After fixing the X axis drive, the CNC-3018XL table moved properly again, so I measured its overall alignment:

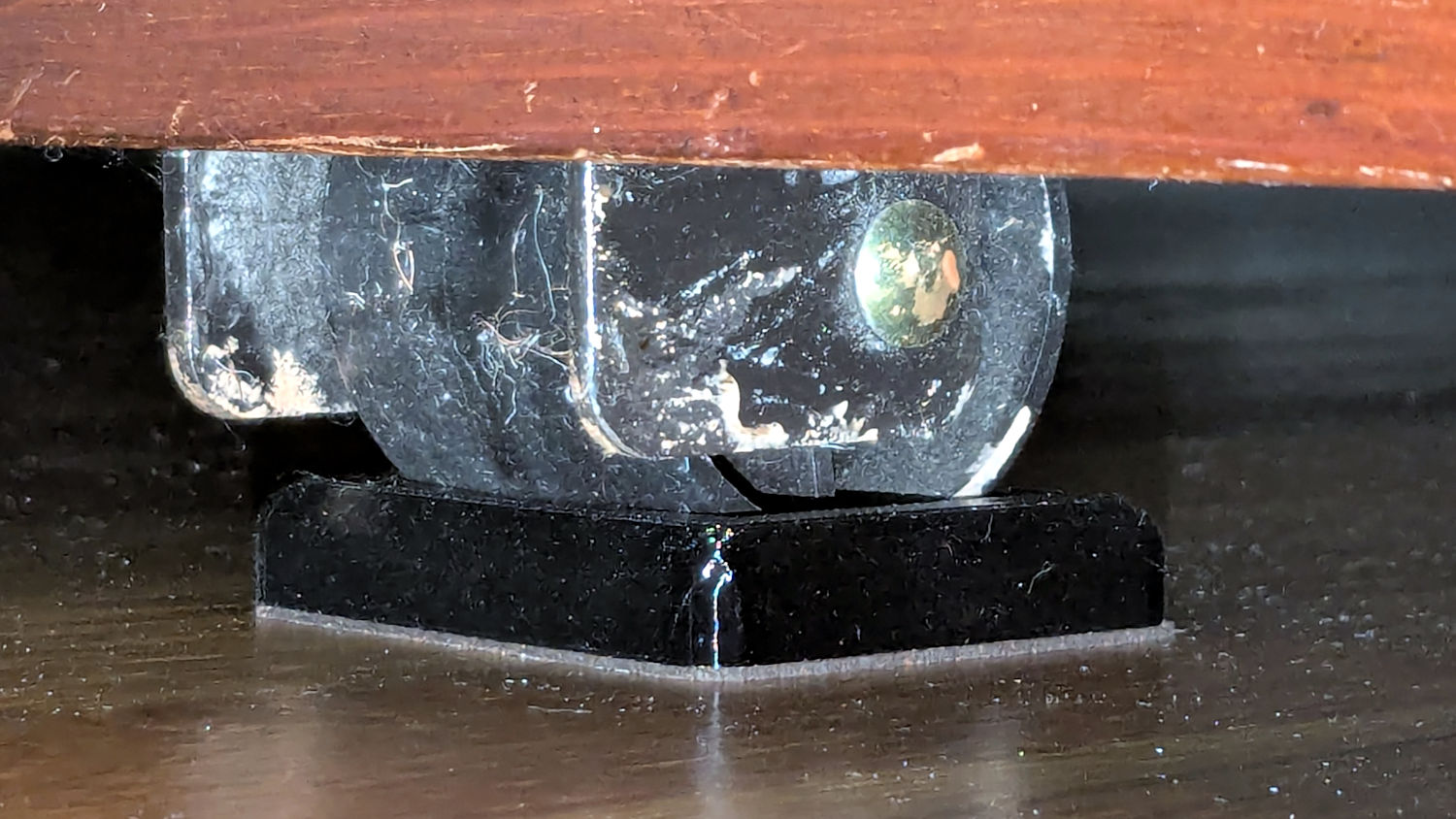

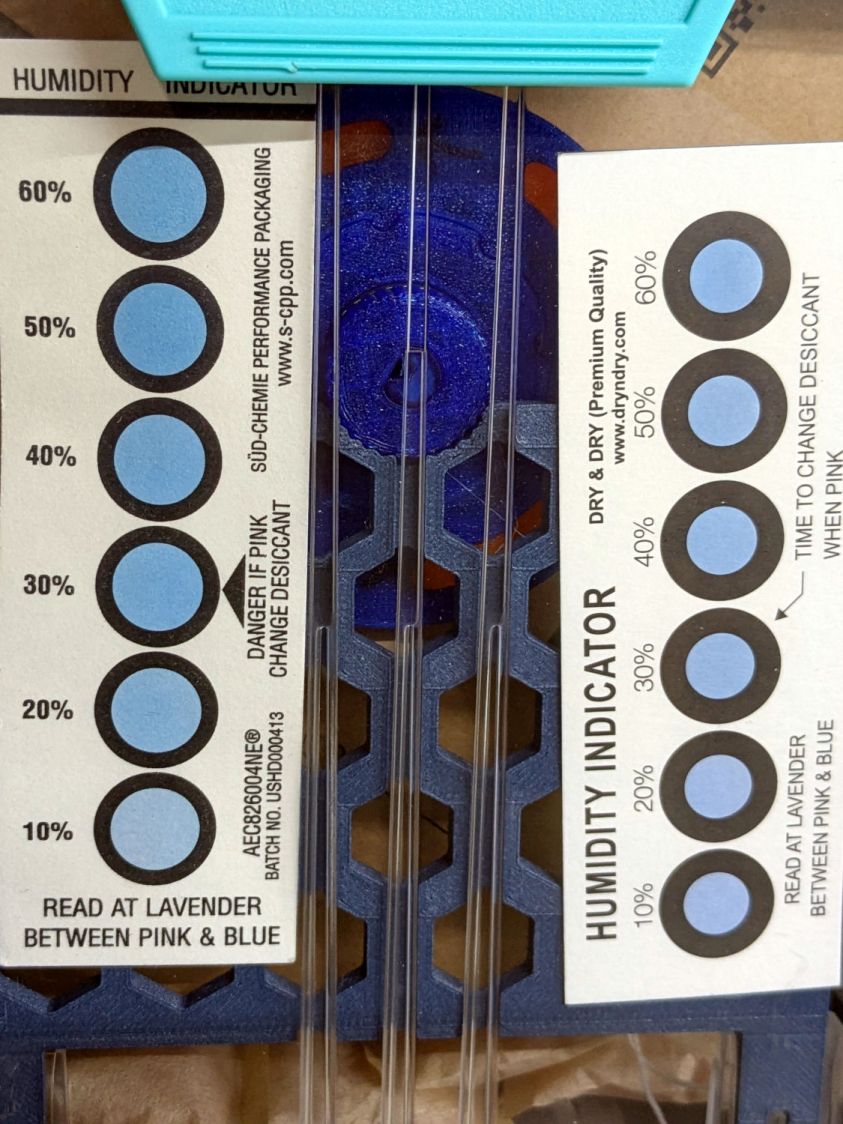

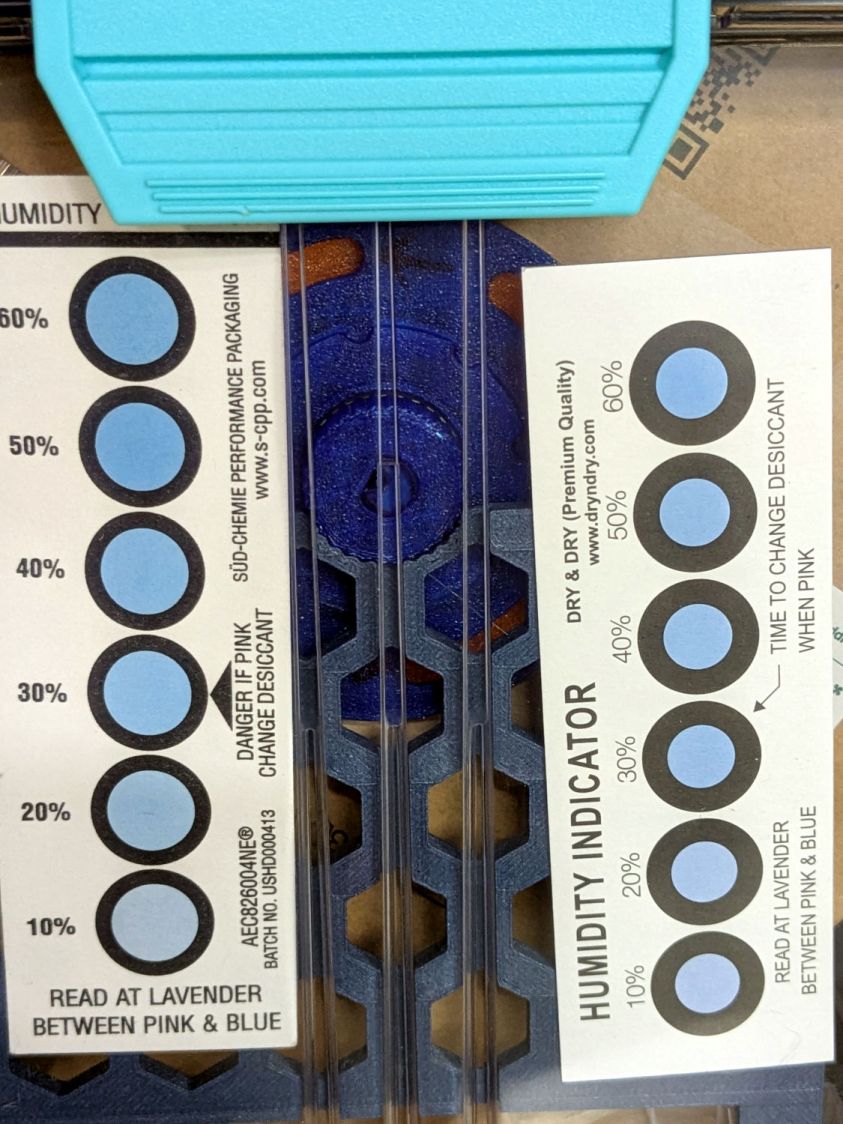

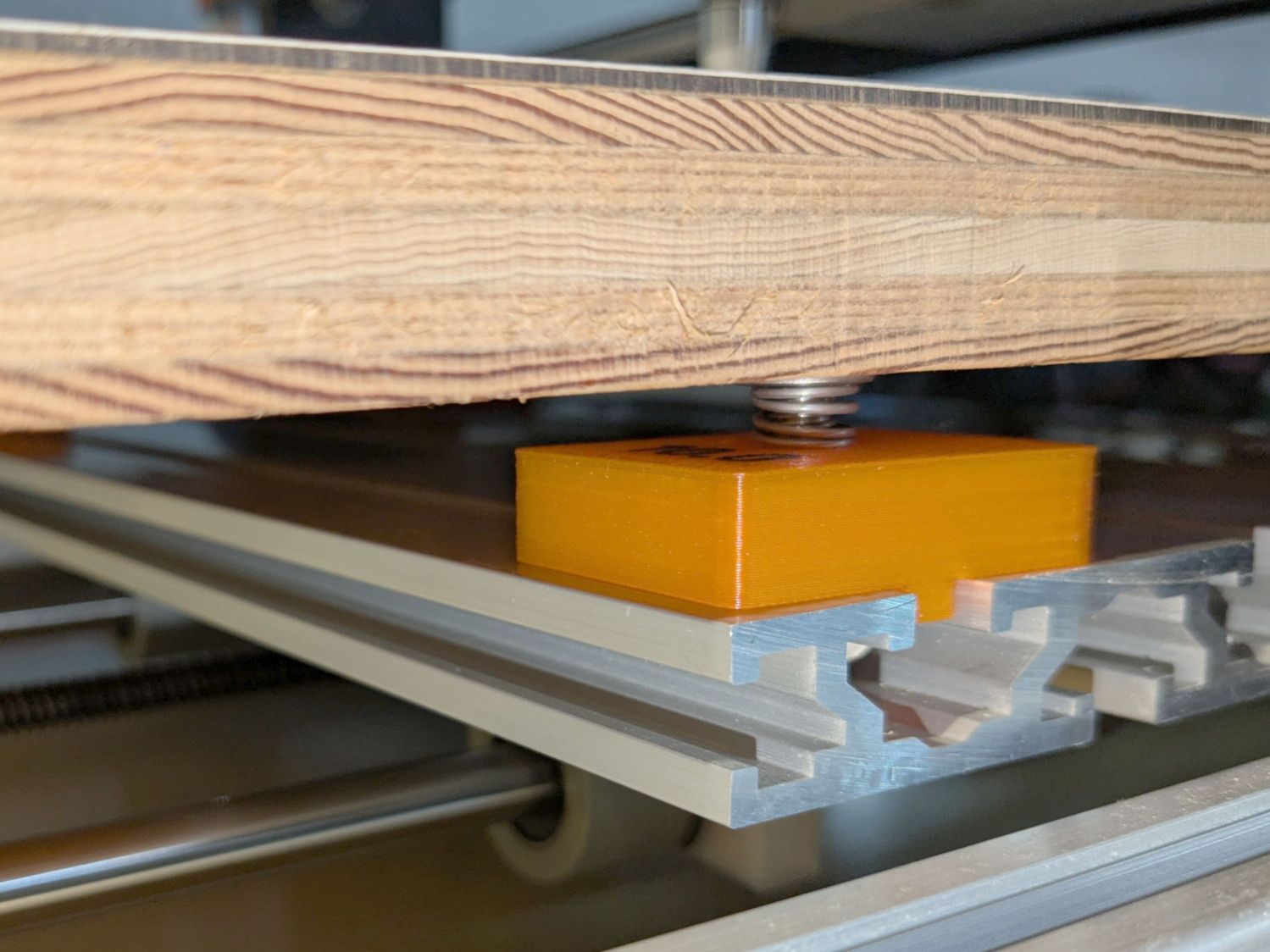

The +Y side (on the left in the photo, keeping in mind I’ve rotated the axes) turned out to be 0.7 mm too low, so I made a set of riser blocks to level the tabletop:

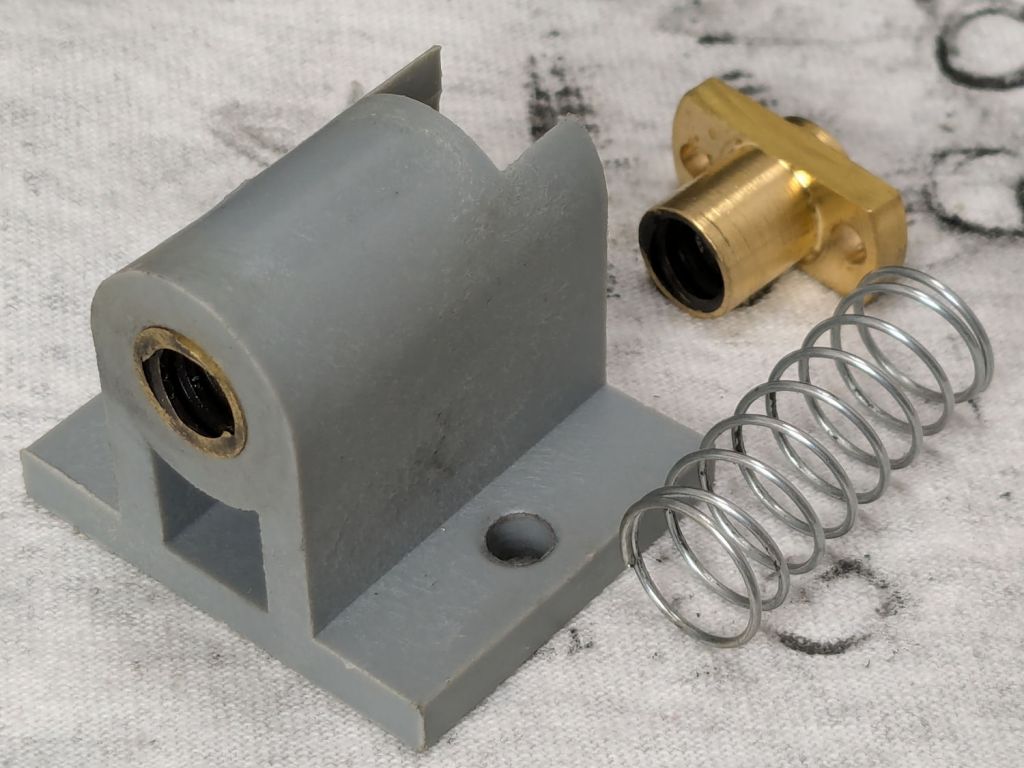

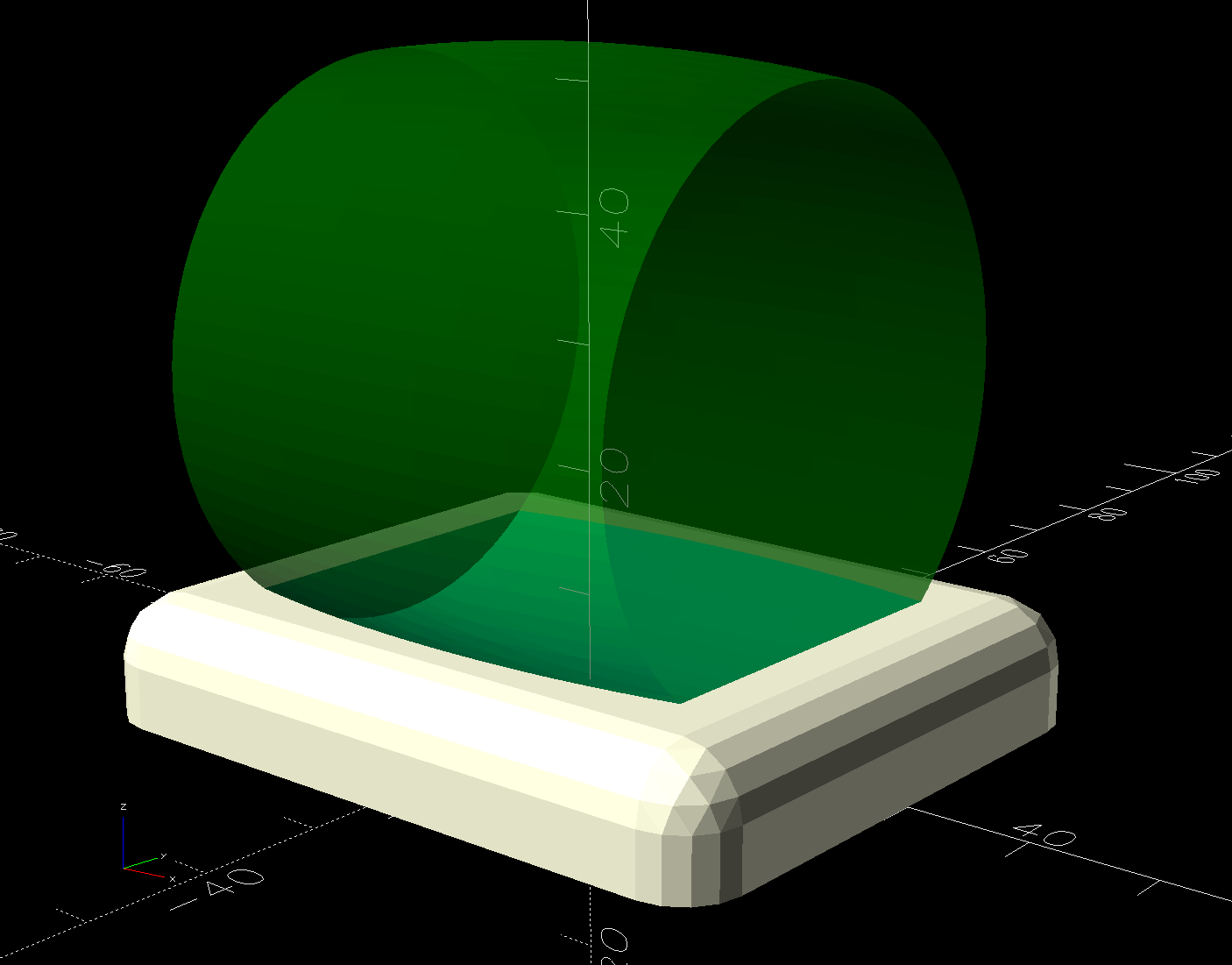

The 10 mm height would ram the tip of a Pilot pen about 10 mm below the tabletop surface, were it not for the spring-loaded pen holder:

