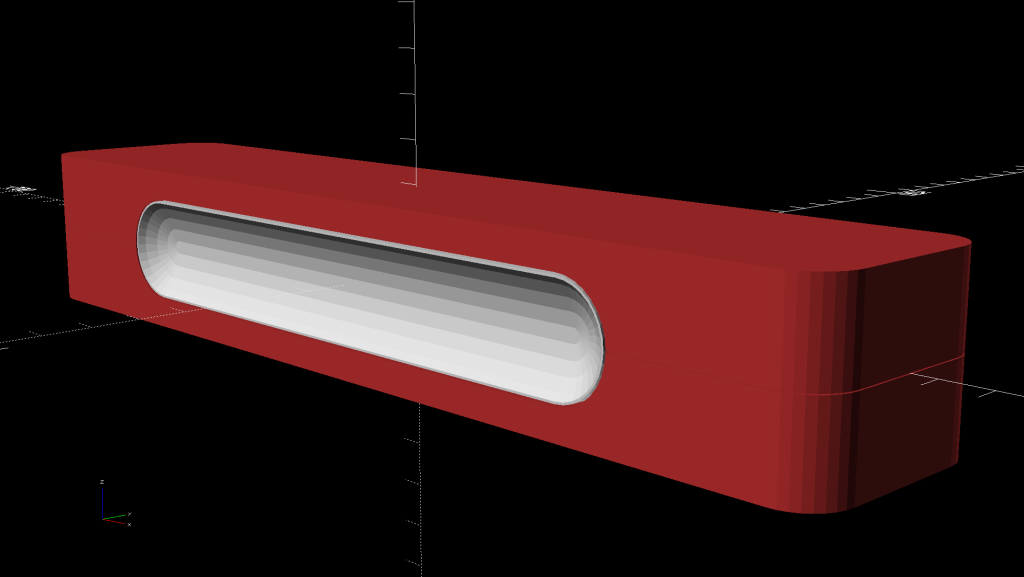

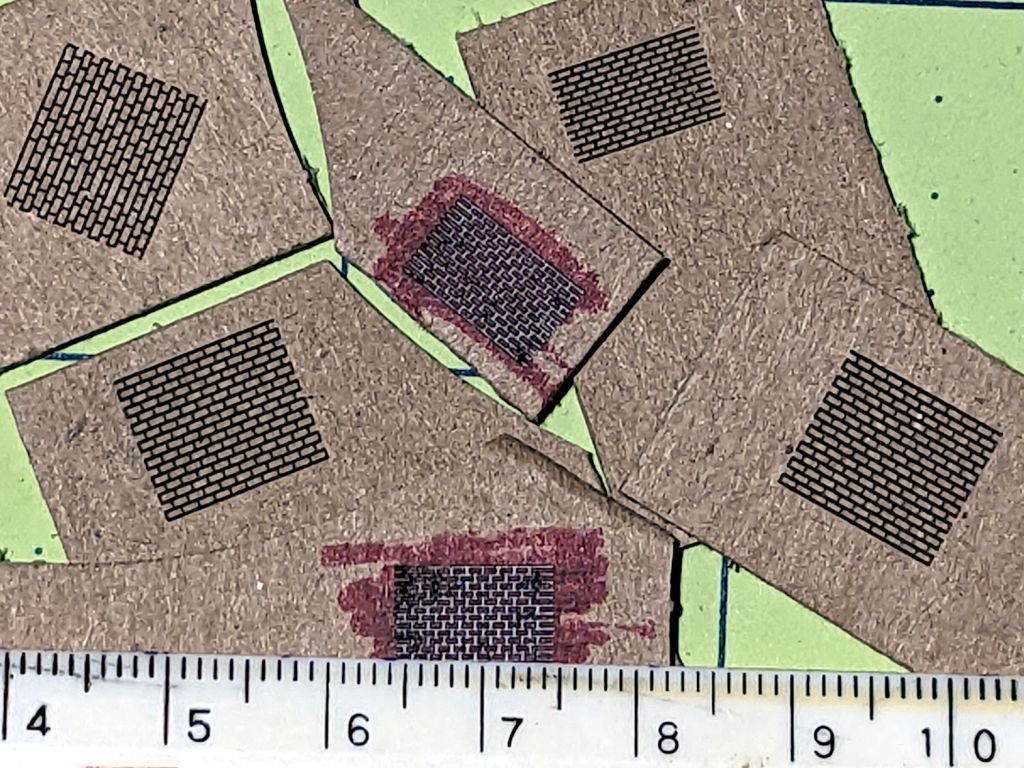

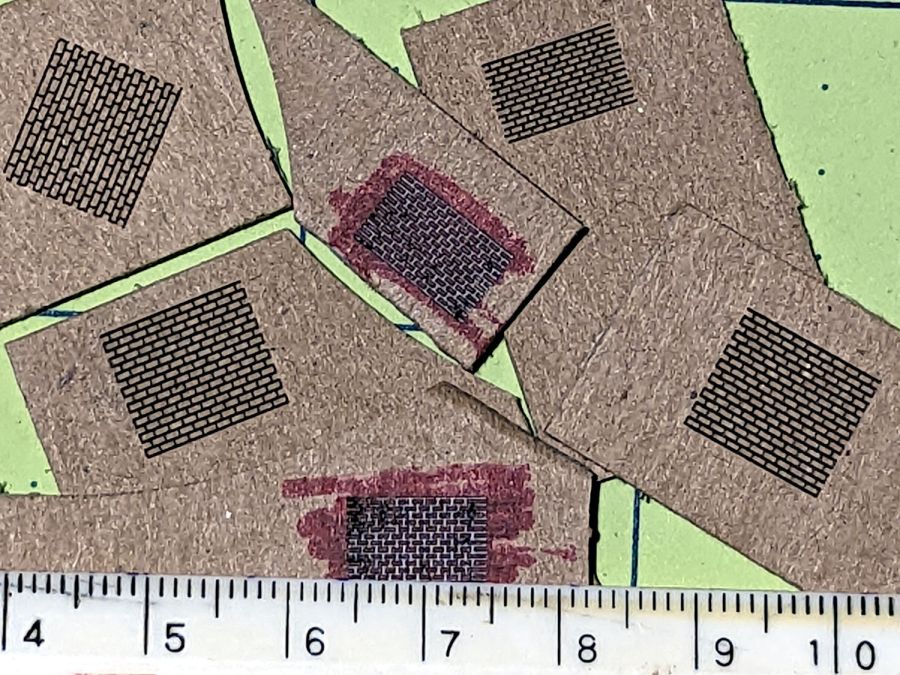

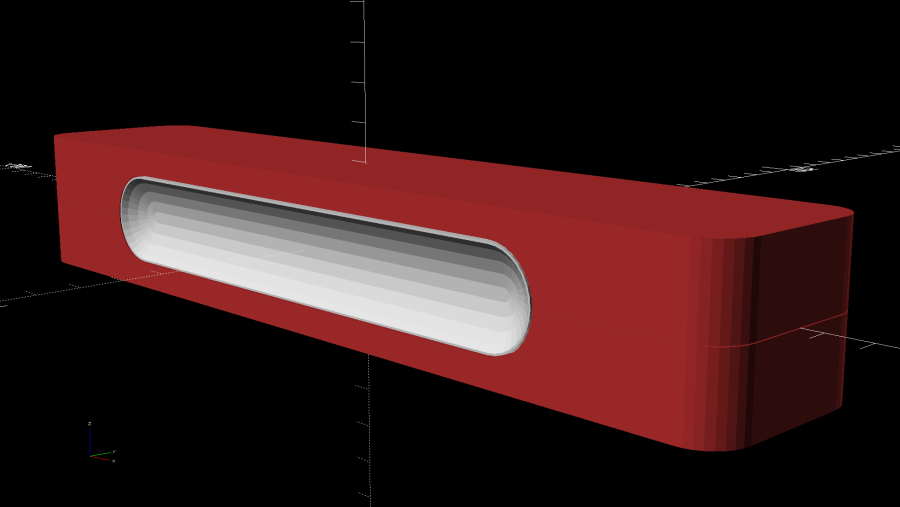

Separating the interior contour of the finger grip from its overall shape let me reduce the woodworking to a simple pocketing operation:

