Having recently emptied the OXO pepper grinder we (mistakenly?) bought as a salt mill, I took it apart for a deep rinsing and cleanup:

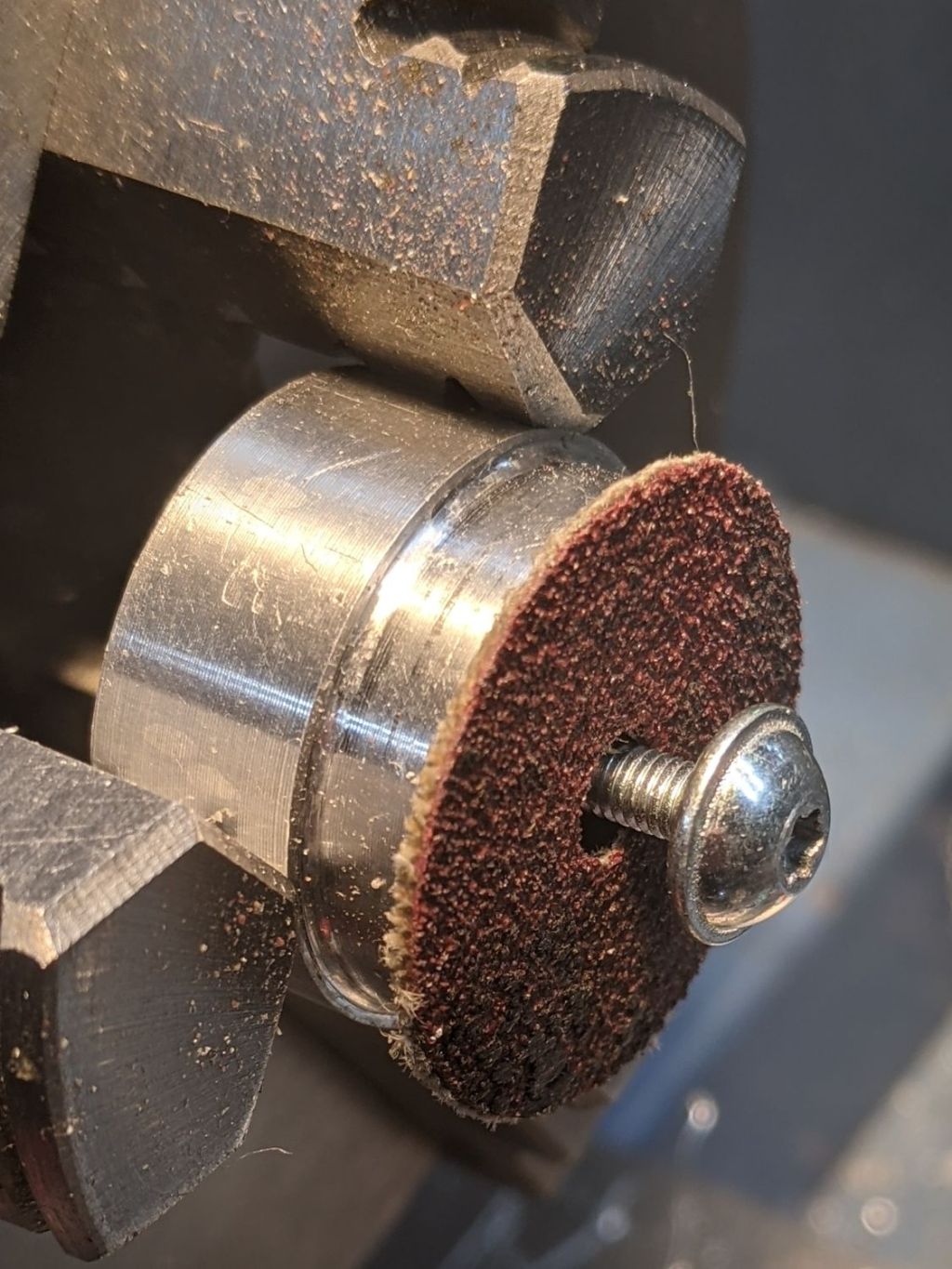

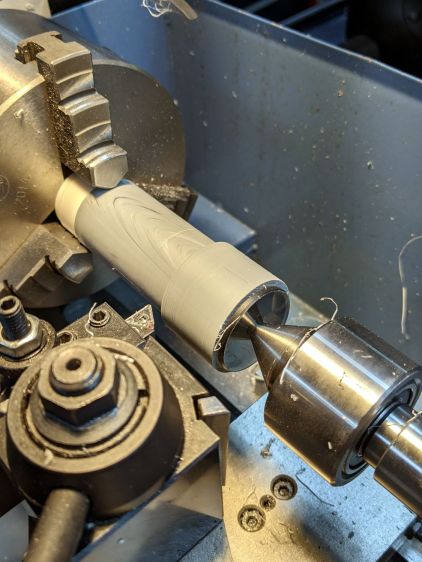

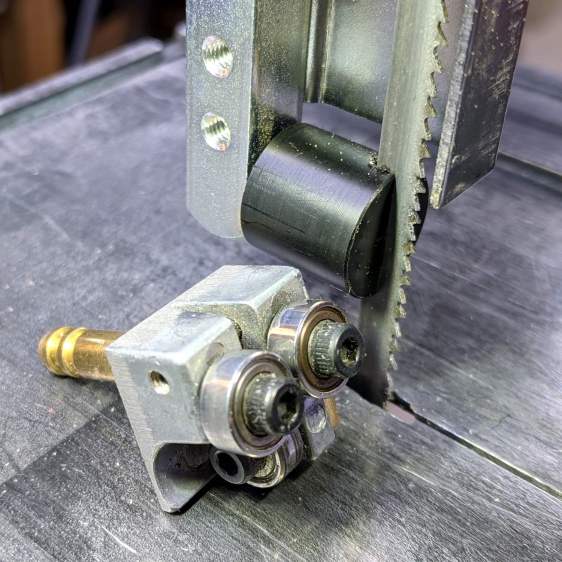

It turns out the somewhat corroded square shaft is aluminum, neither the cheap steel I expected nor the stainless steel it should be. Perhaps OXO cost-reduced the shaft, discovered aluminum is a poor choice in a saline environment, and changed the packaging to compensate?