The 0.7 mm difference in height levels the tabletop:

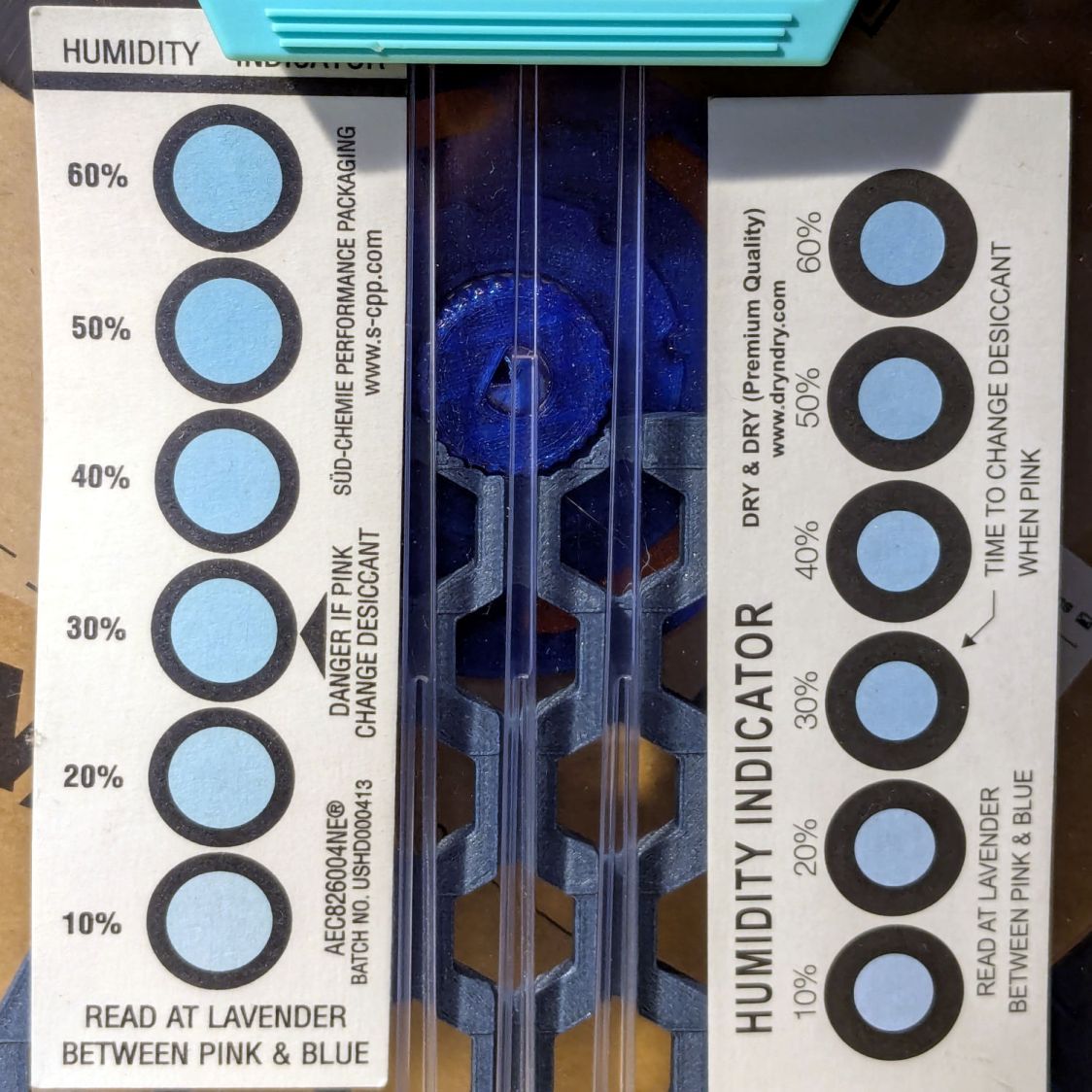

The OpenSCAD code produces an SVG outline I intended to use for a foam pad, but then I found a quartet of springs that worked even better:

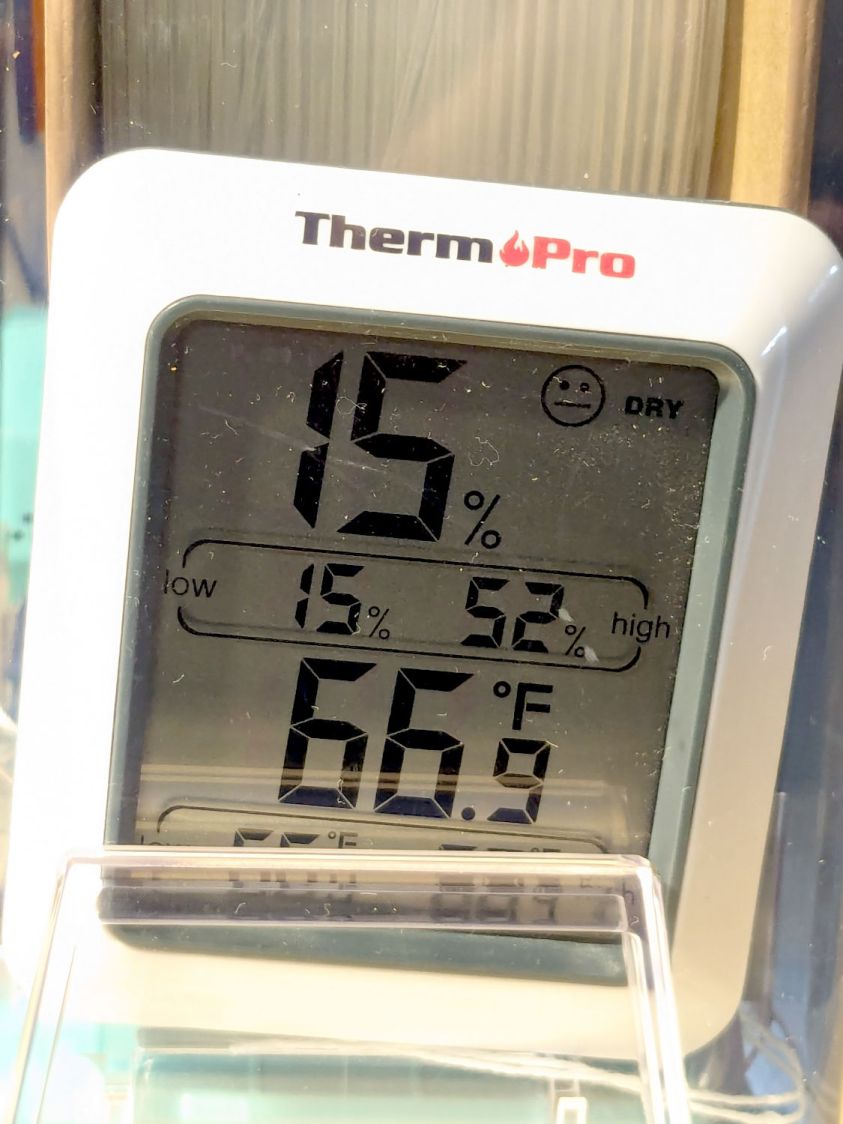

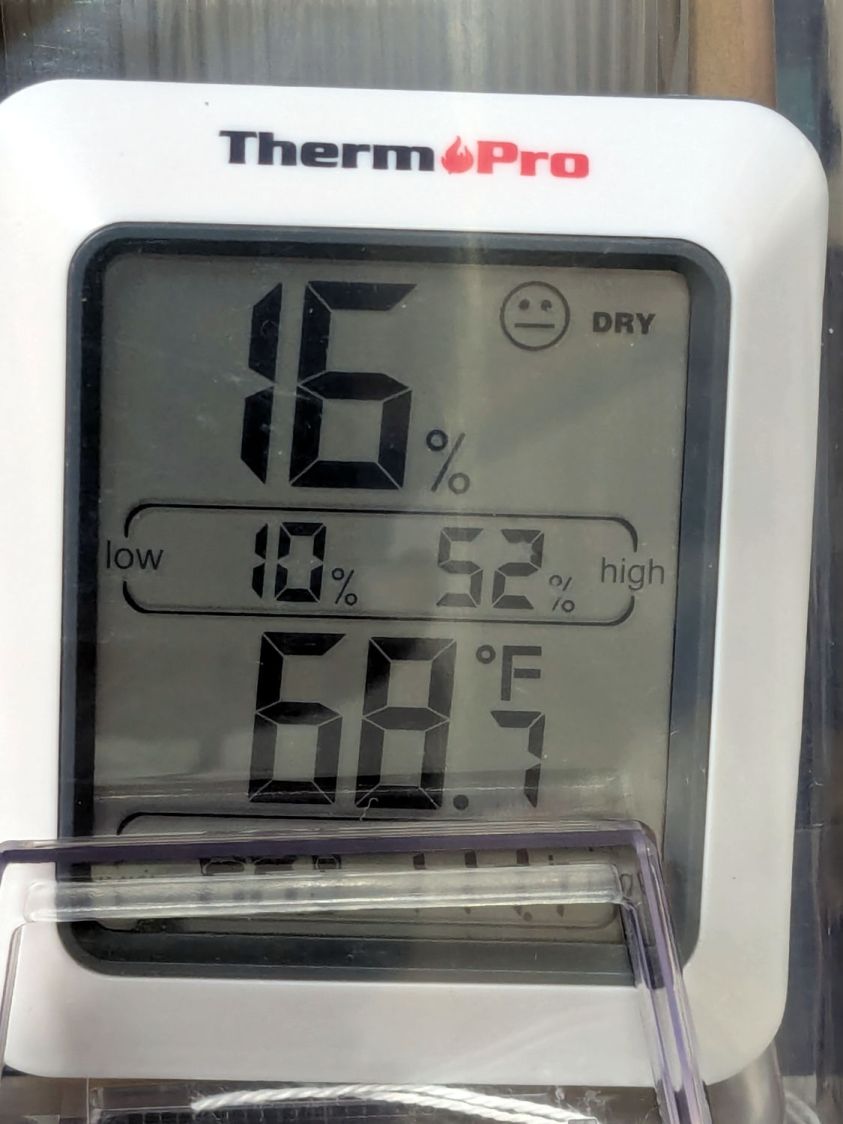

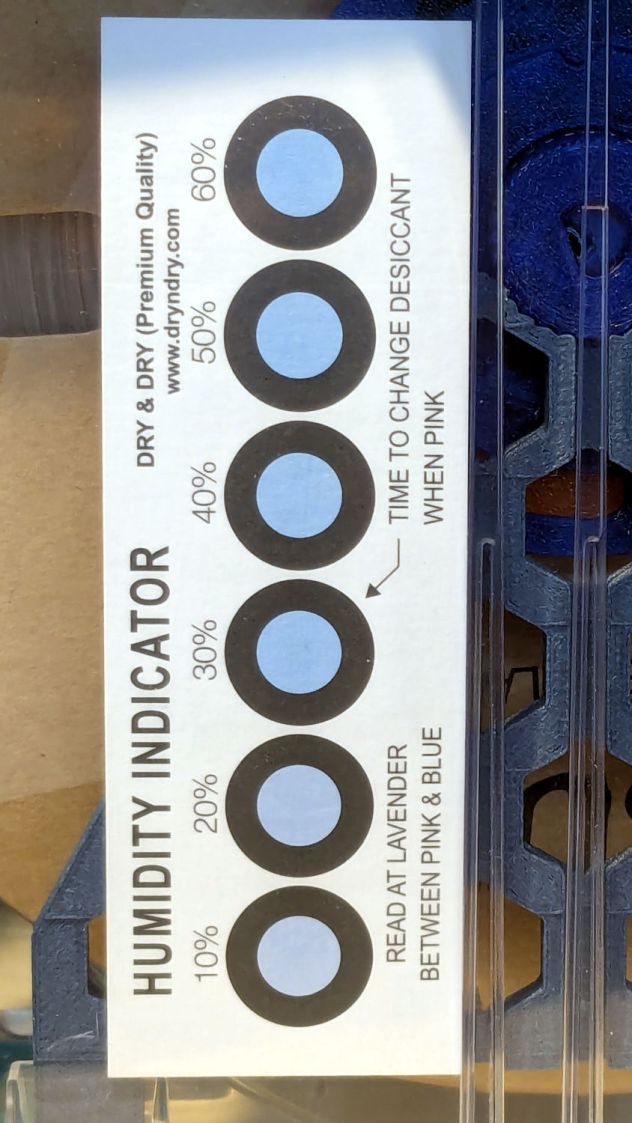

So it’s now aligned within ±0.3-ish mm across the surface, with the unflatness of a slab cut from a 1955-era Formica kitchen countertop accounting for most of the difference in a swale from Quadrant III across the origin to Quadrant I.