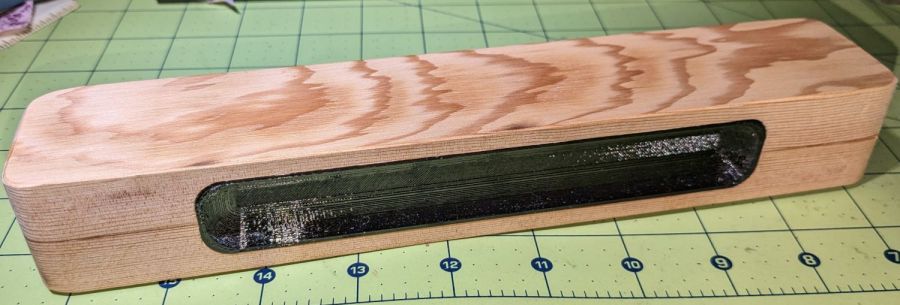

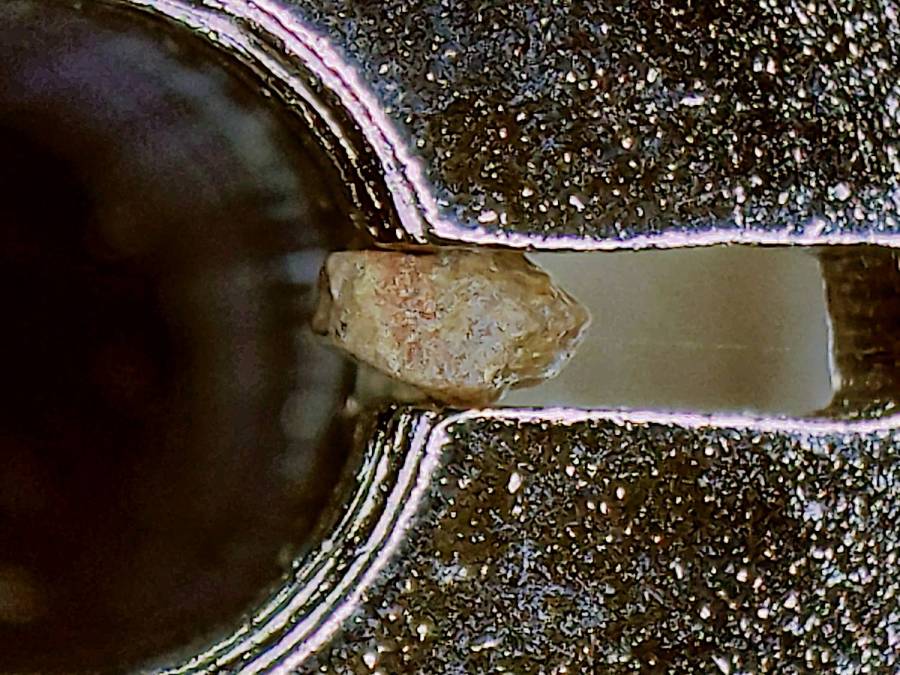

Start by aligning the finished block to put the joint between the pieces parallel to the X axis, then touch off at the center:

A pair of clamps screwed to the tooling plate act as fixtures to align the block when it’s flipped over to mill the other pocket.

