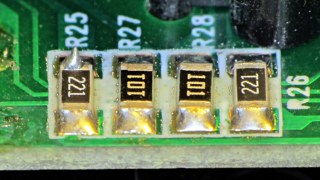

Mary prefers dim digits on the bedroom alarm clock, far below what the usual DIM switch setting provides. I’d slipped a two-stop neutral density filter in front of our old clock’s VFD tube, but the new one has nice green LED digits that ought to have a tweakable current-setting resistor behind the switch. Indeed, a bit of surgery revealed the switch & resistors:

It turns out that the 220 Ω resistors set the DIM current, with the 100 Ω resistors in parallel to set the BRIGHT current. Weirdly, the display operates in two halves: one resistor for the lower and middle segments, the other for the top segments. The resistor numbers give a hint of what the schematic might look like:

The current control isn’t all that good, because the brightness varies with the number of active segments. With 470 Ω resistors (yes, from that assortment) in place, the variation became much more obvious; the LEDs are operating far down on their exponential I-vs-V curve. We defined the result to be Good Enough for the purpose.

Four short screws hold the circuit board in place, but one of them arrived loosely held in a pre-stripped hole. I cut eight lengths of black Skirt filament, anointed them with solvent adhesive, dropped two apiece into each screw hole, and ran the screws back in place. I likely won’t be back in there, so it should be a lifetime fix:

Done!

As with all the trade names you remember from back in the Old Days, the present incarnation of “RCA” has nothing whatosever to do with the original Radio Corporation of America: