotate(i*BendReliefA) { |

|

translate([ClipD/2 + BendReliefCut*BendReliefD/2,0,0]) |

|

circle(d=BendReliefD/cos(180/6),$fn=6); |

|

translate([ClipD/2,0,0]) |

|

square([BendReliefCut*BendReliefD,BendReliefD],center=true); |

|

} |

|

} |

|

translate([(FenderR – FenderM – FenderD/2),0]) // trim ends |

|

square([FenderD,2*FenderD],center=true); |

|

} |

|

|

|

for (a=[-1,1]) // hooks around fender |

|

rotate(a*(FenderA/2)) |

|

translate([FenderR – FenderThick/2,0]) { |

|

difference() { |

|

rotate(1*180/12) |

|

circle(d=FenderThick + 2*ClipThick,$fn=12); |

|

rotate(1*180/8) |

|

circle(d=FenderThick,$fn=8); |

|

rotate(a * -90) |

|

translate([0,-2*FenderThick,0]) |

|

square(4*FenderThick,center=false); |

|

} |

|

} |

|

} |

|

} |

|

|

|

|

|

//———————- |

|

// Ferrule body |

|

|

|

module FerruleBody() { |

|

|

|

translate([0,0,Ferrule[OD]/2 * cos(180/FerruleSides)]) |

|

rotate([0,-90,0]) rotate(180/FerruleSides) |

|

difference() { |

|

cylinder(d=Ferrule[OD],h=Ferrule[LENGTH],$fn=FerruleSides,center=false); |

|

translate([0,0,StayOffset + Protrusion]) |

|

PolyCyl(Ferrule[ID],Ferrule[LENGTH] – StayOffset + Protrusion,FerruleSides); |

|

} |

|

|

|

} |

|

|

|

//———————- |

|

// Generate entire clip at mounting angle |

|

|

|

module FenderClip() { |

|

|

|

union() { |

|

translate([FenderR,0,0]) |

|

difference() { // angle and trim clip |

|

rotate([0,StayAngle,0]) |

|

translate([-(FenderR + ClipThick),0,0]) |

|

Profile(2); // scale upward for trimming |

|

translate([0,0,-ClipHeight]) // trim bottom |

|

cube(2*[FenderD,FenderD,ClipHeight],center=true); |

|

translate([0,0,ClipHeight*cos(StayAngle)+ClipHeight]) // trim top |

|

cube(2*[FenderD,FenderD,ClipHeight],center=true); |

|

} |

|

for (j = [-1,1]) |

|

translate([Ferrule[OD]*sin(StayAngle),j*(FenderR – FenderThick + FenderThick/2),0]) |

|

FerruleBody(); |

|

} |

|

} |

|

|

|

//———————- |

|

// Build it |

|

|

|

|

|

if (Layout == "Profile") { |

|

Profile(); |

|

} |

|

|

|

if (Layout == "Ferrule") { |

|

FerruleBody(); |

|

} |

|

|

|

if (Layout == "Clip") { |

|

FenderClip(); |

|

} |

|

|

|

if (Layout == "Build") { |

|

FenderClip(); |

|

} |