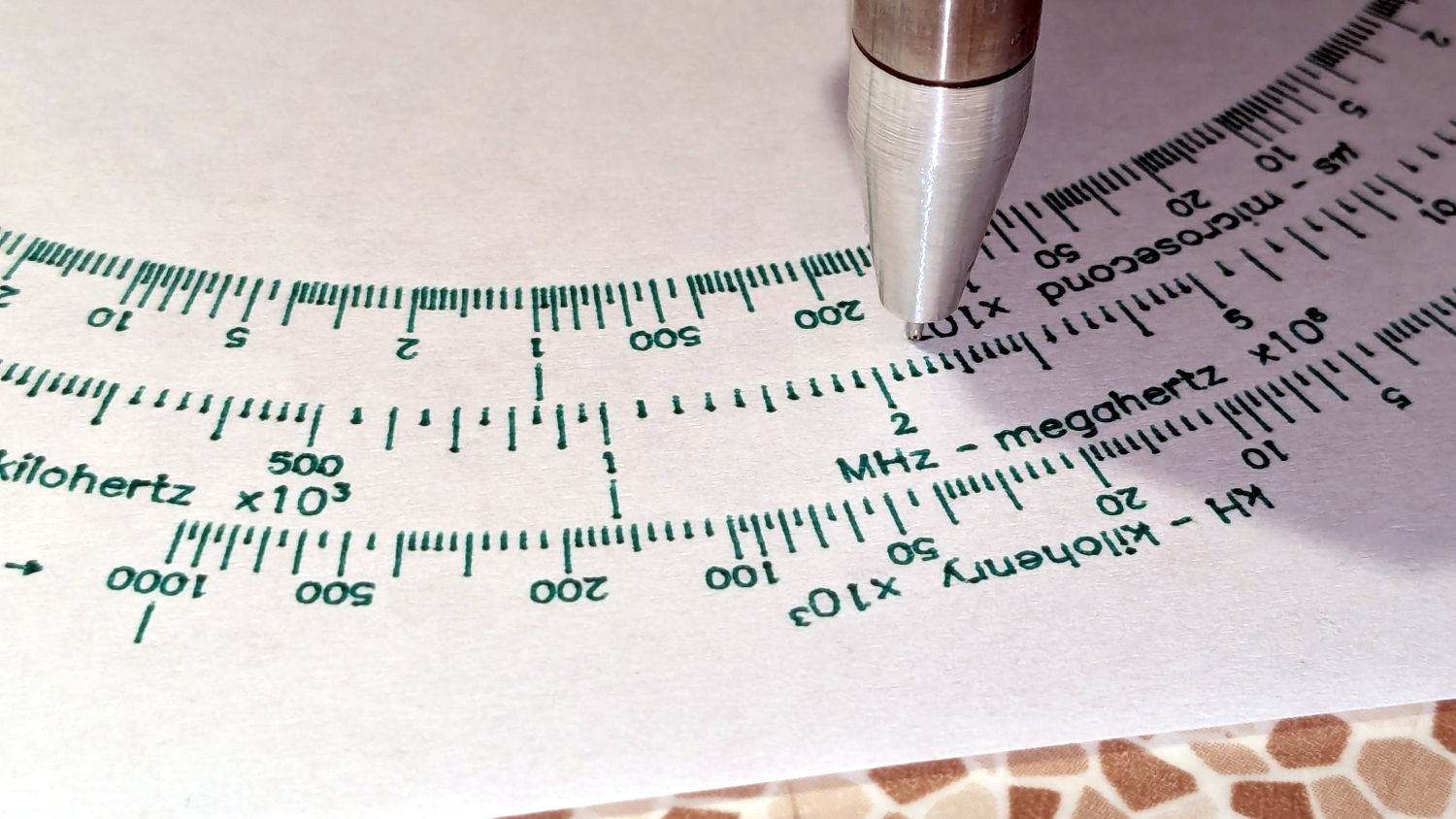

Which a check plot using an old file shows will be Flat Enough for my simple needs:

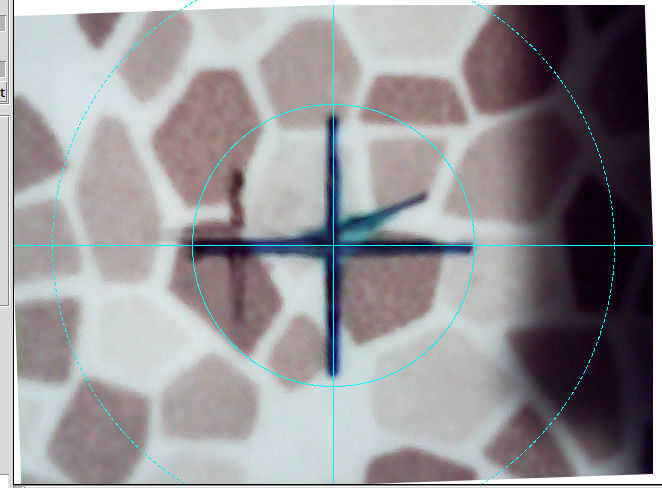

Having the camera alignment remain exactly spot on came as a pleasant surprise:

The faded cross to the left came from the table’s previous position; there’s no positive index between the countertop slab and the underlying T-slots.

Part of the motivation for these blocks was to verify PrusaSlicer automagically handles filament / color changes between two objects, as long as OpenSCAD hasn’t unioned them as part of a common transformation. Not having to cut out the socket around the text simplifies the code from what I’d been doing with previous objects.

The OpenSCAD source code as a GitHub Gist:

| // CNC 3018 table riser blocks | |

| // Ed Nisley – KE4ZNU | |

| // 2025-06-29 | |

| include <BOSL2/std.scad> | |

| Layout = "Show"; // [Show,Build,Outlines] | |

| /* [Hidden] */ | |

| HoleWindage = 0.2; | |

| Protrusion = 0.1; | |

| BlockOA = [40.0,30.0,10.0]; // riser block size | |

| SlotBlock = [8.0,BlockOA.y,3.0]; // alignment in slot | |

| BoltOD = 6.0 + HoleWindage; // central bolt | |

| LogoFont = "Fira Sans Condensed:style=SemiBold"; | |

| LogoSize = 7.5; | |

| LogoColor = "Red"; | |

| LogoThick = 0.4; | |

| //———- | |

| // Define Shapes | |

| module Riser(thick=1,matl="Block") { | |

| LogoText = format_fixed(thick,1); | |

| if (matl == "Text" || matl == "All") | |

| right(BlockOA.x/4) zrot(90) | |

| color(LogoColor) | |

| up(thick + SlotBlock.z + ((matl == "All") ? 0.01 : 0)) | |

| text3d(LogoText,LogoThick + ((matl == "All") ? 0.01 : 0),LogoSize,LogoFont, | |

| anchor=TOP,atype="ycenter"); | |

| if (matl == "Block" || matl == "All") | |

| difference() { | |

| cuboid(SlotBlock,$fn=8*3,anchor=BOTTOM,rounding=2.0,except=[BOTTOM,TOP]) position(TOP) | |

| cuboid(BlockOA,$fn=8*3,anchor=BOTTOM,rounding=2.0,except=[BOTTOM,TOP]); | |

| down(Protrusion) | |

| zrot(180/6) | |

| cyl(2*BlockOA.z,d=BoltOD,$fn=6,anchor=BOTTOM,circum=true); | |

| } | |

| } | |

| //———- | |

| // Build things | |

| if (Layout == "Show") | |

| down(SlotBlock.z) | |

| Riser(BlockOA.z,matl="All"); | |

| if (Layout == "Outlines") { | |

| projection(cut=false) | |

| Riser(BlockOA.z,matl="Block"); | |

| } | |

| if (Layout == "Build") { | |

| up(BlockOA.z + SlotBlock.z) xrot(180) | |

| Riser(BlockOA.z,matl="Block"); | |

| up(BlockOA.z + SlotBlock.z) xrot(180) | |

| Riser(BlockOA.z,matl="Text"); | |

| } |