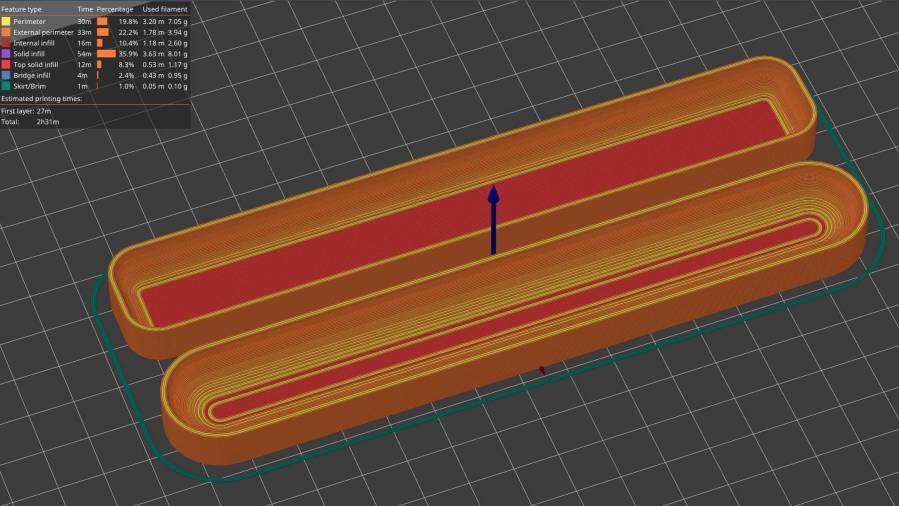

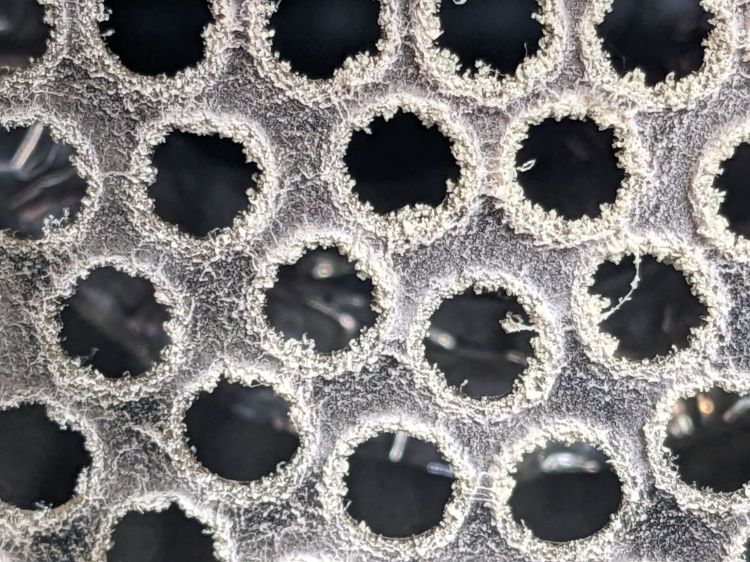

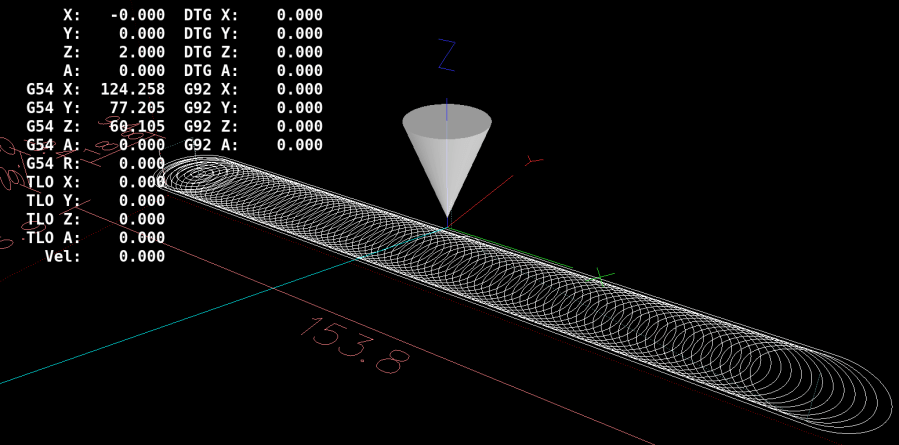

Just to see how it worked, I set up a GCMC program to produce a trochoidal milling pattern using the sample program:

Now, most folks would say the Sherline lacks enough speed and stiffness for trochoidal milling:

Aaaand I would agree with them: chugging along at 24 in/min = 600 mm/min doesn’t put the 10 k RPM spindle speed to good use. Fortunately, oak doesn’t require much in the way of machine stiffness and the trochoid path does ensure good chip clearance, so there’s that.

If I had to do a lot of trochoid milling, I’d tweak the GCMC sample code to short-cut the return path across the circle diameter, rather than air-cut the last half of every circumference.

The code starts by emptying a circular pocket so the trochoid path begins in clear air, rather than trenching into solid wood.

Eventually it finishes the pocket:

After the trochoid finishes, one climb-milling pass around the perimeter clears the little ripple between each trochoid orbit.

Flip it over, clamp it down, touch off the middle, and do it all again.