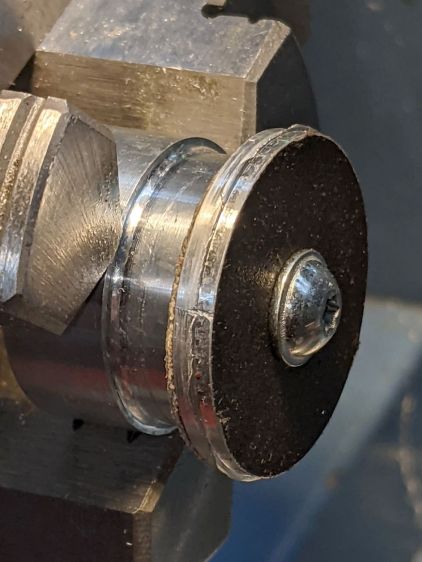

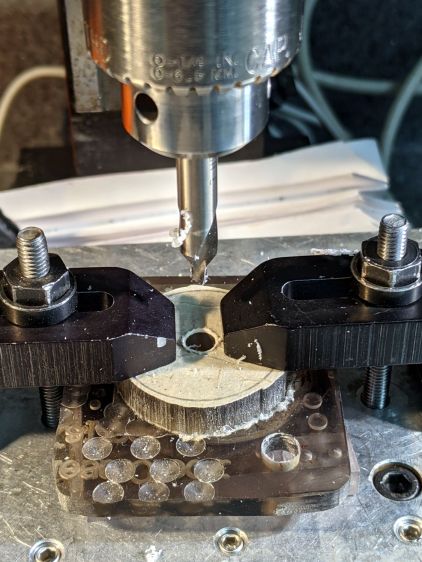

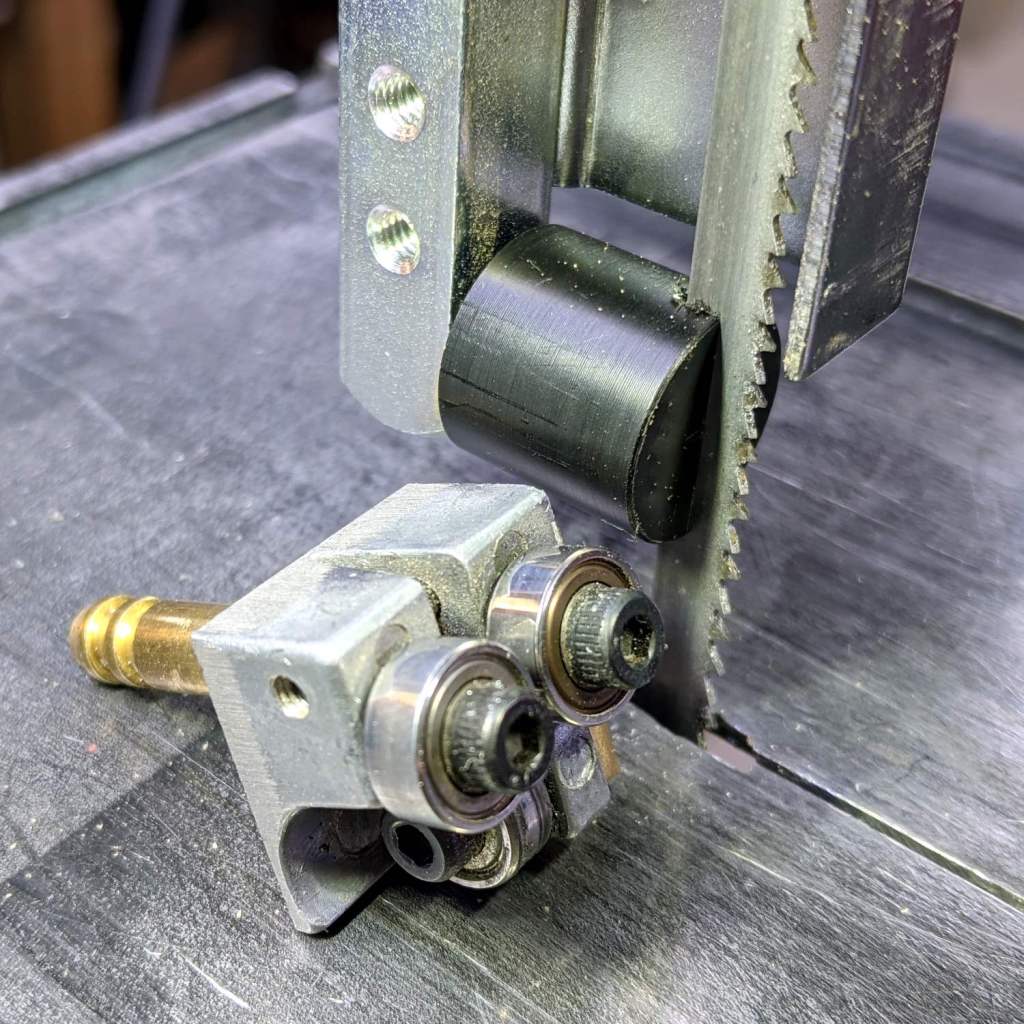

Removing / installing the Jesus clip requires careful whacking with a hollow-tip punch against the shaft, with the whole affair laid flat on shop towels, the handle held down to prevent rotation, and the wrap-around body capturing the escaping clip.

Shaft corrosion as of Summer 2020:

Soaking the body in hot water got rid of salt crusts and filled the shell with water. There being no way to completely dry the thing, I parked it in the sun for a day, refilled it, and was unsurprised when the (dried) salt turned into an assortment of moist crystals.

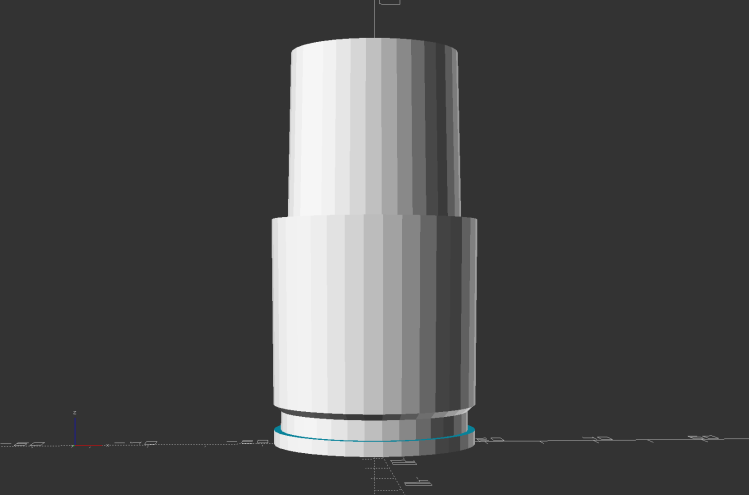

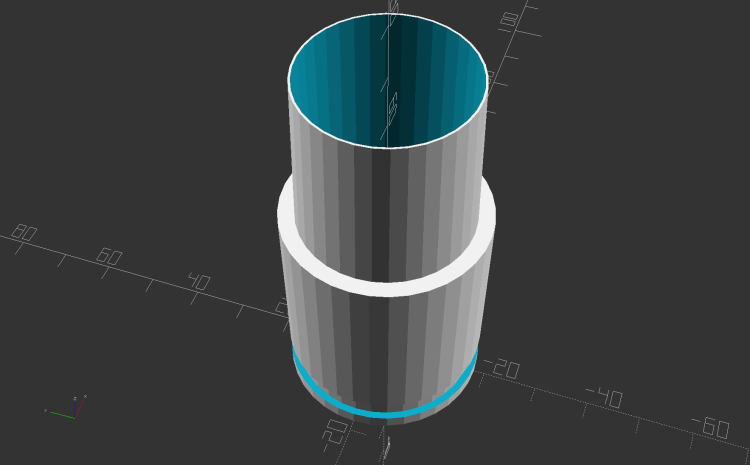

We obviously need a real salt mill …