Lacking a loading dock, I built a level unloading platform in the driveway:

The OMTech 60 W laser cutter arrived inside a generous supply of plywood obviously intended for practice cutting and engraving:

Knowing the crate wouldn’t fit through our “36 inch” basement door, we stripped the cutter down to the crate’s steel-framed baseplate:

I raised the cutter (using the foot-pad screws) enough to slide 3/4 inch planks under the casters so we could roll it over the lip of the crate base.

The specs say it’s 34 inches wide, but, not at all to our surprise, that’s just the cabinet. The hinges on the access hatches and the lid handle make it just over 35 inches wide, which we slowly and carefully verified would not fit through the 34 inch door opening:

Raising the lid to get the handle out of the way, then pushing gently inward on the sides, eased it through without damage to either the cabinet or the door frame:

Standing on the plank let me raise the outer end enough to roll it forward and lower the casters onto the planks inside the door.

It vents through a long-disused flue straight up the chimney:

The supplied aquarium pump circulates five gallons of distilled water to cool the laser tube. My simple test patterns so far haven’t dumped much heat into the water:

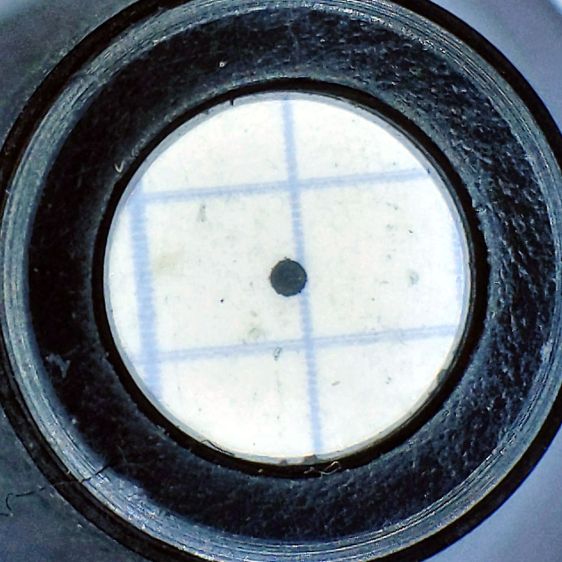

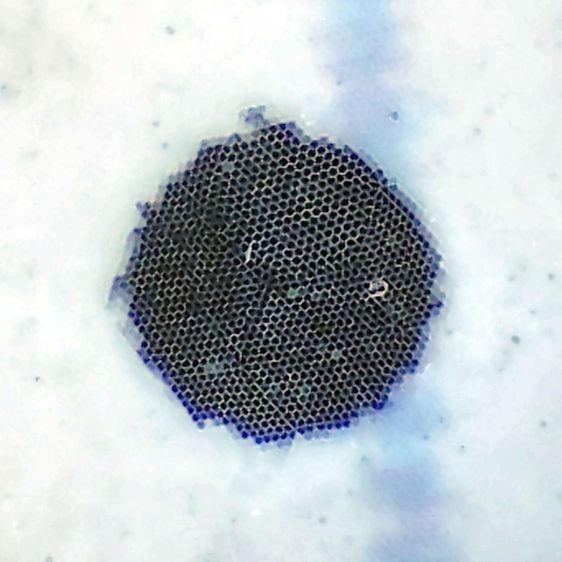

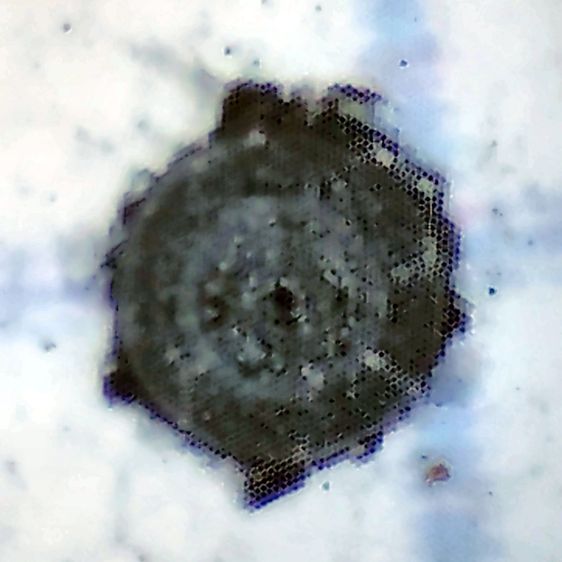

The doily on the left shows 9% power cuts right through paper. Dot Mode fires the laser every 0.25 mm (in this case) for a specified number of milliseconds to reduce the total energy; 3 ms produces dark dots, 1 ms is a pale brown, and 2 ms looks pretty good.

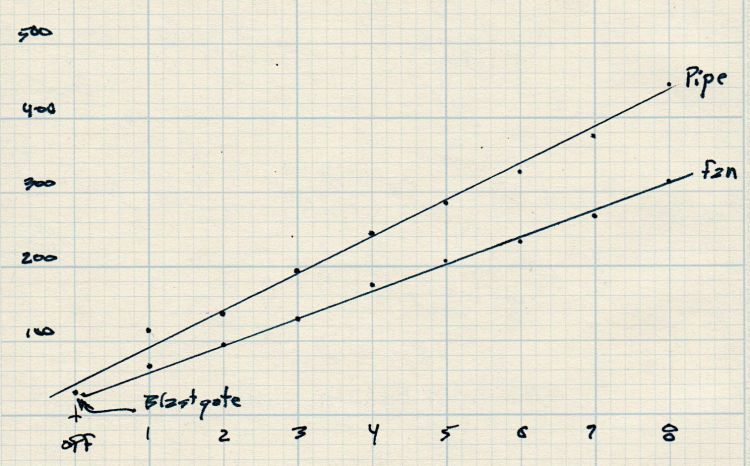

More tinkering is in order …