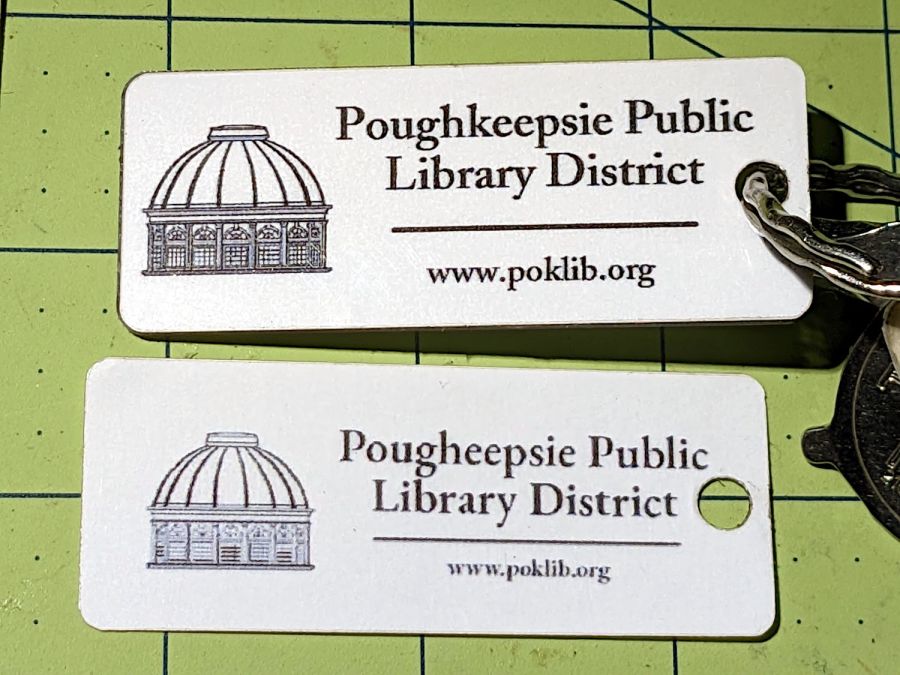

The next step is filling those pockets with a pair of comfy grips.

The GCMC source code as a GitHub Gist:

| // Ironing weight pocketing | |

| // Ed Nisley KE4ZNU – 2023-01 | |

| //—– | |

| // Library routines | |

| include("/opt/gcmc/example/cc_hole.inc.gcmc"); | |

| include("varcs.inc.gcmc"); | |

| include("tracepath_comp.inc.gcmc"); | |

| include("trochoidal.inc.gcmc"); | |

| /* | |

| include("tracepath.inc.gcmc"); | |

| include("engrave.inc.gcmc"); | |

| */ | |

| //—– | |

| // Useful constants | |

| SafeZ = 10.0mm; // above all obstructions | |

| TravelZ = 2.0mm; // within engraving / milling area | |

| BlockHome = [0.0mm,0.0mm,TravelZ]; // Origin on surface at center of pocket | |

| FALSE = 0; | |

| TRUE = !FALSE; | |

| //—– | |

| // Overall values | |

| Socket = [160.0mm,25.0mm,7.0mm]; // raw grip recess into block | |

| RoundEnds = TRUE; // TRUE for smooth rounded endcaps | |

| SocketRadius = RoundEnds ? Socket.y/2 : 10.0mm; | |

| comment("SocketRadius: ",SocketRadius); | |

| CutterDia = 6.32mm – 0.15; // actual cutter diameter – windage | |

| MillStep = 0.25 * CutterDia; // stepover in XY plane | |

| comment("CutterDia: ",CutterDia," MillStep: ",MillStep); | |

| MillClean = MillStep/2; | |

| PlungeSpeed = 150.0mm; // cutter Z plunge into work | |

| MillSpeed = 600.0mm; // XY speed | |

| if (CutterDia > SocketRadius) { | |

| error("Cutter too large for corner radius"); | |

| } | |

| CornerOC = head(Socket,2) – 2*[SocketRadius,SocketRadius]; | |

| comment("CornerOC: ",CornerOC); | |

| Corners = RoundEnds ? // rear left CCW around slot | |

| {-CornerOC/2, CornerOC/2} : | |

| {[-CornerOC.x,CornerOC.y]/2, [-CornerOC.x,-CornerOC.y]/2, [CornerOC.x,-CornerOC.y]/2, CornerOC/2}; | |

| comment("Corners: ", Corners); | |

| if (RoundEnds) { | |

| SlotPerimeter = {[0.0mm,Socket.y/2,-Socket.z]}; // entry point at center rear | |

| SlotPerimeter += {Corners[0] + [0.0mm,SocketRadius]}; | |

| SlotPerimeter += varc_ccw([-SocketRadius,-SocketRadius],SocketRadius) + SlotPerimeter[-1]; | |

| SlotPerimeter += varc_ccw([+SocketRadius,-SocketRadius],SocketRadius) + (Corners[0] + [-SocketRadius,0.0mm]); | |

| SlotPerimeter += {Corners[1] + [0.0mm,-SocketRadius]}; // across front | |

| SlotPerimeter += varc_ccw([+SocketRadius,+SocketRadius],SocketRadius) + SlotPerimeter[-1]; | |

| SlotPerimeter += varc_ccw([-SocketRadius,+SocketRadius],SocketRadius) + (Corners[1] + [+SocketRadius,0.0mm]); | |

| } | |

| else { | |

| SlotPerimeter = {[0.0mm,Socket.y/2,-Socket.z]}; // entry point at center rear | |

| SlotPerimeter += {Corners[0] + [0.0mm,SocketRadius]}; | |

| SlotPerimeter += varc_ccw([-SocketRadius,-SocketRadius],SocketRadius) + SlotPerimeter[-1]; | |

| SlotPerimeter += {Corners[1] + [-SocketRadius,0.0mm]}; | |

| SlotPerimeter += varc_ccw([+SocketRadius,-SocketRadius],SocketRadius) + SlotPerimeter[-1]; | |

| SlotPerimeter += {Corners[2] + [0.0mm,-SocketRadius]}; // across front | |

| SlotPerimeter += varc_ccw([SocketRadius,SocketRadius],SocketRadius) + SlotPerimeter[-1]; | |

| SlotPerimeter += {Corners[3] + [SocketRadius,0.0mm]}; | |

| SlotPerimeter += varc_ccw([-SocketRadius,SocketRadius],SocketRadius) + SlotPerimeter[-1]; | |

| } | |

| //— Begin cutting | |

| goto([-,-,TravelZ]); | |

| goto(BlockHome); | |

| if (!RoundEnds) { // clear corners outward of main pocket | |

| foreach(Corners; xy) { | |

| comment("Plunge corner at: ",xy); | |

| feedrate(PlungeSpeed); | |

| goto(xy); | |

| move([-,-,-Socket.z]); | |

| comment(" pocket"); | |

| feedrate(MillSpeed); | |

| cc_hole(xy,(SocketRadius – MillClean),CutterDia/2,MillStep,-Socket.z); | |

| goto([-,-,TravelZ]); | |

| comment(" done!"); | |

| } | |

| } | |

| comment("Open slot"); | |

| TrochRadius = (Socket.y – CutterDia)/2 – MillClean; | |

| TrochPath = {[-(Socket.x/2 – TrochRadius – CutterDia/2 – MillStep),TrochRadius], | |

| [ (Socket.x/2 – TrochRadius – CutterDia/2 – MillStep),TrochRadius]}; | |

| comment(" clear landing zone"); | |

| xy = [TrochPath[0].x,0.0mm]; | |

| feedrate(PlungeSpeed); | |

| goto(xy); | |

| move([-,-,-Socket.z]); | |

| feedrate(MillSpeed); | |

| cc_hole(xy,Socket.y/2 – MillClean,CutterDia/2,MillStep,-Socket.z); | |

| goto([-,-,TravelZ]); | |

| comment(" trochoid pocket milling"); | |

| feedrate(MillSpeed); | |

| trochoid_move(TrochPath[0],TrochPath[1], | |

| -Socket.z, TrochRadius, MillStep); | |

| goto([-,-,TravelZ]); | |

| comment("Clean slot perimeter"); | |

| feedrate(MillSpeed); | |

| goto([-,-,-Socket.z]); | |

| tracepath_comp(SlotPerimeter,CutterDia/2,TPC_CLOSED + TPC_LEFT + TPC_ARCIN + TPC_ARCOUT); | |

| goto([-,-,TravelZ]); | |

| goto(BlockHome); |

| #!/bin/bash | |

| # Ironing weight finger grip pocketing | |

| # Ed Nisley KE4ZNU – 2023-01 | |

| Flags='-P 4 –pedantic' # quote to avoid leading hyphen gotcha | |

| # Set these to match your file layout | |

| LibPath='/opt/gcmc/library' | |

| Prolog='prolog.gcmc' | |

| Epilog='epilog.gcmc' | |

| #—– | |

| gcmc $Flags \ | |

| –include "$LibPath" –prologue "$Prolog" –epilogue "$Epilog" \ | |

| "Ironing weight grip pocket.gcmc" > "Grip pocket.ngc" |